30 Ferm

PRODUCT INFORMATION

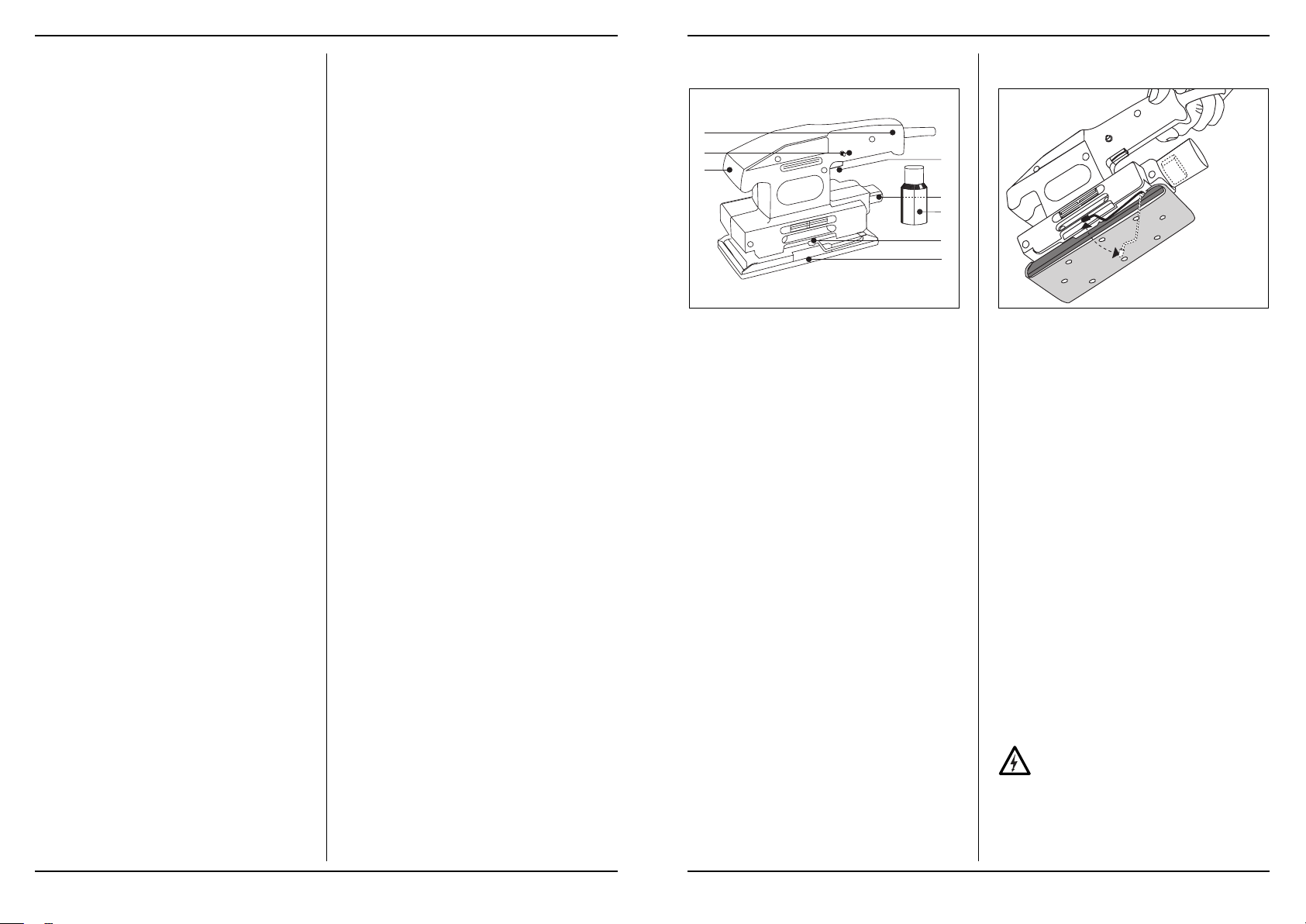

Fig. A.

1. On/off switch

2. Dust exhauster adaptor

3. Dust collection opening

4. Paper clamp

5. Sand sole

6. Handle ( behind)

7. Blocking switch

8. Handle ( front)

OPERATION

Fig. B.

Choice of the sand-paper.

Coarse sand-paper (grain 50) removes in general the big-

ger part of the material and fine sand-paper is used for the

finishing. If the surface is not even, then start with rough

sand-paper. Further you use middlecoarse sand-paper

(grain 80) to remove the scratches left behind by the coar-

se sand-paper and finally you take fine sand-paper (grain

120) for the finishing.

Installing sand-paper.

The sanding machine is provided with a rectangle sand

sole. By tightening the sand-paper it does not wear out that

fast and so it will wear well longer.

• Pull the mains plug out of the power-point;

• Open the hindmost clamp by pressing up the interloc-

king;

• Install the sand-paper under the clamp, see to the pa-

per being in the middle and look after the perforations

in the paper. They have to correspond with those on

the sand sole, so that the dust can be exhausted.

• Put the clamping spring back into the original position.

• Repeat the operation to fix the sand-paper on the front

side.

• Check all the time if the exhaust gaps are not stopped

up when you place the sand-paper, and check if the

perforations in the sand-paper correspond with the ex-

haust gaps.

• Fix the sand-paper as tight as possible.

Before assembly sanding paper always remove

the plug from the mains.