Table of contents

2 Installation instructions VRC 470f 0020124645_00

Table of contents

1 Notes on the installation instructions ..............4

1.1 Observing other applicable documents ................4

1.2 Document storage ......................................................4

1.3 Symbols used ...............................................................4

1.4 Applicability of the instructions ..............................4

1.5 CE label .........................................................................4

1.6 Glossary.........................................................................4

2 Safety ............................................................................5

2.1 Safety and warning information .............................5

2.1.1 Classification of warnings .........................................5

2.1.2 Structure of warnings ................................................5

2.2 Intended use ................................................................5

2.3 Basic safety instructions ...........................................5

2.4 Requirements for cables ...........................................6

2.5 Directives, laws and standards ................................6

3 System description ..................................................7

3.1 System design ..............................................................7

3.2 Functionality.................................................................7

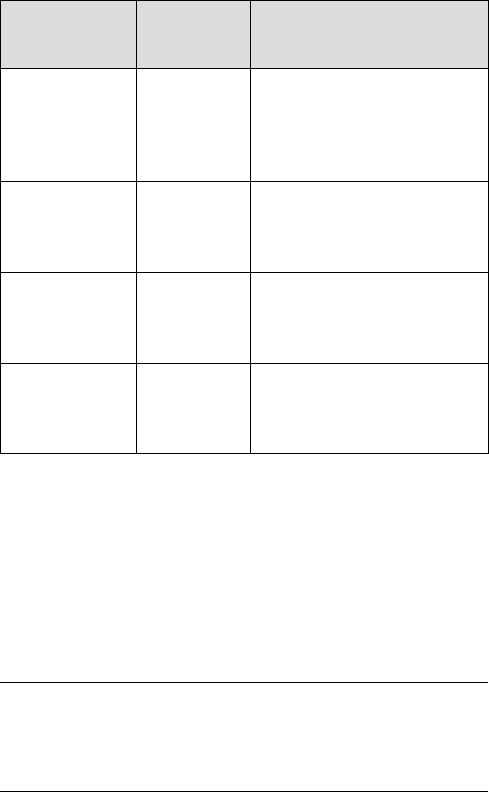

3.3 Appliance design .........................................................8

3.4 Identification plate .....................................................8

3.5 Accessories ...................................................................8

4 Installation ..................................................................9

4.1 Checking the delivery ................................................9

4.2 Requirements for the installation site ...................9

4.2.1 Radio receiver unit .....................................................9

4.2.2 Controller ......................................................................9

4.2.3 Outside temperature sensor/transmitter ..............9

4.3 Fitting the radio receiver unit in the boiler ..........9

4.4 Wall-mounting the radio receiver unit ................. 10

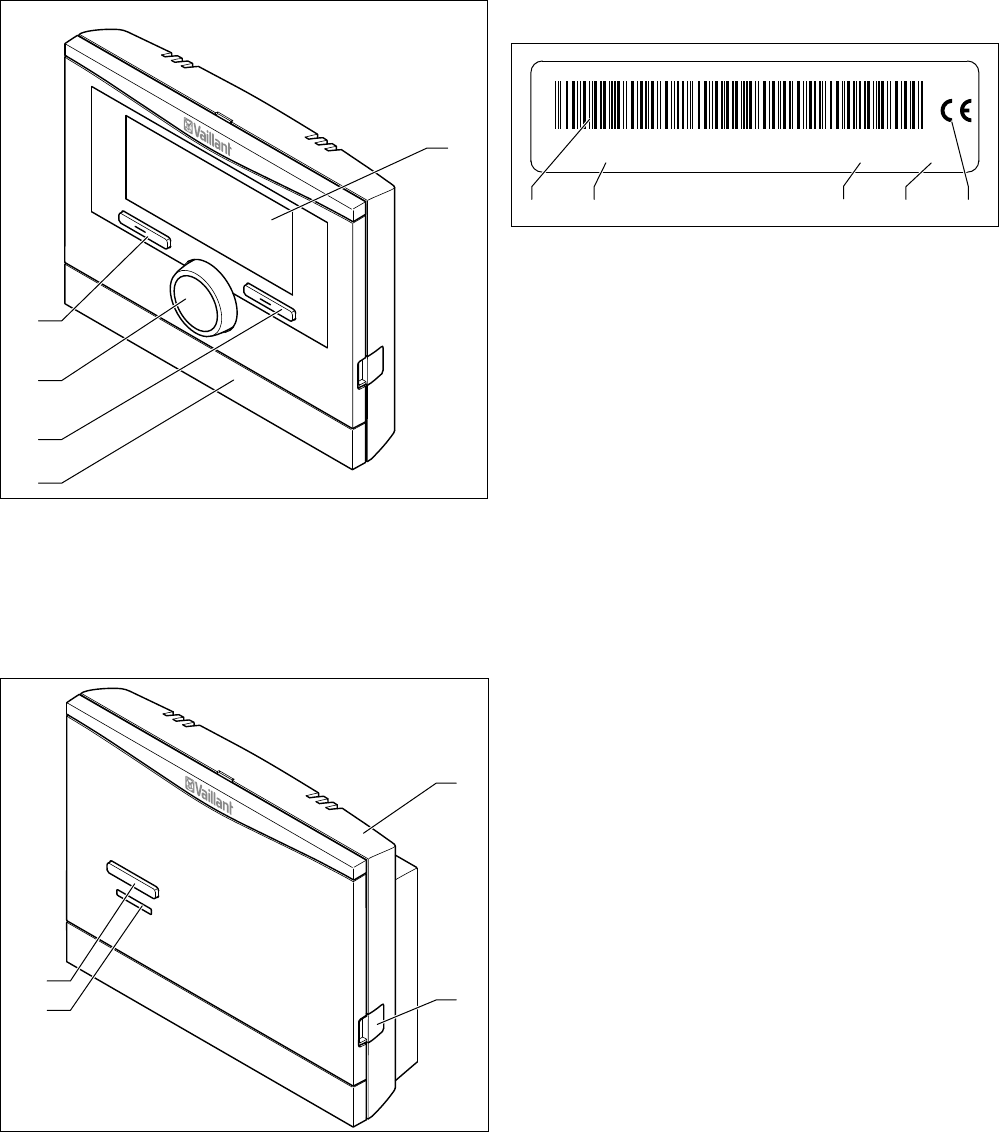

4.4.1 Removing the radio receiver unit from the

wall-mounting base .................................................. 10

4.4.2 Secure the wall-mounting base to the wall ..........11

4.4.3 Fitting the radio receiver unit ..................................11

4.5 Fitting the outside temperature sensor/

transmitter ...................................................................11

4.6 Fitting the controller .................................................13

5 Electrical installation .............................................14

6 Start-up .......................................................................15

6.1 Overview of Installation assistant set-up

options ..........................................................................15

6.2 Making settings for the operator ...........................16

6.3 Setting other parameters for the heating

system ..........................................................................16

7 Operation ....................................................................17

7.1 Overview of menu structure ...................................18

7.2 Overview of Installer level ..................................... 20

