EN

21

1311 12

14

15

REPLACEMENT OF FILTERS:

Floater Filter (PWC-700-4): Replace yearly or earlier according to condition.

Air Intake Filter (PWC-700-2): Replace yearly or earlier according to condition.

Polyester Filter (PWC-700-501): Replace yearly or earlier according to condition.

Motor Intake Filter (PWC-700-533): Replace yearly or earlier according to

condition.

Hepa Filter (PWC-700-516): Replace every 6-12 months.

Low noise filter (PWC-700-518): Replace yearly or earlier according to condition.

9.2 SIMPLY SYSTEM

TM

No need to store up on bags or filters thanks to the SIMPLY SYSTEM

TM

.

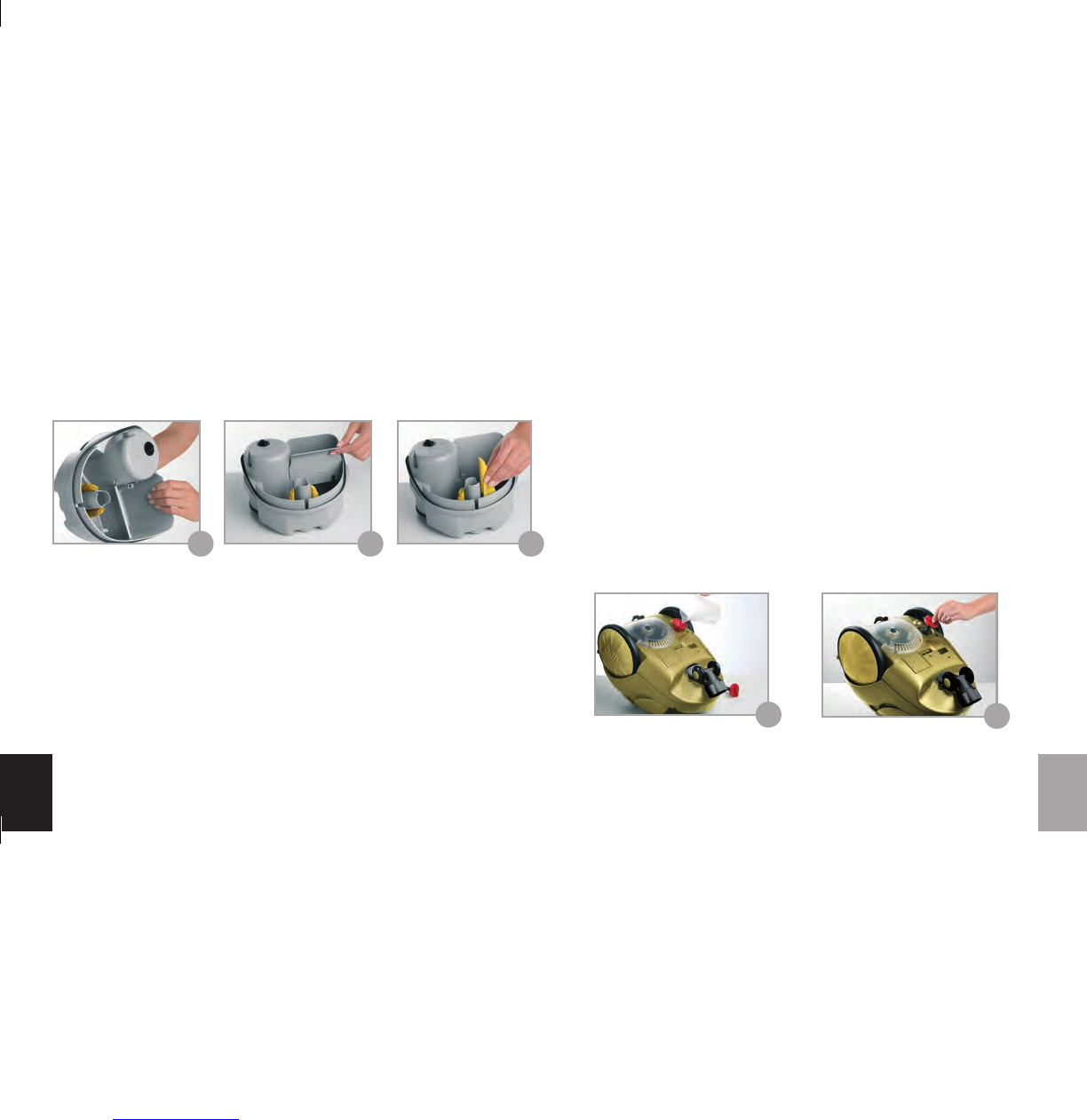

Cleaning the purification tank is all that is required for top TUTTOLUXO 6S

efficiency. At the end of your work, empty the liquid waste of the purification

tank as shown in Pict. 11 .

To make this operation easier, the divider inside the tank can be taken off

(Pict. 12) and it is also advisable to remove the nebulizers (Pict. 13). Rinse tank,

divider and nebulizers with abundant hot water and neutral detergent until all

residues and stains on the tank walls have been removed.

WARNING!

When you take off the divider, make sure that it is put back correctly into the proper

guides with its curved side facing forwards and upwards and that it touches the

bottom (otherwise it won’t slide in). Please be careful, these are delicate pieces.

In case one gets broken or lost, immediately ask for a spare part from your Zepter

Service Centre. Do not use the TUTTOLUXO 6S without it. Allow all pieces to dry

or dry them yourself before replacing them in the machine and closing the cover.

Moisture left inside could create mildew and unpleasant odours.

9.3 CLEANING OF FLEX TUBE:

In order to avoid the arise of smelly mold and deposit inside the flex tube, it

is recommended, once terminated the cleaning, to proceed with the rinsing

hose acting as follows: remove all contents inside the recovery tank, immerse

the hose in a container of clean water (preferably warm) and, with vacuum

regulator on third speed, aspirate about a liter of water.

Repeat two or three times, remembering to empty each time the contents of

the recovery tank.

9.4 DESCALING THE BOILER AND ELECTRONIC SENSOR

Here we will show you how to extend considerably your machine’s

working life thanks to an exclusive technology that allows to prevent

limescale formation in the steam boiler.

After prolonged periods of activity, limescale deposits make no longer

usable the boilers of most steam appliances found on the market.

Your TUTTOLUXO 6S, thanks to an exclusive patented technology, allows to

inspect and clean the special electronic sensor that monitors the boiler water

level.

WARNING!

We strongly advise, after aspirating liquids or solids, to rinse the water bucket

inside and any accessory used, by emptying the tank and aspirating 1 litre

of clean tap water, repeat this twice. Also, please do not leave any aspirated

liquid inside the tank, to prevent the formation of limescale or moulds, and

consequently bad odours.