9

G

B

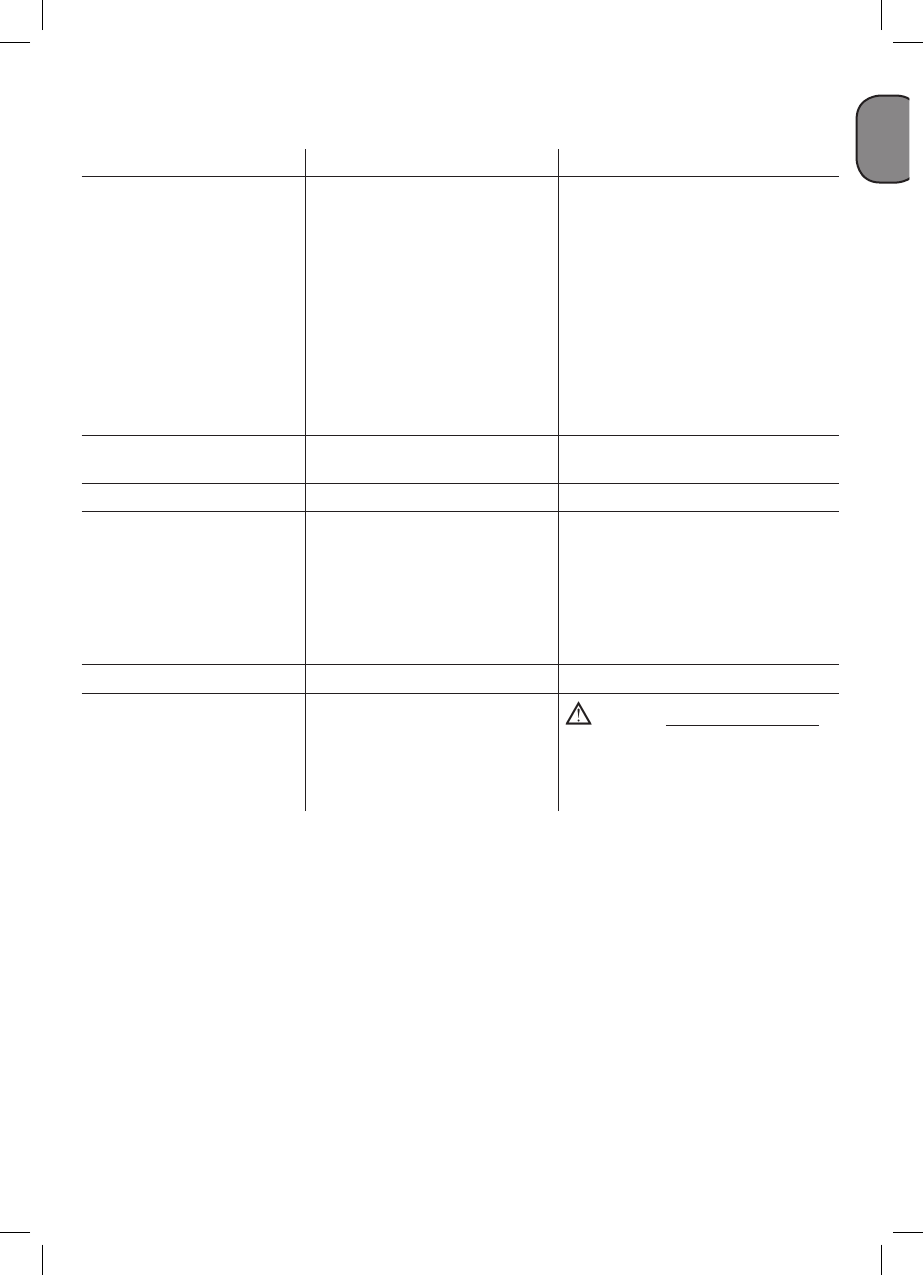

9. TROUBLE SHOOTING GUIDE

Note: Remove power source and drain tank pressure prior to making any repairs or adjustments.

FAULT PROBABLE CAUSE REMEDY

Unit will not run Tank pressure exceeds “cut in”

pressure

Once pressure drops below “cut in”

pressure, the unit will start.

Extension cord causing excessive

amp draw

Check guidelines for proper cord

gauge (use of extension cords is not

recommended).

Fuse or circuit tripped Replace fuse or reset breaker.

Unit not turned on or not plugged in Check pressure switch and verify that it

isintheOnposition.Verifythatunitis

plugged in.

Cold weather conditions (typically

temperatures below freezing)

Place compressor in warmer environment

for at least 30 minutes then try restarting.

Airleaksatttings Fittings loose Tightentting.Checkwithsoapywater.

DONOTOVERTIGHTEN.

Air leak at pressure switch Clogged check valve Remove and clean check valve.

Unit will not build pressure Application requires excessive air

demand

Reduce demand on compressor.

Loose head Tighten bolts on head.

Blown gasket Remove head and check for broken or

deformed gasket. Replace if needed.

Open drain valve Close drain valve.

Unit will not build pressure Worn or broken valves Remove head and replace valves.

Air leak at tank or air tank welds. Damaged air tank

Warning!

Do not drill into, weld or otherwise

modifyairtank.Damagedormodied

tanks can rupture. Replace tank

immediately.

Any other type of operation must be carried out by authorized Service Centers, requesting original parts.

Tamperingwiththemachinemayimpairitssafetyandinanycasemakethewarrantynullandvoid.