30

CONVERSIONS

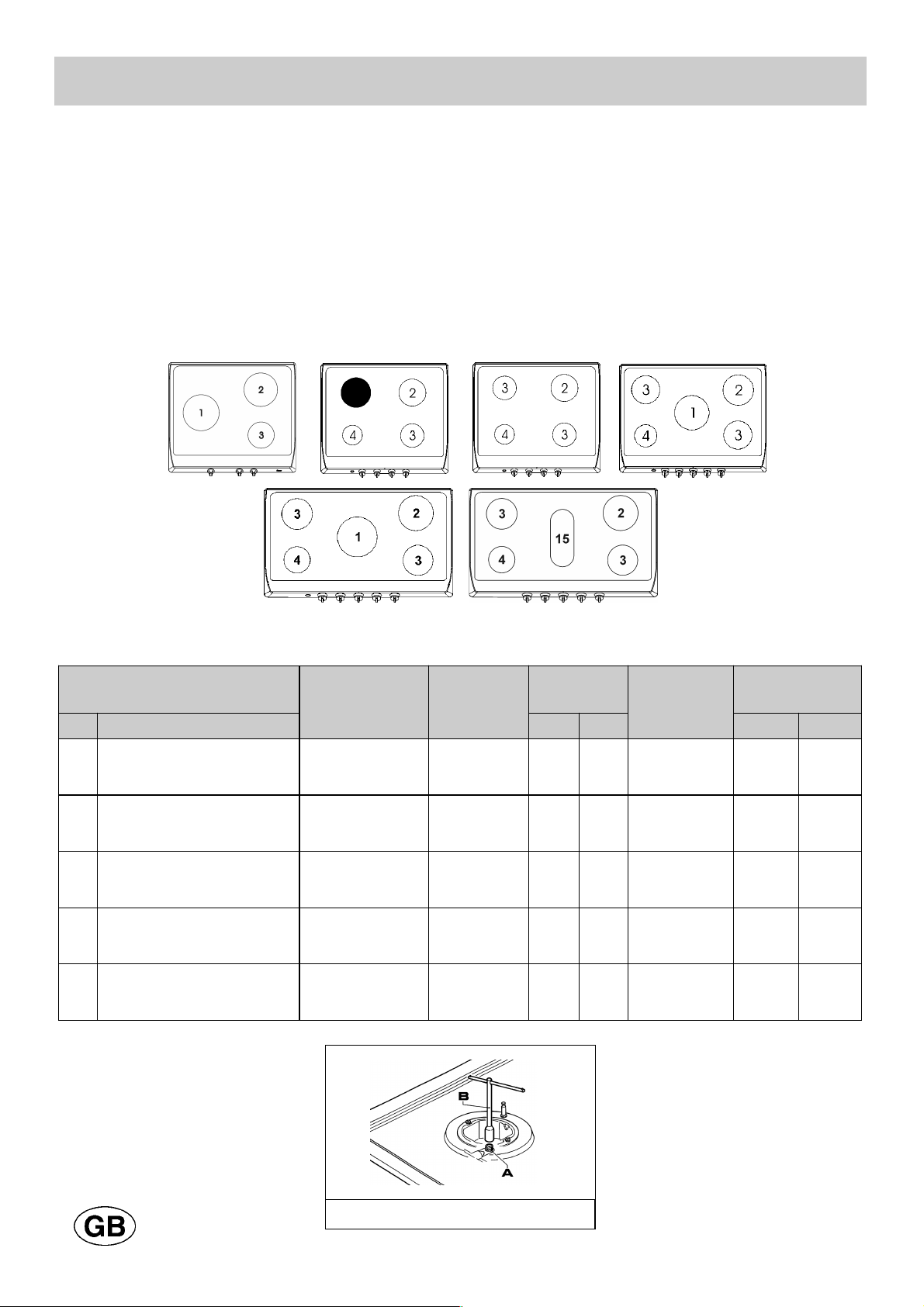

BURNER ARRANGEMENT ON THE HOT PLATE

FIG. 15

11) REPLACING THE INJECTORS

The burners can be adapted to different types of gas by

mounting injectors suited to the type of gas in question. To do

this, first remove the burner tops using a wrench "B". Now

unscrew injector "A" (see fig. 15) and fit a injector corresponding

to the utilized type of gas in its place.

It is advisable to strongly tighten the injector in place.

After the injectors have been replaced, the burners must

be regulated as explained in paragraphs 10. The technician

must reset any seals on the regulating or pre-regulating

devices and affix the label corresponding to the new gas

regulation on the appliance instead of the already existing

one. This label is supplied in the packet containing the

spare injectors.

The envelope with the injectors and the labels can be

included in the kit, or at disposal to the authorized

customer Service Centre.

For the sake of convenience, the nominal rate table also lists the

heat inputs of the burners, the diameter of the injectors and the

working pressures of the various types of gas.

BURNERS GAS NORMAL

PRESSURE

mbar

NORMAL

RATE INJECTOR

DIAMETER

1/100 mm

NOMINAL

HEAT IMPUT(W)

N°

DENOMINACIÓN

g/h l/h Min. Max.

1

ULTRA RAPID G30 - BUTANE

G31 - PROPANE

G20 - NATURAL

28 - 30

37

20 225

221 295 90

90

121 Y 1400

1400

1400 3100

3100

3100

2

RAPID G30 - BUTANE

G31 - PROPANE

G20 - NATURAL

28 - 30

37

20 204

200 267 83

83

117 S 800

800

800 2800

2800

2800

3

SEMIRAPID G30 - BUTANE

G31 - PROPANE

G20 - NATURAL

28 - 30

37

20 127

125 167 65

65

97 Z 500

500

500 1750

1750

1750

4

AUXILIARY G30 - BUTANE

G31 - PROPANE

G20 - NATURAL

28 - 30

37

20 73

71 95 50

50

72 X 400

400

400 1000

1000

1000

15

FISH G30 - BUTANE

G31 - PROPANE

G20 - NATURAL

28 - 30

37

20 204

200 267 83

83

117 S 1400

1400

1400 2800

2800

2800

TABLE