OPERATING INSTRUCTIONS

INTRODUCTION

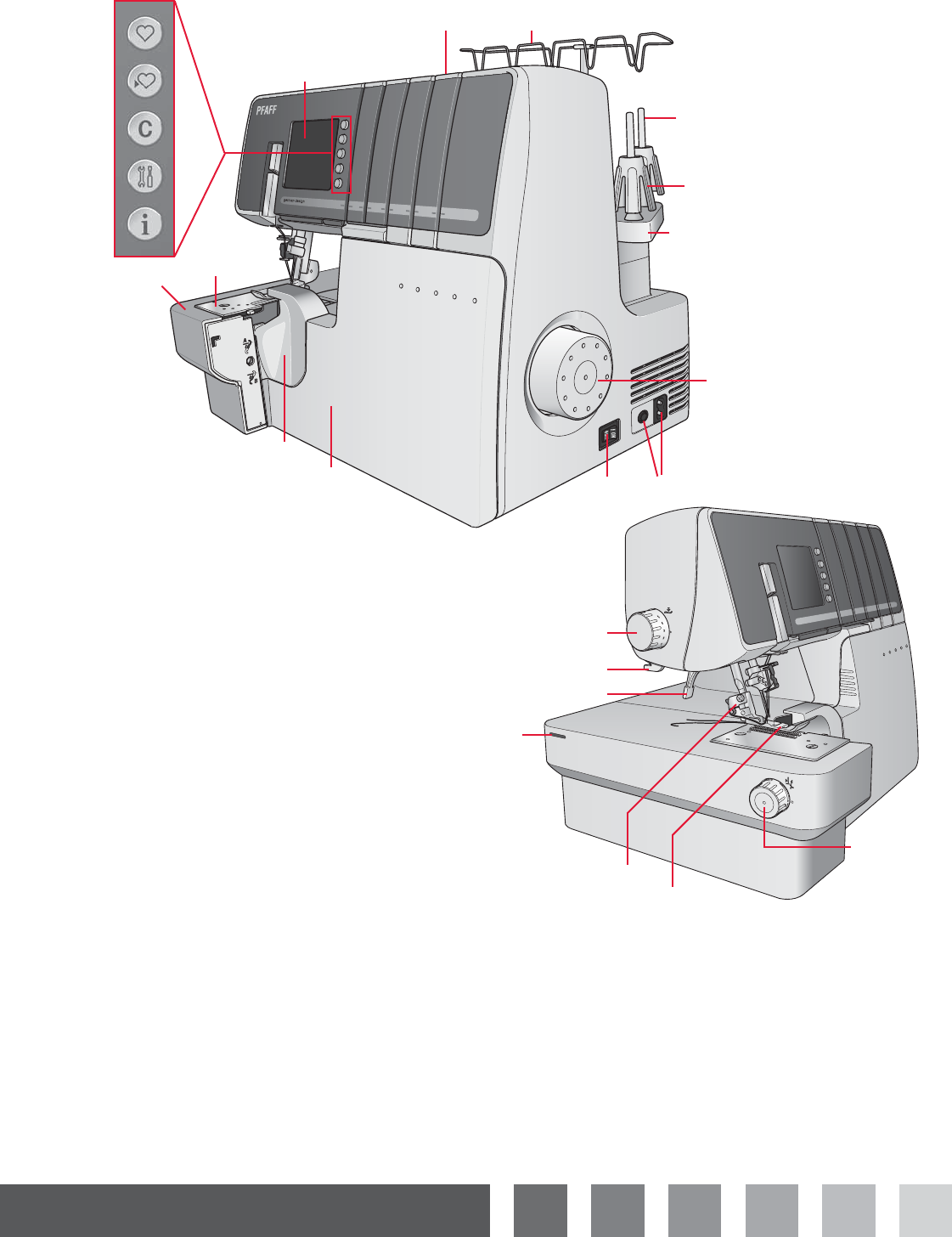

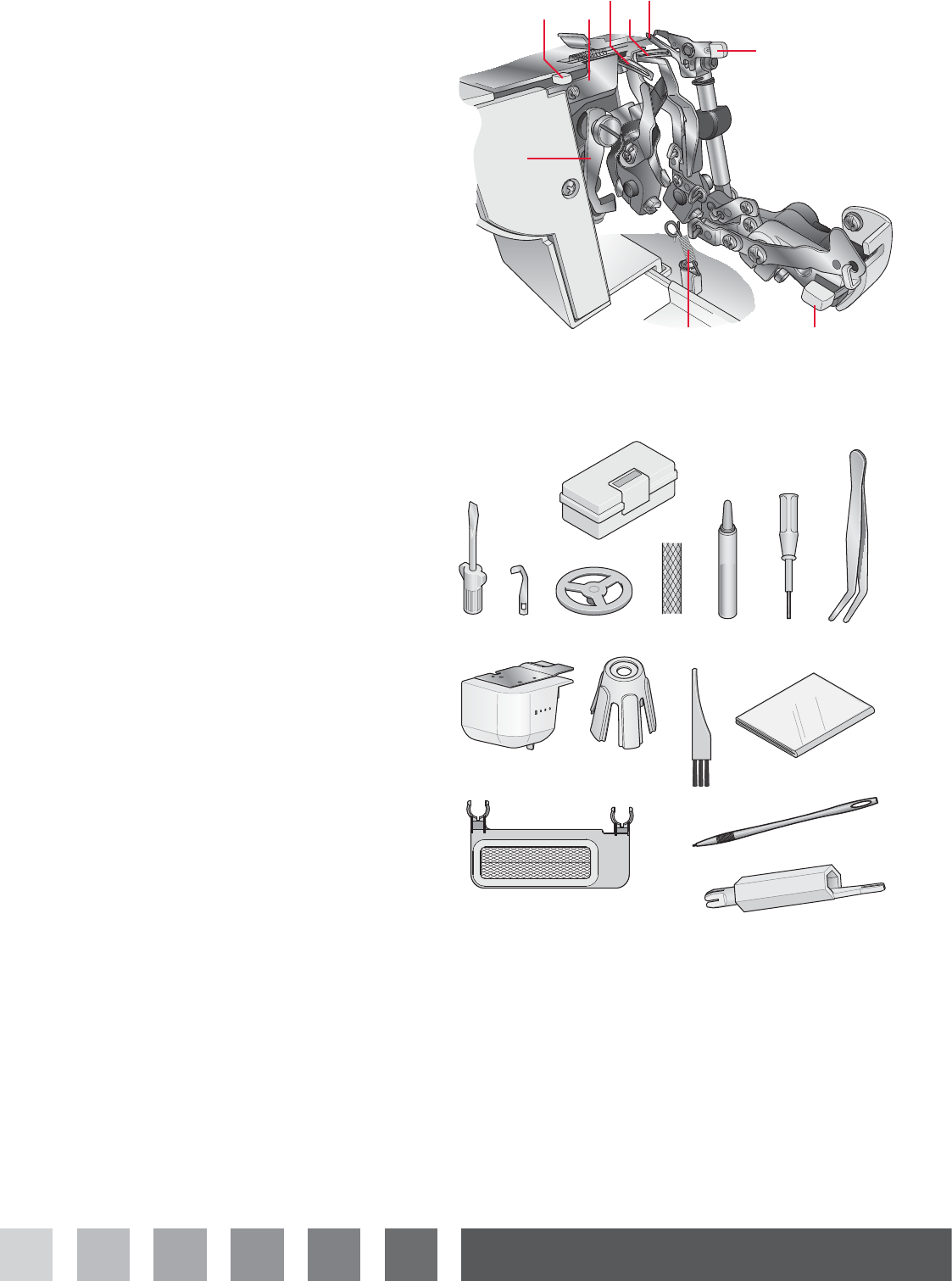

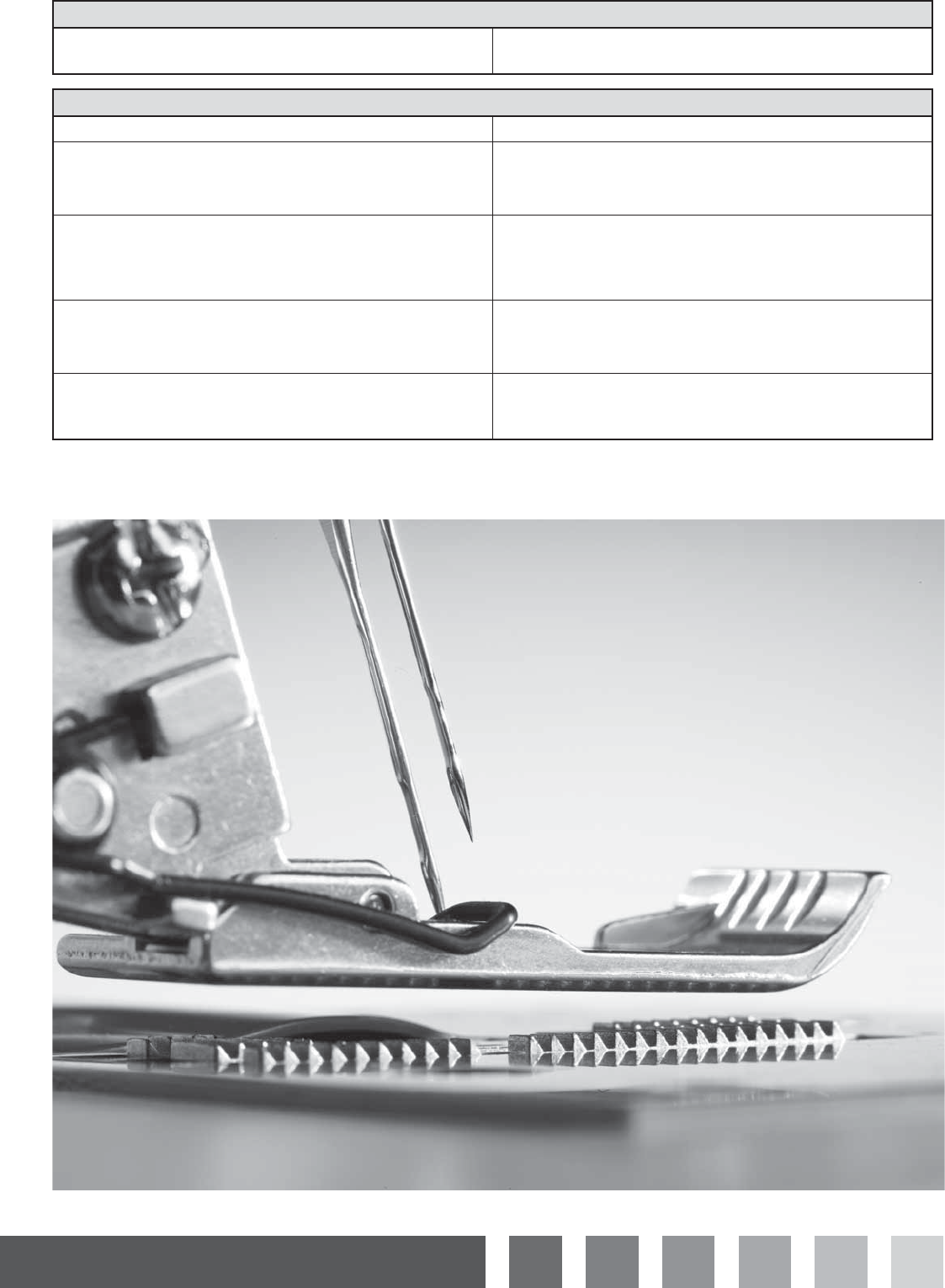

Parts of the machine .................................................................... 4

Accessories ....................................................................................... 5

