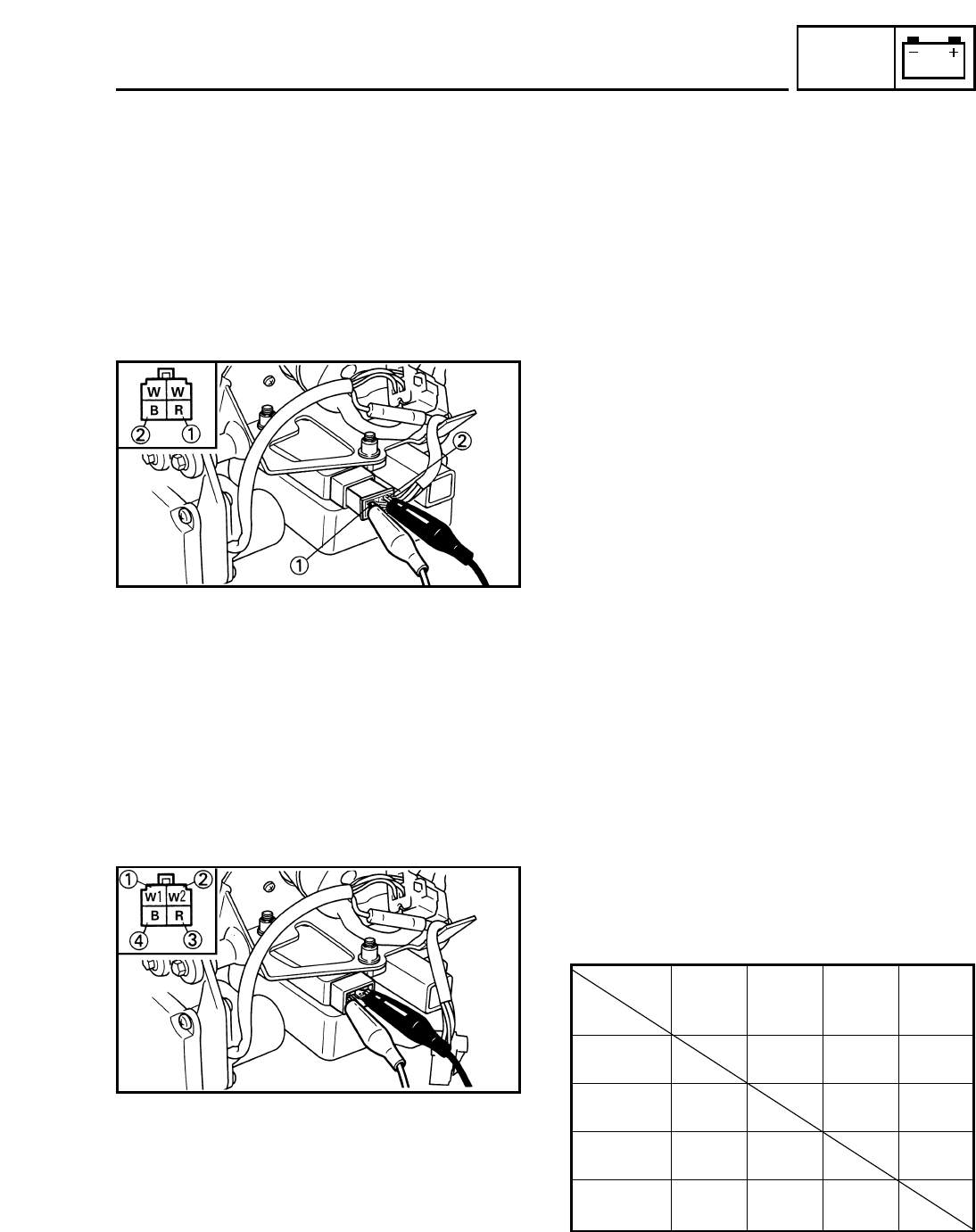

SETTING

7-6

CC

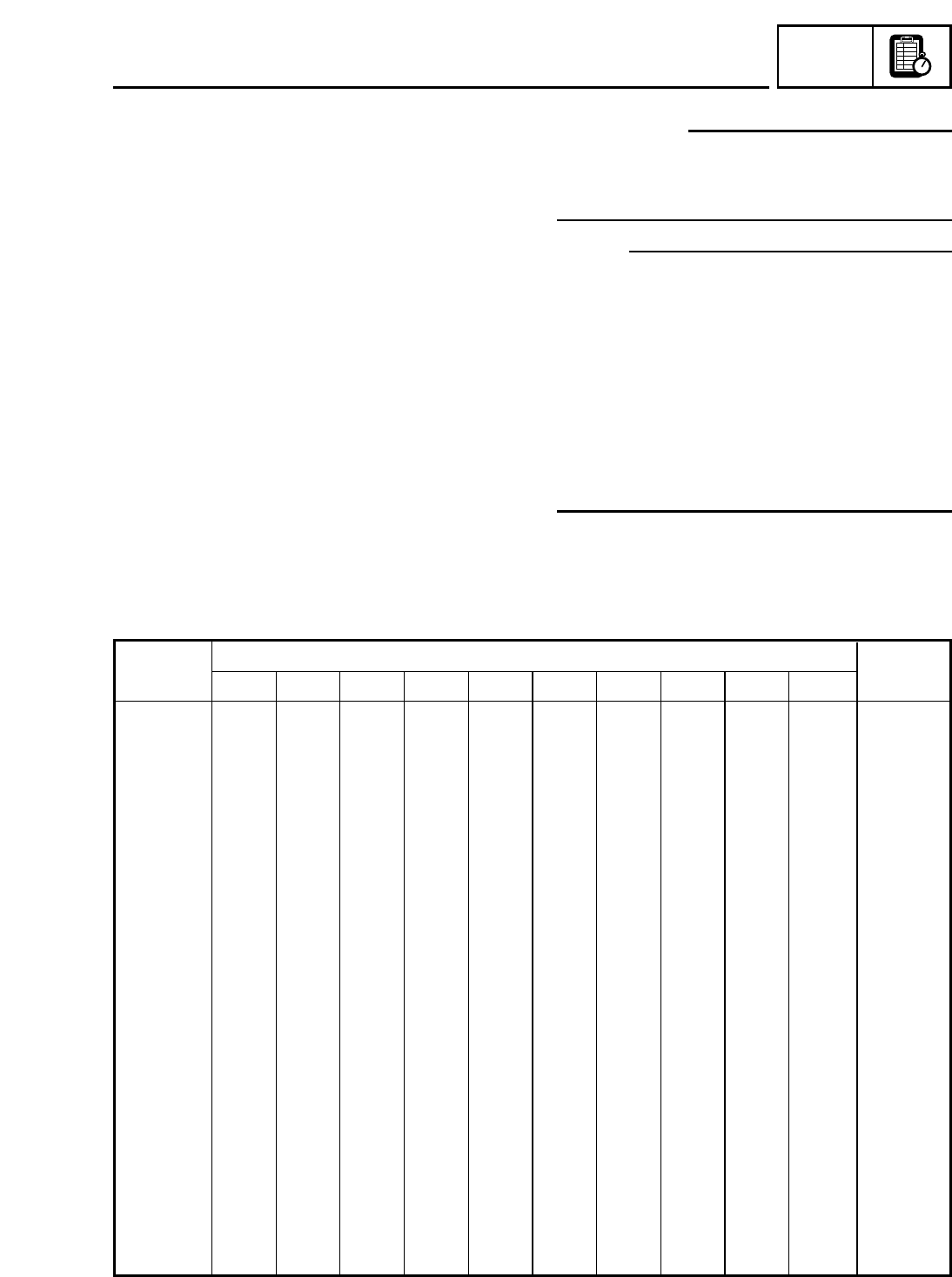

CAUTION:

If a change in conditions require a main jet

of a larger size, use the size to which #20 is

added for safety.

