24 GB/IE/NI/CY/MT

U

To forestall or reduce deformations that

can happen during the material harden-

ing process, it is good to fi x the work-

piece with a device. Avoid stiffening the

welded structure to prevent cracks in the

weld. These problems can be avoided if

there is a possibility of turning the work-

piece so that the weld can be carried

out in two passes running in opposite

directions.

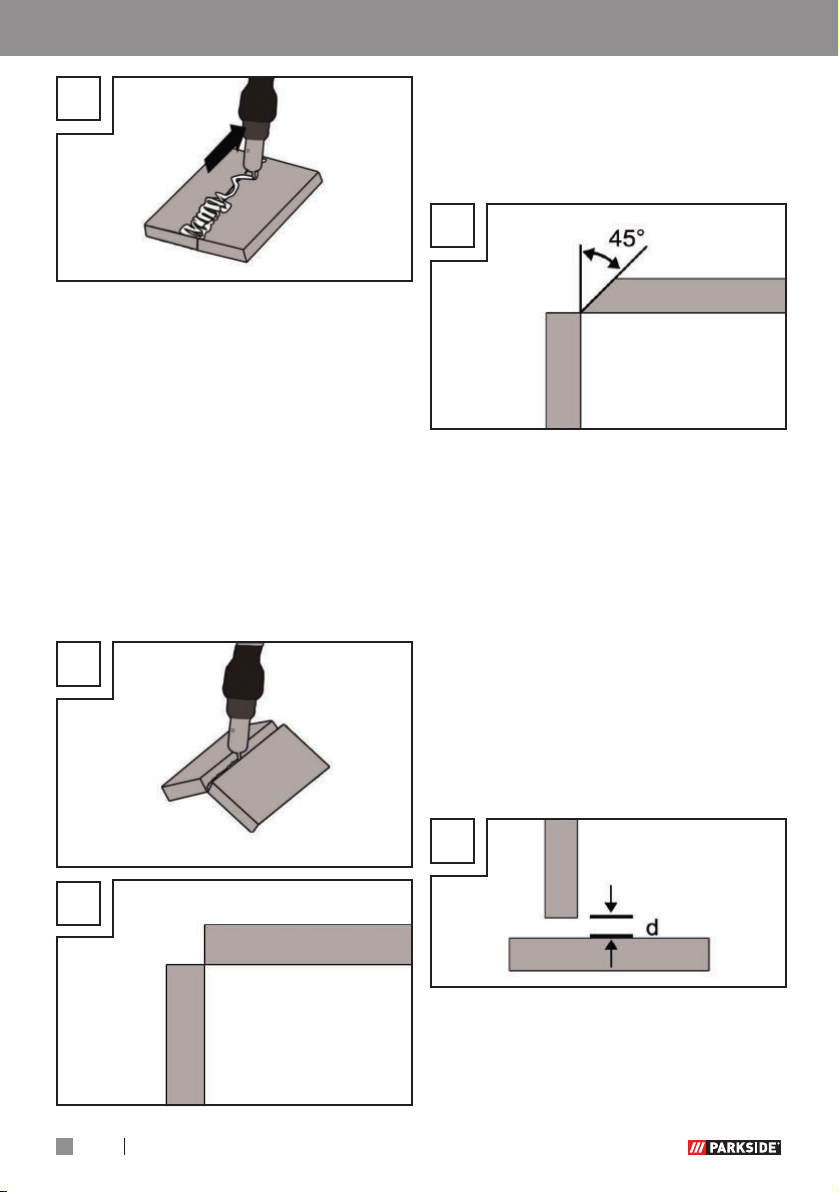

Welds on the outer edge

The preparation for this is very simple

(Fig. V, W).

V

W

However, it is no longer expedient for

thicker materials. In this case, it is better

to prepare a joint as shown below, in

which the edge of the plate is angled

(Fig. X).

X

Fillet weld connections

A fi llet weld is created if the workpieces

are perpendicular to each other. The

weld should be shaped like a triangle

with sides of equal length and a slight

fi llet (Fig. Y, Z).

Welds on an inner edge

The preparation for this weld joint is very

simple and is carried out for thicknesses

of 5 mm. The dimension “d” needs to

be reduced to a minimum and should

always be less than 2 mm (Fig. Y).

Y

However, it is no longer expedient for

thicker materials. In this case, it is better

to prepare a joint as shown in Figure X,

in which the edge of the plate is angled.

Using the device