How to adjust thread tension (manually)

The sewing machine has an automatic computer controlled thread metering system that calculates and delivers

the precise amount of thread for each needle penetration to create the optimum appearance of each stitch. An

override control is available to allow for individual modification for specialized effects.

To change thread tension for special-purpose stitching style, follow procedure described below:

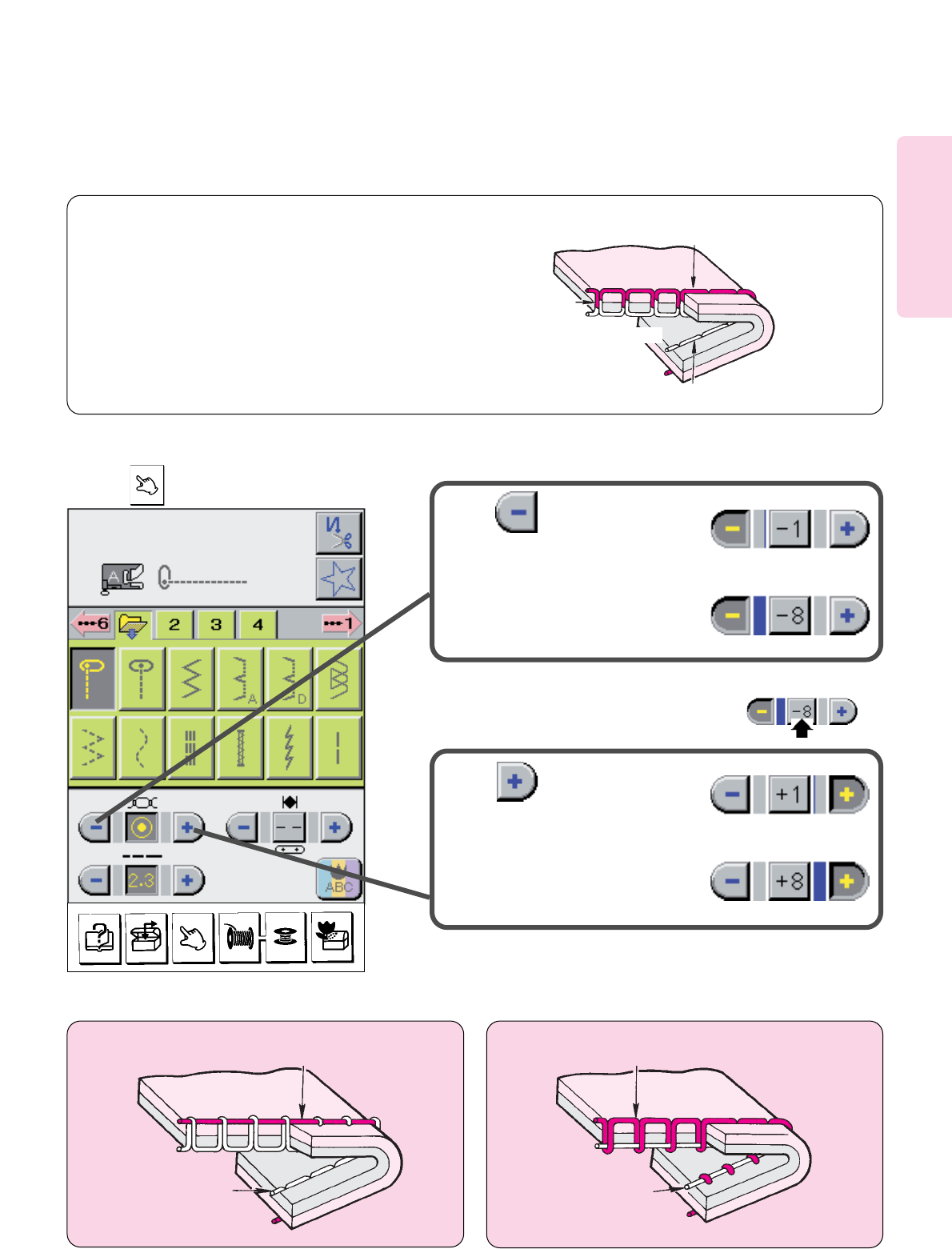

* For straight stitch sewing and most all con-

struction sewing, a well balanced tension is

when the needle thread and the bobbin

thread interlace with each other in the middle

of the fabric thickness.

* For most decorative sewing and embroi-

dery sewing the needle thread and the

bobbin thread should interlace with each

other on the bottom of the fabric thickness.

When thread tension is increased: When thread tension is decreased:

* For shirring and gathering, manually adjust stitch length and thread tension. (See page 43.)

Bobbin thread appears on right side of fabric.

Needle thread appears on wrong side of fabric.

Press to decrease

needle thread tension.

Thread tension decreases

in eight steps.

Press to increase

needle thread tension.

Thread tension increases

in eight steps.

22

Needle thread

Bobbin thread

Middle of fabric

thickness

Fabric

(right side)

Fabric

(right side)

Fabric (wrong

side)

Needle thread

Bobbin thread

Tension shows automatically on the 4 Utility Screens. For all other

screens, tension will be shown on a “pop-up” screen accessed by

pressing key.

_

_

* To return the thread tension to the automatic setting, press the

center of the tension pictogram. For example

touching the -8 will return the machine

to automatic tension setting.

Fabric (wrong

side)

Fabric (wrong

side)

Needle thread

Bobbin thread

Fabric

(right side)

Example of Balanced Tension for Sewing Straight Stitch