Index

1. SOLZAIMA .................................................................................................................... 1

2. TECHNICAL CHARACTERISTICS ....................................................................................... 2

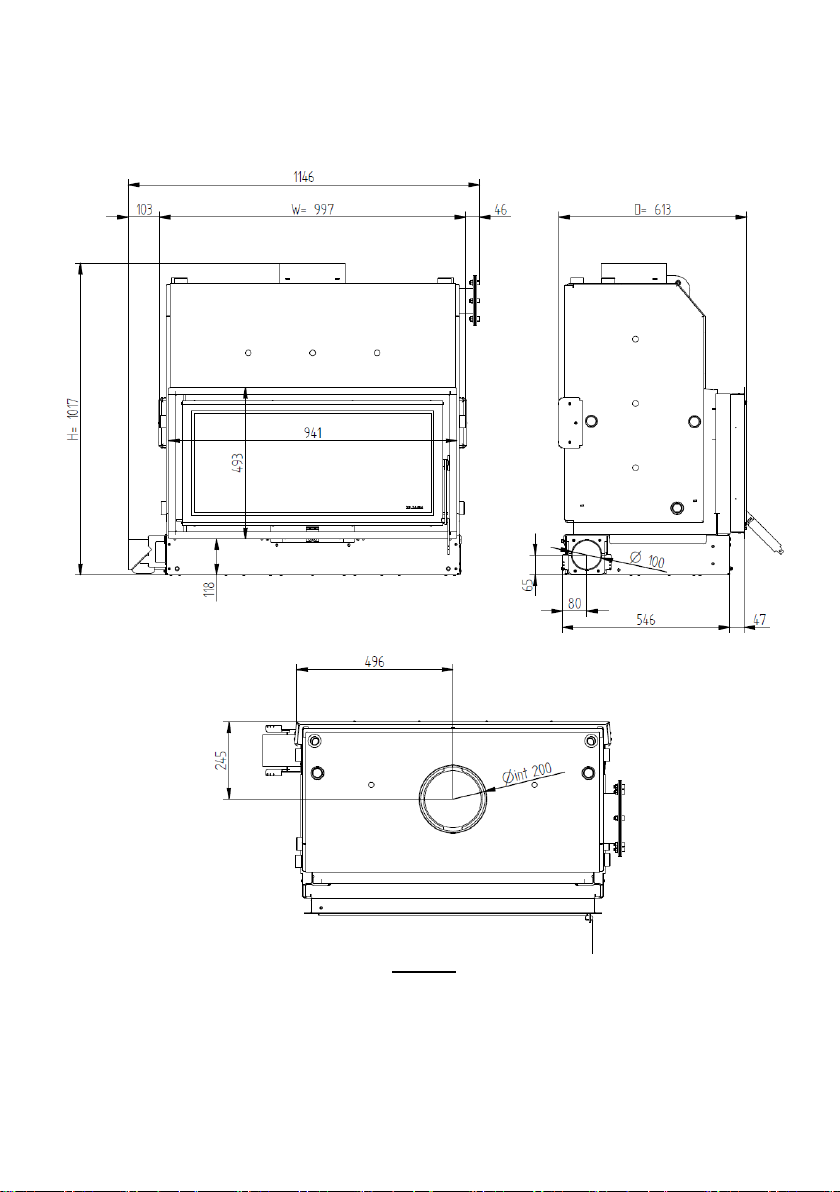

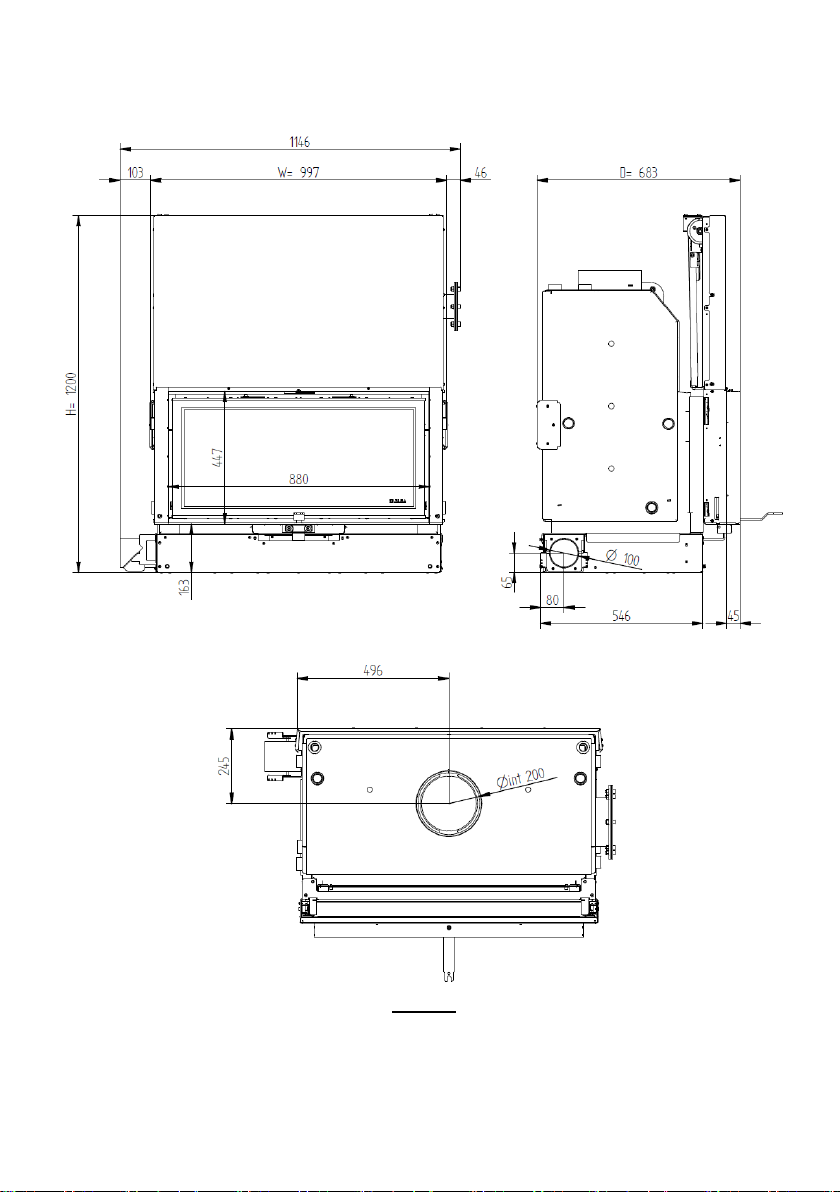

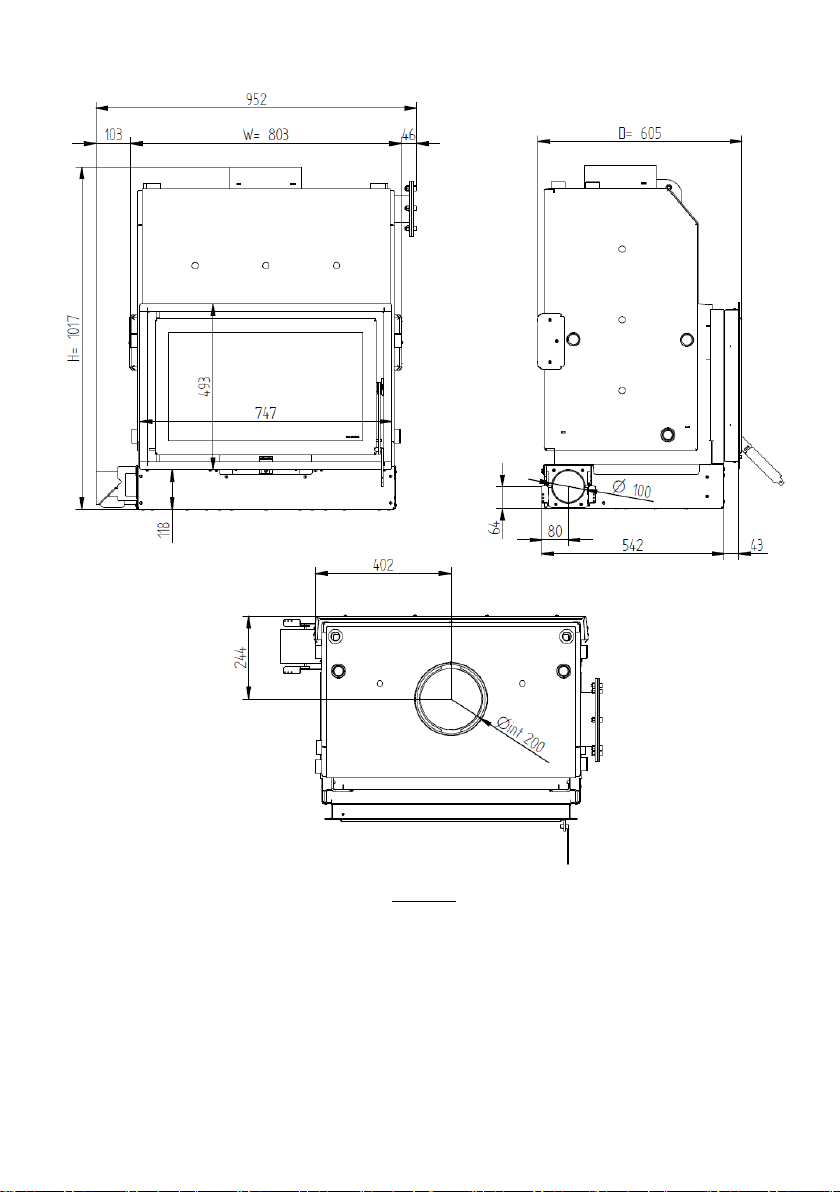

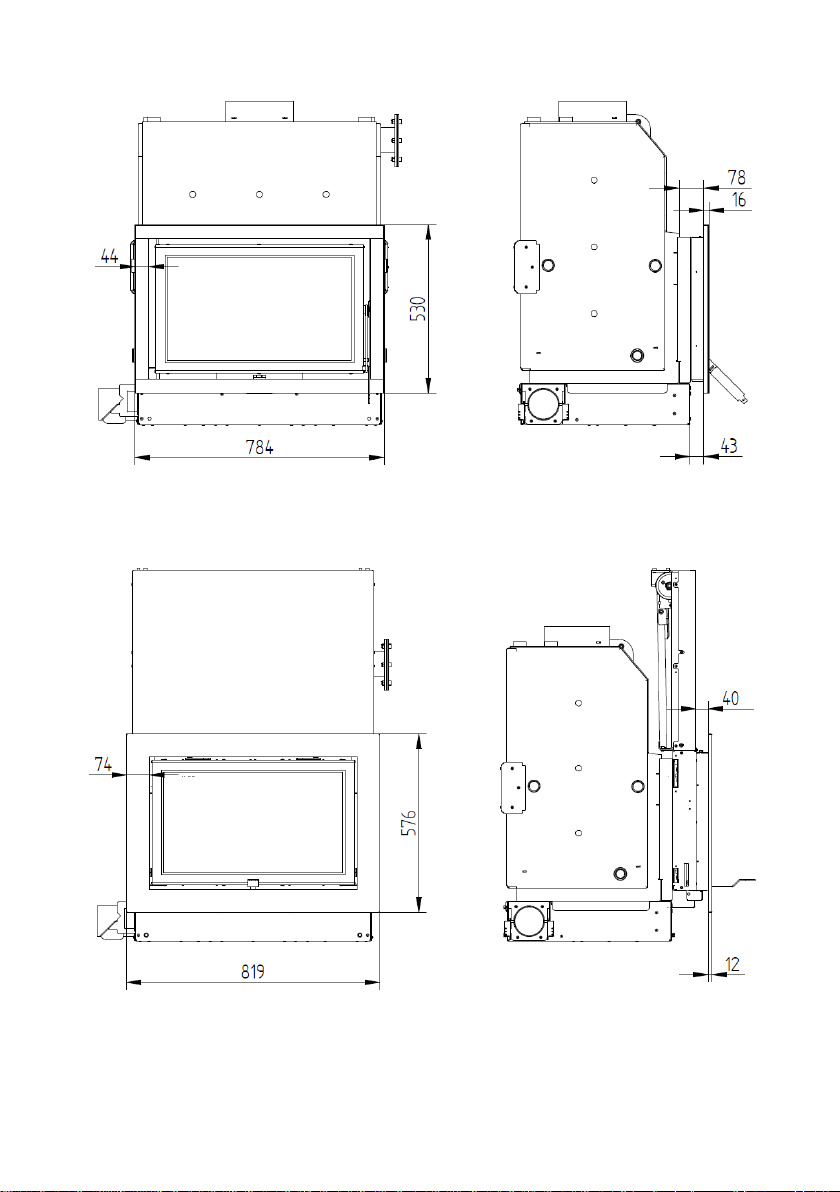

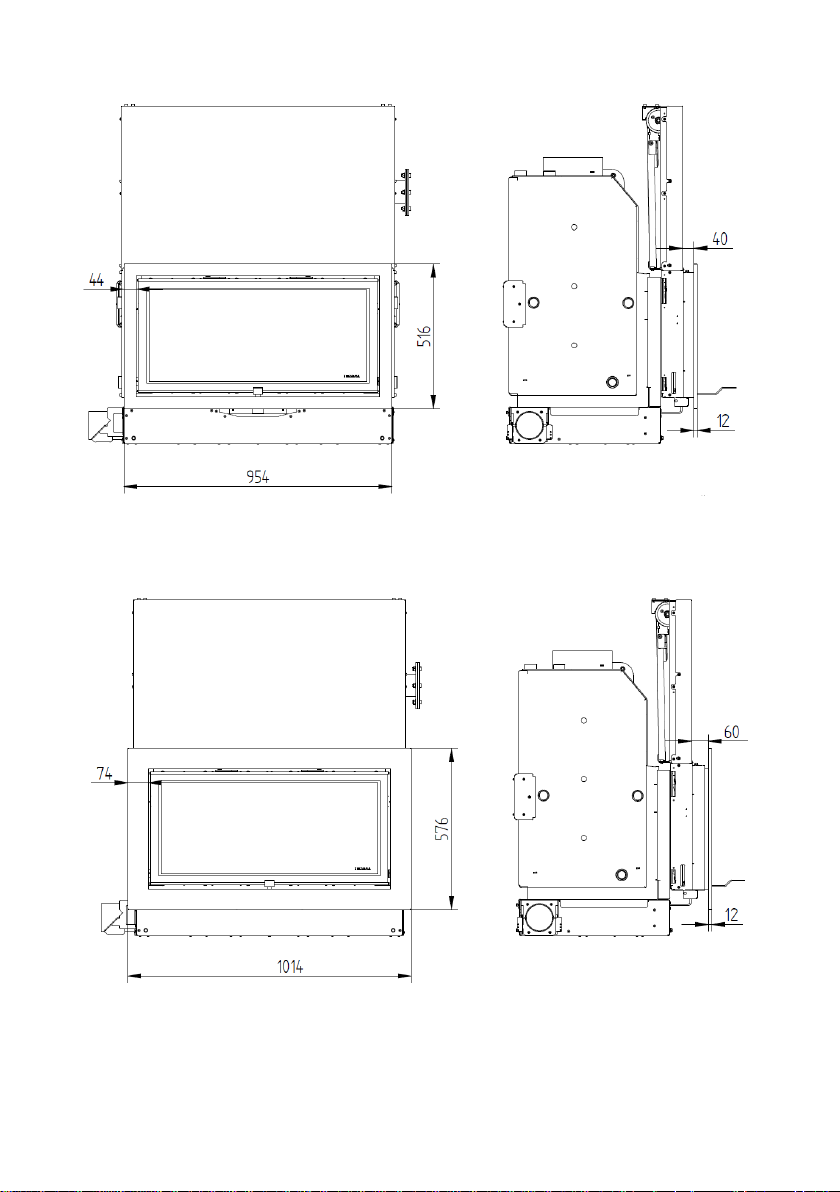

3. GENERAL MEASURES ..................................................................................................... 4

