2

Warning: this manual contains instructions to be used exclusively by the in-

staller and/or a competent person in accordance with the current laws in force.

The end user MUST not make any alterations to the boiler.

Failure to follow the instructions indicated in this manual, which is supplied

with the boiler, could cause injury to persons, animals or damage to property.

UNICAL shall not be held liable for any injury and/or damage.

CONTENTS

1 GENERAL INFORMATION ................................................................................................................................................................................. 3

1.1 Symbols used in this guide ........................................................................................................................................................................... 3

1.2 Correct use of the appliance .........................................................................................................................................................................3

1.3 Information to be passed over to the person in charge of the appliance ......................................................................................................3

1.4 Safety warnings ............................................................................................................................................................................................4

1.5 Standard code for installations......................................................................................................................................................................5

1.6 Installation .....................................................................................................................................................................................................5

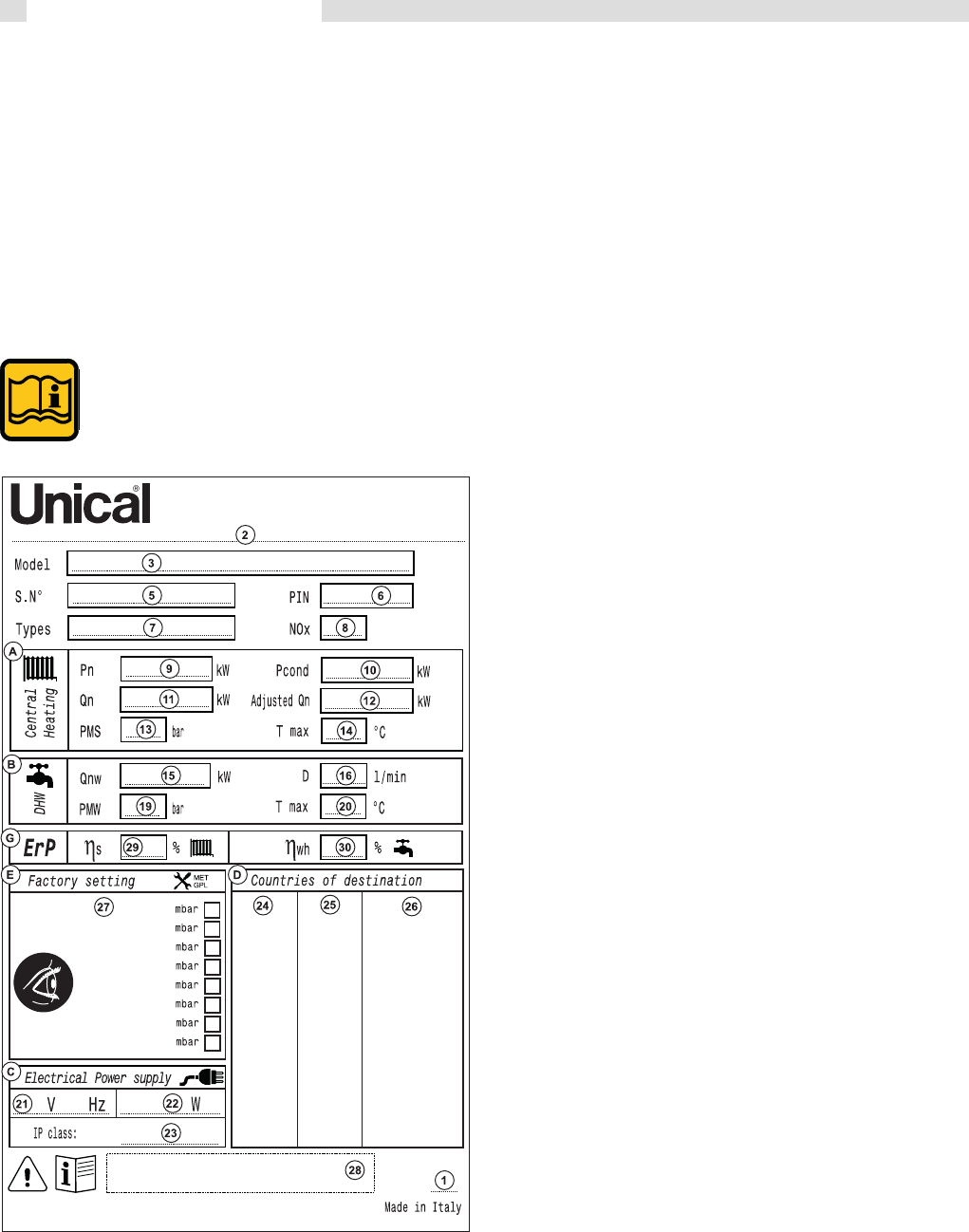

1.7 Data badge ...................................................................................................................................................................................................5

1.8 Water treatment ............................................................................................................................................................................................ 7

1.9 General warnings ..........................................................................................................................................................................................8

2 TECHNICAL FEATURES AND DIMENSIONS ...................................................................................................................................................9

