28 GB/IE/NI/CY/MT

ATTENTION: Always use pliers to remove used electrodes or hot workpieces. Make sure that the

electrode holder is always placed onto an insulated surface after welding. The slag can only be removed

from the seam once it has cooled down. To continue welding an interrupted seam:

First remove the slag at the connection point.

The electric arc is ignited in the weld groove, guided to the connection point, melted properly there

and then continues from that point.

ATTENTION: Welding generates heat. Therefore the welding device must run idle for at least half

an hour after use. Alternatively, you can leave the device to cool for an hour. The device can only be

packed away and stored once the temperature of the device is normal again.

ATTENTION: A voltage which is 10% below the rated input voltage of the welder can have the

following consequences:

The power to the device will reduce.

The arc stops or becomes unstable.

ATTENTION:

The arc radiation can lead to inflammation of the eyes and skin burns.

Casting and welding slag can cause eye injuries and burns.

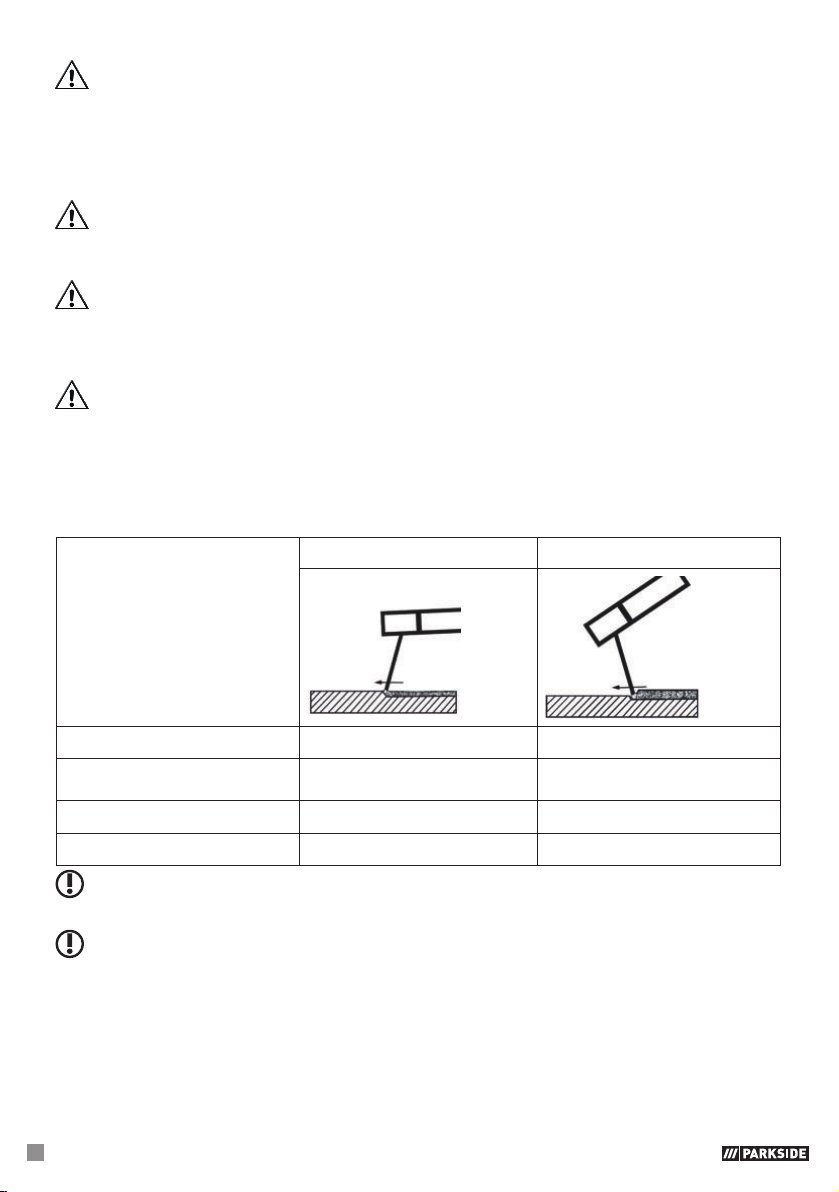

It is essential that you only use the welding cable which is included with the delivery. Choose

between push and drag welding. The following section shows the impact of the direction of

movement on the properties of the weld seam:

Push welding Drag welding

Burn smaller larger

Weld seam width larger smaller

Weld bead flatter higher

Weld seam fault larger smaller

PLEASE NOTE: You decide for yourself which type of welding is most suitable, once you have

welded a sample piece.

PLEASE NOTE: Once it has worn down completely, the electrode must be replaced.

zTIG welding

For TIG welding please follow the instructions for your TIG torch. TIG mode can be activated as

described under “Selecting the welding method”.