NOTE:

• Since this correction coefficient table lacks a

column for humidity, it is advisable to check

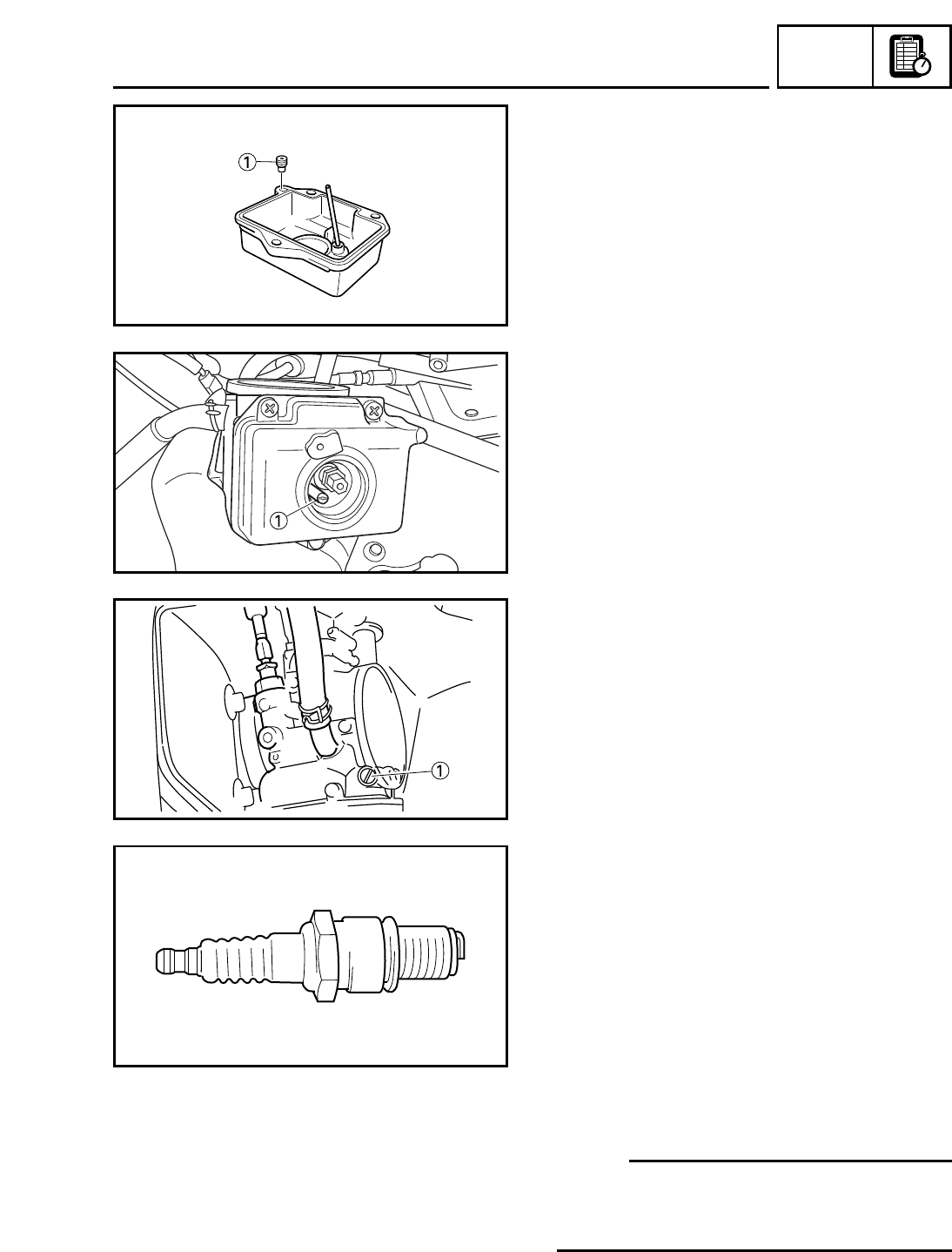

the degree of discoloration of the spark

plug(s) for final selection according to an

explanation under “Atmospheric conditions

and carburetor setting’’ (P7-1).