Optional accessories from INSPIRA™ .................................... 6

PREPARATIONS

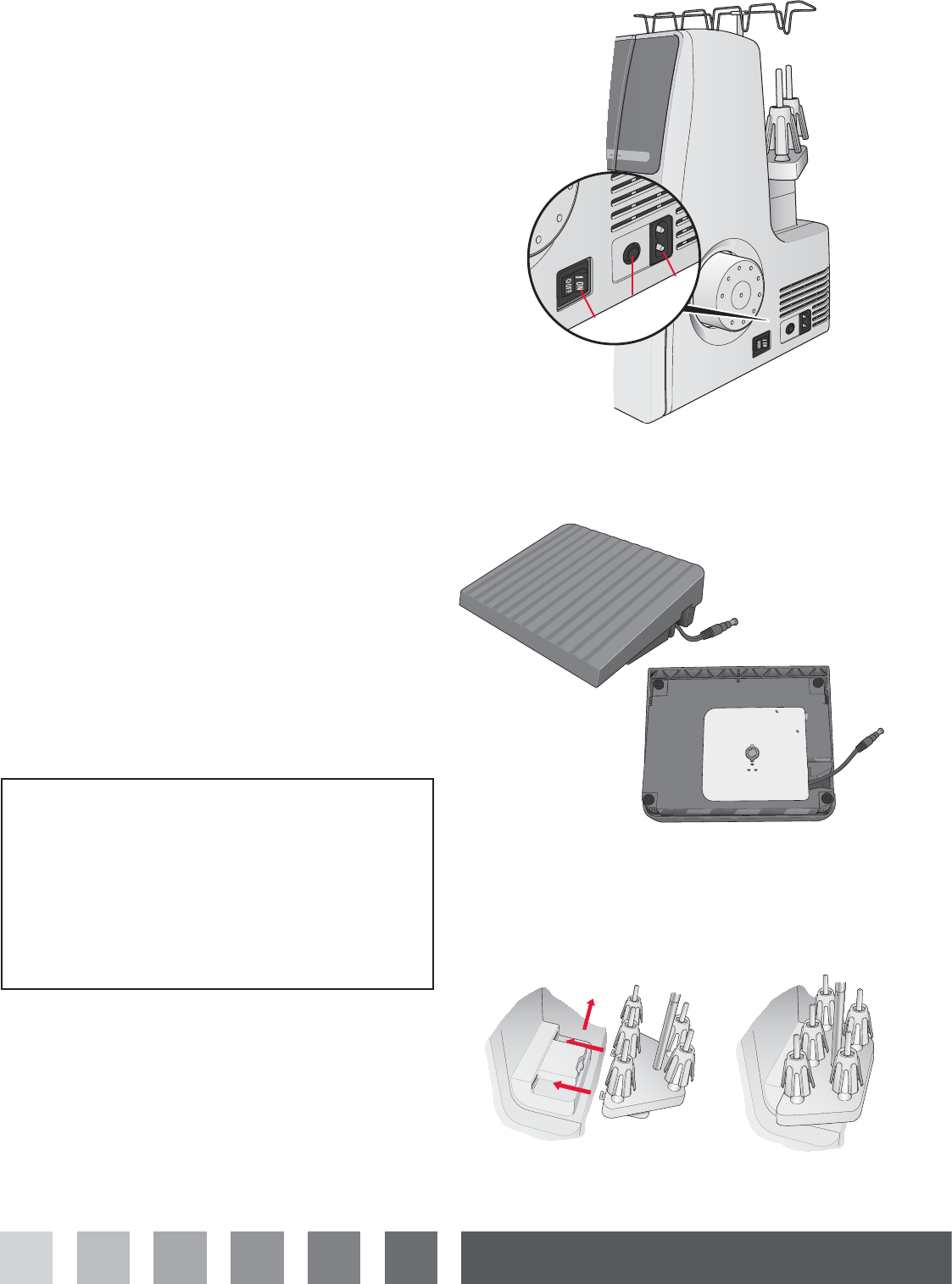

Connecting the foot control and the power supply ........7

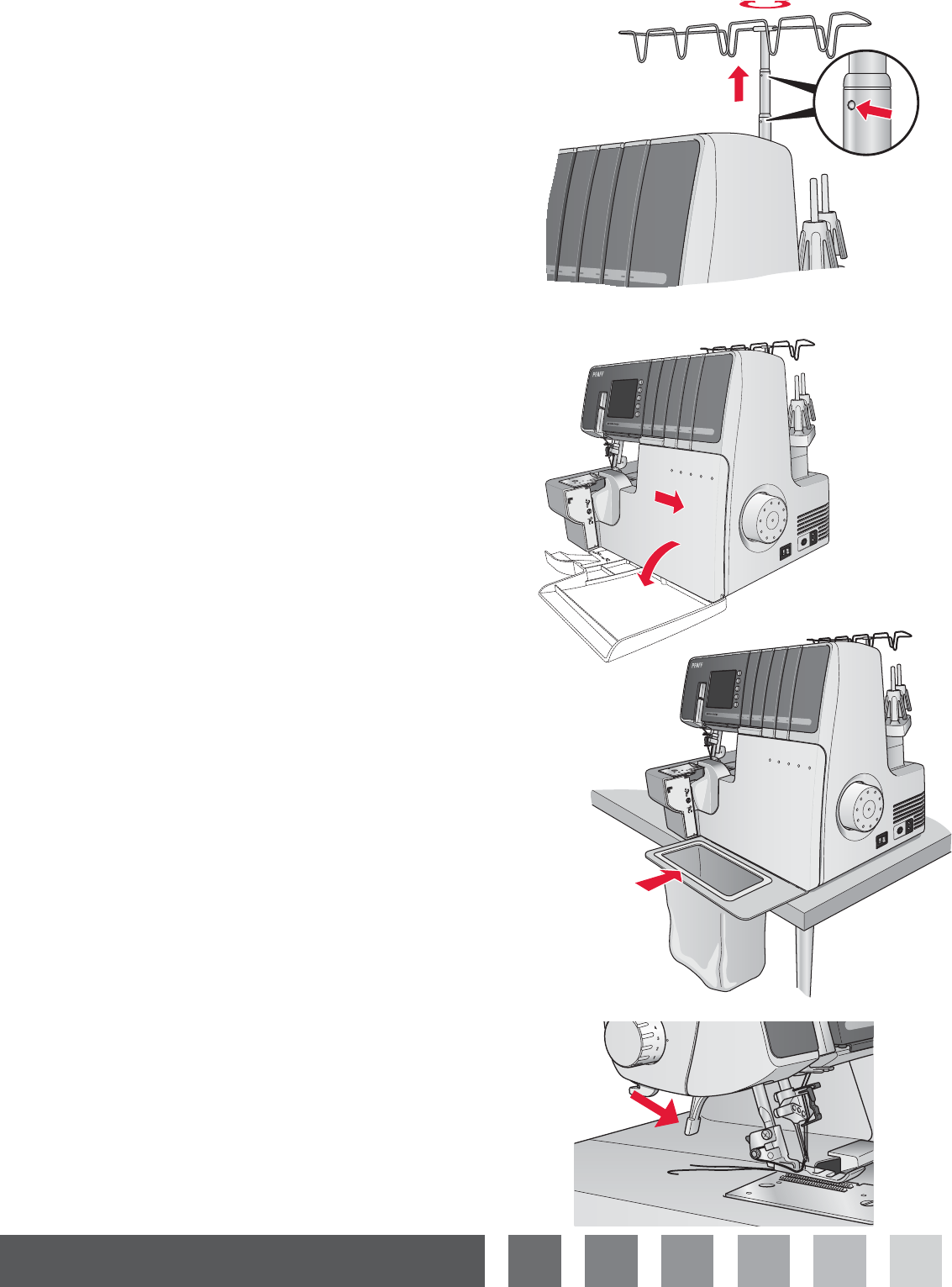

Setting up the spool stand ........................................................ 7

Setting up the telescopic thread stand ................................ 8

Front cover ....................................................................................... 8

Open ..............................................................................................................8

Close .............................................................................................................. 8

Attaching the waste tray ............................................................. 8

Presser foot lift ............................................................................... 8

Changing the presser foot ......................................................... 9

Needle information ....................................................................... 9

Changing the needles .................................................................. 9

Movable upper cutter ...............................................................10

Disengaging, position B ......................................................................10

Engaging, position A ............................................................................10

2-thread overlock converter ....................................................10

Engaging ................................................................................................... 10

Disengaging .............................................................................................10

Upper looper .................................................................................11

Disengaging .............................................................................................11

Engaging ................................................................................................... 11

