27GB/IE/NI/CY/MT

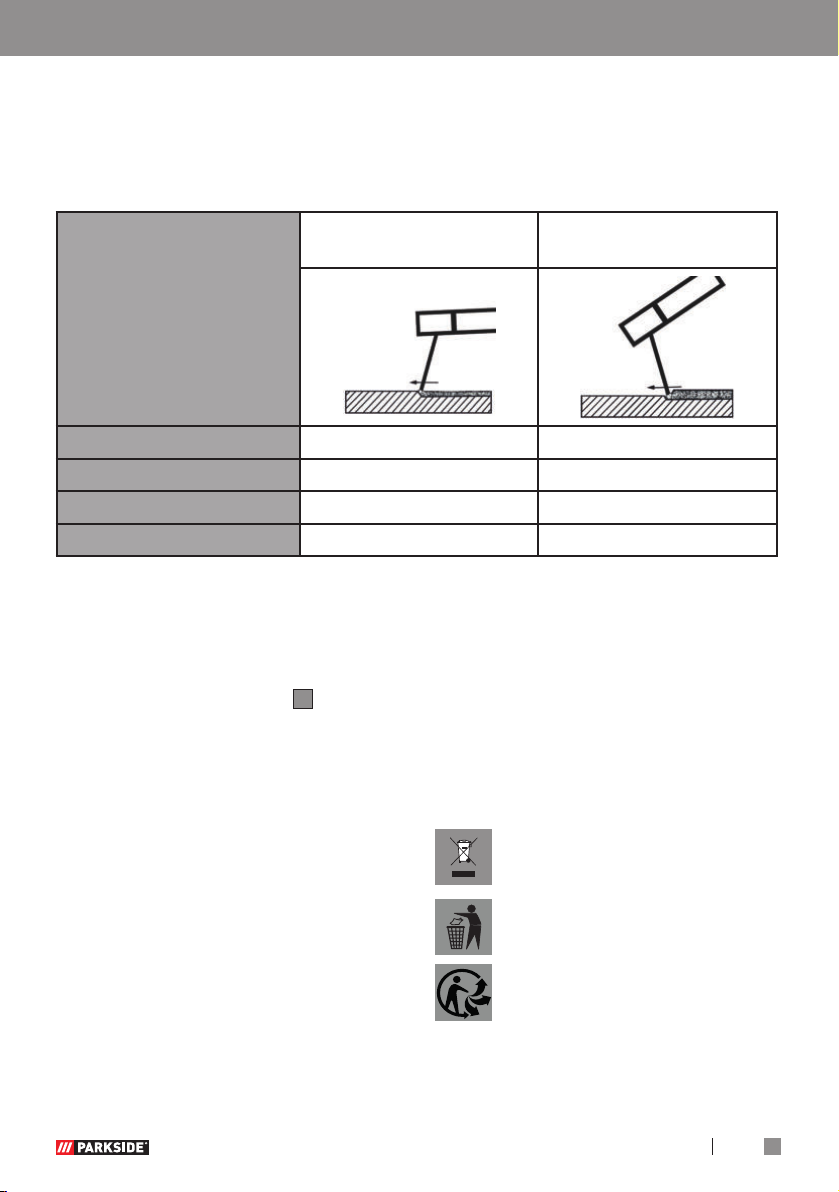

of the direction of movement on the

properties of the weld seam:

Note: You decide for yourself which

type of welding is most suitable, once

you have welded a sample piece.

Note: Once it has worn down com-

pletely, the electrode must be replaced.

Push welding Drag welding

Burn smaller larger

Weld seam width larger smaller

Weld bead fl atter higher

Weld seam fault larger smaller

TIG welding

For TIG welding please follow the

instructions for your TIG torch. You can

select TIG mode by pressing the

welding mode selector key

35

. To do

this select the “TIG” position.

Maintenance and cleaning

Note: The welding device must be

regularly serviced and overhauled for

proper function and for compliance

with the safety requirements. Improper

and wrong operation may cause fail-

ures and damage to the device. Repairs

must only be carried out by qualifi ed

electricians.

Switch off the main power supply

and the main switch of the device

off prior to performing any mainte-

nance work on the welding device.

Clean the welding device and

accessories regularly using air,

cotton waste or a brush.

In case of a defect or a necessary

replacement of equipment parts,

please contact the appropriate

qualifi ed personnel.

Information about

recycling and disposal

Don’t throw away –

recycle!

Please return this device,

accessories and packaging to

your local recycling depot.

Donot dispose of the welding

device in household waste, in

fi re or in water. Devices that are

no longer functional should be recycled

wherever possible. Ask your local

stockist for advice. To do this, please

see 2012/19/EU.

... / TIG welding / Maintenance and cleaning / Information about recycling ...