12 5

CENTRAL HEATING SYSTEM

During the first few hours of operation of the central heating

system, check that all radiators are being heated at an even rate.

Should the upper area of a radiator be at a lower temperature than the

base of the radiator, it should be vented by releasing air through the

venting screw at the top of each radiator. Make sure your installer

shows you how to carry out the operation. Repeated venting will

reduce the quantity of water in the system and this must be

replenished for safe and satisfactory operation of the appliance.

Should water leaks be found in the system or excessive venting be

required from any radiator, your installer or heating engineer should

be contacted and the system corrected.

SEALED HEATING SYSTEM

The appliance will be fitted to a sealed heating

system which is pre-pressurised. Your installer will

advise you on the minimum and maximum pressure that

should be indicated on the pressure gauge. See Fig. 3.

Check regularly that this pressure is maintained and

contact your installer or maintenance engineer if there is

a permanent significant drop in pressure indicated on

the gauge. If the system loses pressure it should be re-

pressurised as instructed by the installer (N.B. Maximum

pressure 2.5 bar).

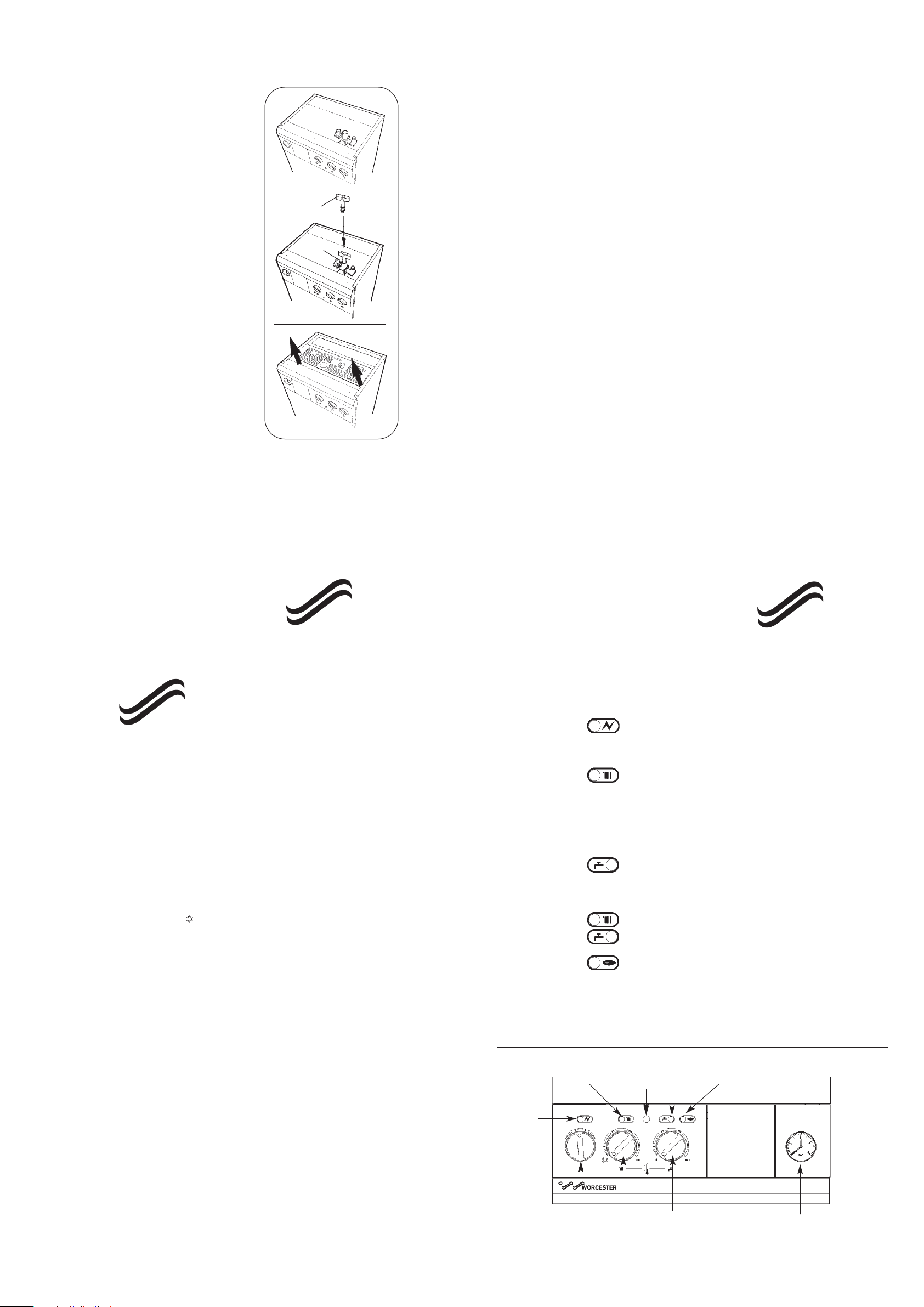

Pressurising The System (See Fig. 2).