Changing to coverstitch table B ............................................11

Stitch À nger lever setting .........................................................11

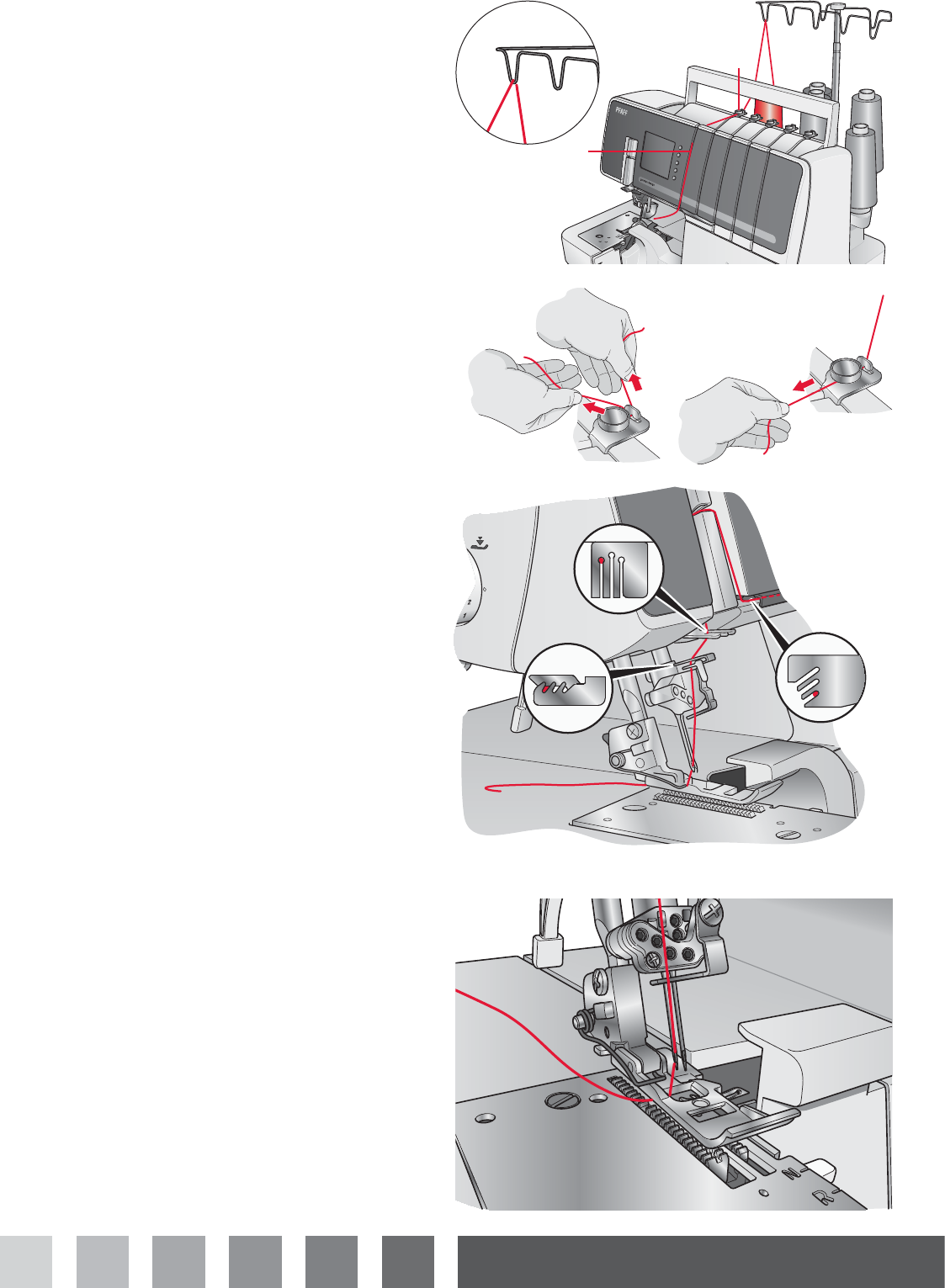

THREADING

General threading information ..............................................12

Threading the upper looper (red) .........................................13

Threading the lower looper (yellow) ....................................14

Threading chainstitch looper (purple) ................................15

Threading the right needle .....................................................16

Threading the left needle ........................................................17

Threading the chainstitch needle .........................................18

Threading the coverstitch needles .......................................19

Threading the right coverstitch needle ........................................ 19

Threading the middle coverstitch/chainstitch needle ...........20

Threading the coverstitch left needle ...........................................21

Needle threader ...........................................................................22

Changing thread ..........................................................................22

TOUCH SCREEN

Touch screen overview ..............................................................23

Select a stitch ................................................................................23

Recommendations ................................................................................23

On-screen stitch adjustments ................................................24

Thread tension .......................................................................................24

