ALICANTE, VALENCIA, ALMERIA

4

Besides the setting of combustion air slider, the chimney is a very important factor affecting the intensity of combustion and thus the

heating performance of your fireplace insert. Increased chimney blast needs smaller supply of combustion air, decreased chimney blast

requires larger supply of combustion air.

When using wooden logs, the supply of combustion air should be reduced at the beginning, until the wood gets completely burnt through

(little fire). If such a procedure causes very high heating performance, lower amount of fuel should be used.

Optimal control of combustion requires experience, especially when the chimney blast is not constant or the fuel wood used is of

changeable quality. When the chimney blast is too strong or when there is too much fuel in the hearth, there is danger of overheating the

paint of fireplace insert. The paint becomes silver-white and shortly starts to peel off the fireplace insert. The manufacturer does not

assume any responsibility for this kind of paint damage. You can repair this failure by fireplace paint (spray).

2.6 Between-seasons operation

When the outside temperatures reach above around 15°C, it can happen with low combustion performance, and in certain conditions,

that the chimney blast is endangered, not drawing the combustion gases completely away (smoke, combustion gases smell). In such

case, clean the grate and increase the supply of combustion air. Add smaller and smaller amounts of fuel and clean the grate more often.

Close the door and the valves of air supply of other devices connected to the same chimney, which are not in use. Check the cleaning

openings of the chimney for tightness.

2.7 Ash removing

To ensure failure-free operation it is necessary to remove the ash from the fireplace insert on time and regularly. The ash box must be

emptied in time to enable the combustion air flow through the grate. Otherwise, there is danger that ash under grate would prevent air

from flowing and the grate would get overheated and deformed due to the lack of cooling.

Ash must be removed from the fireplace insert before putting fuel inside.

2.8 Cleaning and maintenance

Depending on frequency of use, the fireplace insert must be cleaned once or more times per year (in cold state). Cleaning is executed

as follows:

Smoke tube is removed and cleaned outside in appropriate container. Accumulation area of combustion waste may be cleaned using a

steel brush and vacuum cleaner. Subsequently, the smoke tube must be reset between the chimney and the exhaust throat of the

fireplace insert.

NOTE: The fireplace insert can only be used again after cleaning when all parts removed for cleaning have been returned back.

The fireplace insert is covered on the outside with heatproof paint. When the paint is hardened (after few hours at nominal thermal power),

it can be cleaned on surface using dry towel.

This heatproof paint is not resistant to humidity. Therefore do not put any wet objects on the fireplace insert, it could produce rust spots.

The glass in stoker door can be cleaned using a common glass cleaner, when only light sediment appears. Hard sediment can be

removed using a burning cleaner or with fine steel wool.

NOTE: the glass can have sharp edges; therefore use protective gloves when replacing the glass!

If the fireplace insert has not been used for a longer period, before starting to use it again it is necessary to check possible obstruction in

the fireplace insert, flue or chimney.

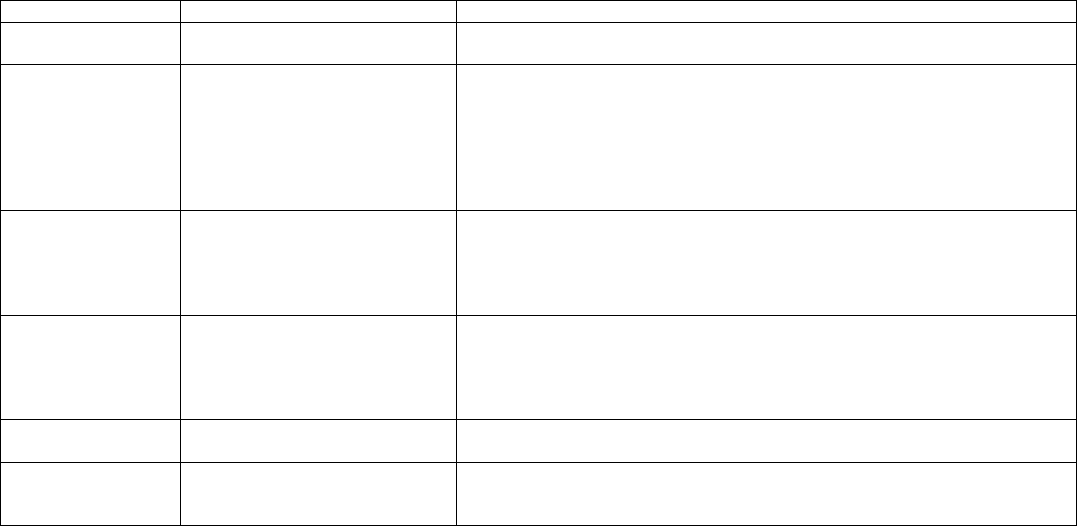

2.9 Problem sources and their solving

In case of failures (e.g. smoke) appearing during operation, contact your local competent chimney sweeper. If damage is caused to the

fireplace insert, contact the shop where you purchased the fireplace insert. These are the most common failures, their sources and

solutions