• As the main nozzle is more susceptible to

other than atmospheric conditions, no correc-

tion coefficient is used for main nozzle set-

ting.

TUN

EC71G002

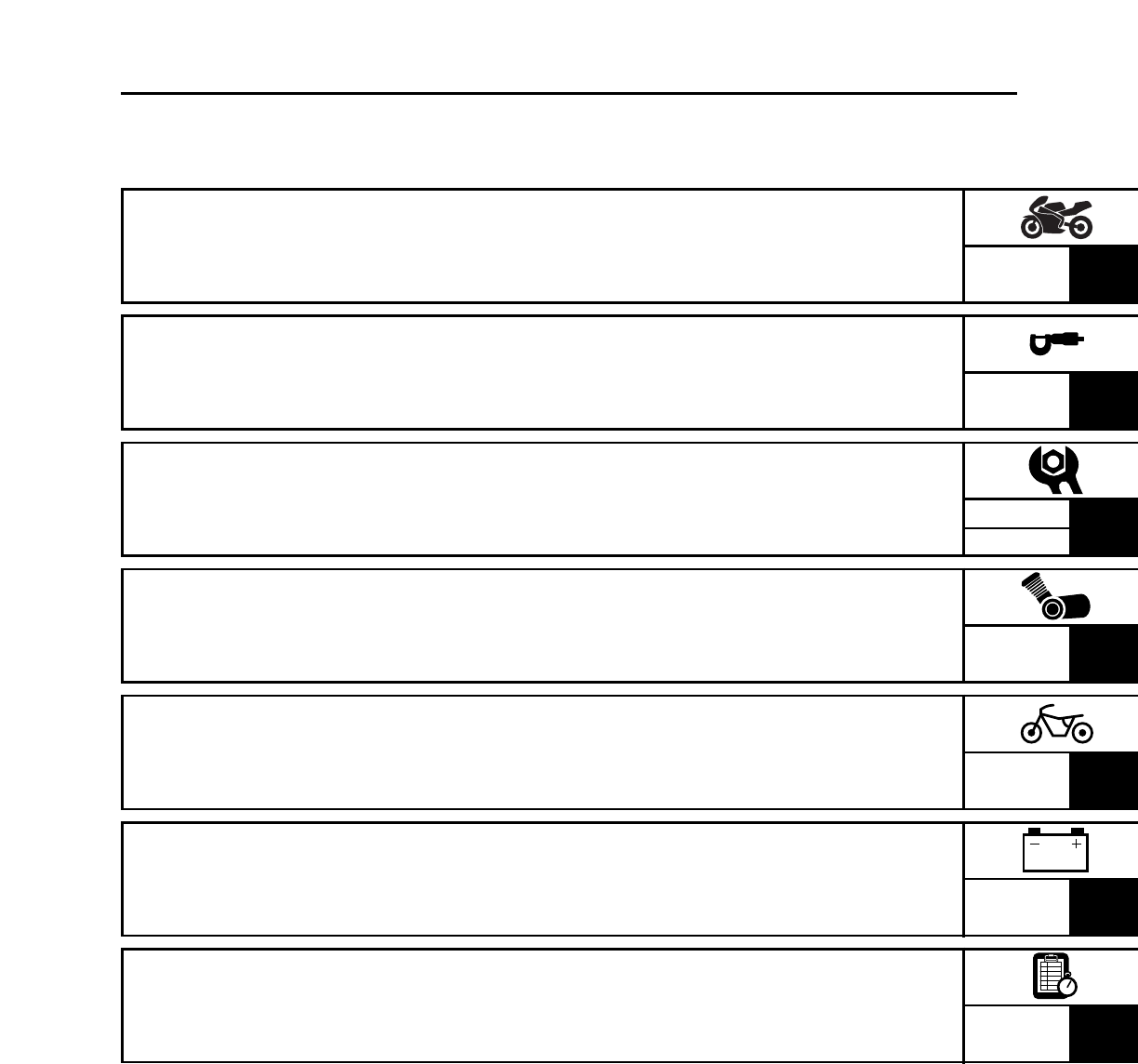

