RUNRACE : Service & Maintenance Manual - rev. 2.0

Page 11.13

11.10. LEAKAGE CURRENT PROBLEMS WITH HITACHI E5

INVERTER

The introduction of Hitachi inverter version E5 on the machine has given rise to problems with

increased earth leakage currents, which result in non-conformance to the relevant regulations for

electromedical equipment.

In fact, in order to keep the emissions within the limits set down by the regulations for light

industry, this inverter version has a capacitive filter to ground on the supply conductors, which

increases the current in the earth conductor up to 1200 µA.

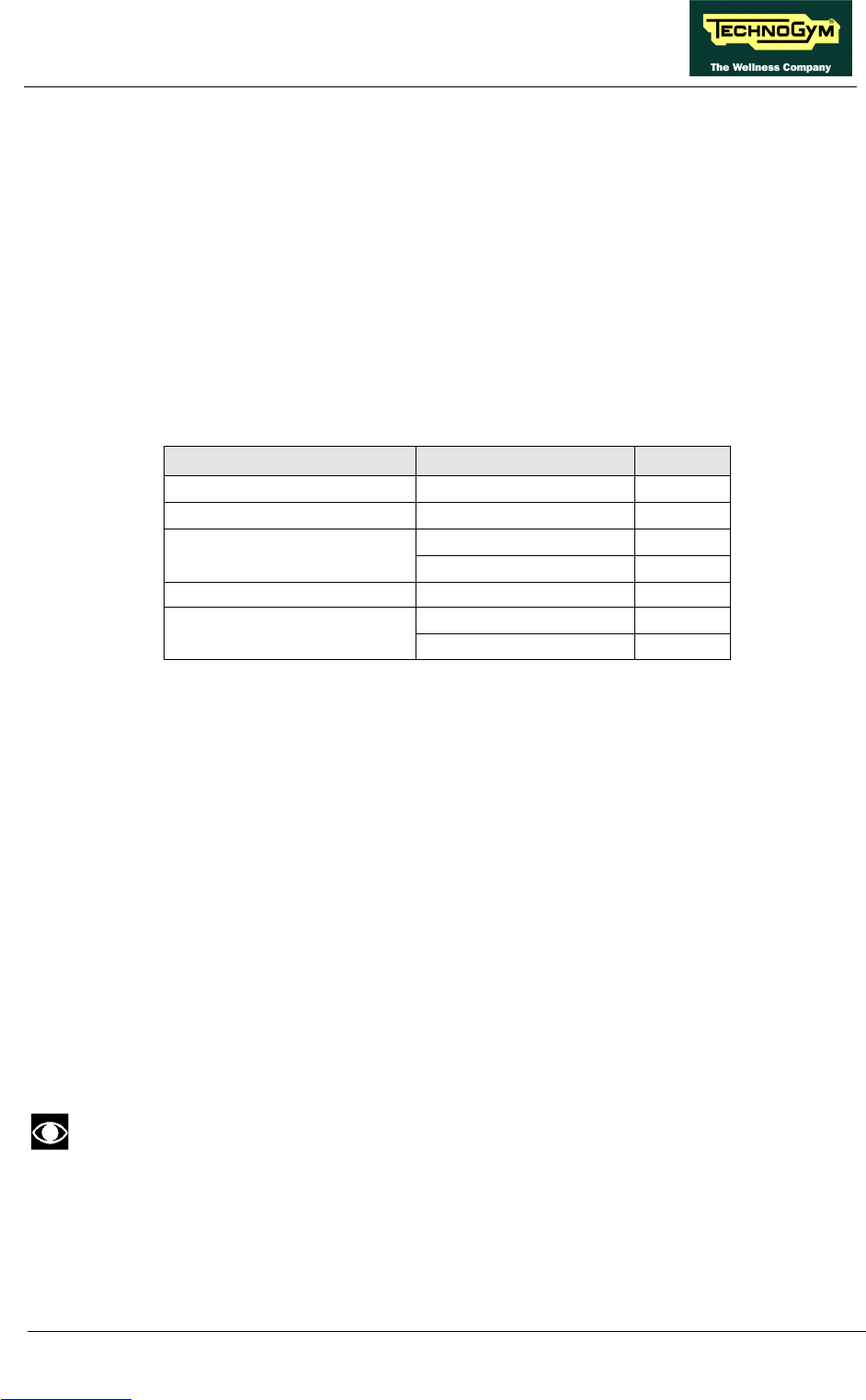

The leakage currents for the individual machine components are detailed in the table below:

COMPONENT Model

I

leakage

Inverter Hitachi J100 E5

1200 µA

Power supply Lambda ZT30-522

300 µA

Schaffner FN350-20-29

4900 µA

Filter

Schaffner FS5458-20-29

350 µA

Transformer - -

with FN350 filter

5400 µ

µµ

µA

TOTAL FOR MACHINE

with FS5458 filter

1850µ

µµ

µA

To ensure conformance to the values prescribed by the regulations in force, pending further

instructions proceed as follows:

• On the Lambda ZT30-522 power supply, eliminate the two capacitors C3 and C4 (2200 pF).

This reduces the leakage of the power supply to approximately 0 µA.

• On the Hitachi E5 inverter, eliminate the two capacitors CNX and CPX (10 nF). This reduces

the leakage of the power supply to approximately 0 µA.

• In place of the Schaffner 350/20/29 filter, use the Schaffner FS5458-20-29 filter specially

manufactured for Technogym, which has order code 0WB018. This filter is installed as standard

on machines with SN 6000120008, or raise the filter off the ground.

• Suspend the Schaffner 350-20-29 filter using insulating spacers and plastic screws. This reduces

the leakage of the filter to approximately 0 µA.

• Replace the Schaffner 660-3/06 filter with the Schaffner 610B-3/06 filter with order code

0WB016.

• Replace the Schaffner 660-10/06 filter with the Schaffner 610B-10/06 filter with order code

0WB015.

Always obtain authorization from the Technogym Service Center before carrying out

this operation.

With these modifications, the machine leakage current is reduced to approximately 400 µA,

bringing it within the 500 µA limit prescribed by the regulations.