Optimum performance of the extractor

hood:

❑

Short, smooth extraction pipe.

❑

As few pipe bends as possible.

❑

Largest possible pipe diameter (prefera-

bly 150 mm ø) and large pipe bends.

❑

Round pipes:

We recommend

for single-motor model,

inner diameter of at least 120 mm

for double-motor model.

inner diameter of at least 150 mm

❑

Flat ducts must have an inner cross-

section equivalent to round pipes

which have an inner diameter of

120/150 mm.

120 mm l approx. 113 cm

2

150 mm l approx. 177 cm

2

❑

If pipe diameters differ: use sealing

strip.

❑

Ensure an adequate air supply for

exhaust-air mode.

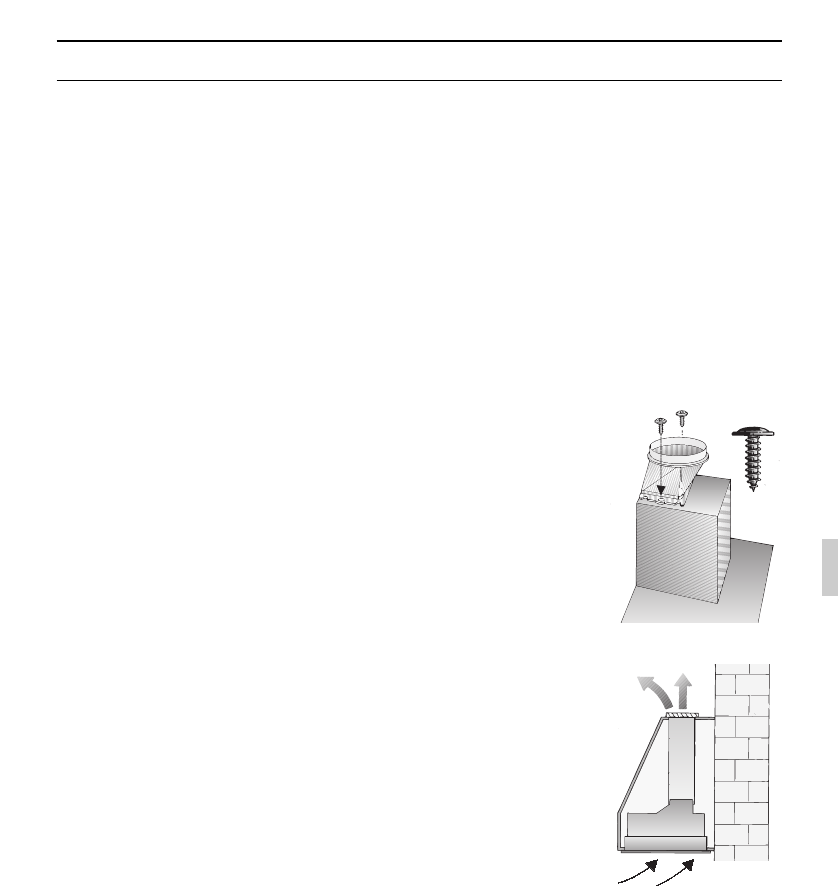

Pipe connection

Extractor hoods with 120 mm Ø air

outlet:

100 mm Ø extraction pipe

❑ Insert the reducing connector into the

air-pipe connector and then attach the

exhaust-air pipe.

120 mm Ø extraction pipe

❑ Attach the exhaust-air pipe directly to

the air-pipe connector.

Extractor hoods with 150 mm Ø air

outlet:

150 mm l extraction pipe

❑ Screw the reducing connector onto the

air outlet.

❑ Attach the extraction pipe to the redu-

cing connector.

150 mm l extraction pipe

❑ Attach the exhaust-air pipe directly to

the air outlet..

ṇ If a one-way flap has been fitted, con-

duct a performance test.

Extractor hoods with rectangular air

outlet:

❑ Screw the enclosed

air-pipe connector

over the air outlet.

Recirculated

air mode

❑

The air cleaned by an additional activa-

ted carbon filter is conveyed back into

the room.

❑

In recirculated air mode the exhaust ope-

ning must be protected by a grille in

order to prevent a mechanical or electri-

cal hazard.

Prior to installation

25