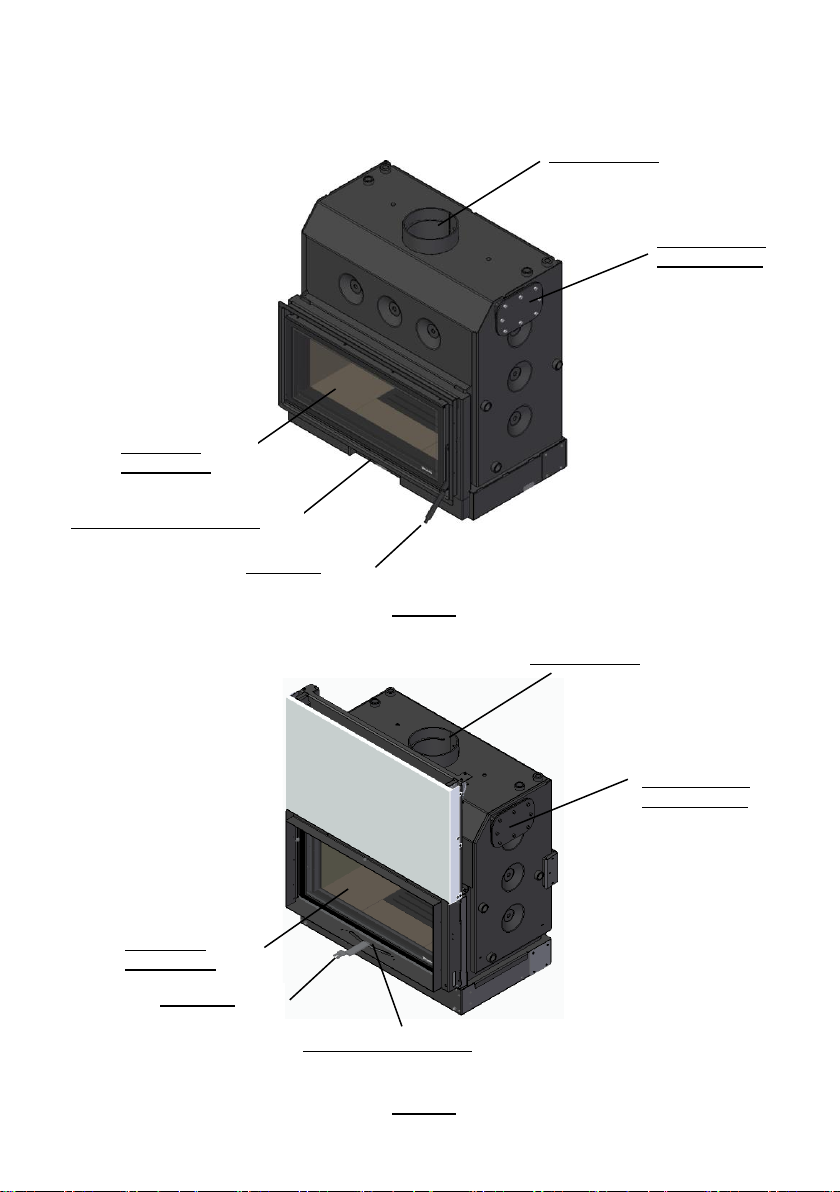

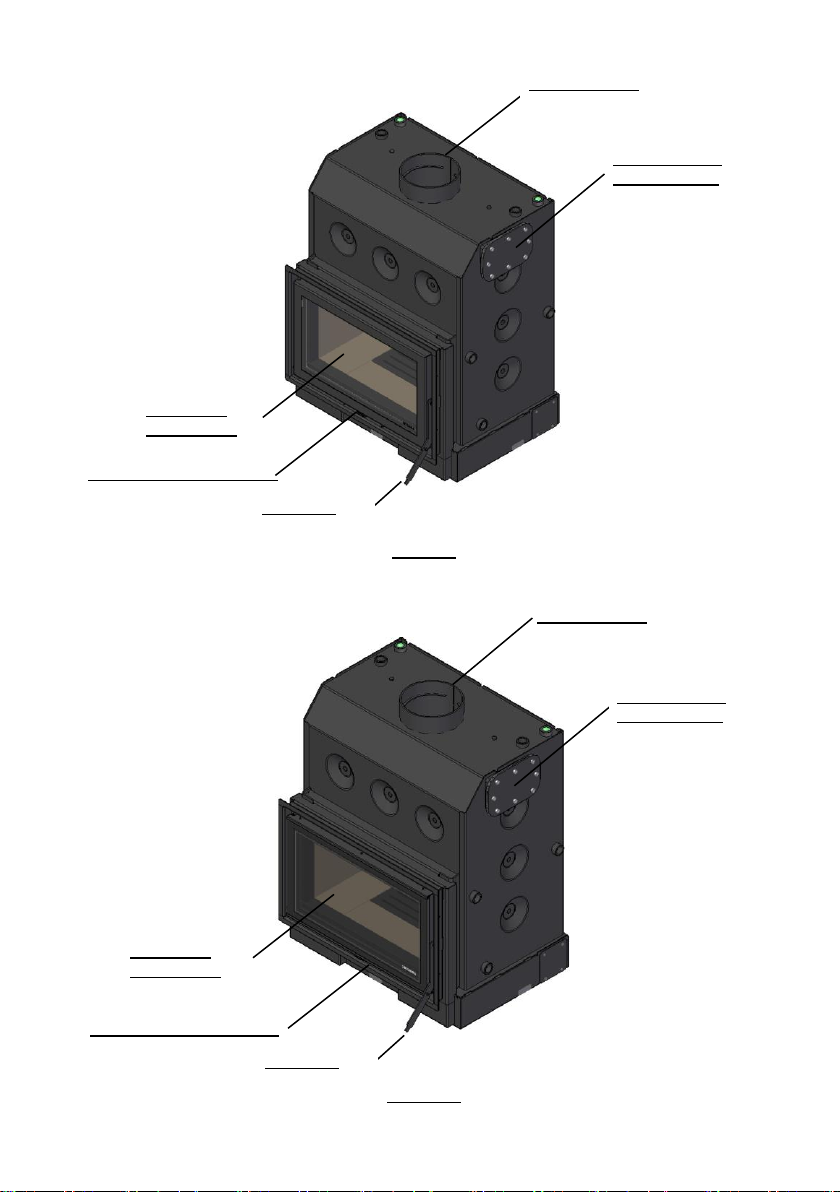

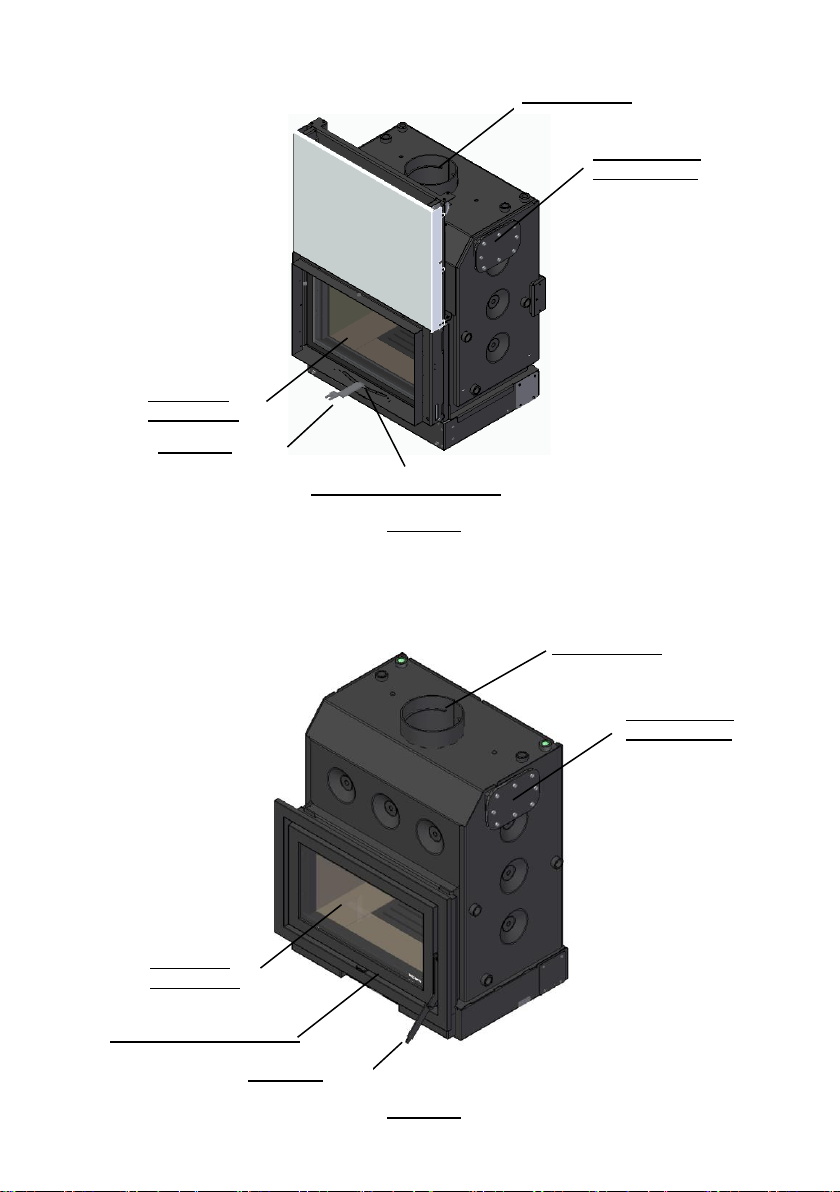

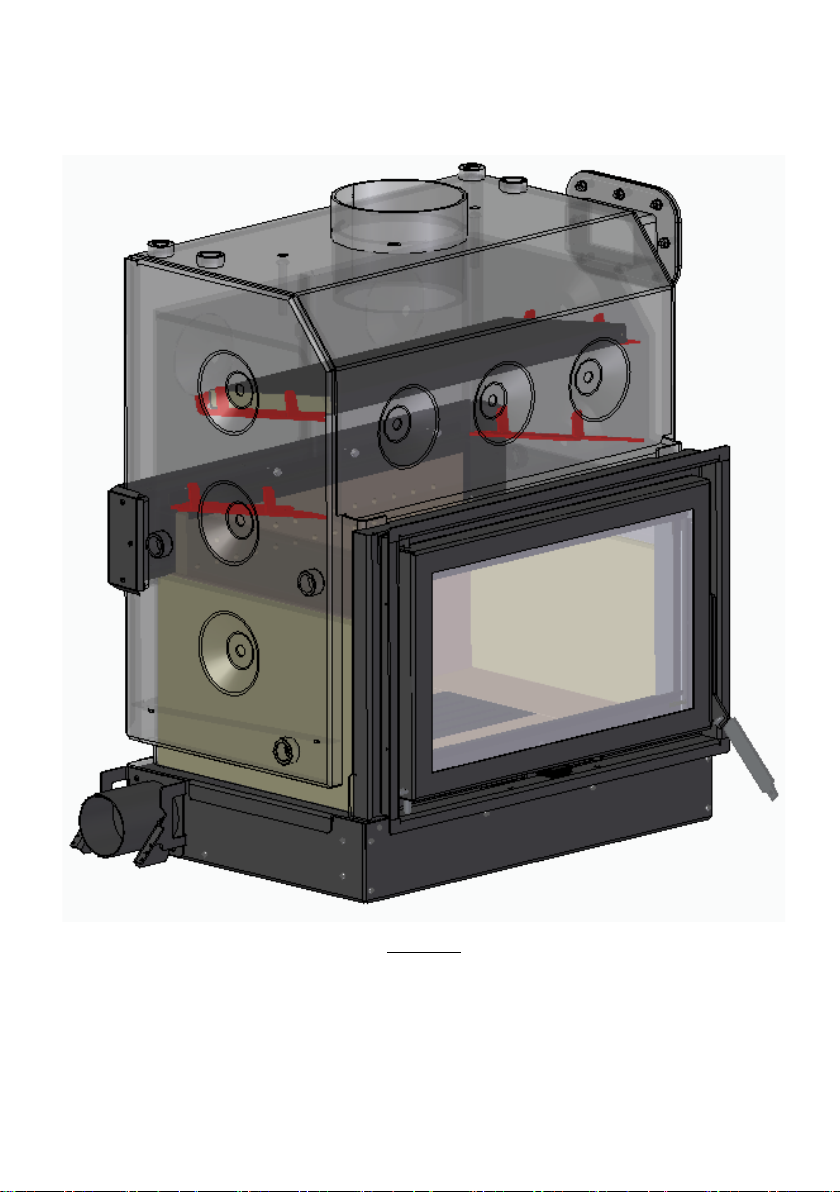

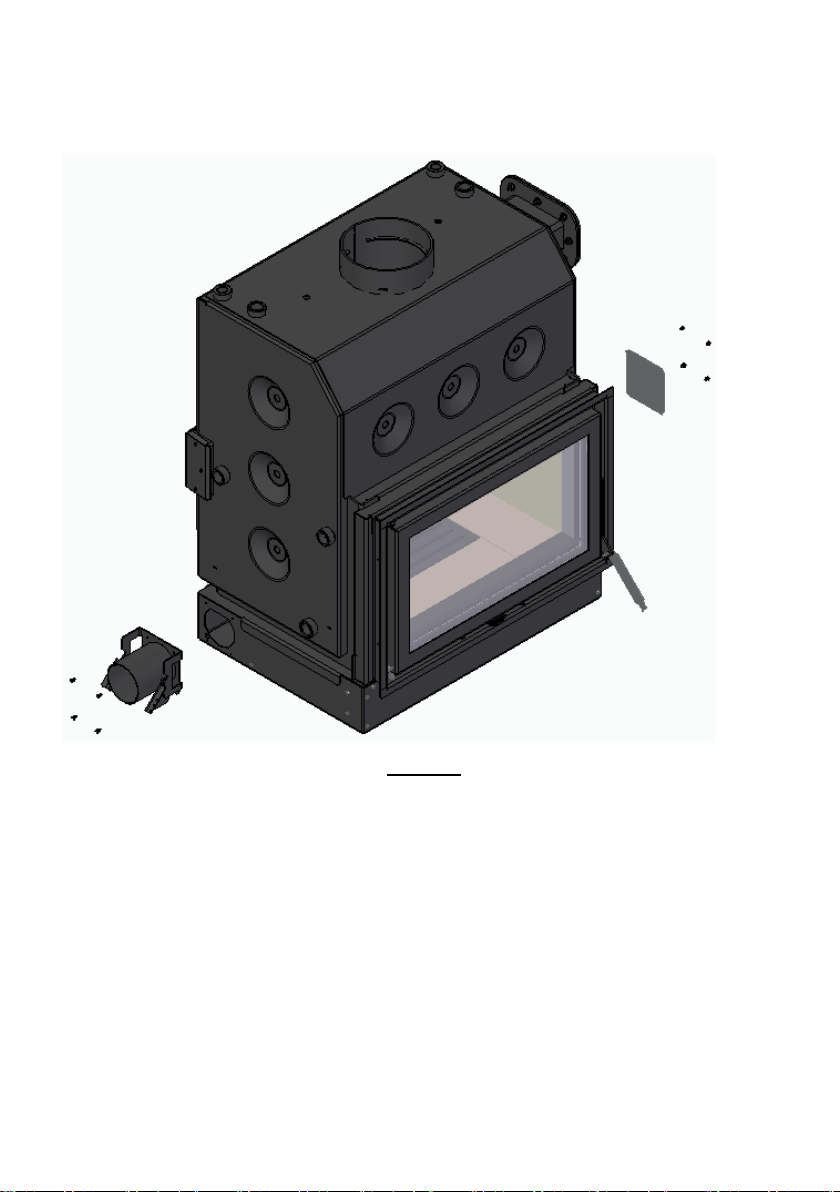

4. KNOW THE EQUIPMENT ................................................................................................ 10

5. MATERIALS OF THE RECUPERATORS ............................................................................... 13

