-

Ik heb een Singer Magic 3000 gekregen van iemand, maar helaas zonder handleiding. Ik heb al verschillende Singerwebsites bezocht en gemaild, maar niemand heeft het ter beschikking. Heeft iemand deze handleiding bijgehouden en is er de mogelijkheid om die online door te geven? Bedankt! Gesteld op 19-10-2024 om 09:16

Reageer op deze vraag Misbruik melden -

Alles ik nieuw. Draad plaats dan is. Problemen aan het Spoel alls begin te naaien dan komt er veel draad aan de naald en kan niet meer verder doen Gesteld op 15-6-2024 om 10:00

Reageer op deze vraag Misbruik melden -

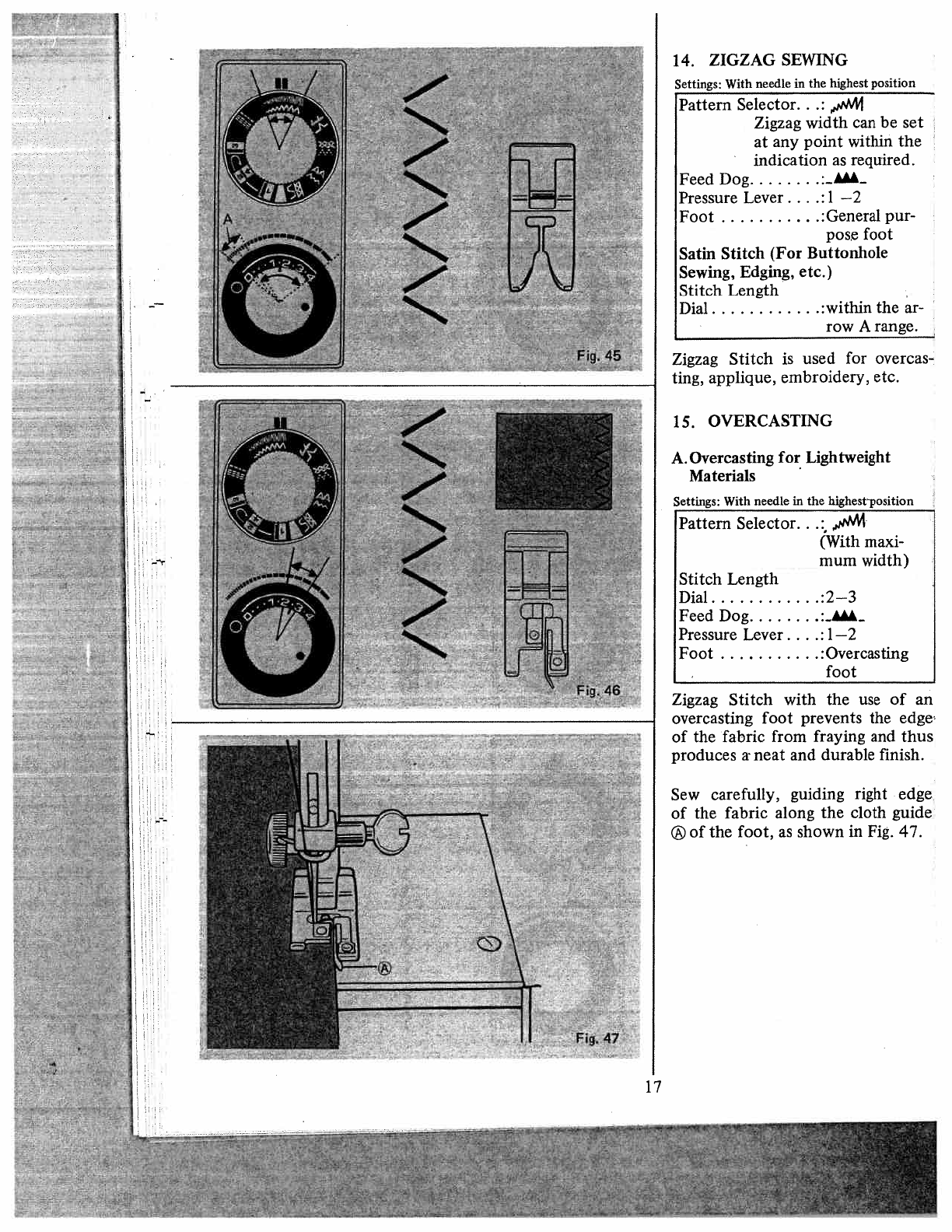

Mijn singer Magic 3000 wil geen zigzag steek maken. Dit is een nieuw machine dat maar een paar keer is gebruikt en daarna 6jaar niet gebruikt is geweest. Ik heb alles geprobeerd maar ze maakt geen enkele zigzag steek. Gesteld op 18-1-2021 om 11:17

Reageer op deze vraag Misbruik melden-

Mijn moeder heeft hetzelfde probleem. Kunt u ondertussen al terug zigzaggen en zo ja, hoe heeft u het opgelost? Geantwoord op 23-6-2021 om 11:21

Waardeer dit antwoord (1) Misbruik melden

-