2.1 Technical features ......................................................................................................................................................................................... 9

2.2 RHS view showing main components .........................................................................................................................................................10

2.3 Dimensions ................................................................................................................................................................................................. 11

2.4 Performance data .......................................................................................................................................................................................12

2.4.1 Performance DATA ErP ......................................................................................................................................................................13

3 INSTRUCTIONS FOR THE INSTALLER ...........................................................................................................................................................14

3.1 General warnings .......................................................................................................................................................................................14

3.2 Packaging ..................................................................................................................................................................................................15

3.3 Removal from the bed and insert foot ........................................................................................................................................................16

3.4 Boiler location in a boiler room ..................................................................................................................................................................16

3.6 Boiler connection ....................................................................................................................................................................................... 18

3.7 Gas connection..........................................................................................................................................................................................19

3.8 Connection return and flow system pipes..................................................................................................................................................20

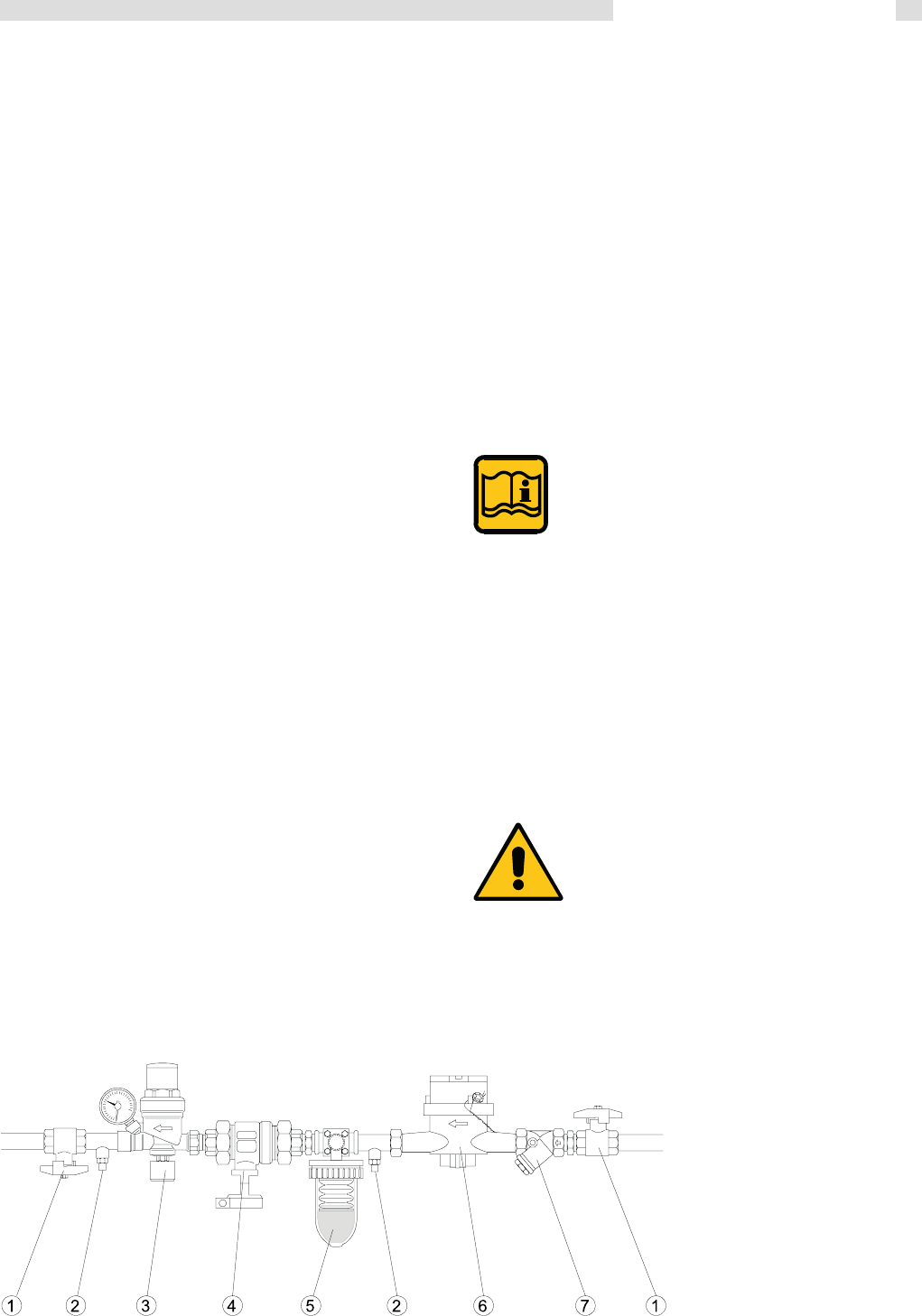

3.9 Additional safety and control devices, according to the Italian Law + primary circuit kit ...........................................................................21

3.10 Mixing header ............................................................................................................................................................................................ 22