6. INSTALLATION ............................................................................................................. 15

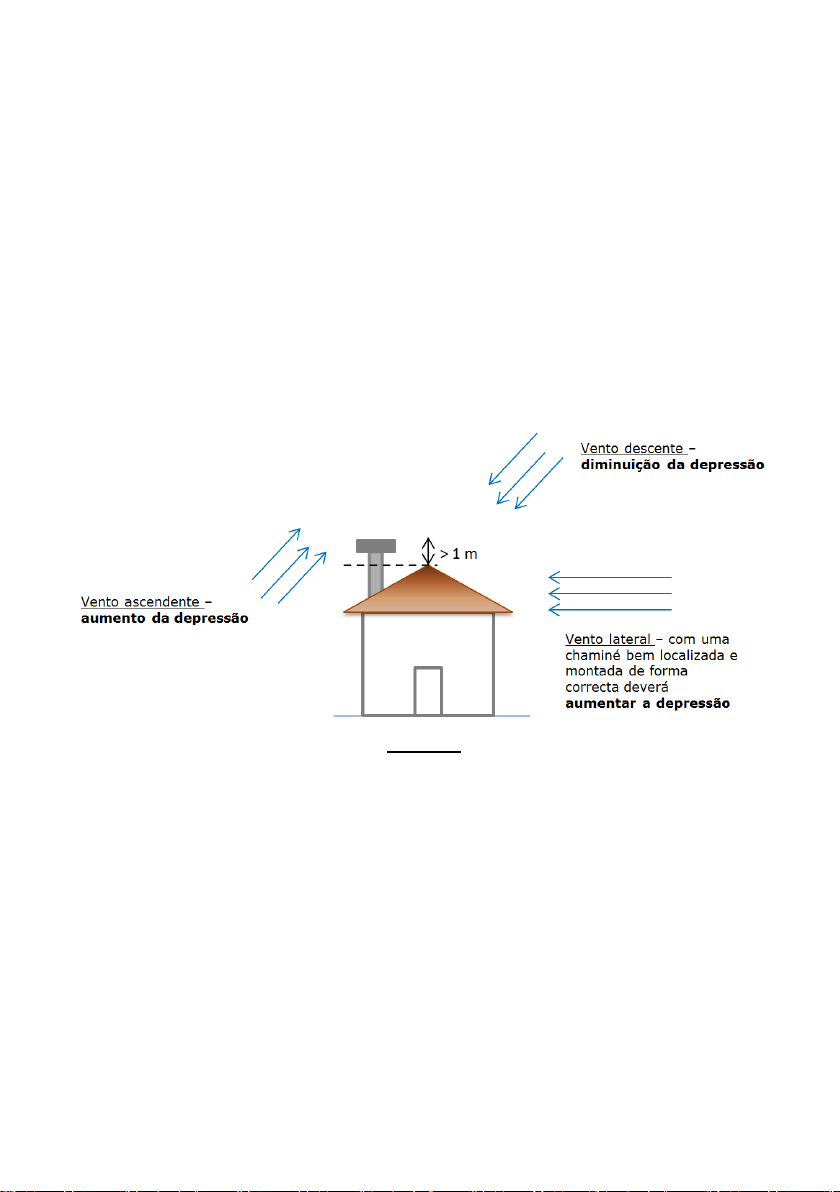

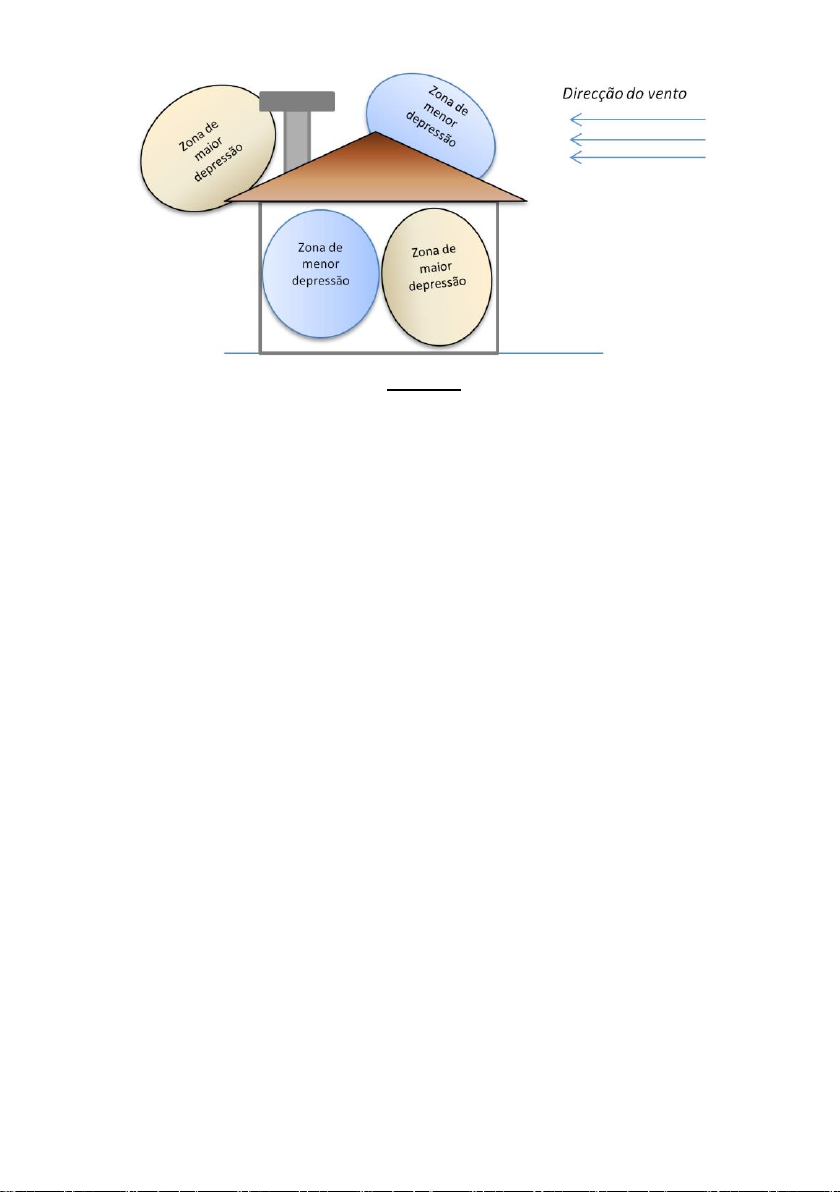

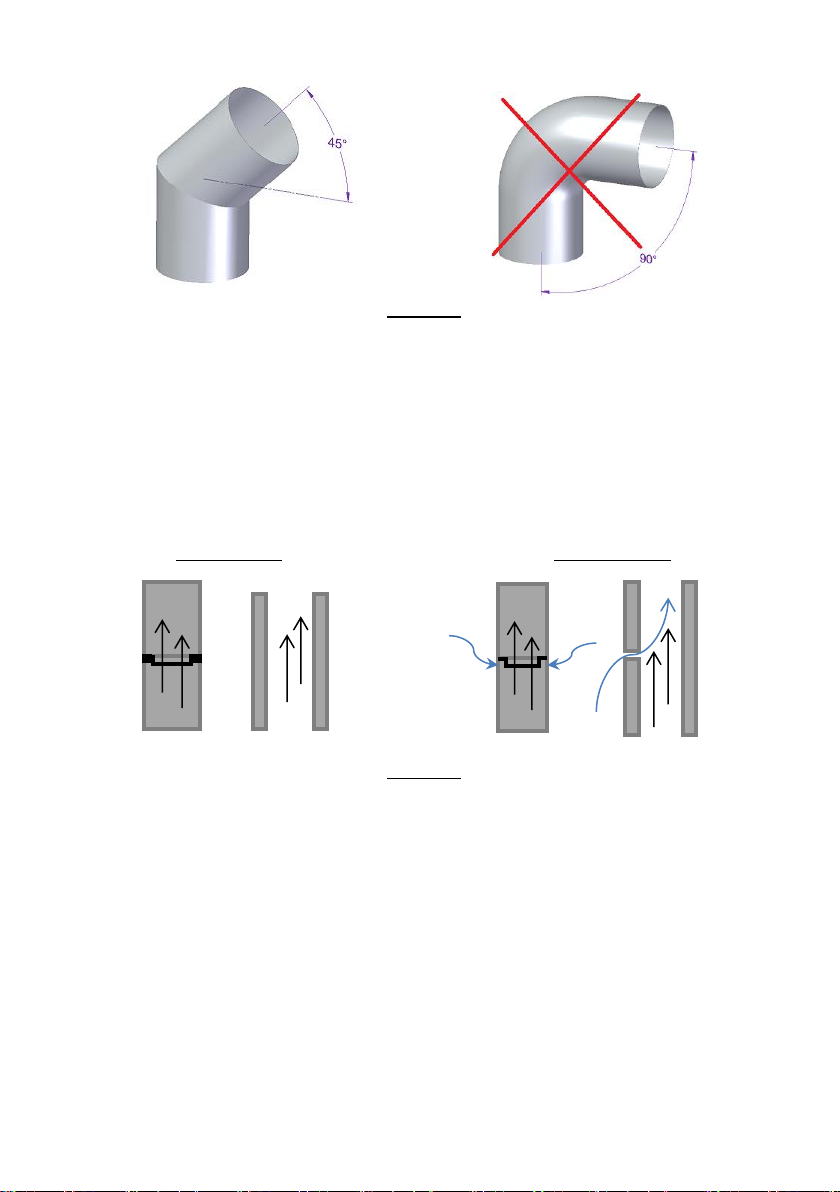

6.1. CIRCULATION OF AIR AND FLUE GASES ............................................................................... 19

