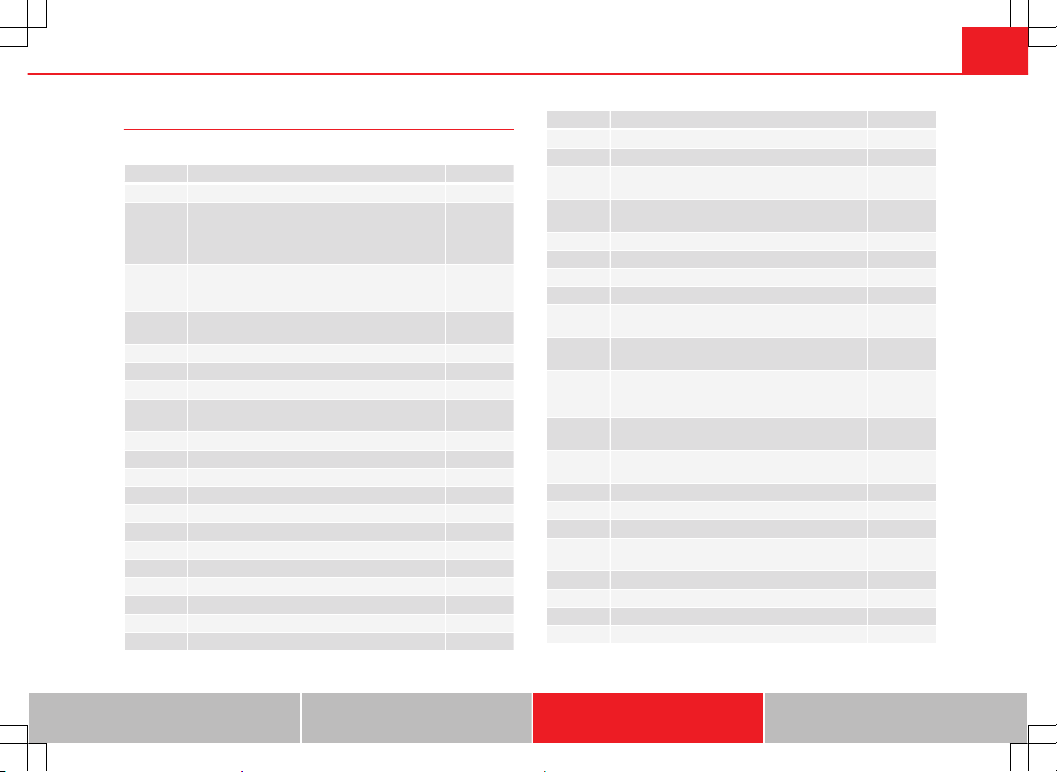

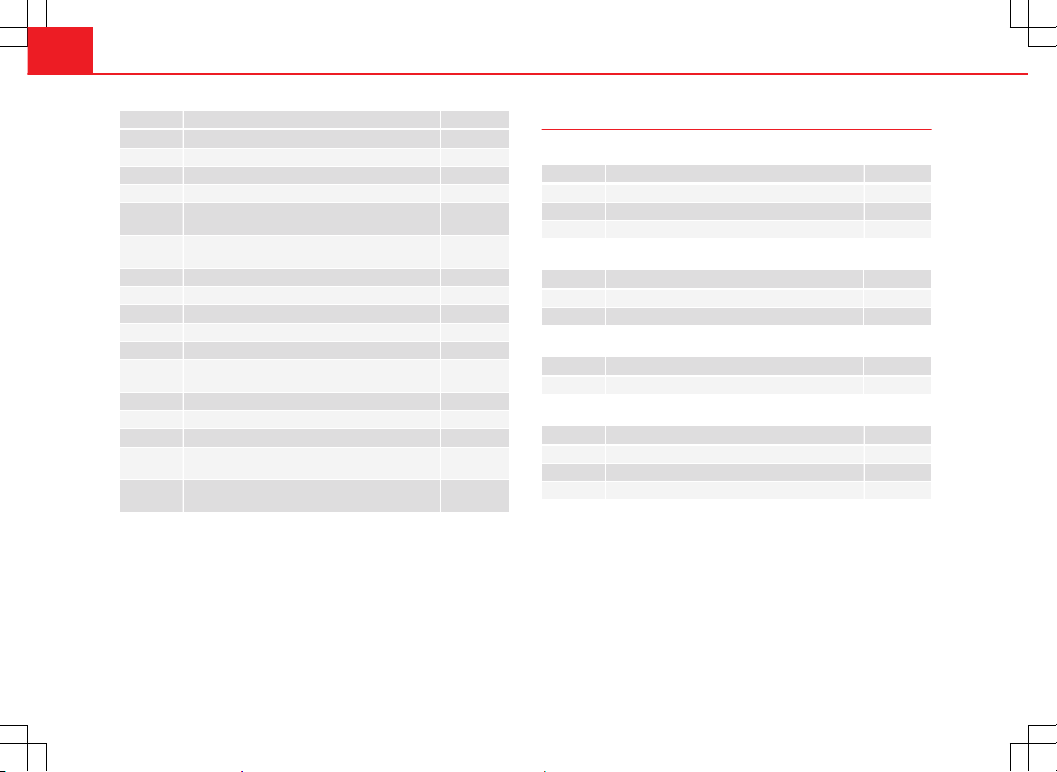

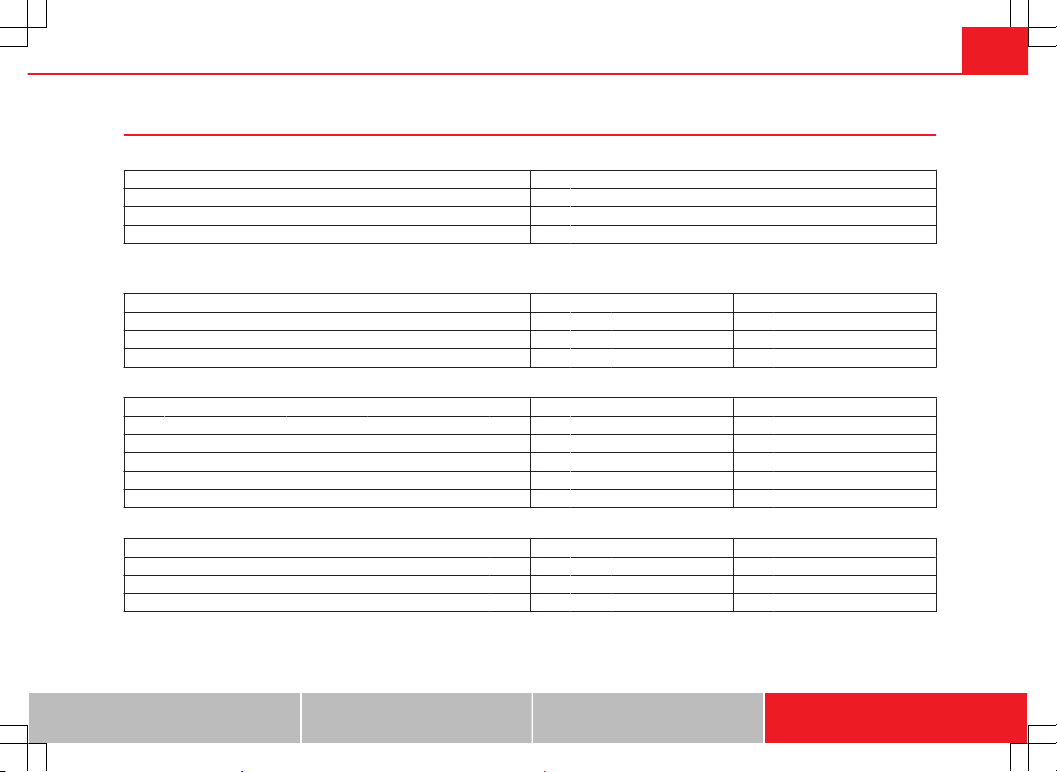

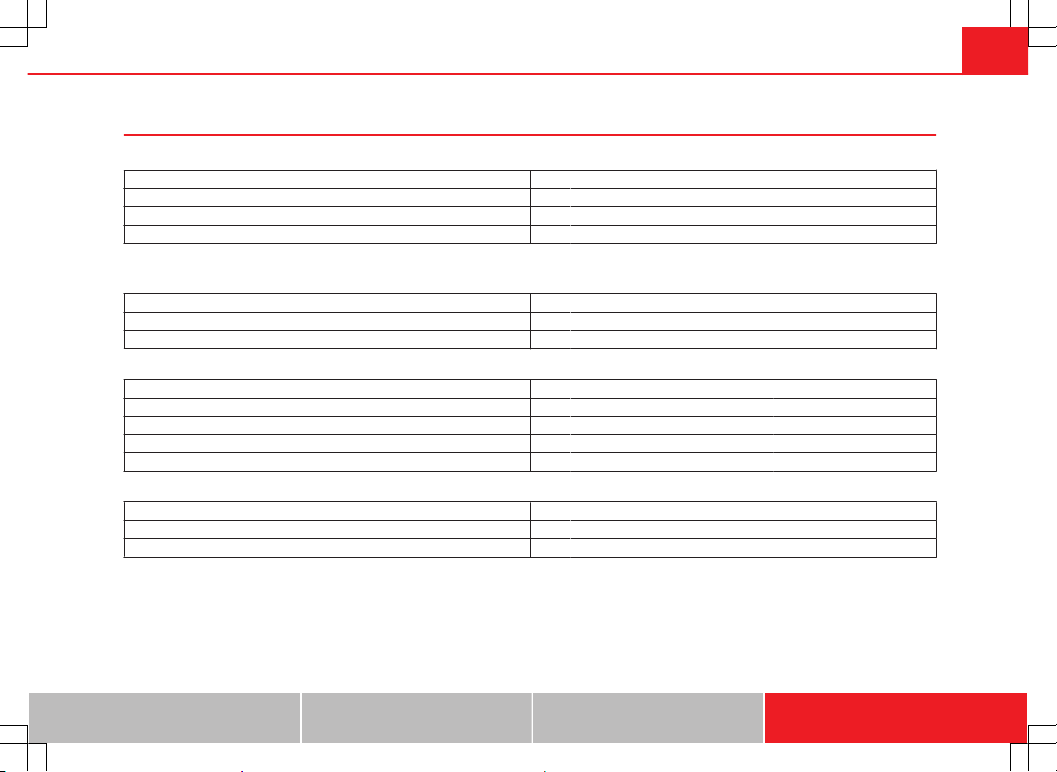

Table of Contents

Manual structure . . . . . . . . . . . . . . . . . . . . 5

Content . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Safety First . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Safe driving . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