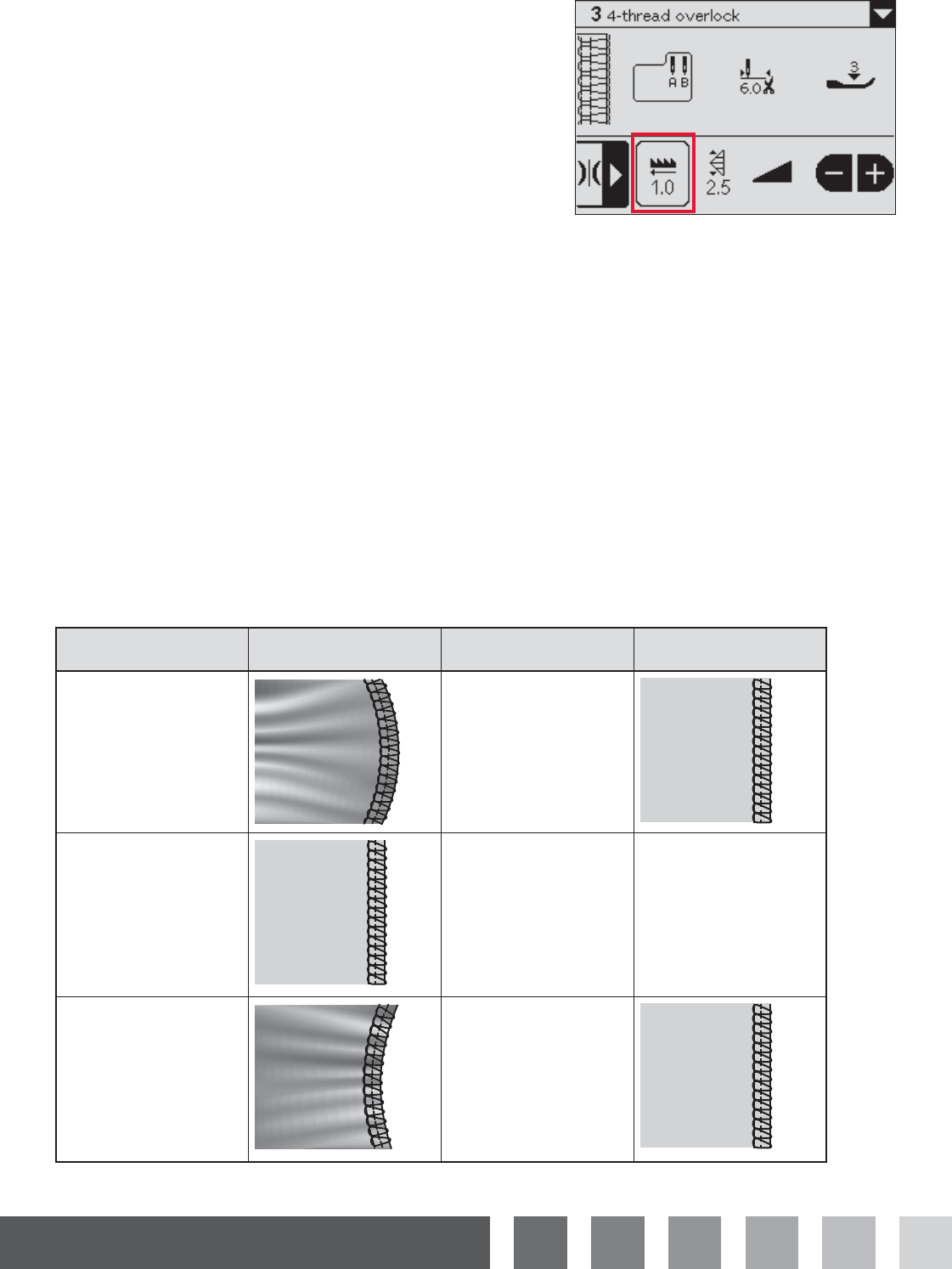

Differential feed ...................................................................................... 24

Stitch length ............................................................................................24

Sewing speed ..........................................................................................24

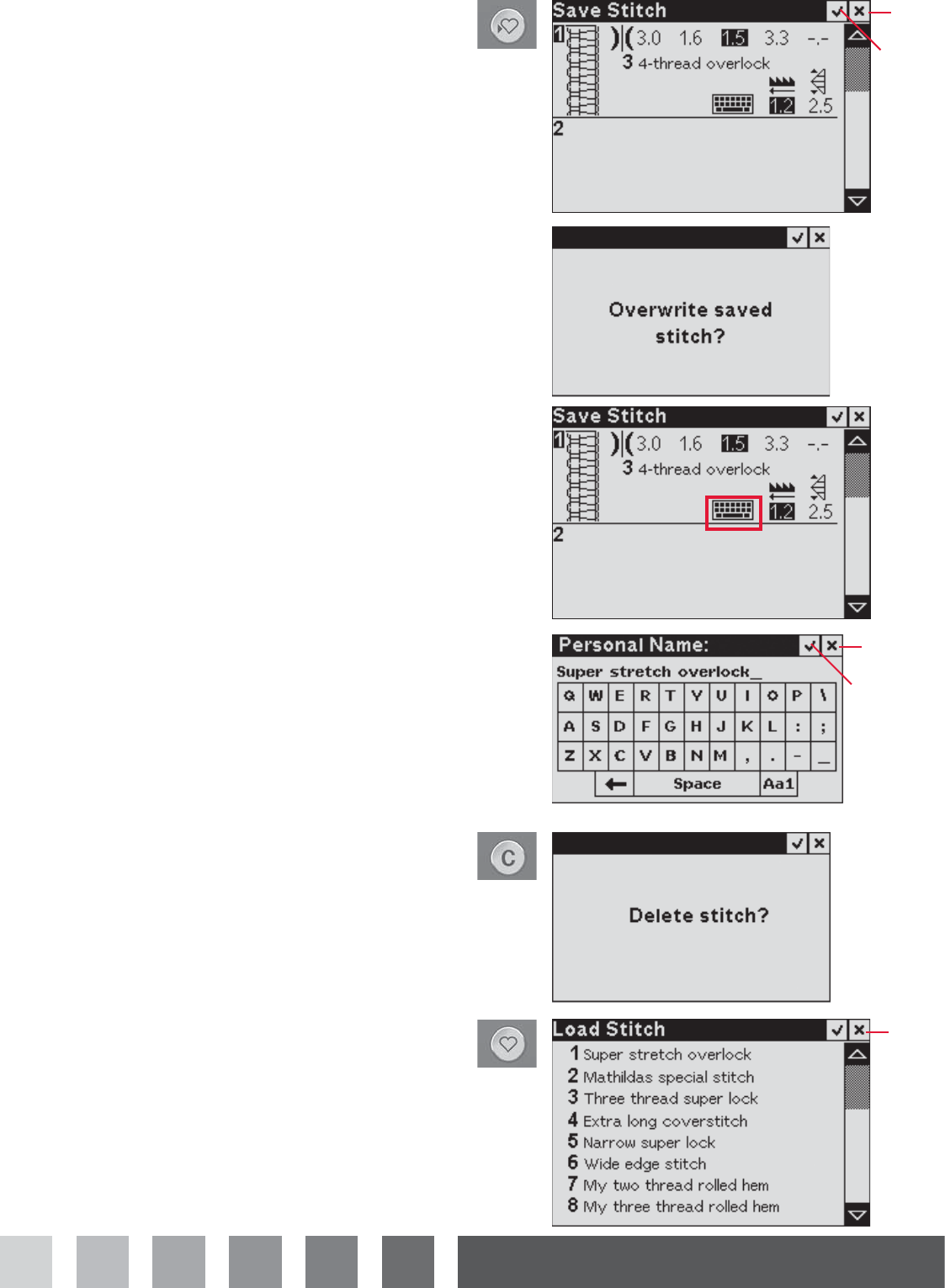

Save Stitch ......................................................................................25

Personal Name .......................................................................................25

Delete personal stitch ..........................................................................25

Load Stitch .....................................................................................25

