7

IMPORTANT INSTALLATION

SPECIFICATIONS

The installer should note that the appliance

that side walls should be no higher than the

hot plate itself. Furthermore, the rear wall, the

surfaces surrounding and adjacent to the

appliance must be able to withstand an

overtemperature of 75 K.

The adhesive used to stick the plastic laminate

to the cabinet must be able to withstand a

temperature of not less than 150° C otherwise

the laminate could come unstuck.

The appliance must be installed in compliance

with the provisions in force.

This appliance is not connected to a device

able to dispose of the combustion fumes. It

must therefore be connected in compliance

with the above mentioned installation

standards. Particular care should be paid to

the following provisions governing ventilation

and aeration.

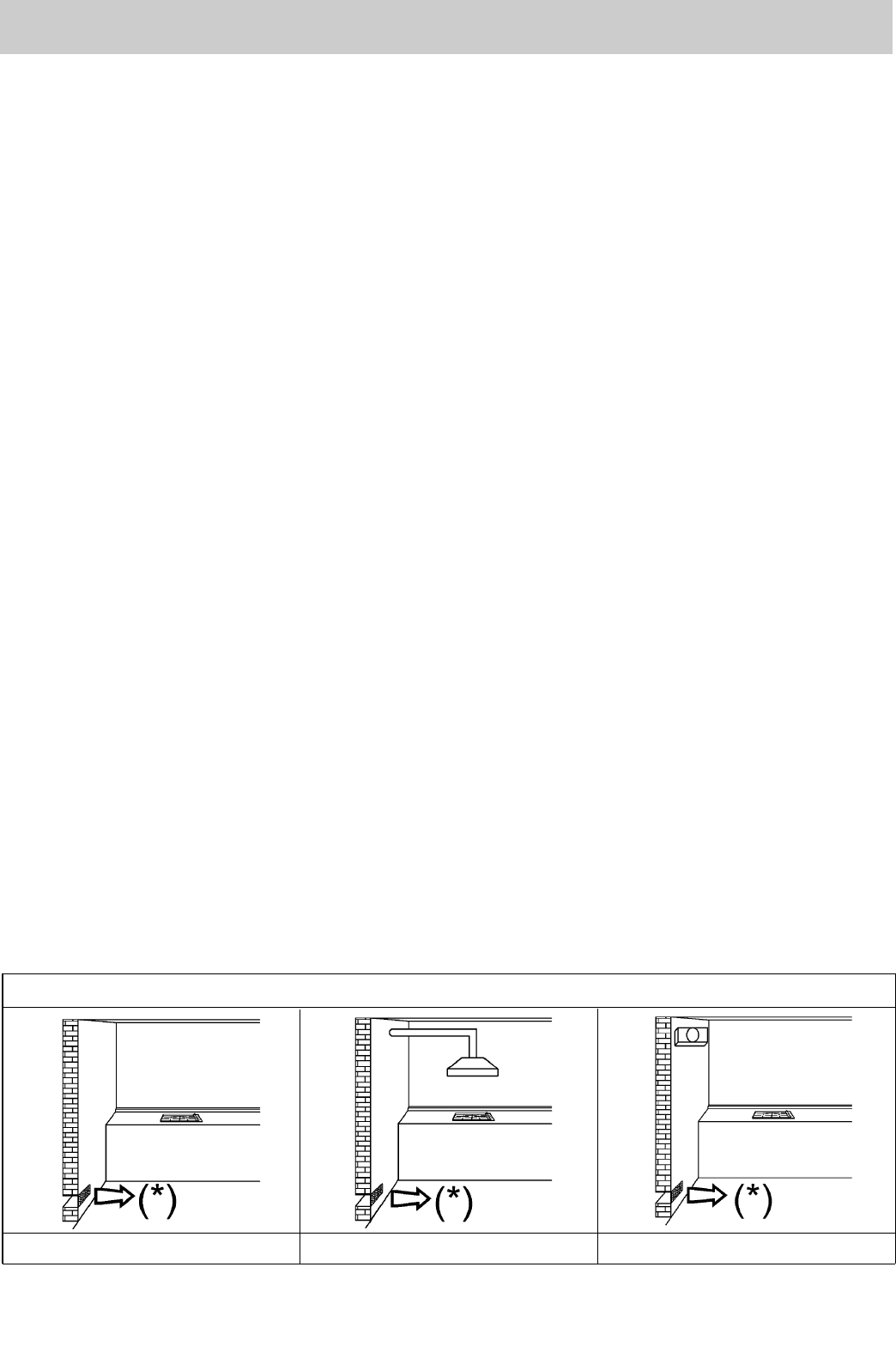

5) ROOM VENTILATION

It is essential to ensure that the room in which the

appliance is installed is permanently ventilated in

order to allow the appliance itself to operate correctly.

the necessary amount of air is that required for regular

gas combustion and ventilation of the relative room,

the volume of which must not be less than 20 m

3

. Air

must naturally flow through permanent openings in

the walls of the room in question. These openings

must vent the fumes outdoors and their section must

be at least 100 cm

2

(see fig. 3). Construction of the

openings must ensure that the openings themselves

may never be blocked. Indirect ventilation by air

drawn from an adjacent room is also permitted, in

strict compliance with the provisions in force.

CAUTION: if the burners of the cooking top are

without safety thermocouple, the ventilation

outlet must have a minimum 200 cm² section.