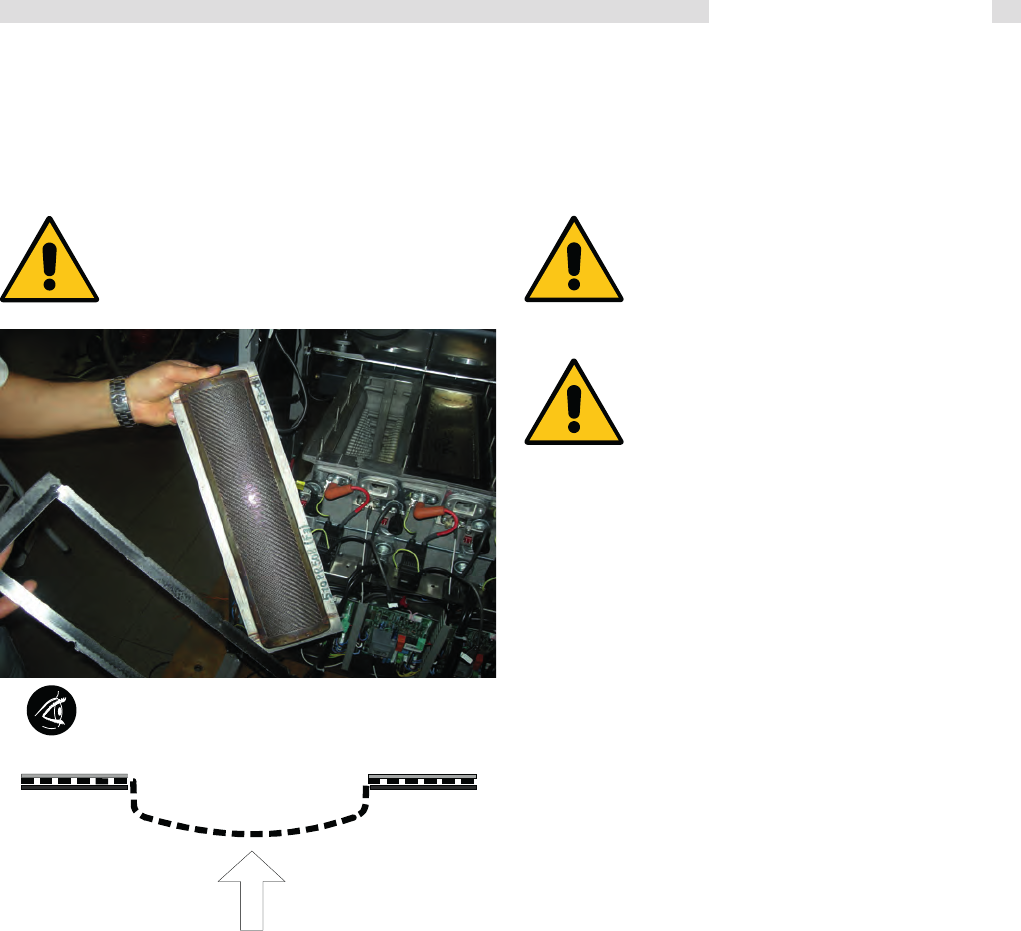

3.11 Mixing header filter ....................................................................................................................................................................................22

3.12 Determination of primary boiler pump or boiler system pump ...................................................................................................................23

3.13 Ballstop valves ...........................................................................................................................................................................................23

3.14 Plate heat exchanger .................................................................................................................................................................................24

3.15 Primary circuit ............................................................................................................................................................................................24

3.16 Condensing drain ......................................................................................................................................................................................26

3.17 Flue chimney connection ...........................................................................................................................................................................27

3.18 Flue mainfold connection .......................................................................................................................................................................... 27

3.19 Electrical connection .................................................................................................................................................................................29

3.20 Wiring diagram ..........................................................................................................................................................................................30

CONNECTING RING PRIMARY (SUPPLIED WITH MODULAR PUMP)................................................................................................. 31

THERMOSTAT ON / OFF CONNECTIONS .............................................................................................................................................31

THERMOSTAT FBR 2 CONNECTION (room sensor) ..............................................................................................................................32

MODULATING THERMOSTAT CONNECTIONS ......................................................................................................................................33

3.21 FUNCTIONAL WIRING DIAGRAM ...........................................................................................................................................................34

3.22 WIRING DIAGRAM FOR CONNECTIONS AND MANAGING ................................................................................................................35

3.23 Installation examples (functional wiring and connections description) ......................................................................................................38

3.24 Cascade manager BCM ............................................................................................................................................................................43

3.25 Filling the system ....................................................................................................................................................................................... 44

3.26 Boiler Freeze protection .............................................................................................................................................................................44

3.27 Burner Adjustment .....................................................................................................................................................................................45

3.28 Emergency functions .............................................................................................................................................................................. 48

3.29 Lighting and shutting down procedures ..................................................................................................................................................... 49

4 SERVICING SCHEDULE ..................................................................................................................................................................................50