25GB/IE/NI/CY/MT

Z

Overlap welds

The most common preparation is that

with the straight weld edges. The weld

can be released using a standard angle

weld seam. Both workpieces must be

brought as close to each other as possi-

ble, as shown in Fig. AB.

AB

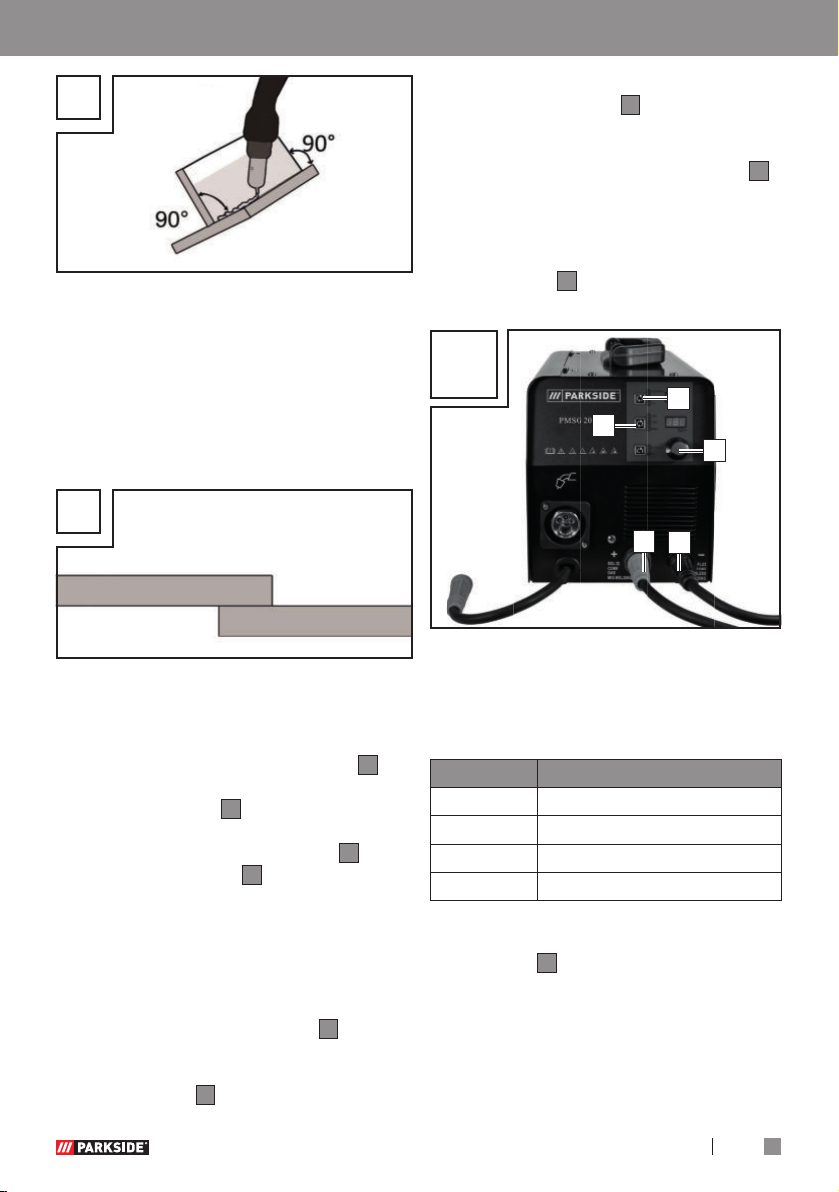

MMA welding

Make sure that the main switch

5

is set to position “O” (“OFF”) or that

the power plug

3

is not plugged

into the socket.

Connect the electrode holder

34

and

the earth terminal

4

to the welding

device, as shown in Fig. AC). Also

refer to the information from the

electrode manufacturer.

Put on appropriate protective cloth-

ing in accordance with the specifi ca-

tions and prepare your workspace.

Connect the earth terminal

4

to the

workpiece.

Clamp the electrode into the elec-

trode holder

34

.

Switch the device on by setting the

main switch to the

5

“I” (“ON”)

position.

Select “MMA” mode by pressing the

selector switch for welding mode

35

,

until the small indicator lamp next to

MMA lights up.

Adjust the welding current using the

rotary switch for welding current

adjustment

6

depending on the

electrode you are using.

AC

34 4

35

36

6

Note: Guideline values for the welding

current to be used, depending on the

electrode diameter can be taken from

the following table.

Ø Electrode Welding current

1.6 mm 40–55 A

2.0 mm 55–65 A

2.5 mm 65–80 A

3.2 mm 80–120 A

Note: By pressing the voltage reducer

selector key

37

you can activate the

voltage reducer function (VRD). The LED

next to “A/VRD” lights up. By doing this

the output voltage is reduced and the

safety for the user during breaks from

welding will be increased.

Using the device / MMA welding