• After the servos are installed, operate each servo over its full travel and check that the pushrods and servo arms do not

bind or contact each other. Also make sure the controls do not require excess force to operate. If there is an objectionable

buzzing sound coming from a servo, there is probably too much resistance in the control. Find and correct the problem.

Even if there is no servo damage, excess battery drain will result.

• Use the mounting plate from the receiver on/off switch as a template for the cutout and screw holes. Mount the switch

on the side of the fuselage opposite the engine exhaust, and where it won’t be inadvertently turned on or off during

handling or storage. Be certain the switch moves without restriction and “snaps” from ON to OFF, and that the cutout

allows full motion of the switch in both directions.

• IMPORTANT: NEVER cut the receiver antenna or mount it in the model folded back on itself. Doing so will change its

electrical length, possibly reducing the distance from the pilot that the model can be controlled (“range”).

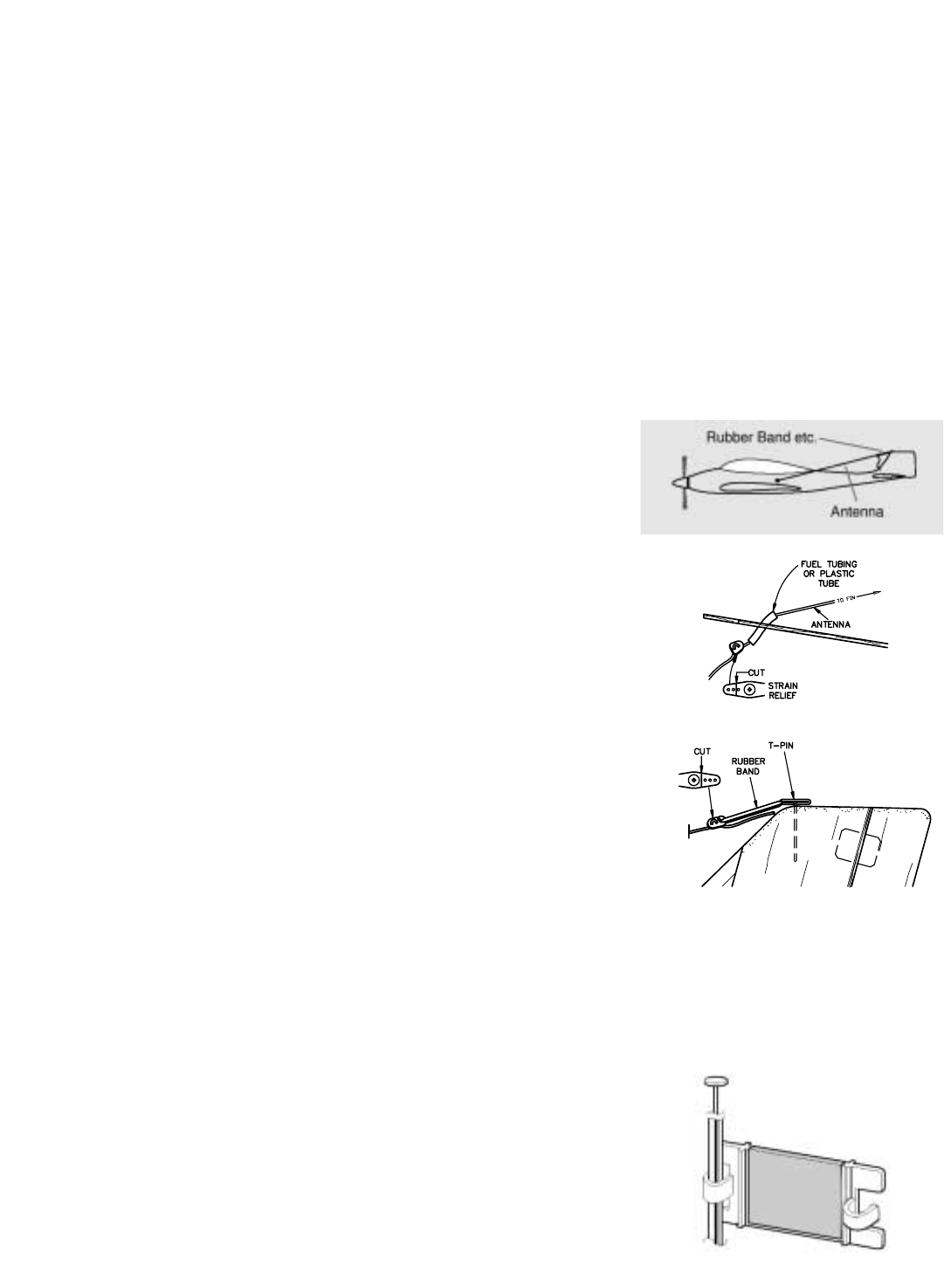

• The receiver antenna may be mounted inside or outside the model:

Internal antenna mounting:

The antenna may be routed down through the inside of the fuselage, or through any non-metallic housing or tube within the

fuselage. Keep the antenna away from metal pushrods, wires and cables; otherwise, range may be decreased. Always perform

a range check before flying (see page 19).

External antenna mounting:

A. Use a cut off servo arm as a

”

stop

”

or strain relief inside the fuselage to

keep tension off the solder joint holding the antenna to the receiver. Guide the

antenna through a hole in the fuselage. (If possible, insulate the hole with a rubber

grommet or a small piece of rubber tubing.)

B. Make a hook from another cut off servo arm. Insert the end of the antenna

through two holes, then connect the hook to a rubber band around a pin inserted into

the vertical stabilizer. Allow any excess antenna length to trail behind the hook.

• The receiver contains precision electronic parts. It is the most delicate (and expensive) radio component on-board the model

and should be protected from vibration, shock and temperature extremes. To protect the receiver, wrap it in R/C foam rubber

or other vibration-absorbing material. If appropriate, waterproof the receiver by placing it in a plastic bag and closing the open

end with a rubber band before wrapping it in foam. If moisture enters the receiver, intermittent operation or a failure may

result. Wrapping the receiver in a plastic bag also protects it from fuel and exhaust residue which, in some models, can work

its way into the fuselage.

Mounting the frequency clip:

• To announce your frequency and avoid potential interference problems, the

frequency number should always be displayed on the transmitter antenna while

flying. Peel the backing from the numbers and apply them to both sides of the

clip. Snap the end of the clip that fits best to the base of the antenna as shown.

You may cut off the other end of the clip.

6