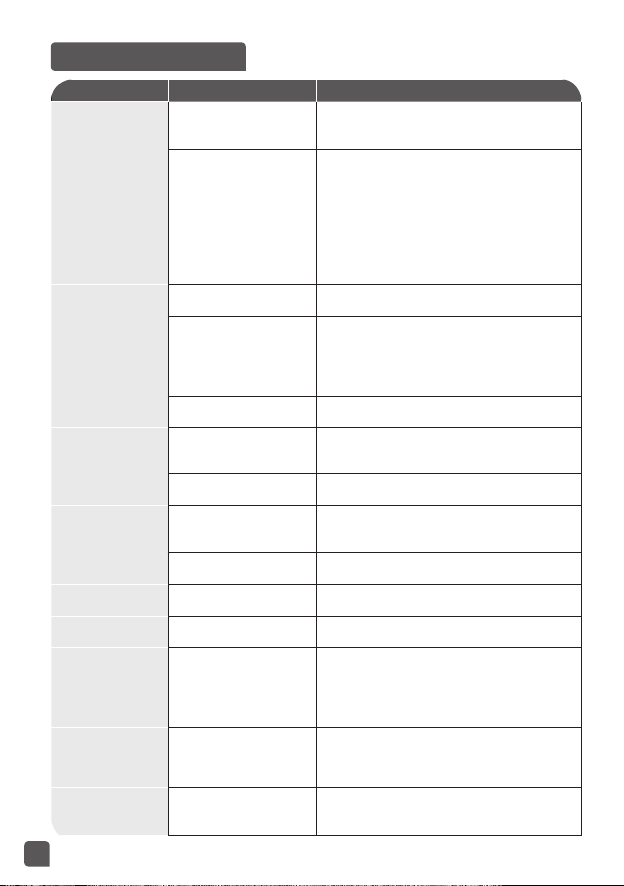

Problem Possible reasons Solutions

Unable to open lid.

Unable to open because

of pressure in the inner

pot.

a.Wait for the pressure in the pot to release

completely.

b. Press and hold the pressure release button.

Pressure in the pot is

fully released but the

float valve is stuck

because it is too dirty,

and therefore unable to

move down.

a. Be sure the pressure is totally released by

leaving to completely cool down for 2 hours

minimum (not under water).

b. Please use a skewer to poke the float

valve, to make it fall down. Be careful, keep

your face away from the lid and the handle

as hot steam/food may be released.

c. Before next use, please clean and wipe

the float valve.

Unable to close lid.

Sealing gasket is not

properly installed. Install the sealing gasket properly.

The float valve is stuck

because it is too dirty,

and therefore unable to

move down.

a. Please use a skewer to poke the float

valve, to make it fall down.

b. Before next use, please clean and wipe

the float valve (see page 18, cleaning steps

of the float valve).

Direction which lid was

closed is incorrect.

Close the lid in the correct direction

according to the instruction manual.

Intense release

of pressure from

pressure limit

valve.

Faulty pressure control

resulted in release of

pressure.

Send to repair and maintenance

department.

Pressure limit valve is in

an incorrect in position.

Gentling press the pressure limit valve to

make it fall into place.

Food is uncooked

Rice/water ratio is

incorrect.

Use the required rice/water ratio

Be sure the releasing valve is not dirty and

creating leakage during cooking.

No electricity from the

power supply. Check the home electric circuit.

E0 displayed on

digital screen.

Lid temperature sensor

is faulty.

Send to repair and maintenance

department.

E1 displayed on

digital screen.

The bottom sensor open

circuit or short circuit.

Send to repair and maintenance

department

E2 displayed on

digital screen. lid is not locked

Check if the program selected requires the

lid totally closed .

If yes, completely lock the lid.

If no, send to repair and maintenance

department.

E5 displayed on

digital screen. Abnormal low pressure.

Check that gasket is properly installed and

cleaned.Check that pressure limit valve falls

down into place and is cleaned.Check that

lid fixing nut is well tightened.

Steam leaking

from lid.

The sealing gasket was

not properly installed.

Remove the gasket, clean it and reinstall the

sealing gasket properly, in correct position (see

page 18, cleaning steps of the lid gasket).