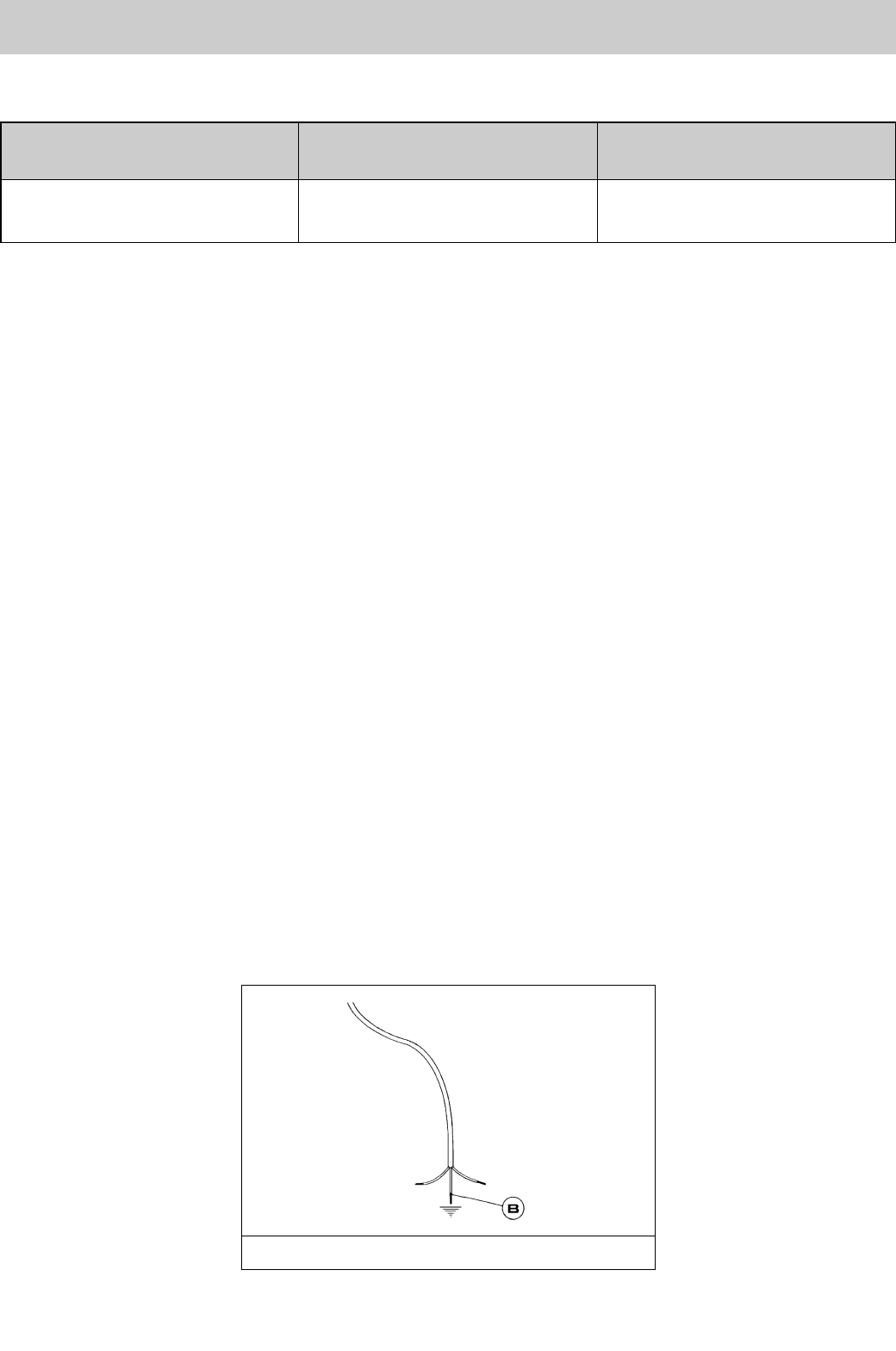

6) LOCATION AND AERATION

Gas cooking appliances must always dispose of their

combustion fumes through hoods. These must be

connected to flues, chimneys or straight outside. If it

is not possible to install a hood, an electric fan can be

installed on a window or on a wall facing outside (see

fig. 4). This must be activated at the same time as

the appliance (see fig. 5), so long as the

specifications in the provisions in force are strictly

complied with.