8 Description of functions ....................................... 27

8.1 Service information ..................................................27

8.1.1 Entering contact details ..........................................27

8.1.2 Entering the service date .......................................27

8.2 System configuration: System ...............................27

8.2.1 Reading the system status .....................................27

8.2.2 Reading the water pressure of the heating

system .........................................................................27

8.2.3 Reading the DHW heating status ..........................27

8.2.4 Reading the collector temperature ......................27

8.2.5 Setting the frost protection delay ........................28

8.2.6 Setting the pump blocking time ...........................28

8.2.7 Setting the maximum preheating time ...............28

8.2.8 Setting the maximum pre-switch-off time ..........28

8.2.9 Setting the temperature threshold for

constant heating .......................................................28

8.2.10 Setting the raising temperature ............................29

8.2.11 Reading the software version ................................29

8.2.12 Configuring the heating circuit .............................29

8.3 System configuration: Heat generator ................29

8.3.1 Reading the status of the heat generator ..........29

8.3.2 Reading the value of the VF1 temperature

sensor ..........................................................................29

8.3.3 Activating the low loss header .............................29

8.4 System configuration: HEATING 1 and, if

relevant, HEATING 2 .................................................29

8.4.1 Activating the heating circuits .............................29

8.4.2 Reading the end of the current time period ......29

8.4.3 Setting the target room temperature ................. 30

8.4.4 Reading the current room temperature............. 30

8.4.5 Setting the set-back temperature (set-back

temp.) .......................................................................... 30

8.4.6 Reading the target flow temperature ................. 30

8.4.7 Reading the current flow temperature............... 30

8.4.8 Reading the status of the heating circuit

pump ........................................................................... 30

8.4.9 Reading the status of the heating circuit

mixer valve ................................................................ 30

8.4.10 Activating room temperature control ............... 30

8.4.11 Activating automatic summer time detection .. 30

8.4.12 Setting the heating curve ........................................31

8.4.13 Setting the minimum flow temperature for

heating circuits ...........................................................31

8.4.14 Setting the maximum flow temperature for

the mixing circuit .......................................................31

8.4.15 Reading the status of advanced functions ..........31

8.4.16 Specifying control modes outside time

periods ..........................................................................31

8.5 System configuration: Domestic hot water ........32

8.5.1 Setting the target temperature for domestic

hot water cylinder (desired hot water

temperature) .............................................................. 32

8.5.2 Reading the current temperature of the

domestic hot water cylinder ..................................32

8.5.3 Reading the status of the cylinder charge

pump ............................................................................32