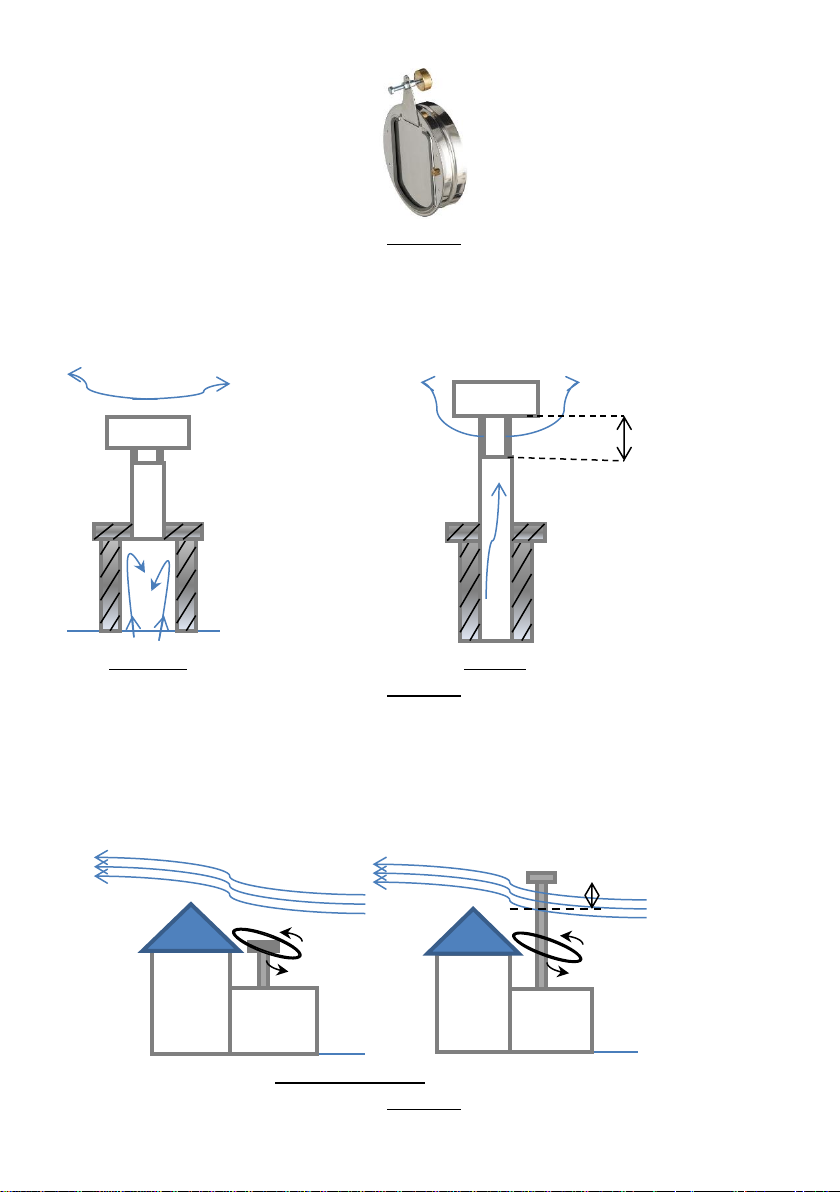

6.1.1. THEORETICAL NOTIONS FOR THE INSTALLATION OF CHIMNEYS ................................................. 19

6.1.2. INSTALLATION ADVICE .............................................................................................. 21

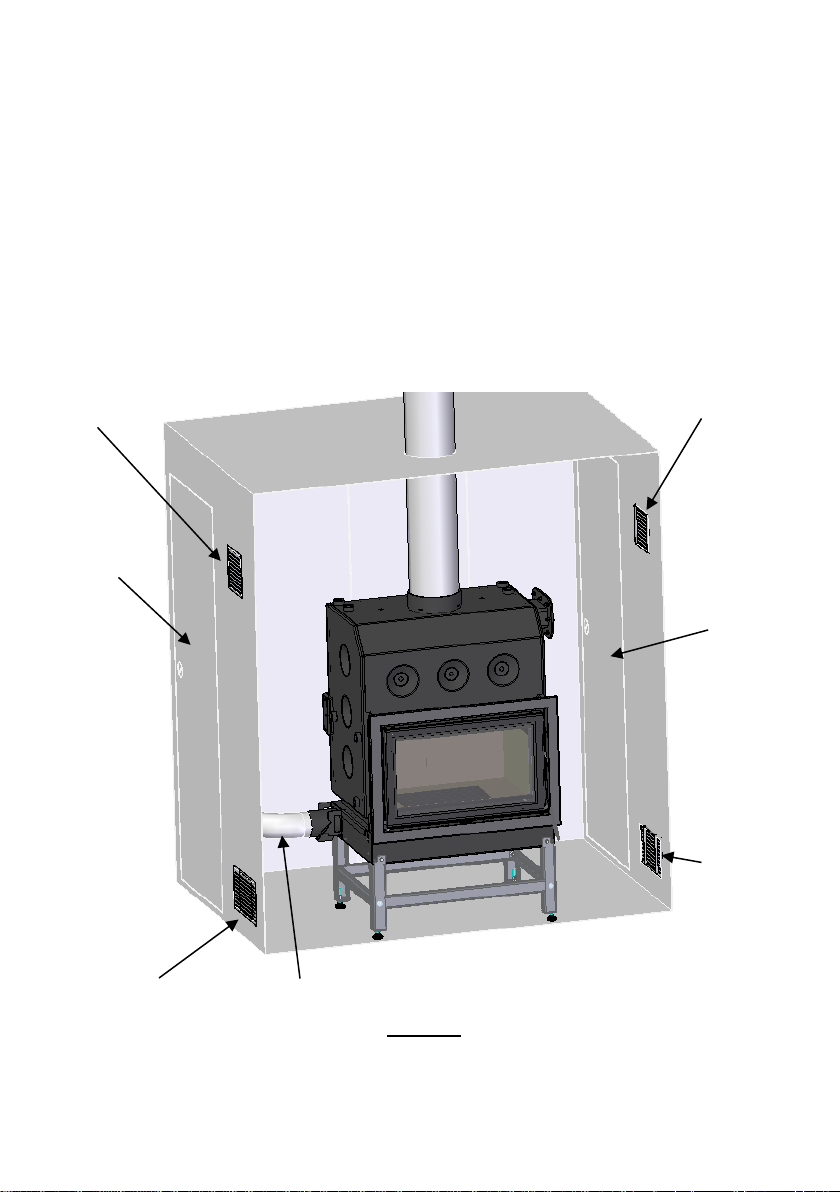

6.2. INSTALLATION LOCATION REQUIREMENTS ............................................................................ 24

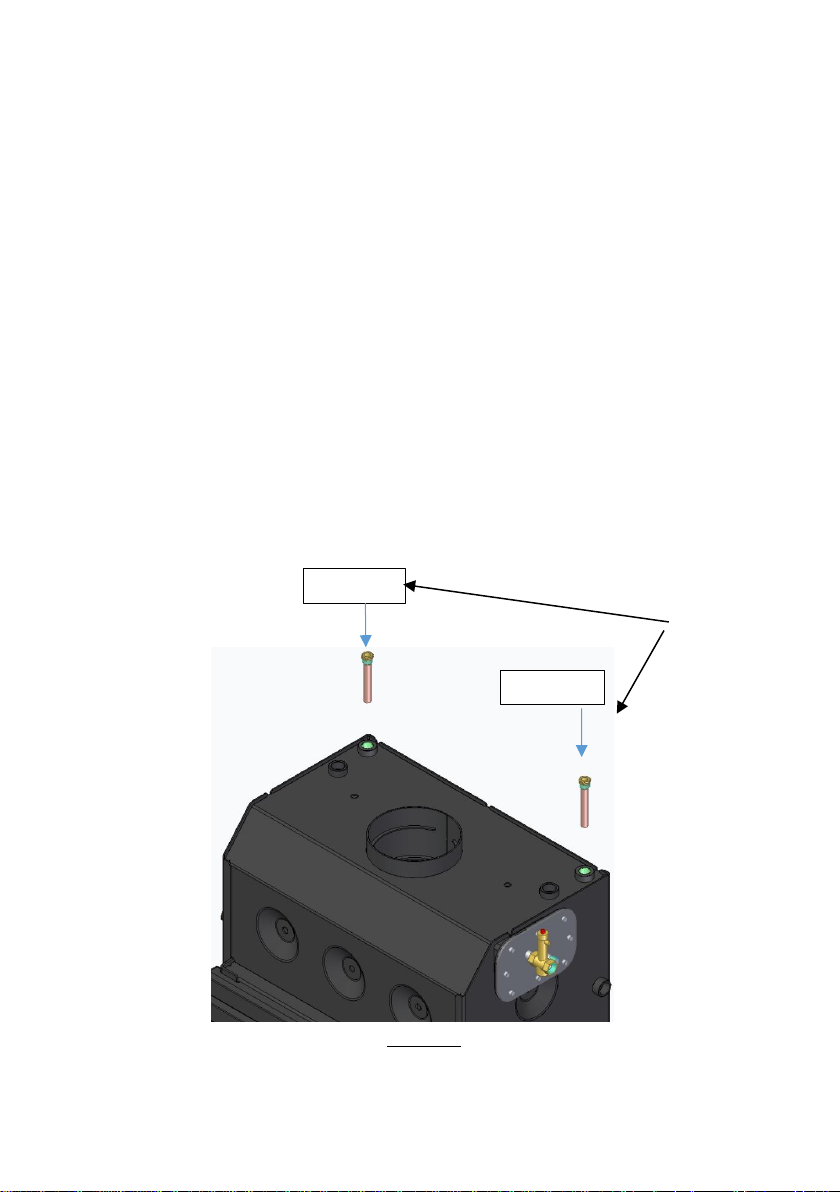

6.3. HYDRAULIC INSTALLATION ............................................................................................. 28

6.4. OPTIONAL TRIM RIM .................................................................................................... 30

6.4.1. TRIM HOOP MODELS ................................................................................................. 30

