12

Important information

Installation Instructions:

Old appliances are not worthless

rubbish. Valuable raw materials can be

reclaimed by recycling old appliances.

Before disposing of your old appliance,

render it unusable.

You received your new appliance in a

protective shipping carton. All packaging

materials are environmentally friendly and

recyclable. Please contribute to a better

environment by disposing of packaging

materials in an environmentally-friendly

manner.

Please ask your dealer or inquire at your

local authority about current means of

disposal.

The extractor hood can be used in

exhaust air or circulating air mode.

Always mount the extractor hood over

the centre of the hob.

Minimum distance between electric

hob and bottom edge of extractor hood:

430 mm, Fig. 1.

The extractor hood must not be

installed over a solid fuel cooker – a

potential fire hazard (e.g. flying sparks) –

unless the cooker features a closed,

non-removable cover and all national

regulations are observed.

The smaller the gap between the

extractor hood and hotplates, the greater

the likelihood that droplets will form on the

underside of the extractor hood.

Additional information concerning gas

cookers:

When installing gas hotplates, comply

with the relevant national statutory

regulations (e.g. in Germany: Technische

Regeln Gasinstallation TRGI).

Always comply with the currently valid

regulations and installation instructions

supplied by the gas appliance

manufacturer.

Only one side of the extractor hood

may be installed next to a high-sided unit

or high wall. Gap at least 50 mm.

Minimum distance on gas hotplates

between the upper edge of the trivet

and lower edge of the extractor

hood: 650 mm, Fig. 1.

