85

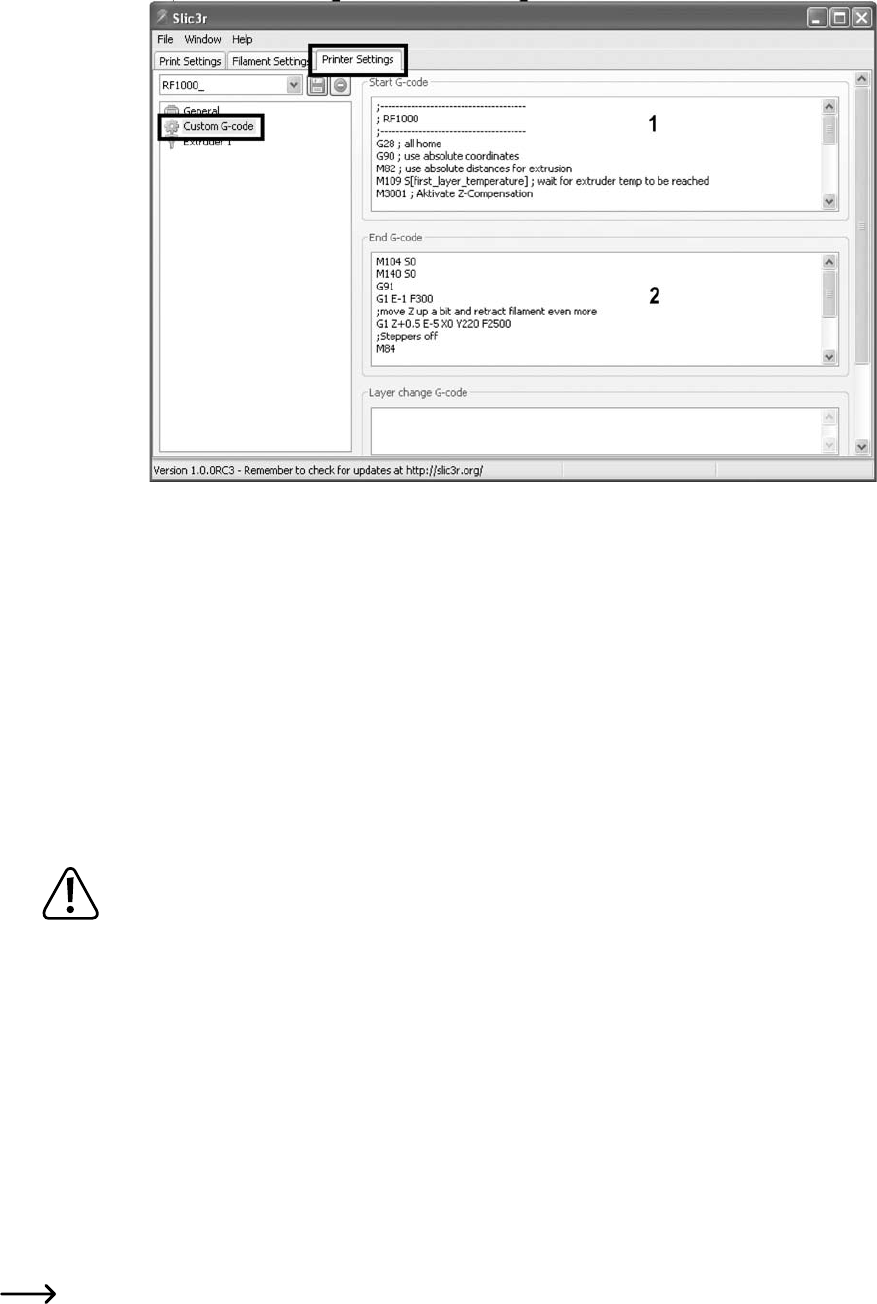

(1) The starting code contains the first commands that the 3D printer performs. Here, e.g. a Z-compensation can be started.

The Z compensation is unnecessary if the distance between the extruder nozzle and heating plate is set manually with the

buttons of the operating fields (as described before when starting a printing process).

Procedure

for determination of the correct command:

Move the printer to the home position.

Switch o the motors and return to the main menu display.

Move the extruder and the heating plate so that the extruder is placed centrally above the heating plate.

Place a normal, singly folded printer paper (80 g/m²) between the extruder and heating plate.

Move

the heating plate with the buttons for the heating plate movement up until the paper can just be moved. A distance of

approx. 0.2 mm is set here.

Do not move the heating plate up too far. Danger of breaking the heating plate!

Read the printing plate oset from the home position in the display (Z value in the second display line).

Convert

the oset read to motor steps according to the following formula:

642 x distance value = number of steps to be set

Example: Your measured -0.27 mm >> 642 x (-0.27) = -173.34 steps (also about -173 steps)

This means that the starting code must be moved up by 173 steps (- => up / + => down)

The Z-compensation command then would be:

M3000

M3004 S-173 (-173 is the number of the determined steps for the Z-motor)

(2) The end code will be performed at the end of the print and could contain, e.g. the run into a removal position for the printed

object.

Detailed information on the G-Codes can be found, e.g., in http://reprap.org/wiki/G-code