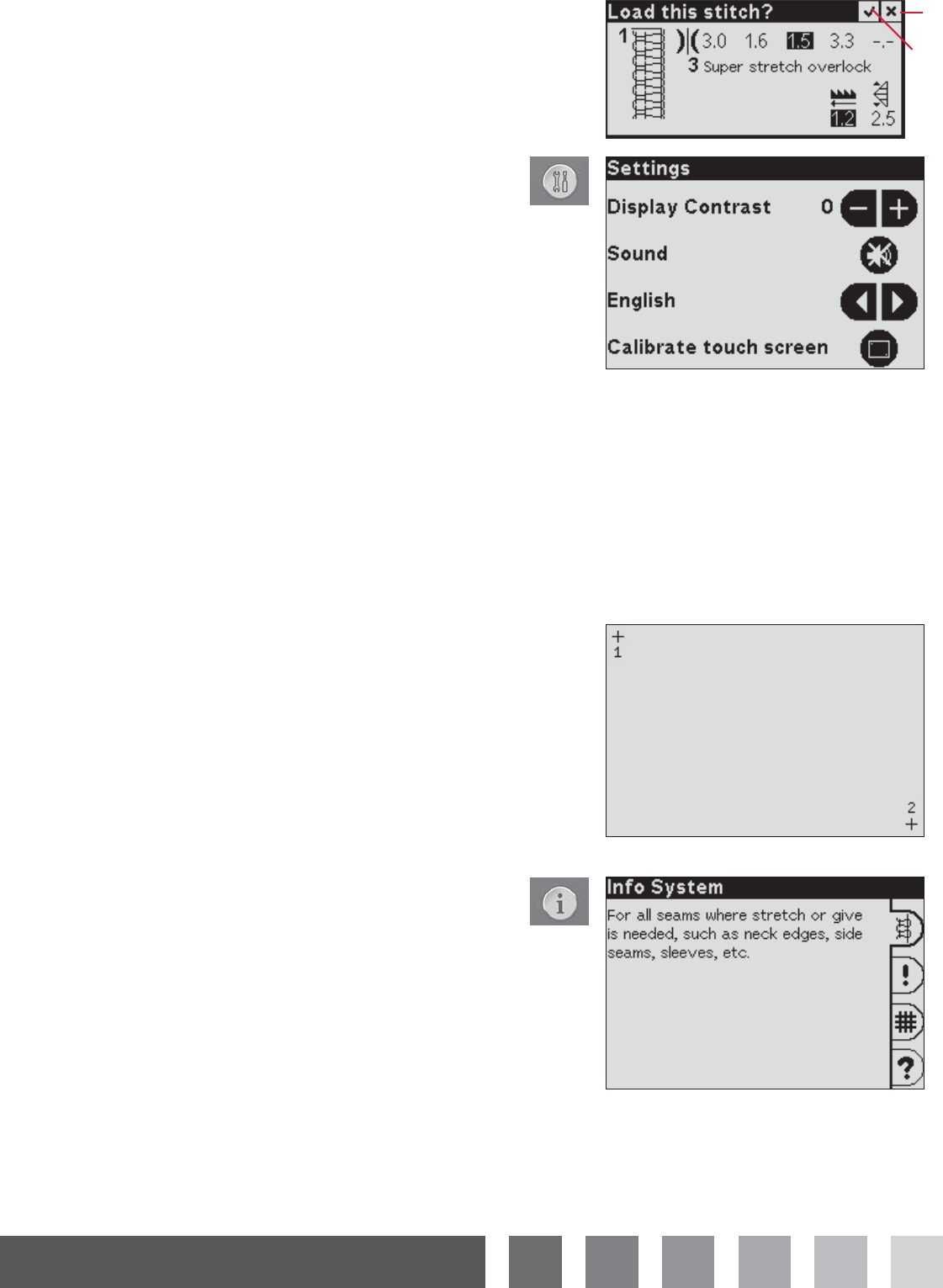

Settings menu ...............................................................................26

Display contrast .....................................................................................26

Sound .........................................................................................................26

Language .................................................................................................. 26

Calibrate touch screen ........................................................................26

Info System ....................................................................................26

Pop-ups ...........................................................................................27

STITCHES & SEWING TECHNIQUES

Stitch overview ..............................................................................28

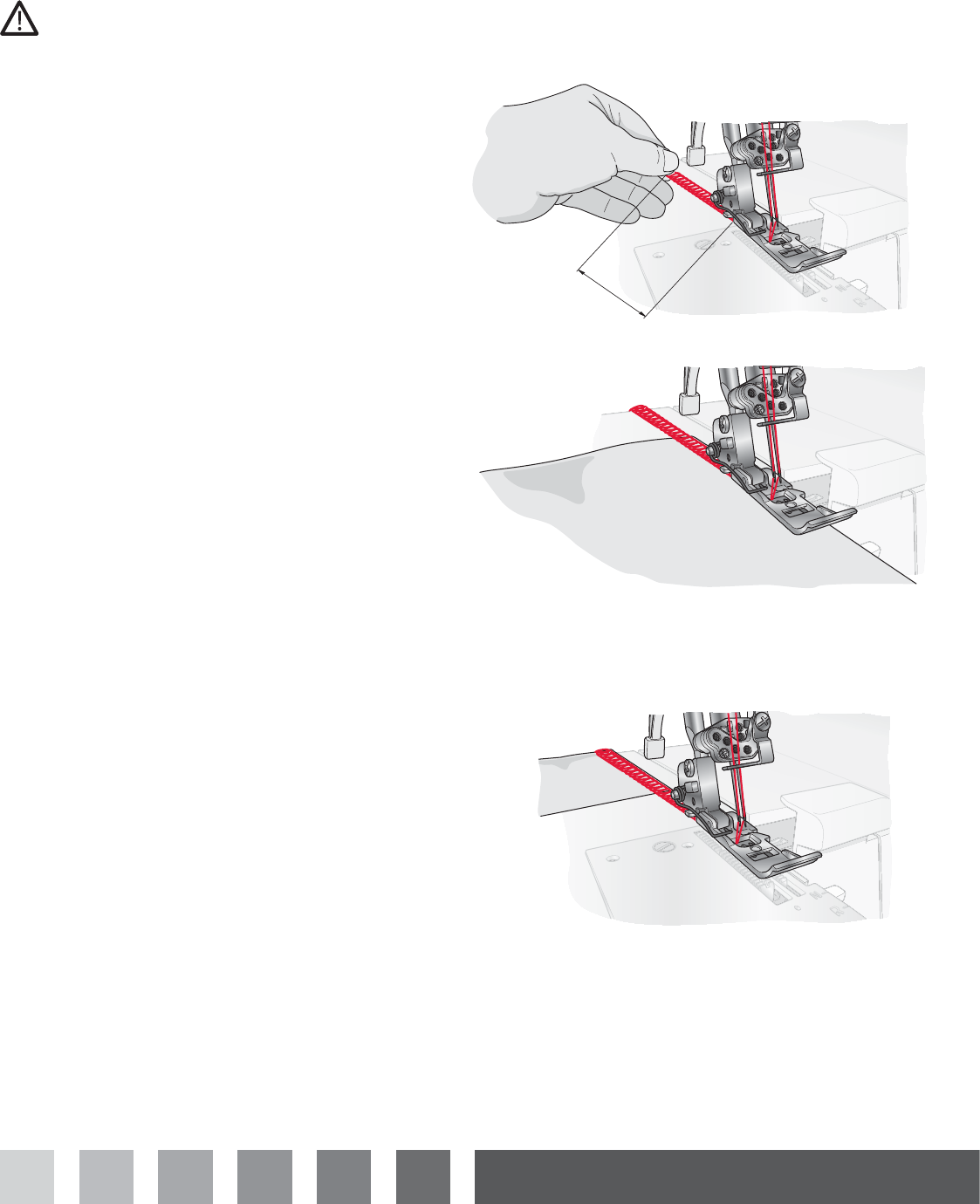

Start sewing ...................................................................................33