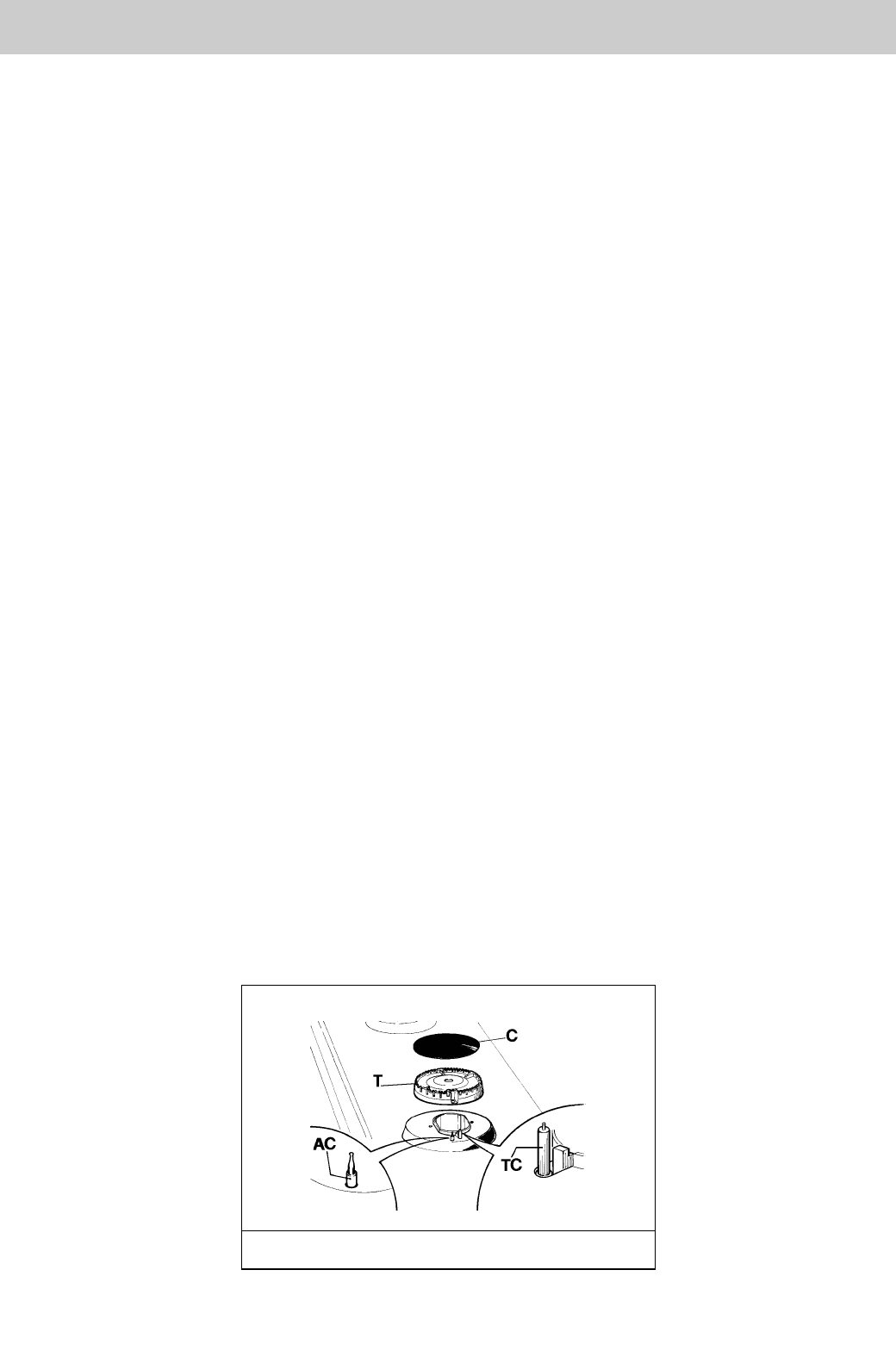

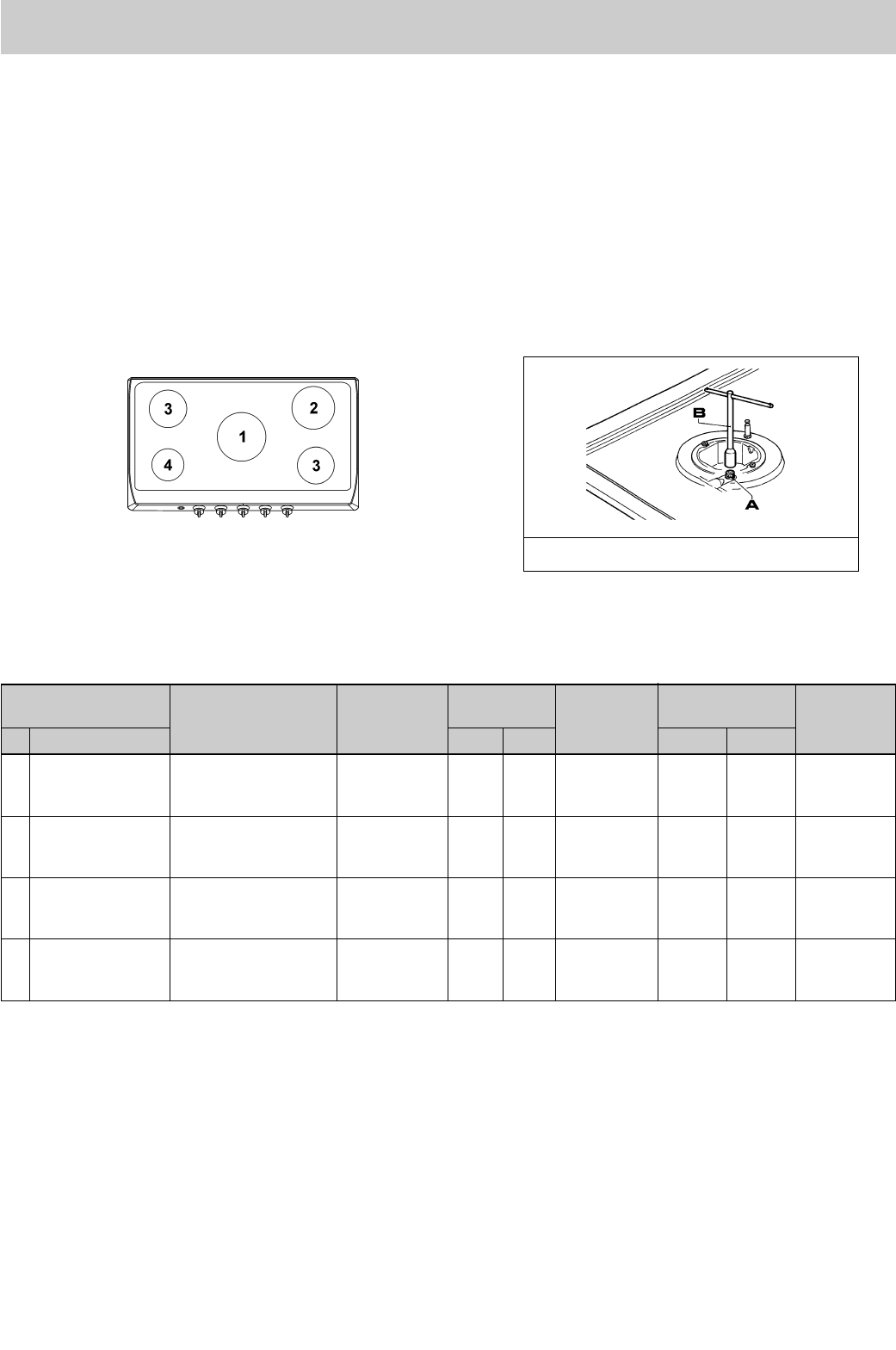

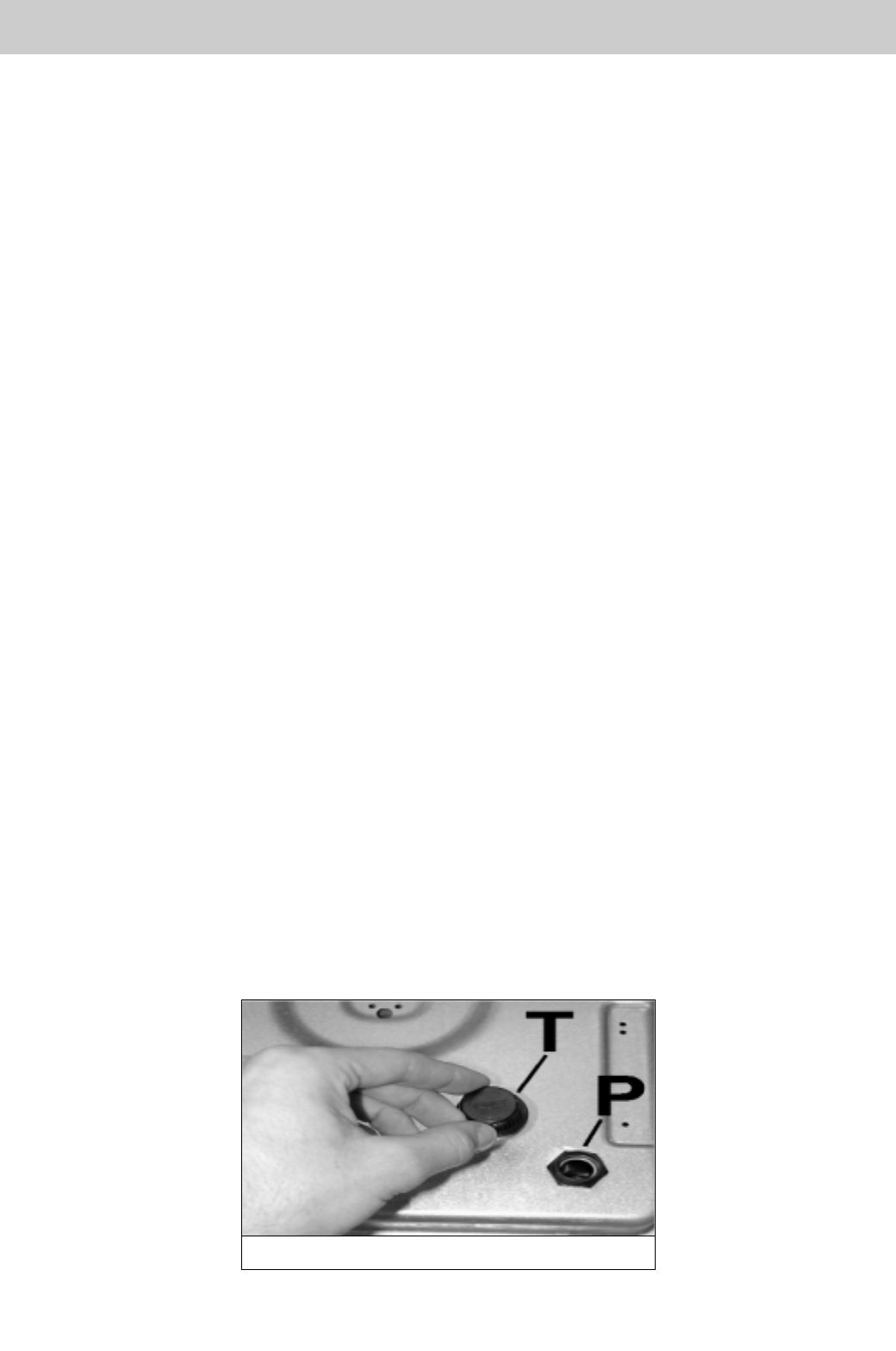

7) GAS CONNECTION

Before connecting the appliance, check that the

values on the data label affixed to the underside

of the hot plate correspond to those of the gas

and electricity mains in the home.

A label on the appliance indicates the regulating

conditions: type of gas and working pressure.

Gas connection must comply with the pertinent

standards and provisions in force.

When gas is supplied through ducts, the appliance

must be connected to the gas supply system:

o with a rigid steel pipe. The joints of this pipe must

