5

Maintaining

the Hot Water

Heating System

The hot water heating system

is filled with a mixture of

40 % glycol (in a similar

manner as for motor vehicle

engines, but not Diesel

engines) and 60 % water. In

cases of ambient temperatu-

res of less than -25°C, the

glycol content may be in-

creased up to a maximum

of 50 %.

The heating water should be

changed about every two

years, since important pro-

perties such as corrosion pro-

tection will become ineffec-

tive.

The level of the liquid in the

expansion container must be

checked regularly. The level

of the liquid should be about

1 cm above the „MIN“ mar-

king when the heating sy-

stem is cold.

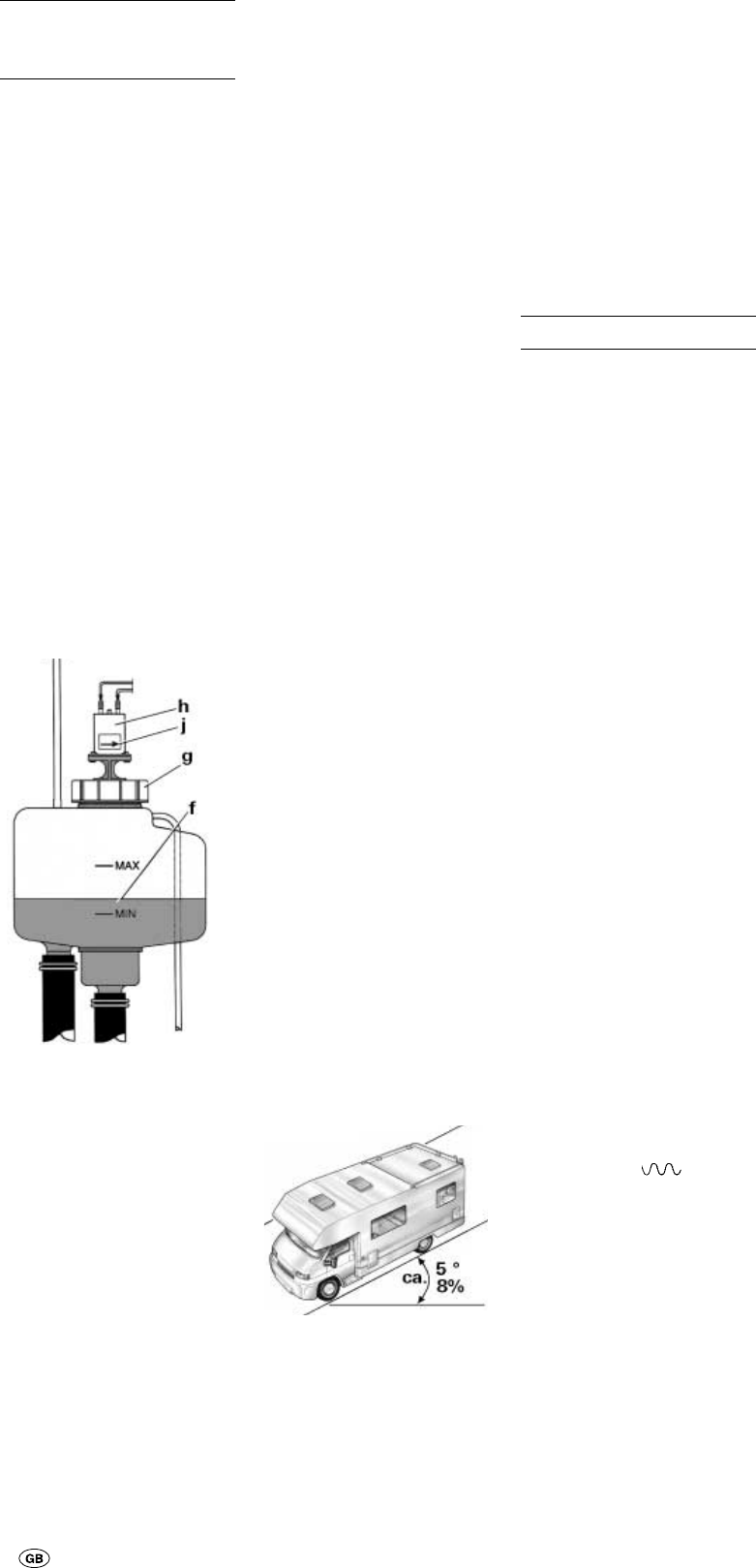

Expansion vessel

f = Filling level of the heating

water

g = Cover for topping up the

heating water

h = Circulating pump

j = Direction of run of the

circulating pump

(anti-clockwise)

Caution: Before topping up,

the glycol content is to be

checked in order to avoid too

high a proportion of glycol.

Topping up is carried out via

the expansion container. To

do this, open the cover (g) of

the expansion container. Add

the heating water slowly

until the level of the liquid (f)

is about 1 cm above the

„MIN“ marking.