Pin Placement ........................................................................................33

Chain off ....................................................................................................33

Rolled edge sewing .....................................................................34

Coverstitch sewing ......................................................................34

Machine set up .......................................................................................34

Start sewing .............................................................................................34

Securing the coverstitch seam end ...............................................34

Flatlock sewing .............................................................................35

Standard Á atlock stitch .......................................................................35

Ornamental Á atlock stitch .................................................................35

Ladder stitch ........................................................................................... 35

Chainstitch sewing ......................................................................36

Machine set up .......................................................................................36

Start and end of sewing ..................................................................... 36

Sewing hints ..................................................................................36

Pintuck sewing .......................................................................................36

Sew in Circles .......................................................................................... 36

Securing the thread chain .................................................................36

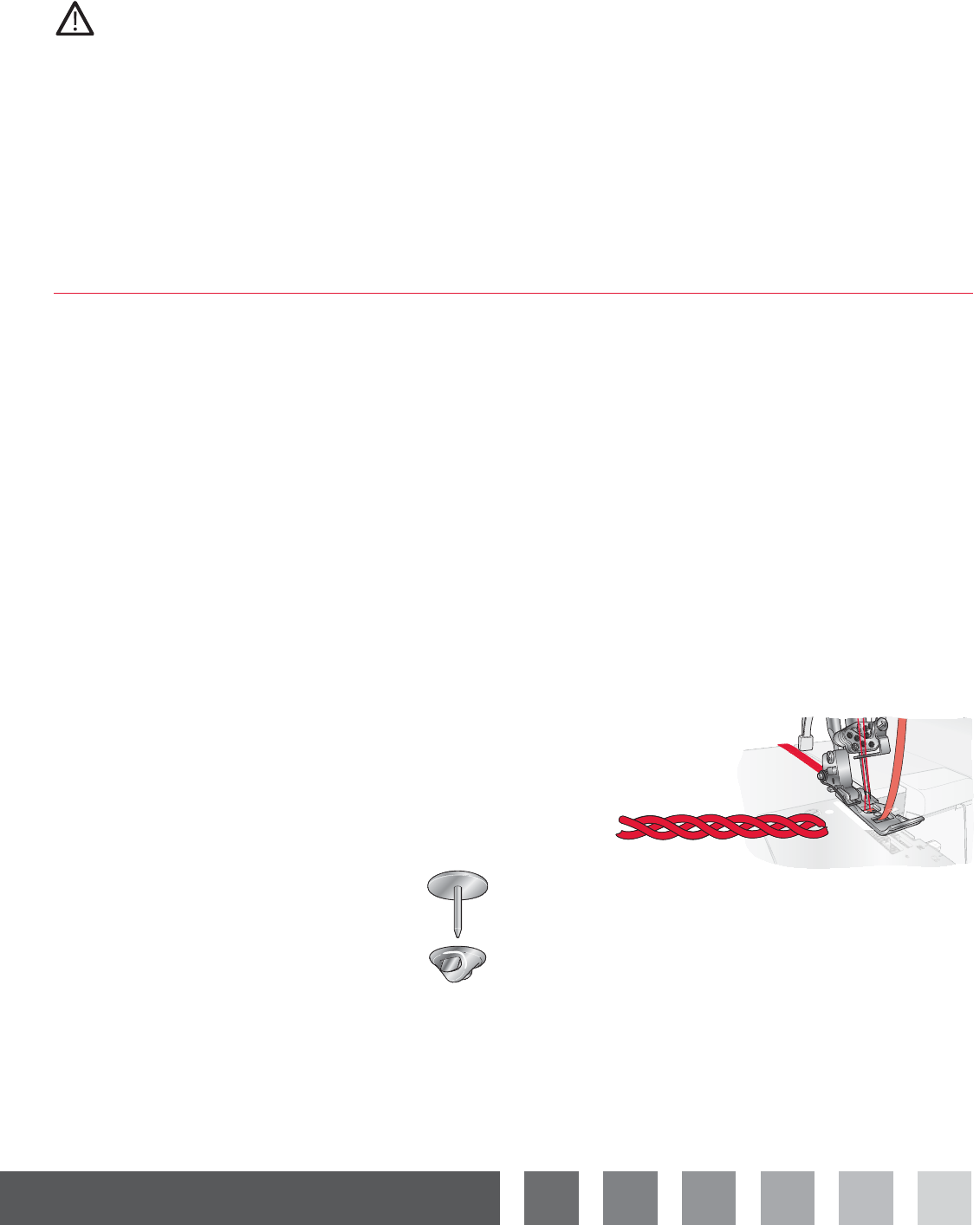

Braiding by chaining off .....................................................................36

Lowering the needle(s) .......................................................................36

STITCH ADJUSTMENTS

Stitch width adjustment ...........................................................37

Width adjustment by changing needle position ...................... 37

Width adjustment with the cutting width dial ...........................37

Presser foot pressure adjustment ........................................37

Stitch length adjustment ..........................................................37