consist of threaded fittings conforming to the

standards.

o With copper pipe. The joints of this pipe must consist

of unions with mechanical seals.

oWith seamless flexible stainless steel pipe. The

length of this pipe must be 2 meters at most and the

seals must comply with the standards.

When the gas is supplied by a bottle, the appliance

must be fuelled by a pressure governor conforming to

the provisions in force and must be connected:

owith a copper pipe. The joints of this pipe must

consist of unions with mechanical seals.

oWith seamless flexible stainless steel pipe. The

length of this pipe must be 2 meters at most and the

seals must comply with the standards. It is advisable

to apply the special adapter to the flexible pipe. This

is easily available from the shops and facilitates

connection with the hose nipple of the pressure

governor on the bottle.

o With rubber hose pipe in compliance with standards.

The diameter of this hose pipe must be 8 mm and its

length must be no less than 400 mm and no more

than 1500 mm. It must be firmly fixed to the hose

nipple by means of the safety clamp specified by

standards.

At the connection end, verify the gasproof using a

soap solution, never a flame.

WARNINGS:

- Remember that the gas inlet union on the

appliance is a 1/2" gas parallel male type in

compliance with ISO 228-1 standards.

- Installation of stainless steel pipe and rubber

hose pipe must ensure that it is never able to

touch mobile parts of the built-in cabinet (eg.

drawers). Furthermore, it must not pass

through compartments that could be used for

storage purposes.

- The appliance complies with the provisions of

the following EEC Directives:

90/396 + 93/68 regarding gas safety.

The installer should bear in mind that the mixed

appliance is the Y type. The rear wall, adjacent

and surrounding surfaces must therefore be able

to withstand an overtemperature of 75 K.