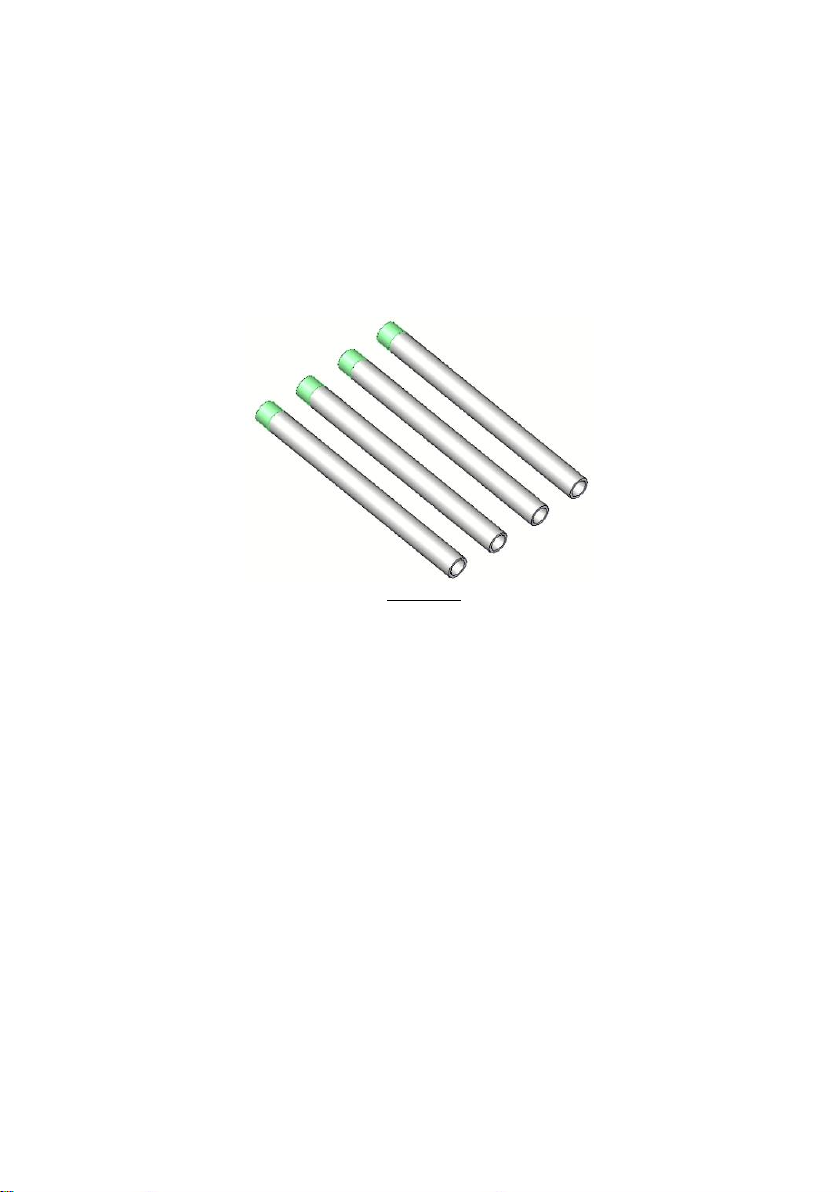

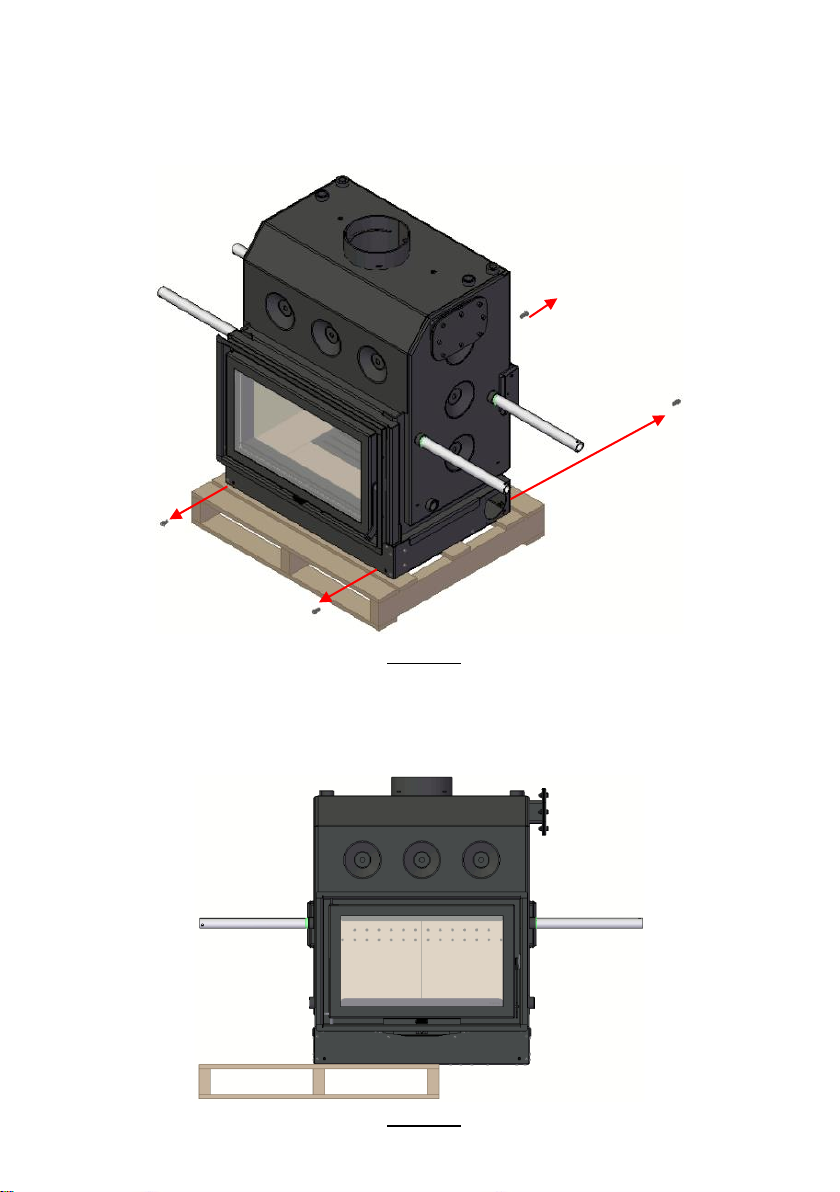

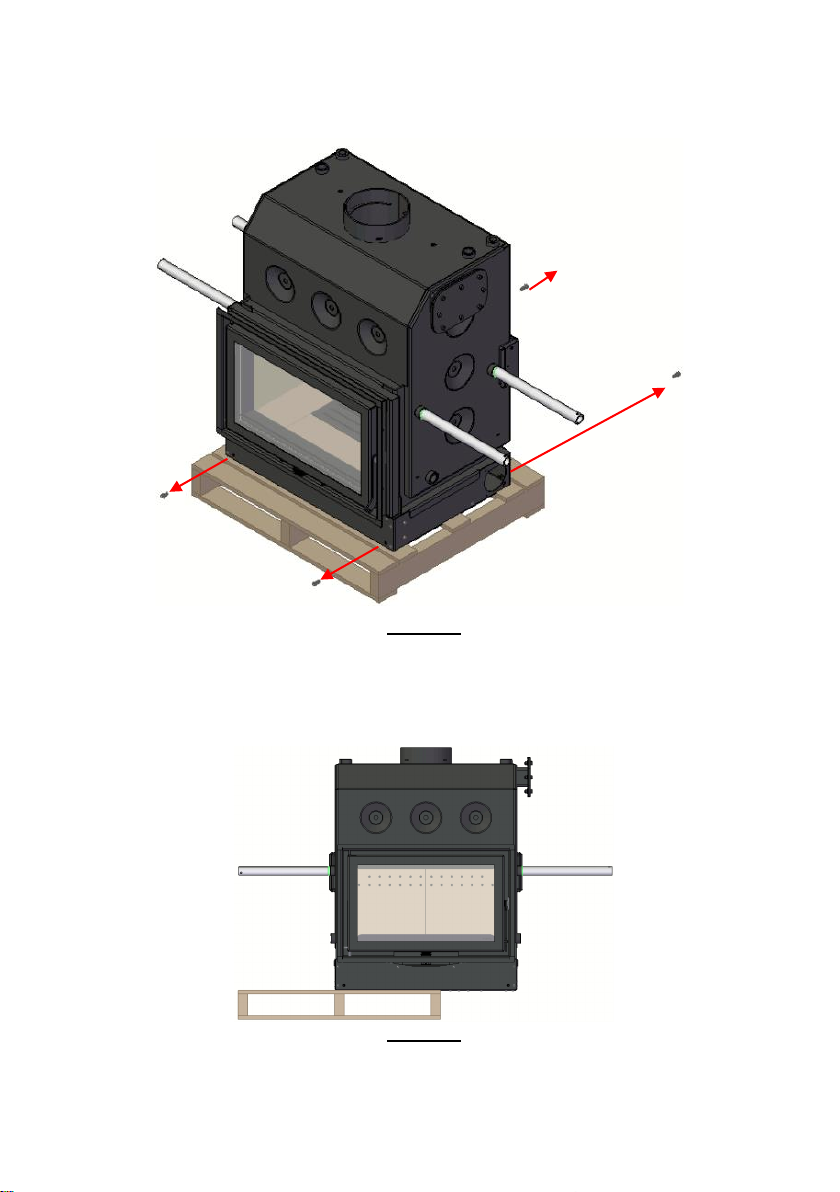

6.4.2. TRANSPORT BARS .................................................................................................... 37

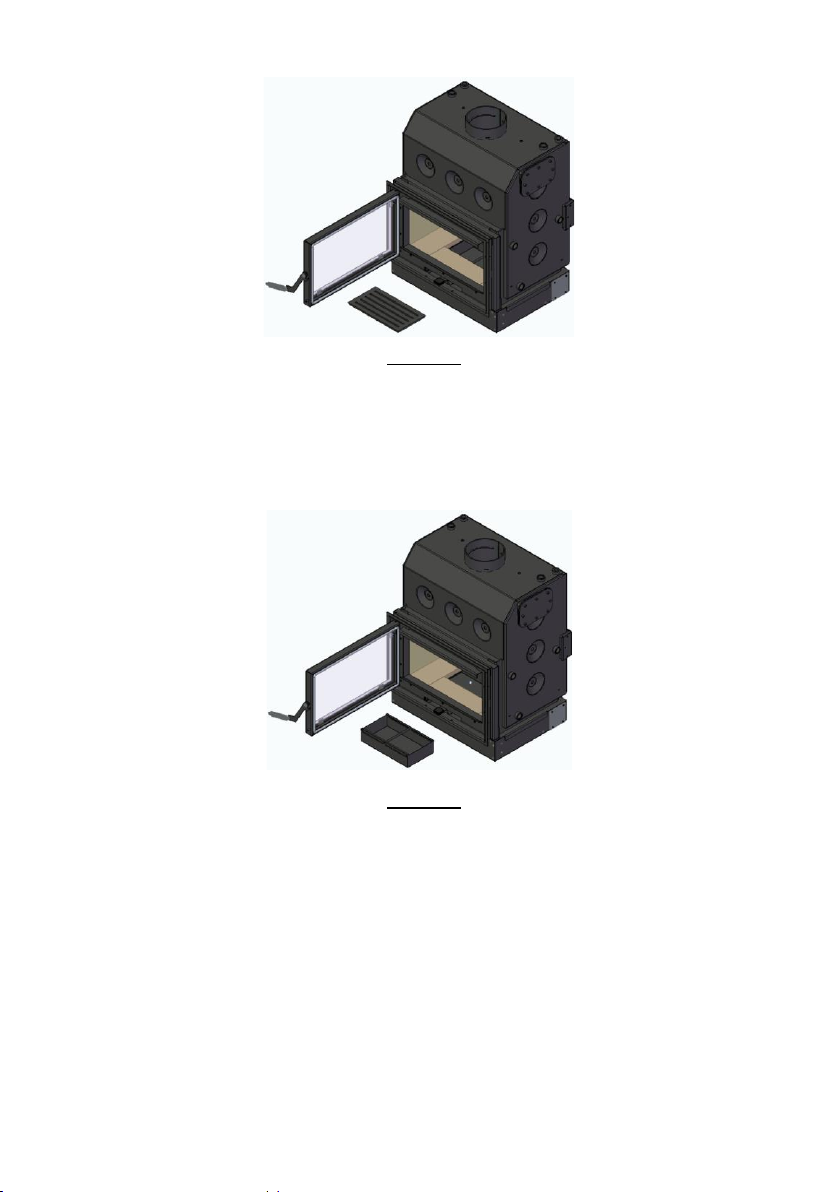

6.4.3. TRANSPORT WHEELS ................................................................................................ 37

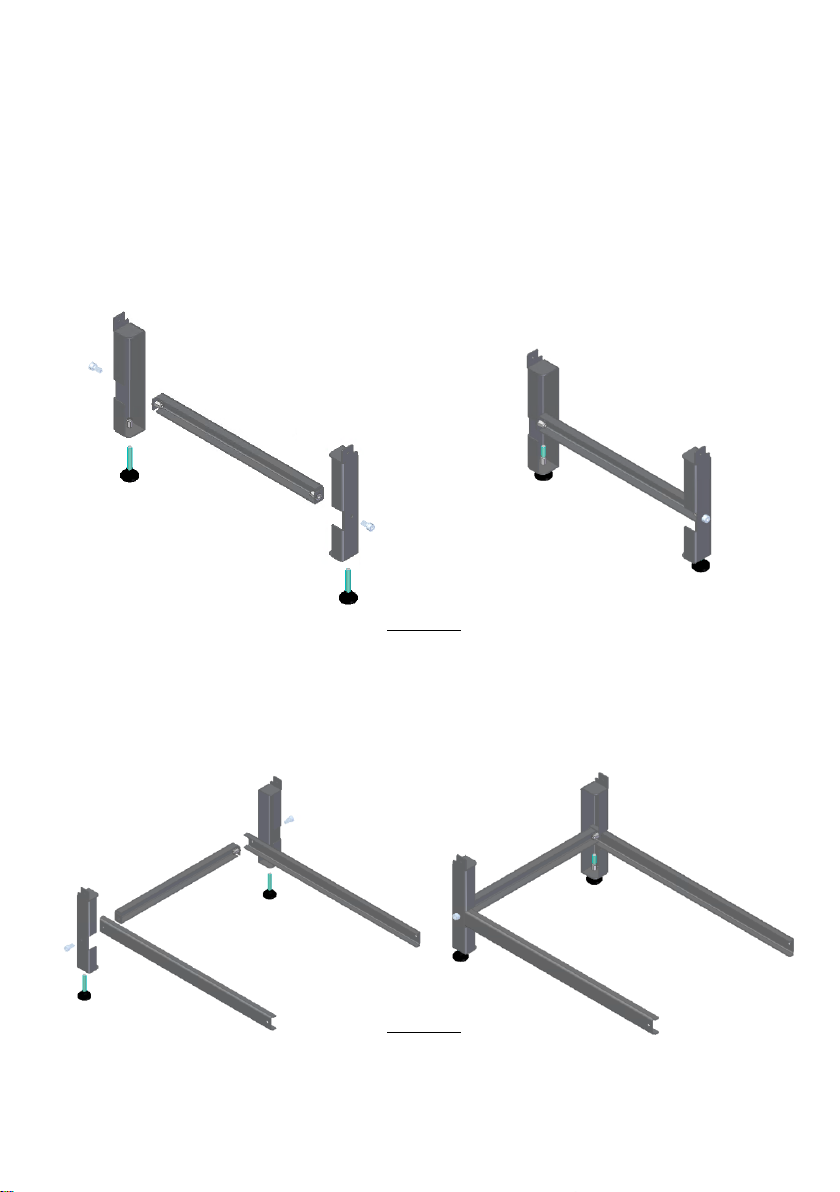

6.4.4. AUXILIARY LEVELING TABLE ........................................................................................ 40