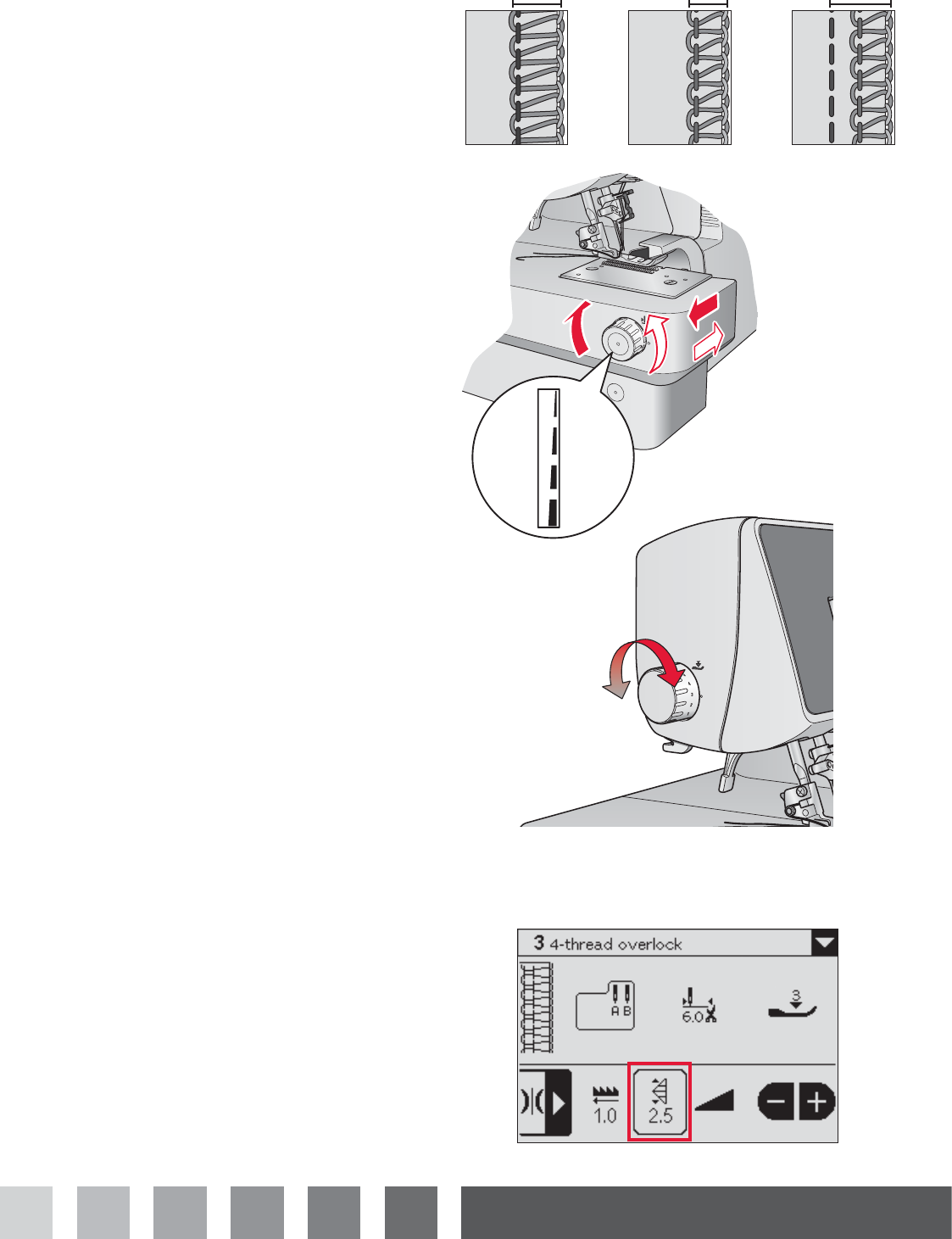

Differential feed adjustment ...................................................38

Gathered overlock (stretch, knit fabrics) .....................................38

Stretch overlock (lightweight fabrics) ........................................... 38

Thread tension À ne tuning ......................................................39

MAINTENANCE

Machine maintenance ...............................................................41

Cleaning .................................................................................................... 41

Cleaning the touch screen ................................................................. 41

Oiling ..........................................................................................................41

Replacing the movable upper cutter ............................................41

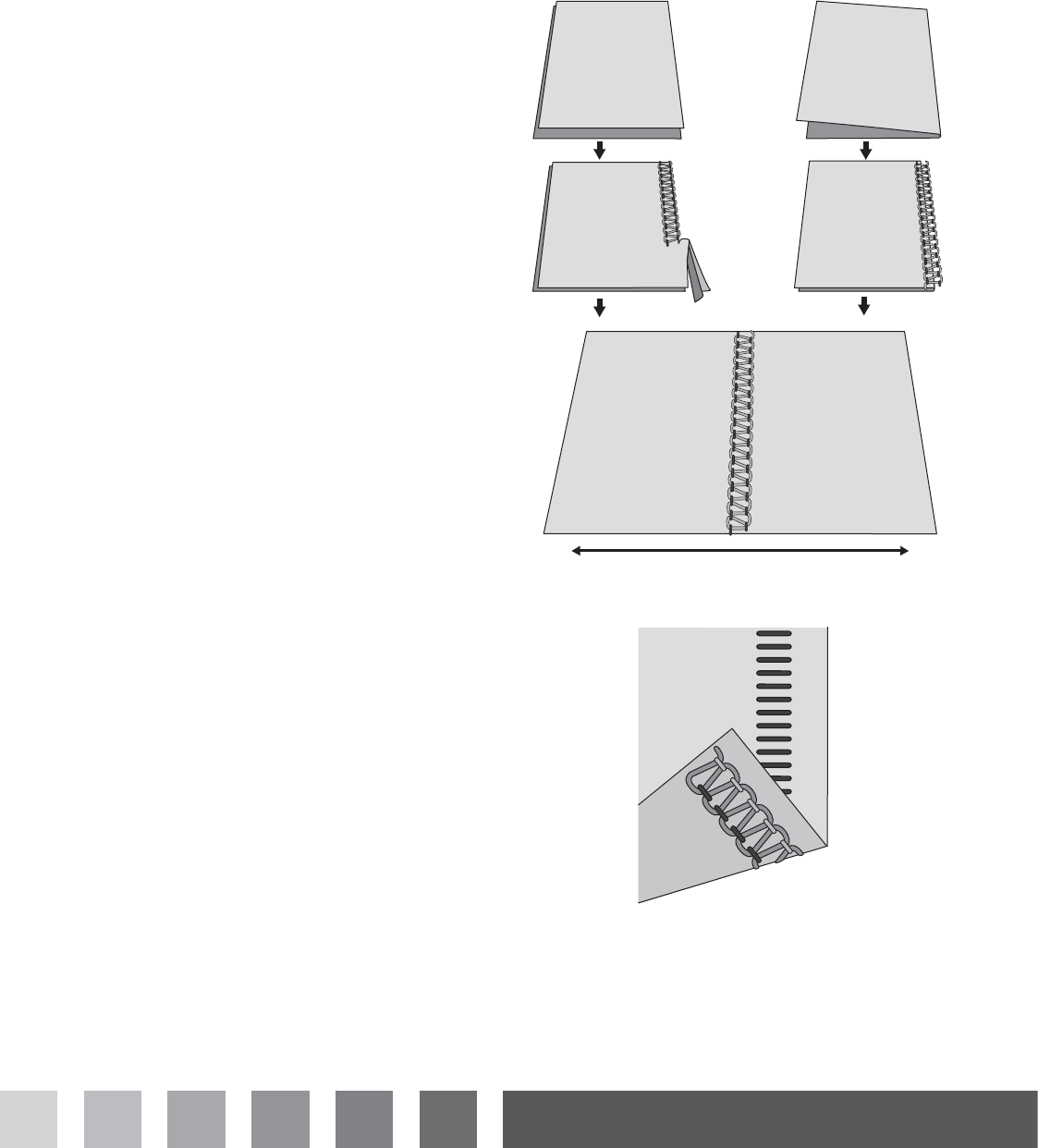

Storage .............................................................................................42

Servicing ..........................................................................................42

Trouble shooting ..........................................................................42

Machine speciÀ cations ..............................................................43

Intellectual Property ...................................................................43