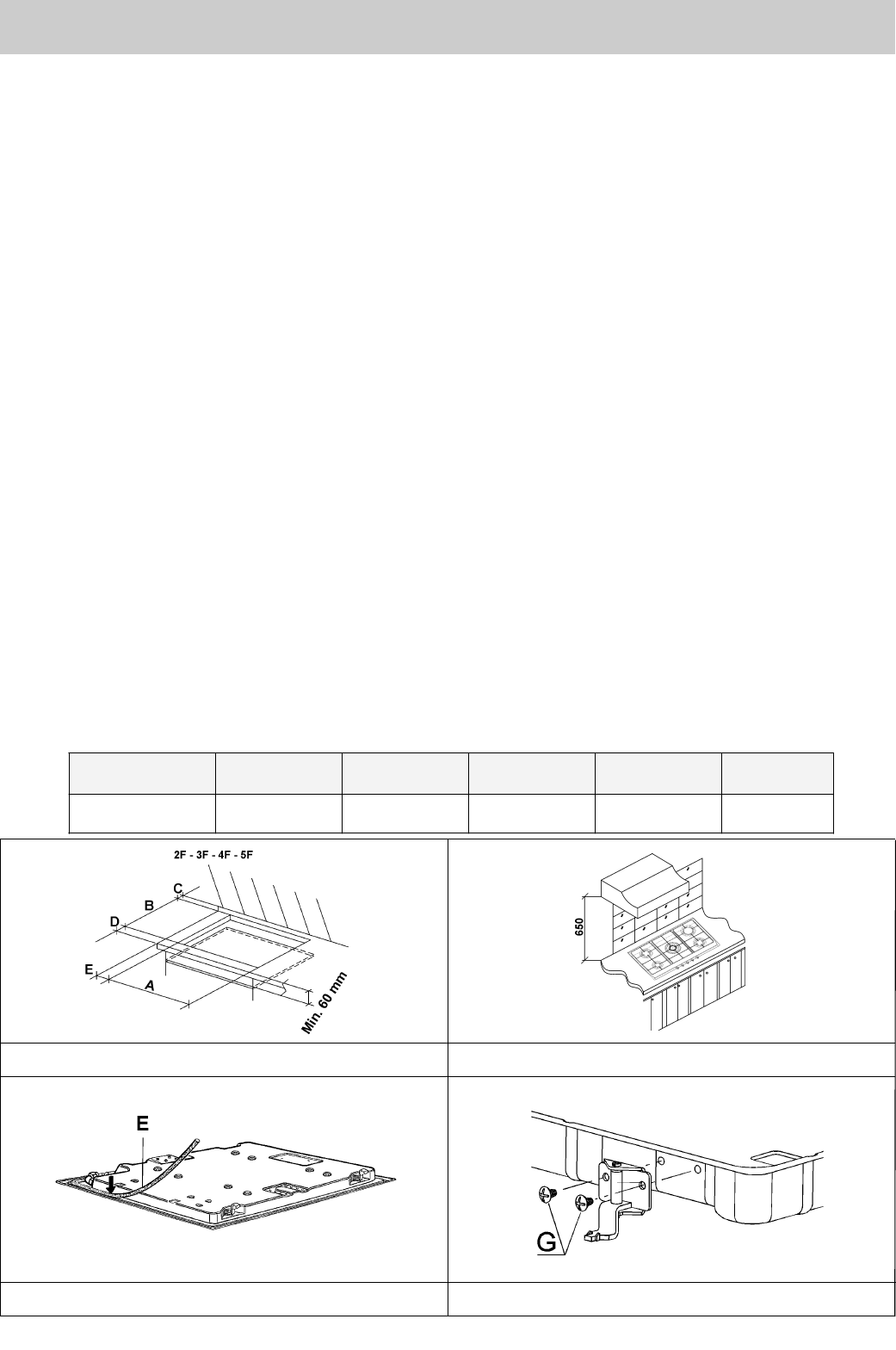

INSTALLATION