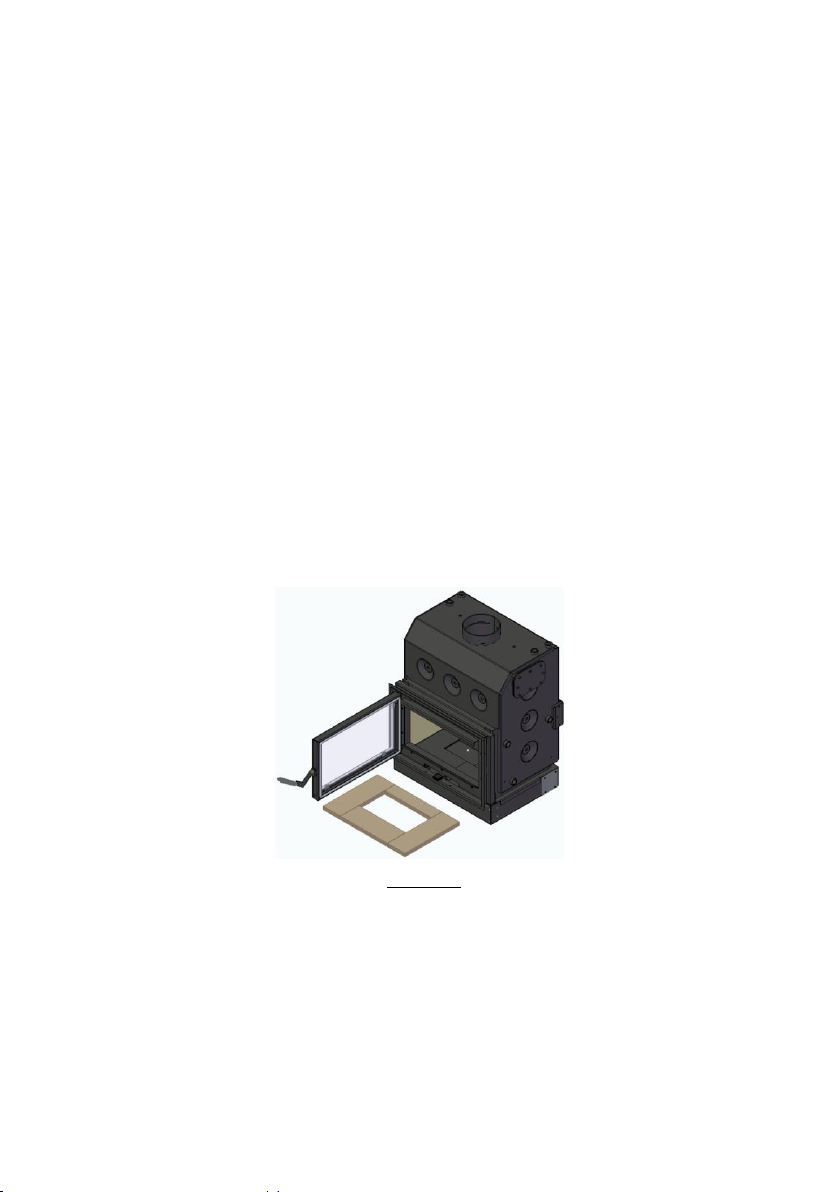

6.4.5. ANTI-PACKAGING KIT ............................................................................................... 47

7. MAIN PARTS OF THE RECUPERATOR ............................................................................... 50

8. INSTRUCTIONS FOR USE .............................................................................................. 52

8.1. FUEL ..................................................................................................................... 52

8.1.1. POWER ................................................................................................................ 53

8.1.2. ENERGY EFFICIENCY ................................................................................................. 53

8.2. FIRST USE ............................................................................................................... 54

8.3. INSTRUCTIONS FOR USE OF THE RECUPERATOR ..................................................................... 55

8.3.1. ADJUSTMENT OF COMBUSTION CONTROL .......................................................................... 55

8.3.2. FIRING ................................................................................................................ 57

8.3.3. REFUEL ............................................................................................................... 57

8.4. SAFETY ................................................................................................................... 59

8.5. CLEANING AND MAINTENANCE ......................................................................................... 59

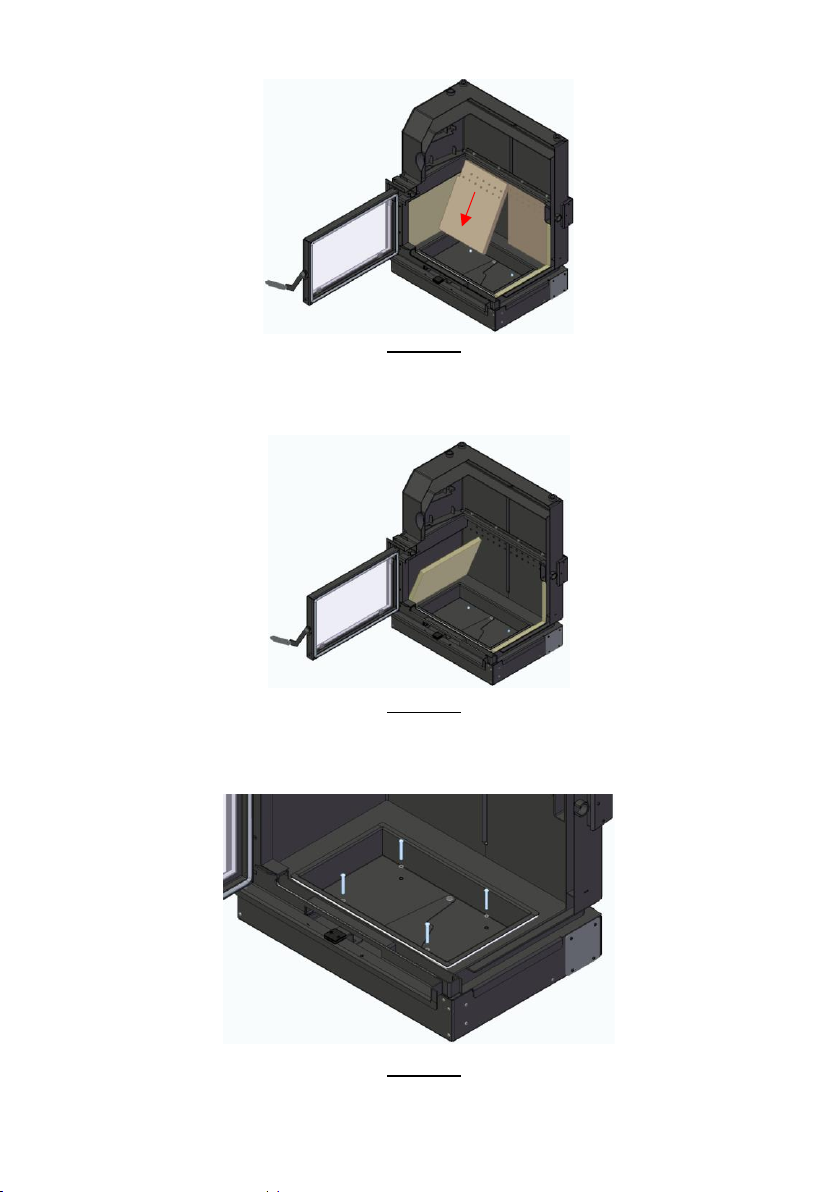

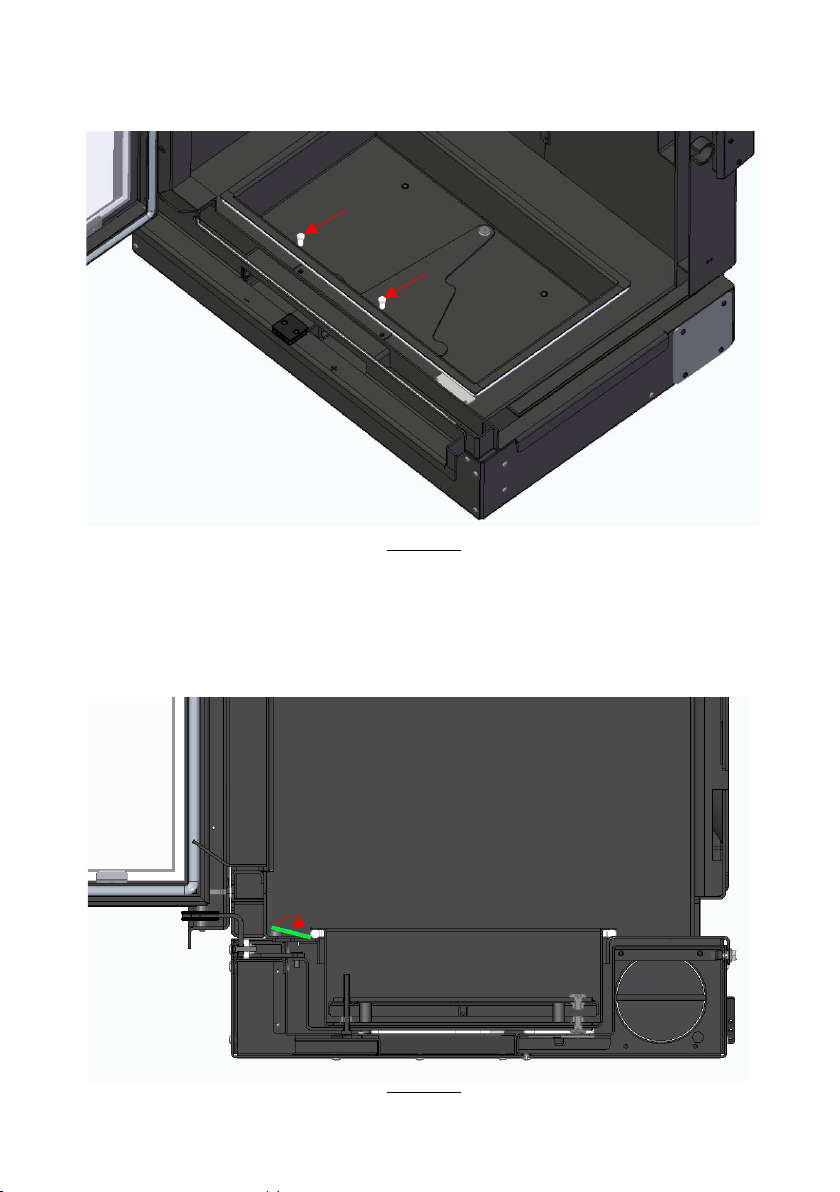

8.5.1. DAILY CLEANING ..................................................................................................... 60

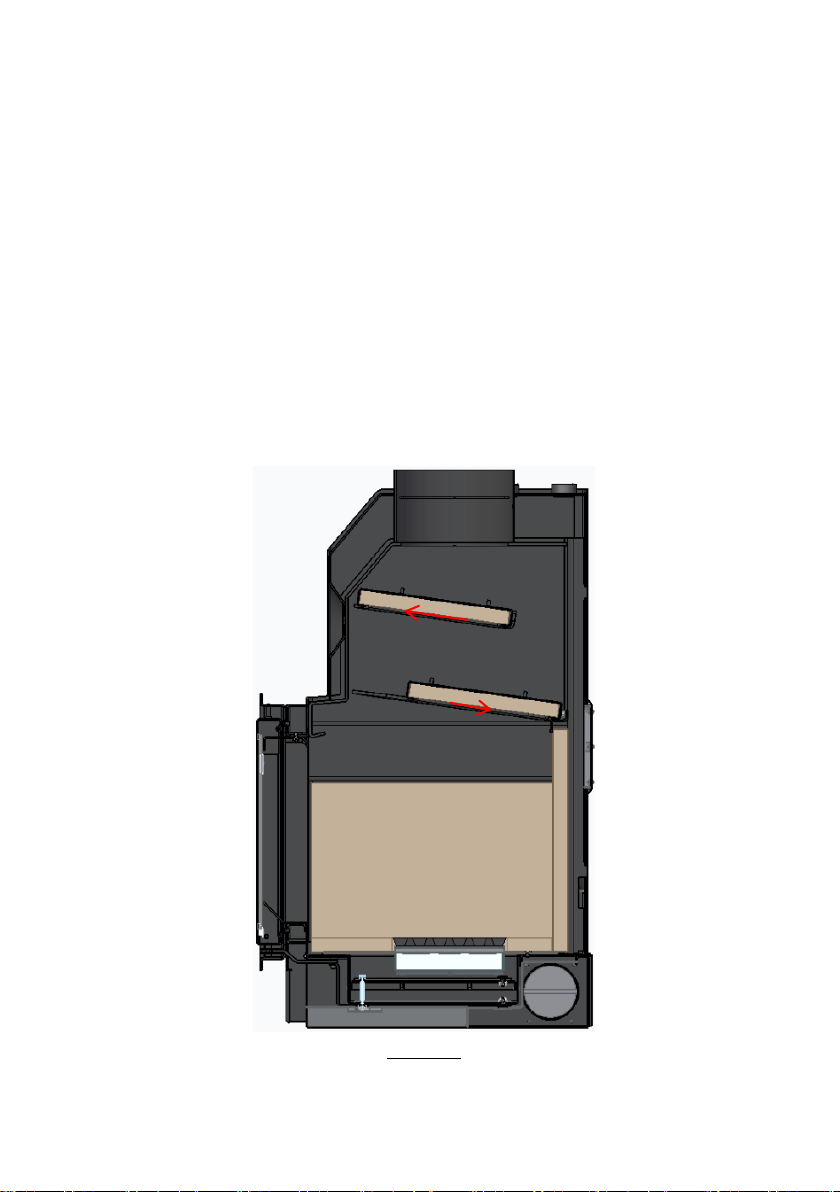

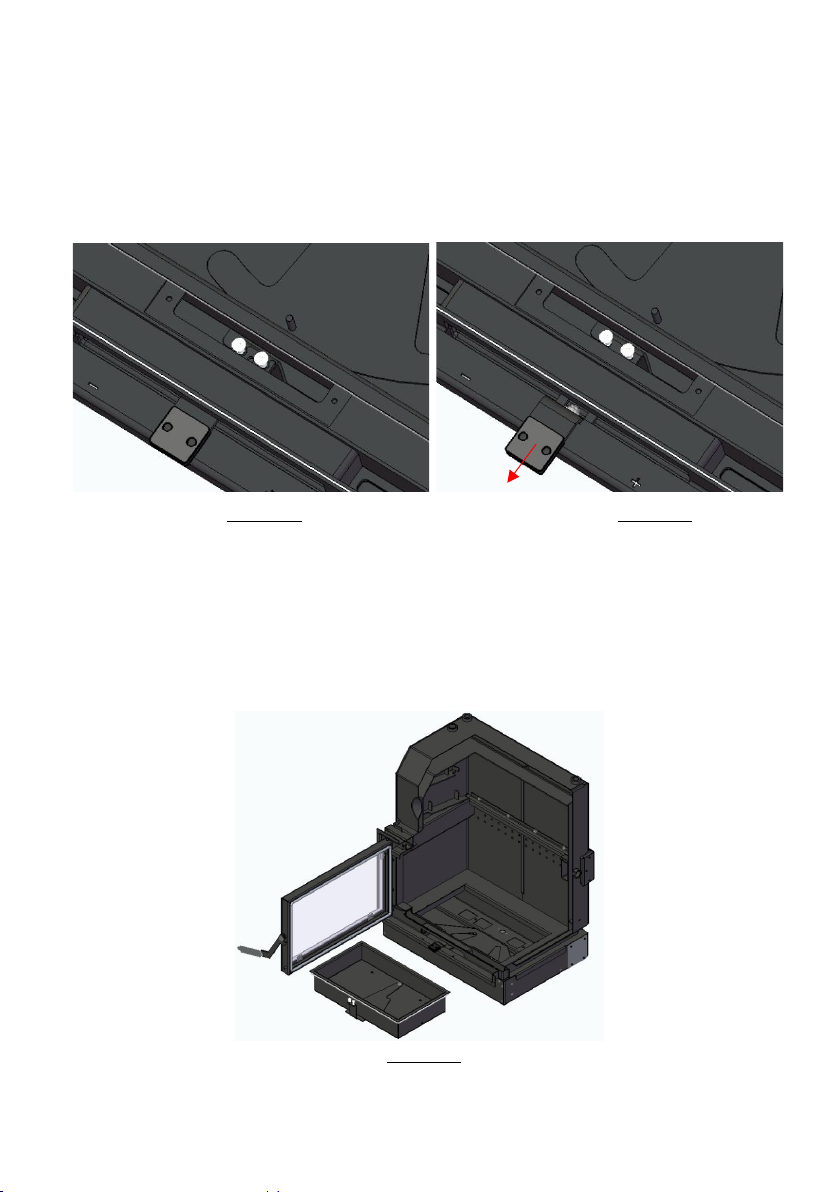

8.5.2. ADDITIONAL CLEANING ............................................................................................. 61