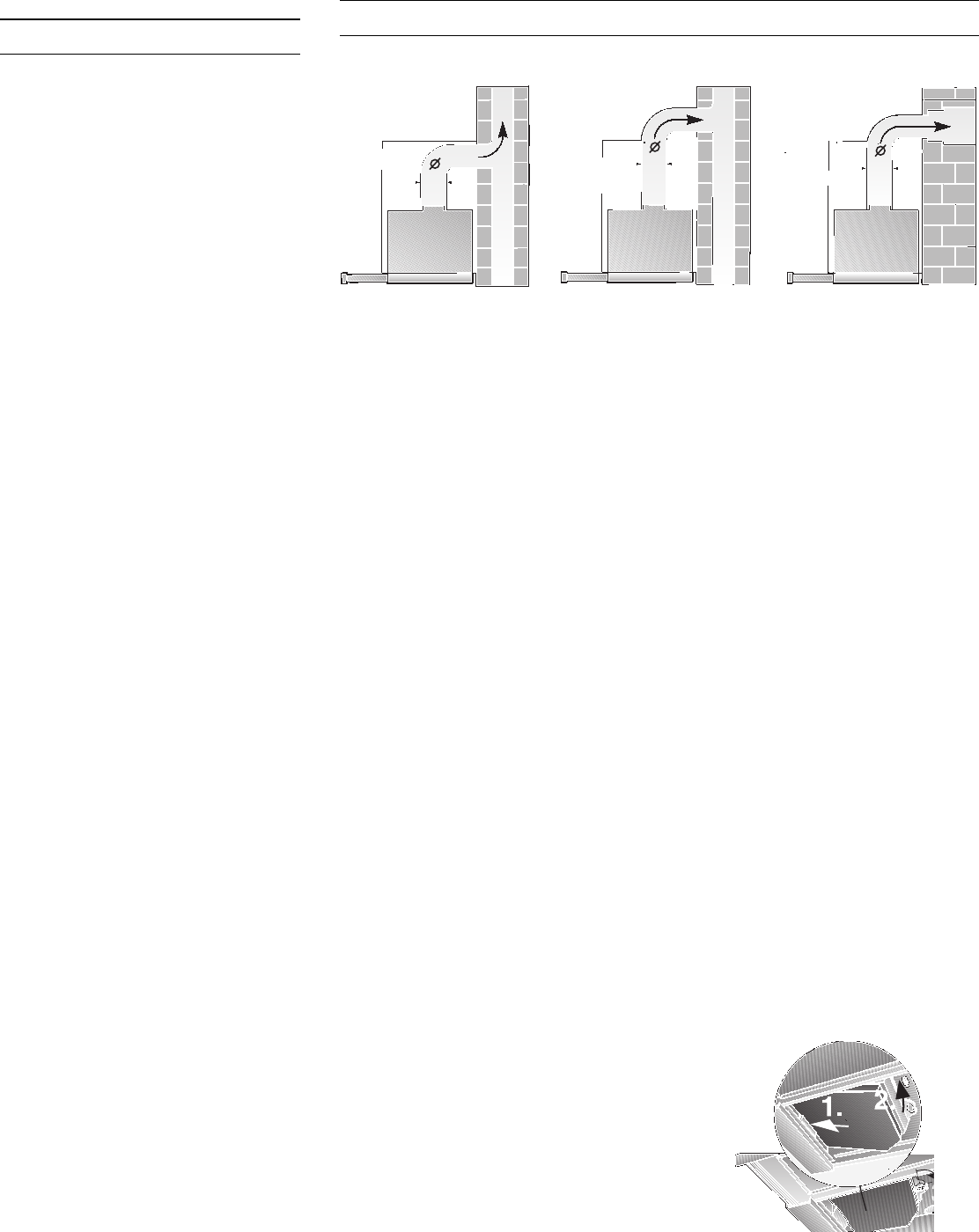

The exhaust air is discharged upwards

through a ventilation shaft or directly

through the outside wall into the open.

D

Exhaust air must not be discharged via

a smoke or exhaust gas flue which is

already in use or via a shaft which is used

for ventilating rooms in which fireplaces are

located.

Discharge exhaust air in accordance

with official and statutory regulations

(e.g. national building regulations).

Discharge of air into smoke or exhaust air

flues which are not in use requires the

consent of a heating engineer.

D

If the extractor hood is operated in

exhaust-air mode at the same time as a

flue-type heater (e.g. gas, oil or solid-fuel

heater, instantaneous water heater, boiler),

ensure that there is an adequate air

supply which the heater requires for

combustion.

Safe operation is possible provided that the

partial vacuum in the room in which the

heater is installed does not exceed 4 Pa

(0.04 mbar).This can be achieved if the

combustion air is able to flow through non-

lockable openings, e.g. in doors, windows

and in conjunction with an air supply/air-

intake wall box or by other technical proce-

dures such as reciprocal interlocking.

If the air intake is inadequate, there is a

risk of poisoning from combustion gases

which are drawn back into the room.

An air-intake/exhaust-air wall box by itself is

no guarantee that the limiting value will not

be exceeded.

Note: When assessing the overall

requirement, the combined ventilation

system for the entire household must be

taken into consideration. This rule does not

apply to the use of cooking appliances,

such as hobs and gas cookers.

The extractor hood can be used without

restriction in circulating air mode – with an

activated carbon filter.

For exhaust air mode a one-way flap

should be installed in the extractor hood

unless already installed in the exhaust air

pipe or wall box.

If a one-way flap is not enclosed with the

extractor hood, you purchase one from

your dealer.

If the exhaust air is conveyed through

the outside wall, a telescopic wall box

should be used.

Prior to installation

Exhaust-air mode

For optimum extractor hood efficiency:

K

Short, smooth air exhaust pipe.

K

As few bends in the pipe as possible.

K

Diameter of pipe to be as large as pos-

sible (ideal is l 120 mm ) and no tight

bends in pipe.

If long, rough exhaust-air pipes,

many pipe bends or smaller pipe

diameters are used, the air extraction

rate will no longer be at an optimum

level and there will be an increase in

noise.

The manufacturer of the

extractor hoods accepts no liability

for complaints which can be

attributed to the design and layout of

the pipework.

K

Round pipes:

We recommend

Internal diameter at least. 120 mm.

K

Flact ducts must have an internal

cross-section that equates to that of

round pipes with a 100/120 mm internal

diameter.

There should be no sharp bends.

l 100 mm approx. 078 cm

2

l 120 mm approx. 113 cm

2

If pipes have different diameters:

K

Insert sealing strip.

K

For exhaust-air mode, ensure that

there is an adequate supply of fresh air.

Exhaust outlet connection:

Pipe diameter: 100 or 120 mm.

K

Insert the enclosed outlet connector and

twist it as far as it will go.

K

If the pipe diameter is 120 mm, cut out

the inner part of the outlet connector.