ENGLISH

41

SEASONAL CLEANING (implemented by the DEALER)

• Clean the stove internally and externally

• Carefully clean the heat exchange tubes

• Carefully clean and remove dirt from the combustion chamber and the relative compartment

• Clean fans, verify mechanical and clamp loosening

• Clean smoke channel (replace seals on smoke exhaust pipe)

• Clean smoke duct (see weekly cleaning)

• Clean smoke extraction fan compartment, flow sensor and check thermocouple.

• Clean, inspect and scrape any residue from the ignition resistance compartment and if necessary, replace it

• Clean/check the Synoptic Panel

• Visually inspect the electrical wires, connections and power cable

• Clean the pellet hopper and check loosening of the feed screw - gear motor assembly

• Replace the door seal

• Functionality test: load the feed screw, ignite, let it run for 10 minutes and shutdown

If the stove is used very often, it is recommended to clean the smoke channel every 3 months.

Cleaning the smoke duct

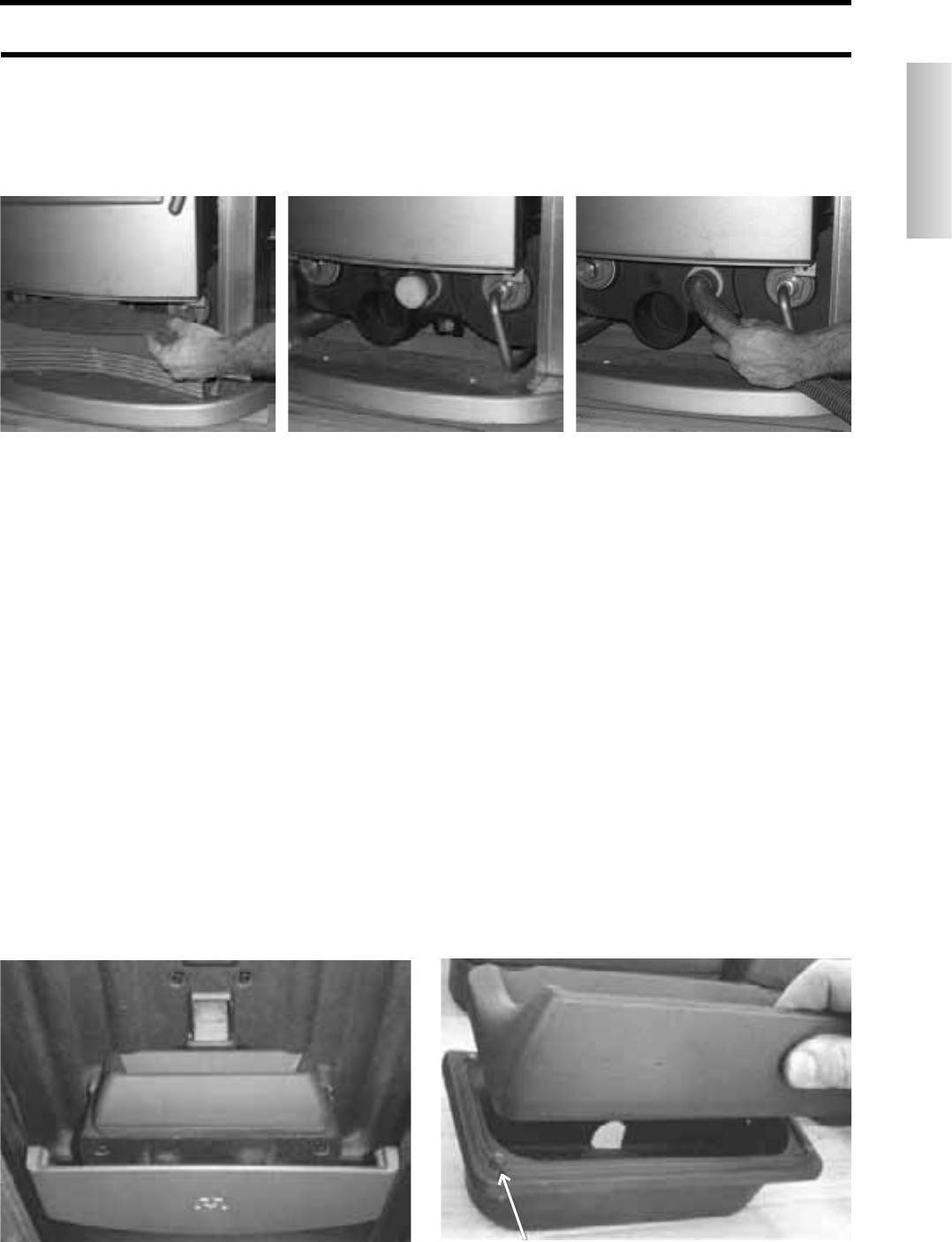

• With the stove off and cold, move the cleaning rods energetically (see page 40). Remove the lower cast iron front panel (fig. D),

the silicone stopper * (fig. E) and vacuum the residue (fig. F).

The amount of residue will depend on the type of fuel and system.

Failure to carry out this cleaning procedure may cause the stove to block.

Once the procedure is implemented, ensure that the inspection hatch (silicone stopper) is closed properly.

fig. D fig. E fig. F

Ensure that the lower combustion chamber centering pins fit into the relative upper combustion chamber

centering holes (figura 2).

ATTENTION !!!

After implementing a normal cleaning procedure, INCORRECT coupling of the upper and lower combustion

chambers can compromise the stove’s performance.

Therefore, before igniting the stove, ensure that the combustion chambers are correctly coupled as shown in

(figura 1).

*

fig. 1

fig. 2

MAINTENANCE