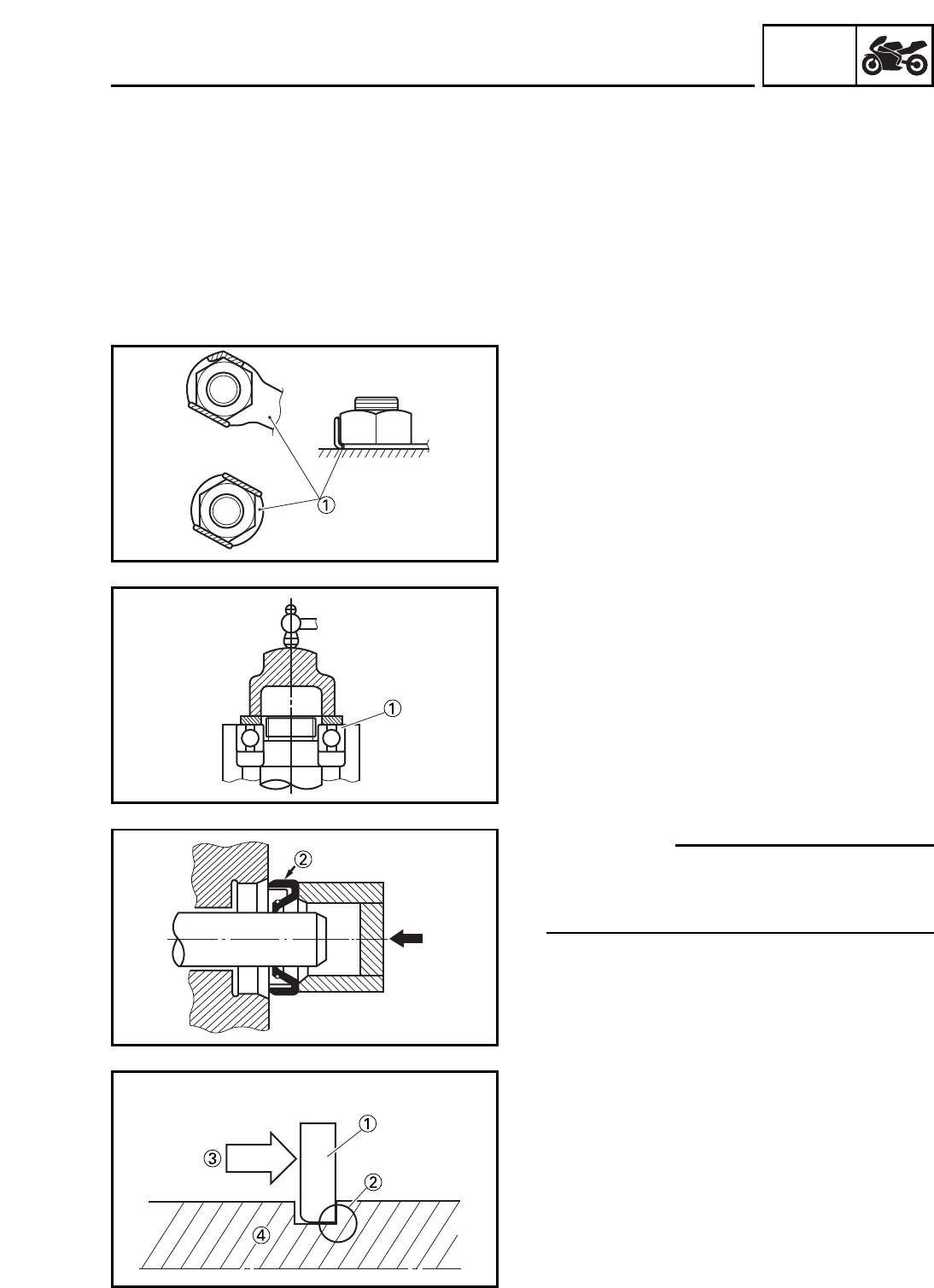

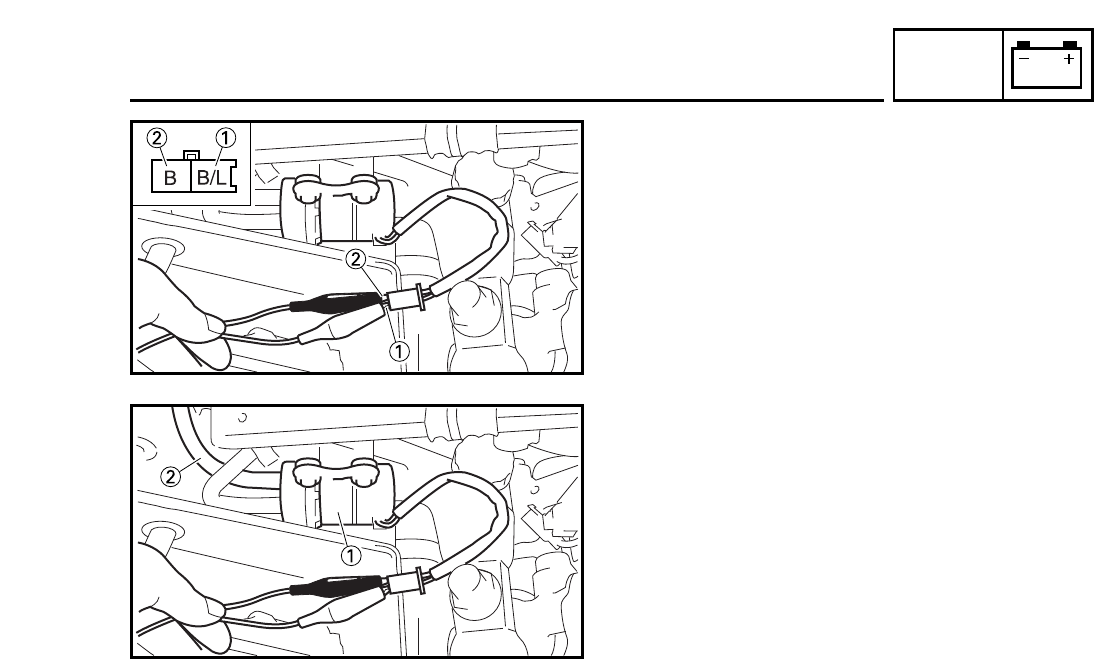

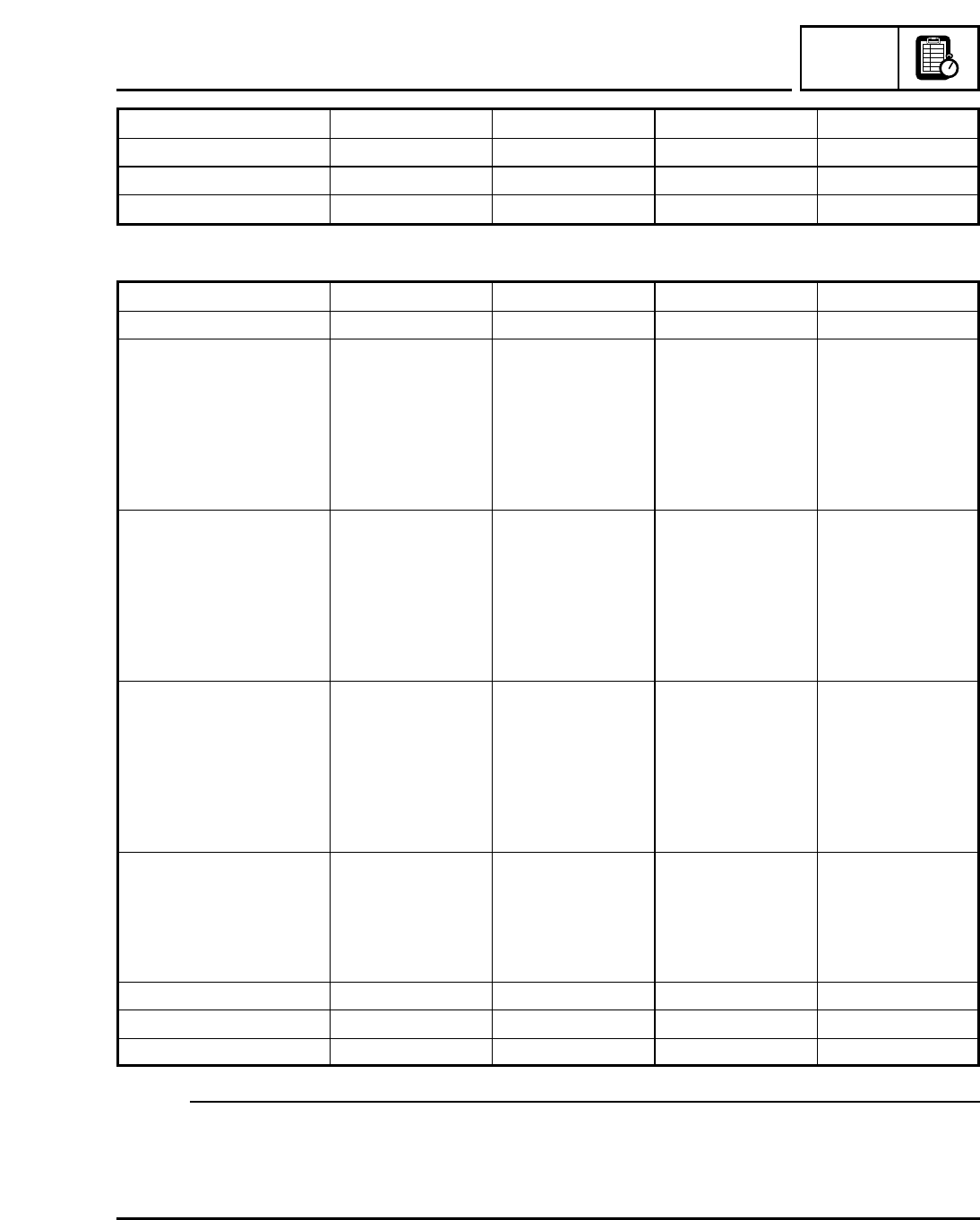

Table of correction coefficients for carburetor setting

Air

pressure

Air temperature °C (°F)

Altitude

hPa (mmHg)

-5 (23) Zero (32) 5 (41) 10 (50) 15 (59) 20 (68) 25 (77) 30 (86) 35 (95) 40(104)

m (ft)

1040 (780) 112.2 110.2 108.2 106.3 104.4 102.6 100.9 99.3 97.7 96.1 -220 (-722)

1033 (775) 111.5 109.4 107.5 105.6 103.7 102.0 100.3 98.6 97.0 95.5 -165 (-541)

1027 (770) 110.8 108.7 106.8 104.9 103.1 101.3 99.6 98.0 96.4 94.8 -110 (-361)