(If in doubt leave this procedure to your installer).

Remove the bottom panel to gain access to the

filling loop assembly.

Insert the bayonet end of the filling key into the

corresponding cut outs in the filling loop housing and

twist to lock the key in place.

Turn the grey knob anti-clockwise to allow water

ingress and fill until the required pressure is reached.

Turn the grey knob clockwise to stop filling and

remove. Remove the filling key by lining up the bayonet

end of the key with the cut outs in the filling loop

housing and withdrawing the key.

N.B. The key must always be removed from the

filling loop housing after the system has been filled to

prevent accidental filling and to comply with Bylaw 14

of the Water Bylaws Scheme.

Store the key in a safe place for future use and refit

the bottom panel.

GENERAL NOTES

9

INDICATOR LIGHTS

Mains electricity indicator:

OFF : No mains electricity to the appliance

ON : Mains electricity is connected to the

appliance

Central heating demand indicator:

OFF : No demand for heat to the central

heating circuit

ON : Central heating demand

FLASHING SLOW : Ignition lockout

(once per second)

FLASHING FAST : Appliance fault (other than ignition

(five times per second) lockout)

Domestic hot water demand indicator:

OFF : No demand for domestic hot water

ON : Domestic hot water demand

FLASHING FAST : Air flow fault.

(five times per second)

Central heating and domestic hot water demand indicators:

BOTH FLASHING SLOW : Overheat cut-off

(once per second)

Flame detection indicator:

OFF : Burner off

ON : Burner on

8

OPERATION OF

CONTROLS

A diagnostic system is provided which gives a flashing light

display on the facia panel. Press the reset button to attempt to restart

the appliance. If the appliance does not return to normal operation

then contact your installer/engineer or Worcester Bosch advising of

the appliance serial number and the flashing light sequence, i.e.

which lights flash and at what speed.

More than 30% of all calls made to our contact centre reporting

appliance faults or breakdowns prove to be false alarms, as there is often

a simple explanation for the apparent malfunction.

So, to help you save time and money – not to mention frustration

and inconvenience – please refer to the General Information, Notes and

Lighting Instructions ensuring all controls are set correctly.

If, after following the instructions the appliance still fails to operate

correctly call the Worcester Contact Centre on 08457 256206.

Arrangements will be made for an engineer to call as soon as possible.

If it is known or suspected that a fault exists on the appliance it

must not be used until the fault has been corrected by a competent

person.

CALL-OUT CHARGES

All of our field service engineers are factory trained.

If you request a visit from an engineer and your appliance has been

installed within the last 12 months, no charge will be made for parts

and/or labour, providing:

•The appliance was commissioned correctly on installation.

•An appliance fault is found and the appliance has been installed

within the past 12 months.

A call-out charge will be made where:

•The appliance has been installed for over 12 months, or

•Our Field Service Engineer finds no fault with the appliance (see

note), or

•The cause of breakdown is with other parts of your

plumbing/heating system, or with equipment not supplied by Worcester.

NOTE: Invoices for attendance and/or repair work carried out on

your appliance by any third party will not be accepted.

APPLIANCE FAILS TO

OPERATE

(See also label on inside of appliance front cover).

The appliance is fitted with the following controls:

See fig. 3.

OPERATING SWITCH

In the ‘0’position there is no mains electricity to the

appliance.

In the ‘I’ position mains electricity is connected to the

appliance.

CENTRAL HEATING TEMPERATURE

CONTROL

The position of this knob will determine the temperature of the

water delivered to the radiators between the ‘I’ and ‘MAX’ position.

When the knob is turned anti-clockwise past the ‘I’ position towards

the ‘’(Summer Position), then the appliance will operate in the

HOT WATER mode only and no heat will be delivered to the radiators.

DOMESTIC HOT WATER TEMPERATURE

CONTROL

The position of this knob will determine the temperature of the

water delivered at the domestic hot water taps between the ‘0’ and

the ‘MAX’ position.

By slightly reducing the flow of domestic water from the tap, the

delivery temperature of the water will be further increased. This is of

particular advantage in the winter, for example to increase bath water

temperature. Also this will provide an added advantage of reducing

the delay before hot water is obtained.

FACIA MOUNTED PROGRAMMER (if fitted)

Your installer may have mounted either a mechanical or an

electronic programmer into the facia of your appliance. Operating

instructions are supplied with the programmer.

RESET BUTTON

Press this button in for five seconds if any of the indicator lights

are flashing.

SYSTEM PRESSURE GAUGE

The red needle has been set to show the sealed system pressure

which is required for the appliance to operate effectively. The grey

needle will show the actual pressure in the system.

Fig. 2.

Grey

Knob

Filling Key

Fig. 3. Controls.

Operating

switch

Mains

electricity

indicator

Reset

button

Flame detection

indicator

DHW demand

indicator

Central heating

demand indicator

CH temp

control knob

DHW temp

control knob

System pressure

gauge

26CDi XTRA