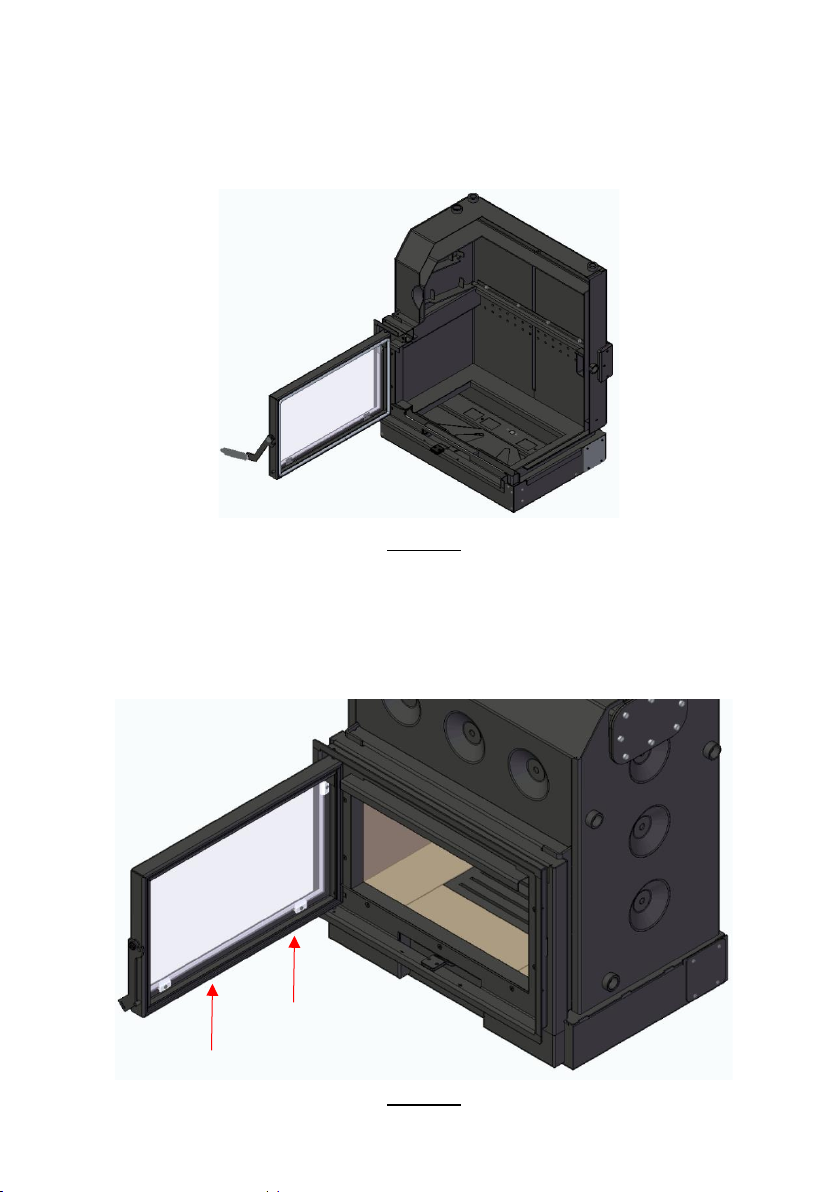

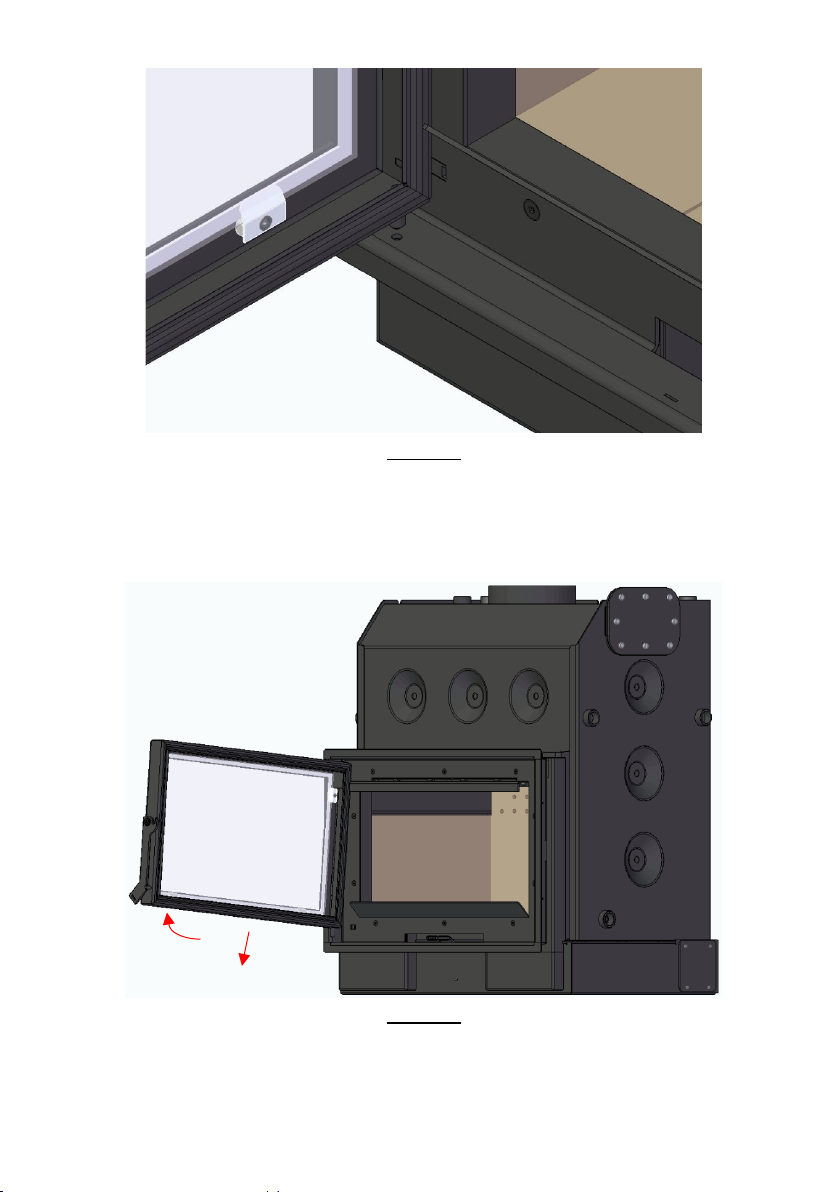

8.5.3. REMOVE THE DOOR .................................................................................................. 67

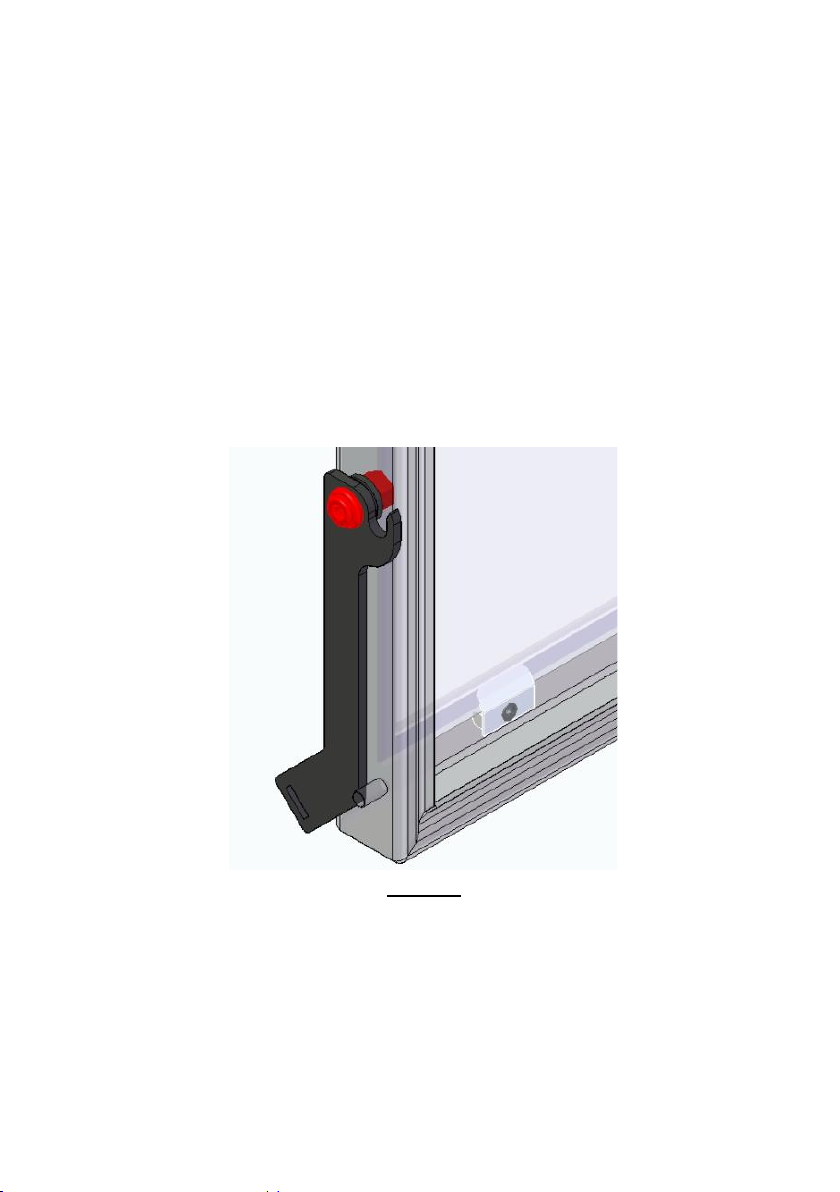

8.5.4. ADJUST THE PORT ................................................................................................... 69

9. TROUBLESHOOTING SOME ISSUES ................................................................................ 70

10. END OF LIFE OF A RECUPERATOR .................................................................................. 71

11. SUSTAINABILITY .......................................................................................................... 71