1020 (765) 110.0 108.0 106.1 104.2 102.4 100.7 99.0 97.3 95.8 94.2 -55 (-180)

1013 (760) 109.3 107.3 105.4 103.5 101.7 100.0 98.3 96.7 95.1 93.6 Zero (Zero)

1007 (755) 108.6 106.6 104.7 102.9 101.1 99.3 97.7 96.1 94.5 93.0 56 (184)

1000 (750) 107.9 105.9 104.0 102.2 100.4 98.7 97.0 95.4 93.9 92.4 112 (367)

993 (745) 107.2 105.2 103.3 101.5 99.7 98.0 96.4 94.8 93.3 91.8 168 (551)

987 (740) 106.5 104.5 102.6 100.8 99.1 97.4 95.7 94.2 92.6 91.1 224 (735)

980 (735) 105.7 103.8 101.9 100.1 98.4 96.7 95.1 93.5 92.0 90.5 281 (922)

973 (730) 105.0 103.1 101.2 99.4 97.7 96.1 94.4 92.9 91.4 89.9 338 (1,109)

967 (725) 104.3 102.4 100.5 98.8 97.1 95.4 93.8 92.2 90.7 89.3 396 (1,299)

960 (720) 103.6 101.7 99.8 98.1 96.4 94.7 93.1 91.6 90.1 88.7 453 (1,486)

953 (715) 102.9 101.0 99.2 97.4 95.7 94.1 92.5 91.0 89.5 88.1 512 (1,680)

947 (710) 102.1 100.3 98.5 96.7 95.0 93.4 91.9 90.3 88.9 87.5 570 (1,870)

940 (705) 101.4 99.6 97.8 96.0 94.4 92.8 91.2 89.7 88.2 86.8 629 (2,064)

933 (700) 100.7 98.9 97.1 95.4 93.7 92.1 90.6 89.1 87.6 86.2 688 (2,257)

927 (695) 100.0 98.1 96.4 94.7 93.0 91.4 89.9 88.4 87.0 85.6 747 (2,451)

920 (690) 99.3 97.4 95.7 94.0 92.4 90.8 89.3 87.8 86.4 85.0 807 (2,648)

913 (685) 98.5 96.7 95.0 93.3 91.7 90.1 88.6 87.2 85.7 84.4 867 (2,845)

907 (680) 97.8 96.0 94.3 92.6 91.0 89.5 88.0 86.5 85.1 83.8 928 (3,045)

900 (675) 97.1 95.3 93.6 92.0 90.4 88.8 87.3 85.9 84.5 83.1 989 (3,245)

893 (670) 96.4 94.6 92.9 91.3 89.7 88.2 86.7 85.2 83.9 82.5 1,050 (3,445)

887 (665) 95.7 93.9 92.2 90.6 89.0 87.5 86.0 84.6 83.2 81.9 1,111 (3,645)

880 (660) 94.9 93.2 91.5 89.9 88.3 86.8 85.4 84.0 82.6 81.3 1,173 (3,848)

873 (655) 94.2 92.5 90.8 89.2 87.7 86.2 84.7 83.2 82.0 80.7 1,236 (4,055)

867 (650) 93.5 91.8 90.1 88.5 87.0 85.5 84.1 82.7 81.4 80.1 1,299 (4,262)

860 (645) 92.8 91.1 89.4 87.9 86.3 84.9 83.4 82.1 80.7 79.4 1,362 (4,469)

853 (640) 92.1 90.4 88.8 87.2 85.7 84.2 82.8 81.4 80.1 78.8 1,425 (4,675)

847 (635) 91.3 89.7 88.1 86.5 85.0 83.6 82.2 80.8 79.5 78.2 1,489 (4,885)

840 (630) 90.6 89.0 87.4 85.8 84.3 82.9 81.5 80.2 78.9 77.6 1,554 (5,099)