If the liquid level drops more

than is anticipated given the

normal rate of evaporation,

the system must be checked

for leaks (rubber connections,

drain cock, bleeding valves,

etc.). Flush away any water

containing glycol which may

have leaked out by using

fresh water, and dry carefully.

Bleeding the hot

water heating system

Depending on how the hea-

ting system is installed, there

may still be air in the system

after filling (or topping up).

Air in the system will be ap-

parent either due to noises in

the expansion container or

due to unsatisfactory heating

performance. If the heating

performance is inadequate,

the heating water cannot cir-

culate and the system will

only heat up in parts.

1. Heat up the Aquatherm sy-

stem.

2. Before bleeding the hea-

ting system, shut down the

circulating pump by swit-

ching the heating system off.

3. Next, open the bleeding

valves one after another until

no more air emerges (the ar-

rangement of the bleeding

valves depends on the instal-

lation. Please consult the

operating instructions for

your vehicle for more details).

4. Switch the heating system

on again and check whether

the entire system is heating

up.

Repeat the procedure if

necessary.

Tip: If there is still air in the

system after repeat bleeding,

the air can be made to rise

upwards by setting the ve-

hicle at an angle (e.g. on a

street with a pronounced gra-

dient or by means of a jack).

Park the vehicle in this positi-

on, wait a few moments, and

then open the bleeding valve

at the highest point until no

more air emerges. Then set

the vehicle at an angle in the

other direction, and repeat

the bleeding process at the

topmost point.

Note: For professional use in

workshops, we recommend

the use of a special bleeding

device (available from Truma)

for clean and simple bleeding

of the heating system.

The heating fuse is located

on the electronic control cir-

cuit board of the device.

The fine-wire fuse located on

the electronic control circuit

board may only be replaced

by a fuse of the same design

(1.25 A slow-acting fuse,

IEC 127/2-III).

Technical Data

Gas type: Liquid gas

(propane/butane)

Operating pressure:

30 mbar, (or 28 mbar butane/

37 mbar propane)

Rated thermal output:

1900 W

Gas consumption: 140 g/h

Heating water content:

10 litres

Max. water pressure:

0.5 bar

Current consumption at

12 V Heating system

Ignition: 0.17 A

Heating up: 0.08 A

Stand-by: 0.04 A

Circulating pump: Max. 1 A

Current consumption

230 V at power stage

500 W: 2.2 A

1000 W: 4.5 A

2000 W: 8.7 A

Weight (without contents)

Aquatherm: Approx. 6,8 kg

Aquatherm EL: Approx. 7,5 kg

Conformity Declaration:

The Truma-Aquatherm hea-

ting system has been proto-

type-tested by the DVGW

and fulfils the requirements

of the EC Gas Appliance

Directive (90/396/EEC) and

the jointly-applicable EC

Directives. The CE Product

Identity Number for EU

countries has been issued:

CE-0085BL0190

General design approval

by the Federal Motor Ve-

hicle Bureau: S 326

General safety notes

In event of leaks in the

gas system or if there is a

smell of gas:

- extinguish all naked

flames!

- do not smoke!

- switch off the appliances!

- shut off the gas cylinder!

- open the windows!

- do not actuate any elec

trical switsches!

- have the entire system

checked by an expert.!

1. Repair jobs are only to

be carried out by an ex-

pert.

2. Any alteration to the appli-

ance (including exhaust duct

and cowl) or the use of spare

parts and accessories which

are important for the functio-

ning of the heater and which

are not original Truma parts,

as well as the non-observan-

ce of the installation and ope-

rating instructions, shall lead

to the cancelling of the gua-

rantee and exclusion of liabili-

ty claims. It also becomes il-

legal to use the appliance,

and in some countries this

even makes it illegal to use

the vehicle.

3. The operating pressure

for the gas supply is

30 mbar (or 28 mbar buta-

ne/37 mbar propane) and

must correspond to the

operating pressure of the

appliance (see name

plate).

4. In Germany only, liquid

gas installations must comply

with the DVGW form G 607

for motor vehicles or G 608

for water sport vehicles.

The gas system must be

tested every 2 years by a li-

quid gas expert (DVFG, TÜV,

DEKRA). This inspection

must be confirmed on the

test certificate in accordance

with the DVGW-form G 607

or G 608.

The vehicle owner is

always responsible for

arranging the inspection.

5. In other countries the re-

spectively valid regulations

must be observed. For your

own safety it is absolutely ne-

cessary to have the com-

plete gas installation regularly

checked by an expert (every

2 years at the latest).

6. Do not operate the water

heater when refuelling the

vehicle and when in the

garage.

7. During the initial operation

of a brand new appliance (or

after it has not been used for

some time), a slight amount

of fumes and smell may be

noticed for a short while. This

can be remedied by running

the heater at maximum out-

put and ensuring adequate

room ventilation.

For the gas system only gas

pressure regulators with pro-

tection against excess pres-

sure, such as regulators with

safety valves according to

DIN 4811 and VP 306, may

be used. We recommend the

Truma DUB vehicle regulator