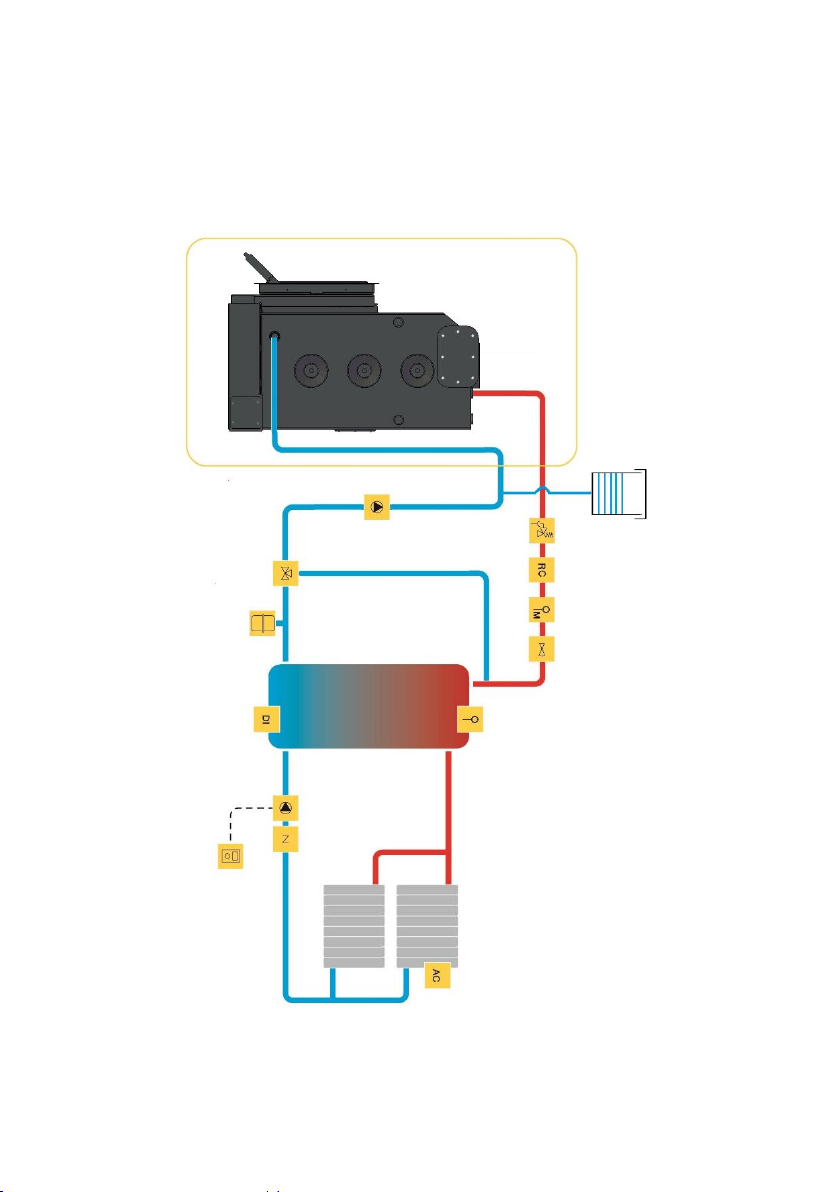

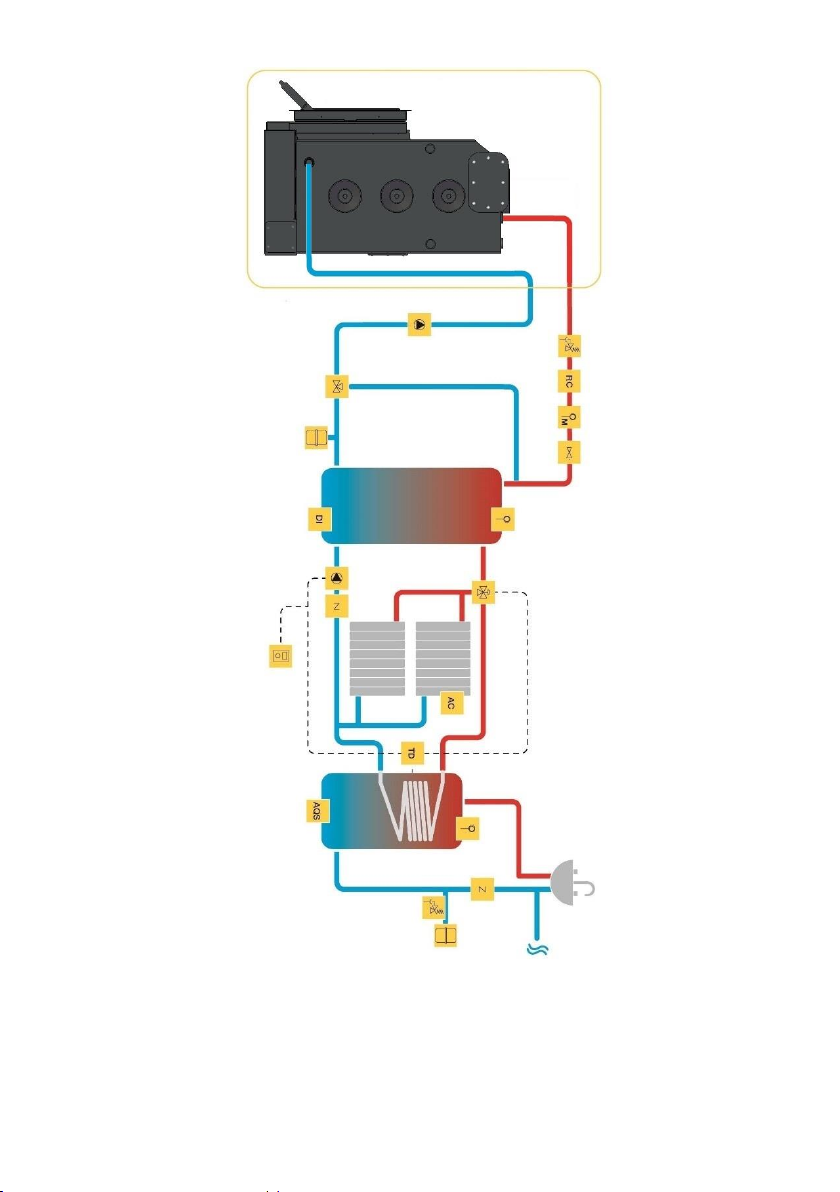

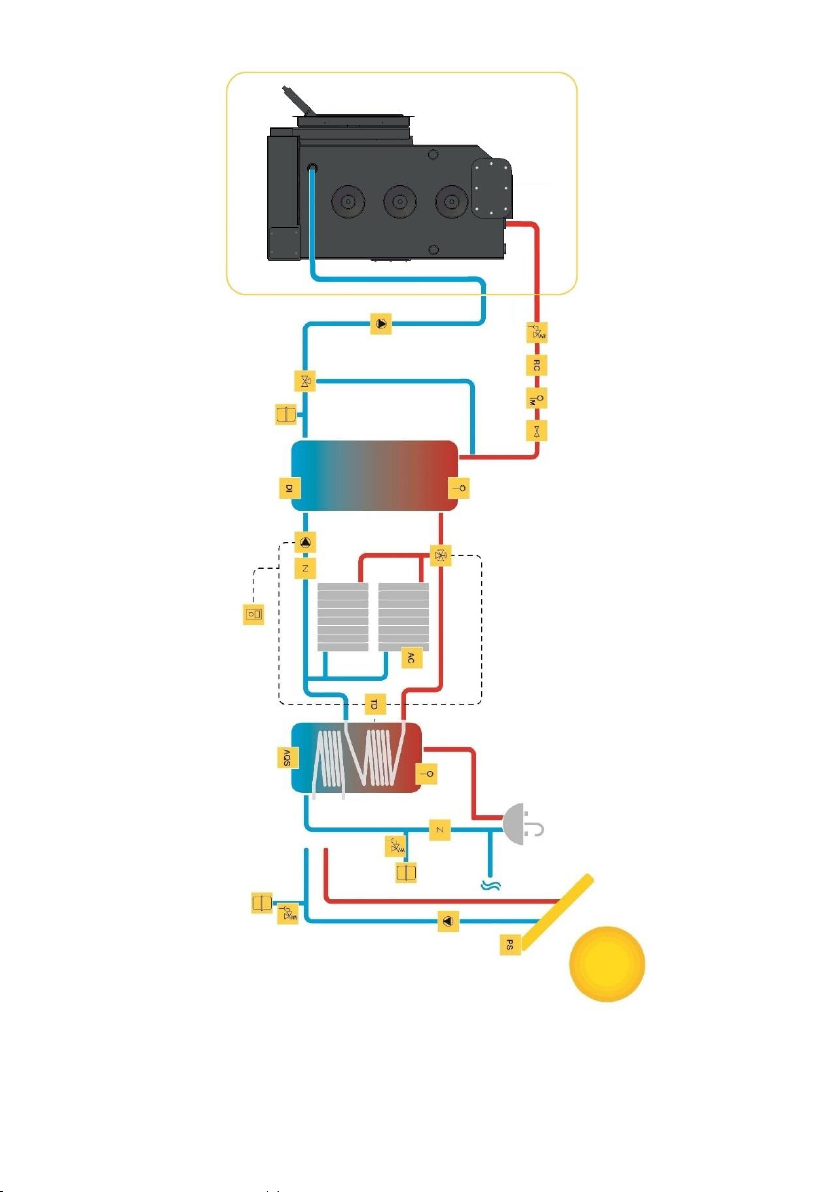

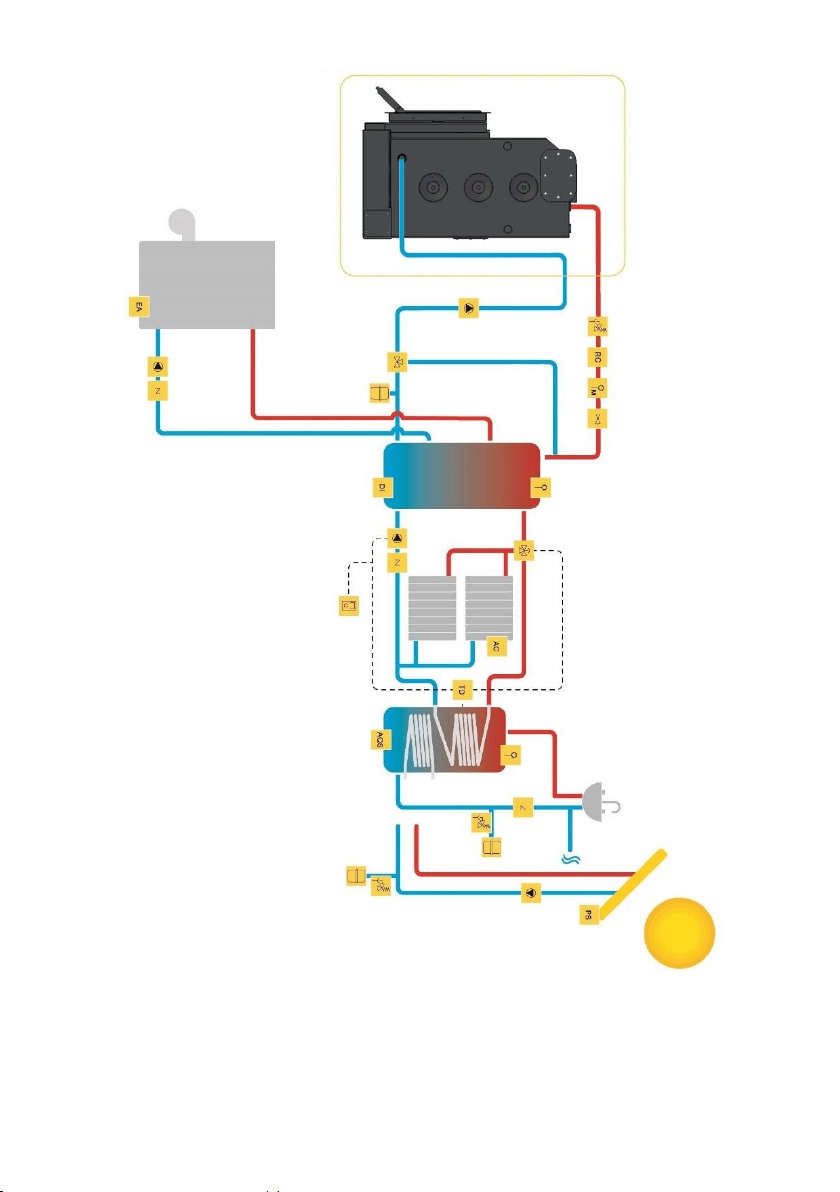

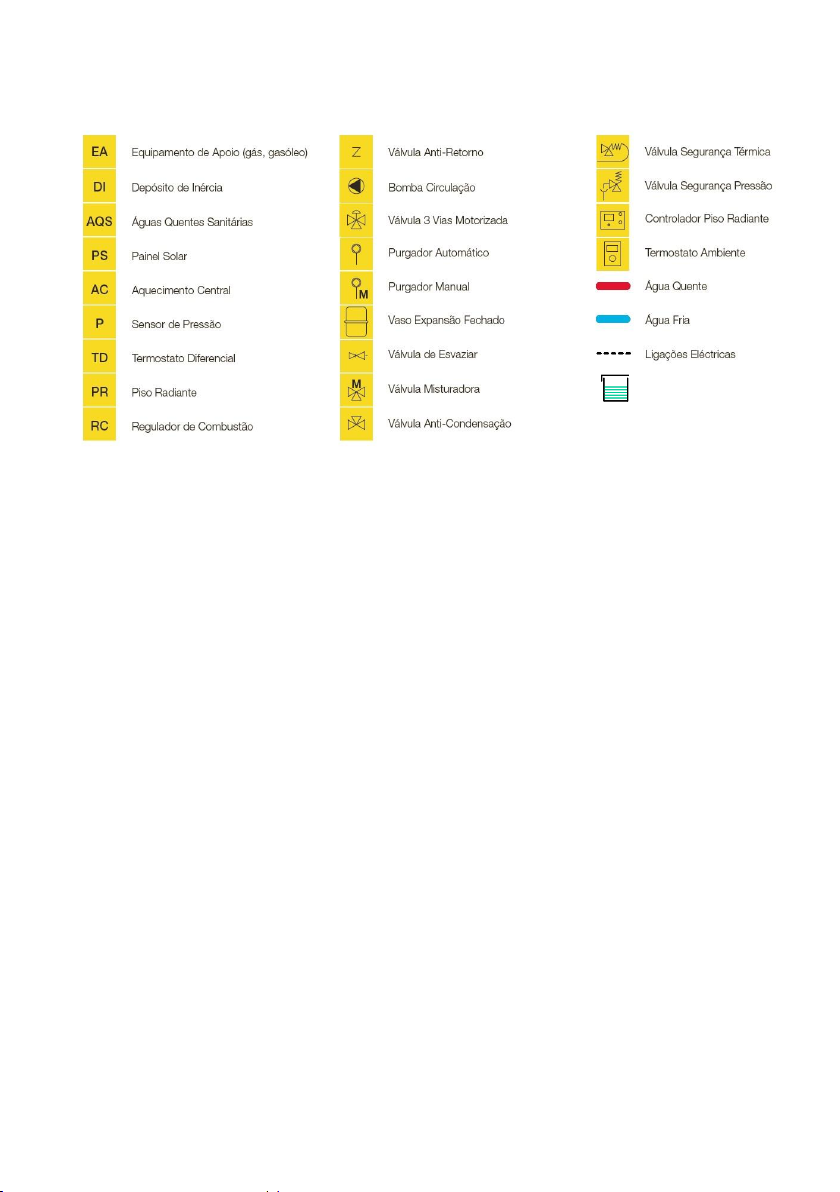

12. INSTALLATION SCHEMAS .............................................................................................. 72

13. GLOSSARY ................................................................................................................. 77

14. WARRANTY .................................................................................................................. 79

15. DECLARATION OF PERFORMANCE................................................................................... 87