To keep your espresso machine in proper working order there a few

maintenance procedures that should be carried out at various intervals.

Cleaning Cycle - A cleaning cycle should be done on a weekly basis for

heavy use or a bi-weekly basis for light use to maintain optimum

performance. If the machine is being used in a commercial setting then a

daily cleaning should be done.

Descaling - The descaling feature is great for keeping the boiler free from

mineral deposits and should only be performed when the descaling alarm is

shown on the display. (See menu section for setting alarm). Although this

feature will allow the use of hard water in the machine it is still strongly

recommended to use soft water to prolong the life of the machine.

Piston O-Ring - The machine comes equipped with a spare piston o-ring

which should be replaced on a yearly basis. To replace the o-ring, unplug the

machine and allow it to cool off. Open the front door and then remove the

brew chamber cover. Use a small dental pick or flat blade screwdriver to

carefully remove the old o-ring. Then work the new o-ring on to the piston.

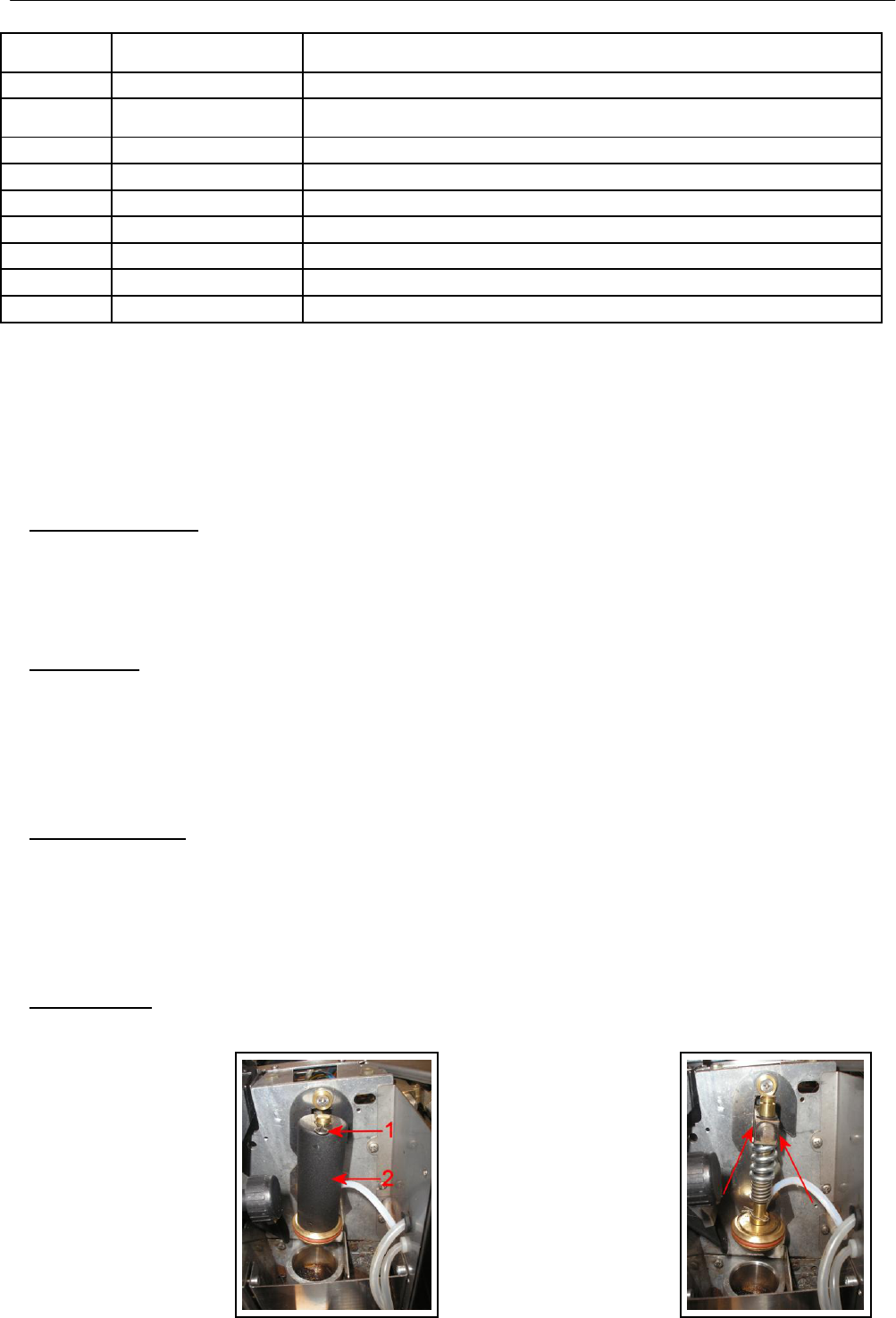

Lubrication - The piston slide assembly should be lubricated every 6 months

with a high temperature food grade lubricant such as Dow 111.

To lubricate the slide,

unplug the machine and

let it cool off. Remove the

top cup tray and then

remove the 4 phillips

screws holding the top on.

With the top removed

slide off the clip # 1 and

then slide the plastic

cover # 2 off the piston.