4

2. Important! Read carefully before carrying out any work!

This control unit may only be connected and put into operation by qualified and

suitably trained specialist personnel. For the purpose of this description qualified and

suitably trained specialist personnel are persons who are adequately instructed or

supervised by qualified electricians and are thus in a position to recognize the hazards

that electricity can cause. Moreover, they must hold qualifications consistent with the

work being carried out, in particular they must be

• knowledge of applicable electro-technological regulations,

• have received training in the use and maintenance of adequate safety equipment,

• as well as first aid training.

Before carrying out any cabling work, it is essential to disconnect the

control unit from the mains supply.

Observe local safety regulations!

Always lay mains cable and control cable separately!

Control voltage 24 V DC.

Before putting the control unit into operation, it is essential to ensure

that there are no persons or objects within the door's area of operation,

since a number of settings set the door in motion.

All available emergency command devices must be tested prior to initial

operation.

The door operator may only be installed with the door closed!

After installation and initial operation, those persons or their

representatives responsible for operating the door system must be shown how

the door system works!

No cables may be fed into the top of the control unit.

For technical reasons, the first time the control unit is switched on, the

door opens fully.

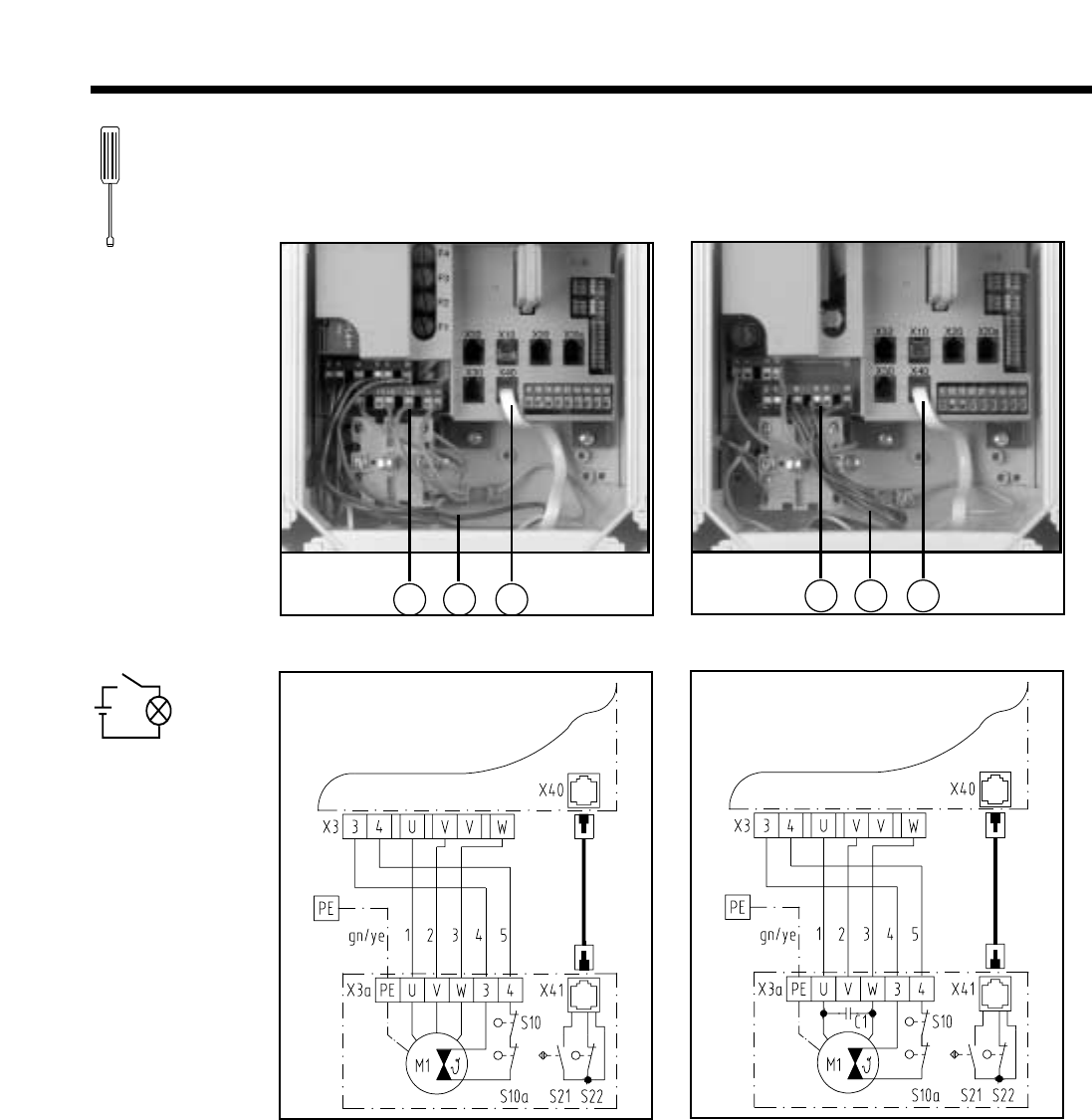

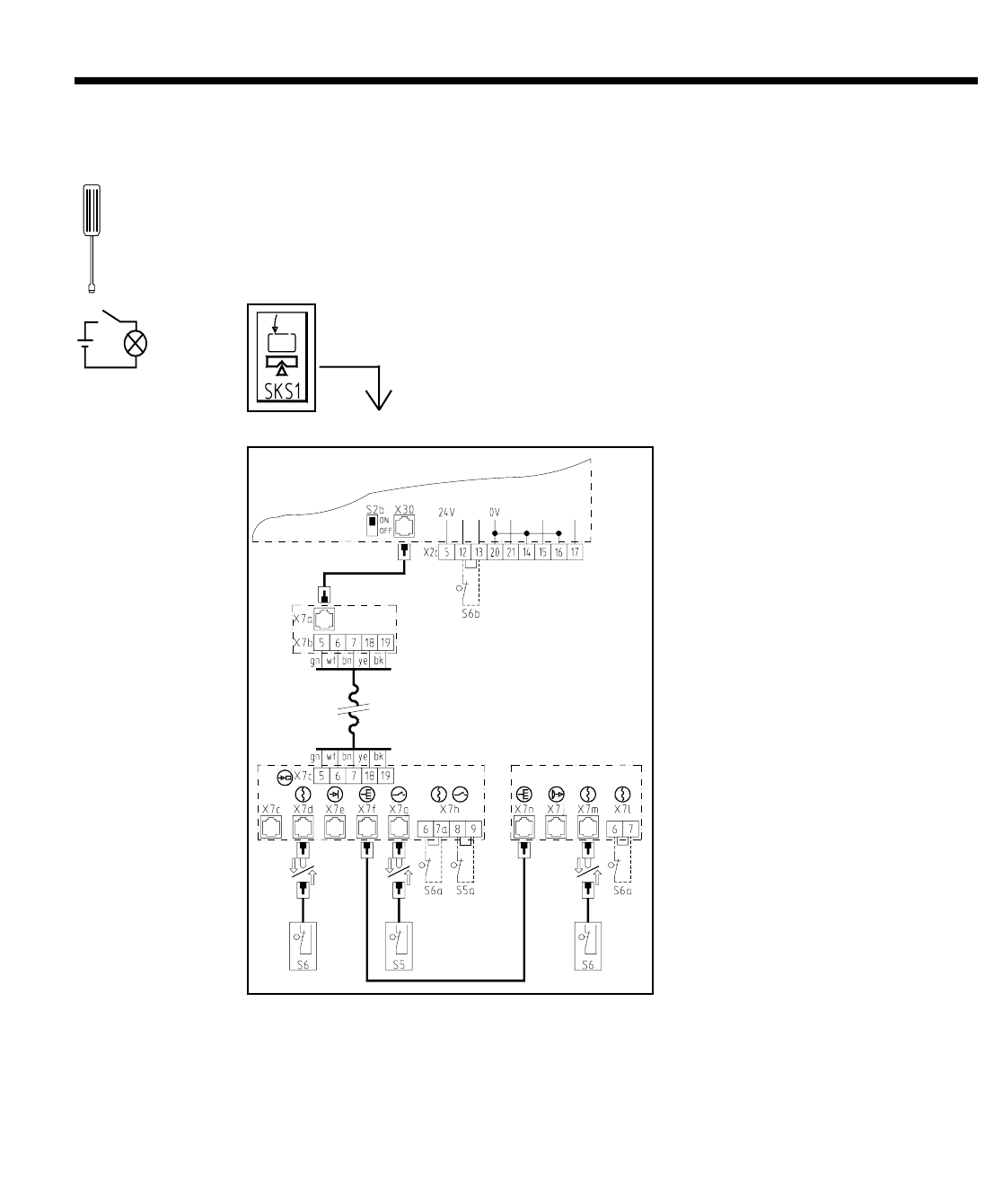

To carry out programming, the S11 programming switch on the main circuit

board must be set at the ON position. After initial operation it is

essential that this switch be returned to the OFF position in order to

prevent unintentional reprogramming of the control unit.

Special note for installation according to protection category IP 65:

At the very latest following initial operation, the plug connection to the

mains must be replaced by a direct mains connection with a mains isolator

switch!

Non-compliance with these warning and safety instructions can

lead to bodily injury and material damage.