GB/IE/NI/CY/MT 19

zReplacing the welding core

The pre-installed welding core 15 is designed for aluminium wire. The welding core 36 which is not

pre-installed is suitable for steel and stainless steel as well as for flux-cored wire. Undo the locking nuts

34, by rotating them anti-clockwise. Then pull the welding core 15 out of the cable assembly with direct

connection 7 and now guide the new welding core with the narrow end first, into the cable assembly

with direct connection 7. Push the complete new welding core through and then fix it with the locking

nuts 34.

When connecting the torch with the core 36 (not pre-installed), first push the small tube 31 into the (lower)

opening provided for this purpose on the Euro central connector of the welder. In this way the liquid

pumping of the wire will be guaranteed.

zAdaptation of device to solid welding wire with inert gas

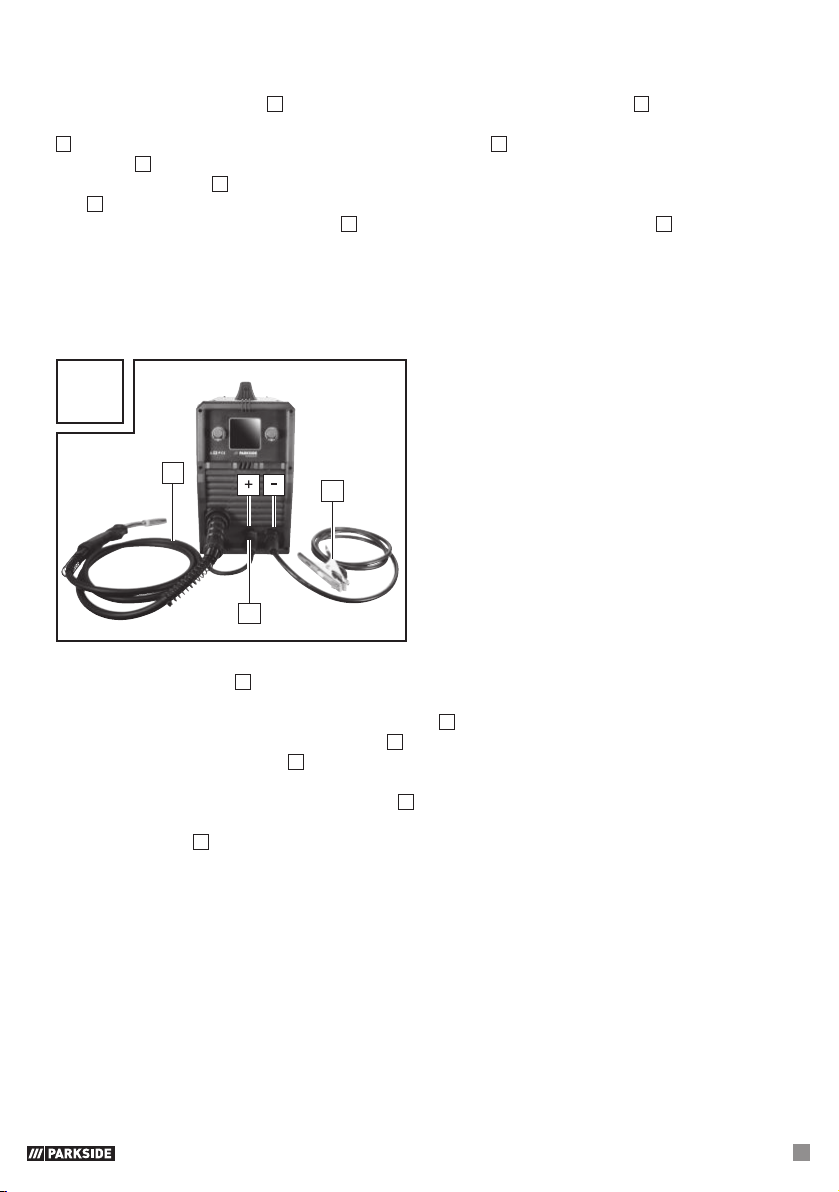

The correct connections for solid wire welding when using inert gas are shown in Fig. S.

T

6

4

7

First connect the plug 6 with the connector marked with the “+” (see Fig. T). To fix it in place, rotate

in a clockwise direction. If you are in any doubt, then please contact a professional.

Connect the cable assembly with direct connection 7 to the appropriate connector (see Fig. T).

Tofix the connection, tighten the fixing ring 7a in a clockwise direction.

Then connect the earth cable 4 with the corresponding connector, marked with the “-” (see Fig. T).

To fix the connection in place, rotate in a clockwise direction.

Pull the protective cap off the gas connection 24 on the back of the device.

Now connect the inert gas feed including the pressure reducer (not included with the delivery) to the

gas connection 24 (see Fig. C). Inert gas is required if you are not using flux-cored wire with

integrated solid inert gas. If necessary, observe the notes for your pressure reducer (not included

with the delivery). You can use the following formula as a guideline for adjusting the gas flow:

Wire diameter in mm x 10 = gas flow in l/min

For example, using 0.8 mm wire, will give a value of approx. 8 l/min.