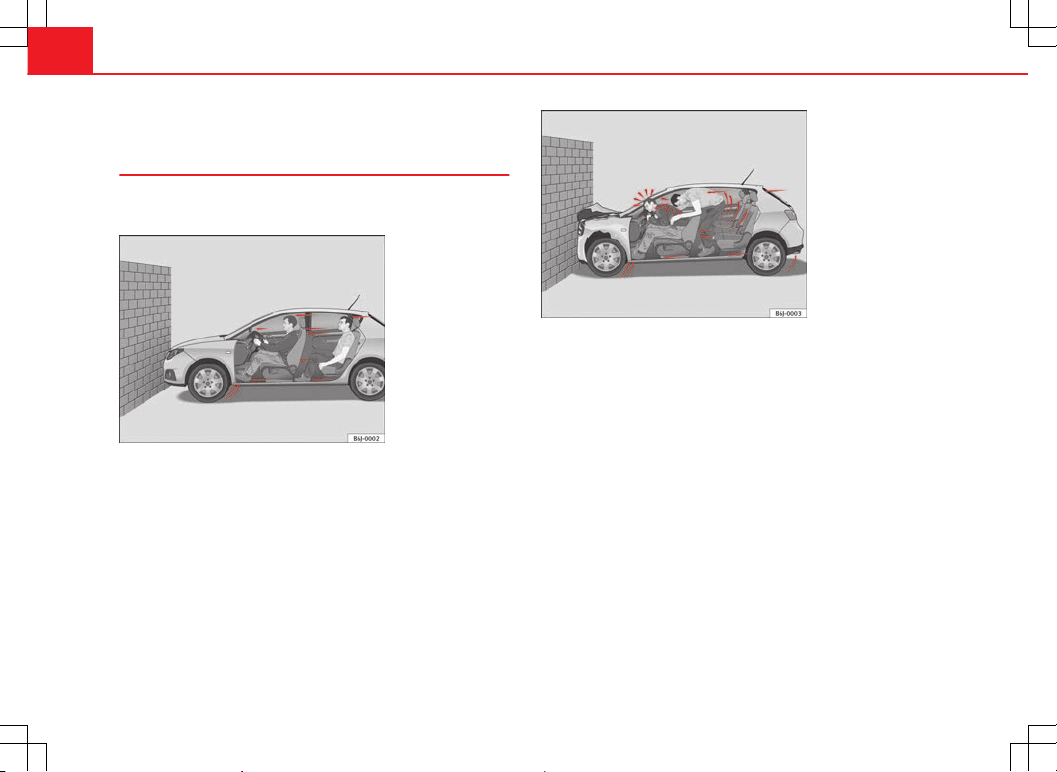

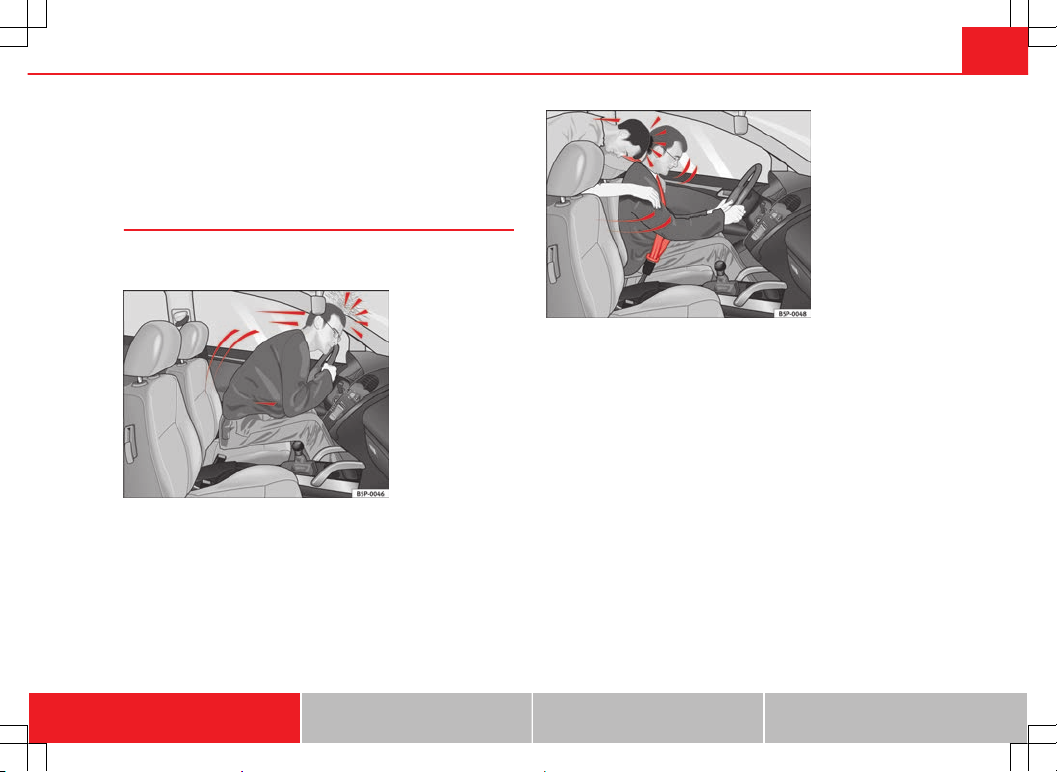

Brief introduction . . . . . . . . . . . . . . . . . . . . . . . . . 7

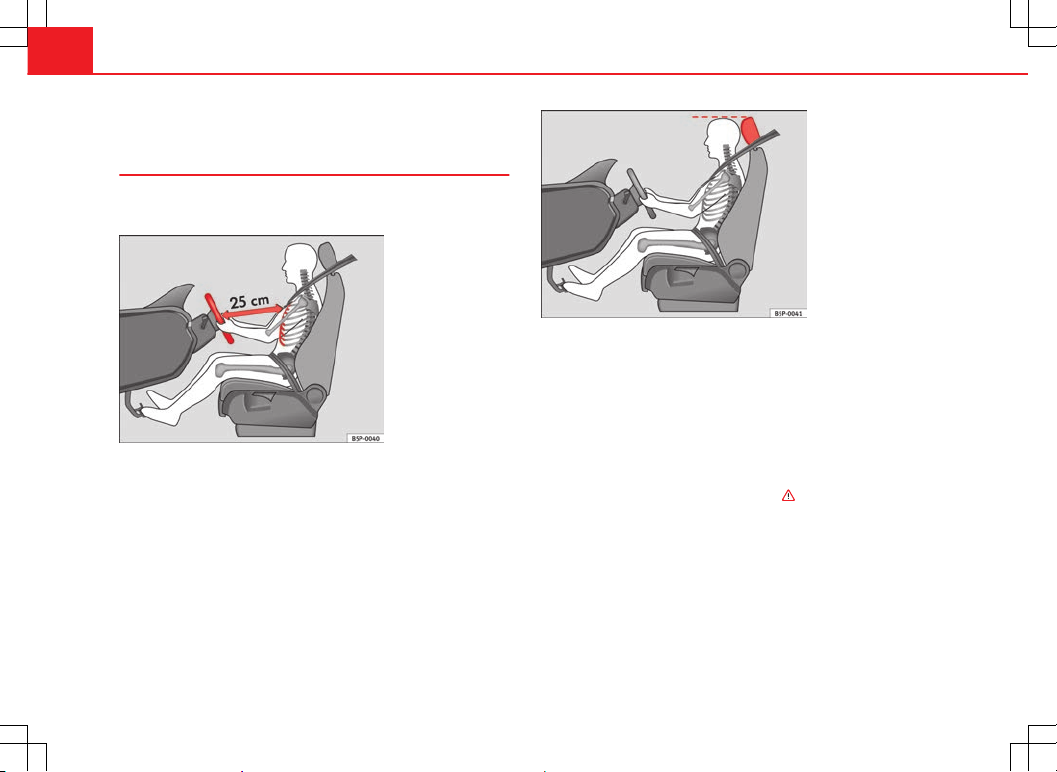

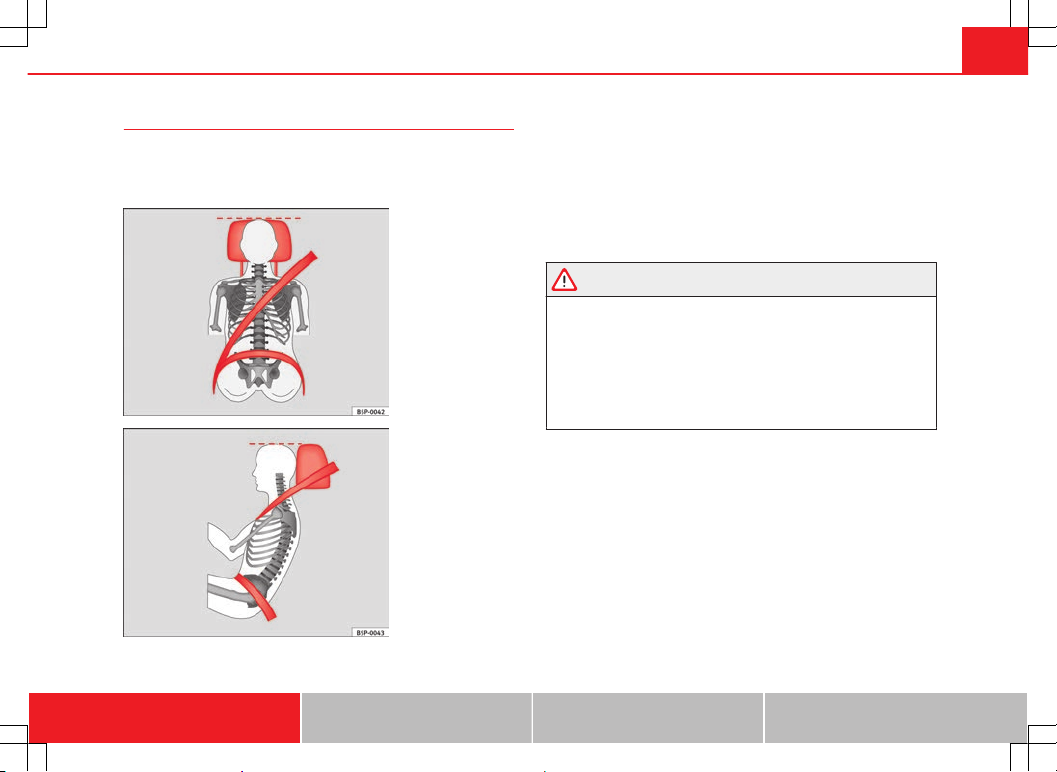

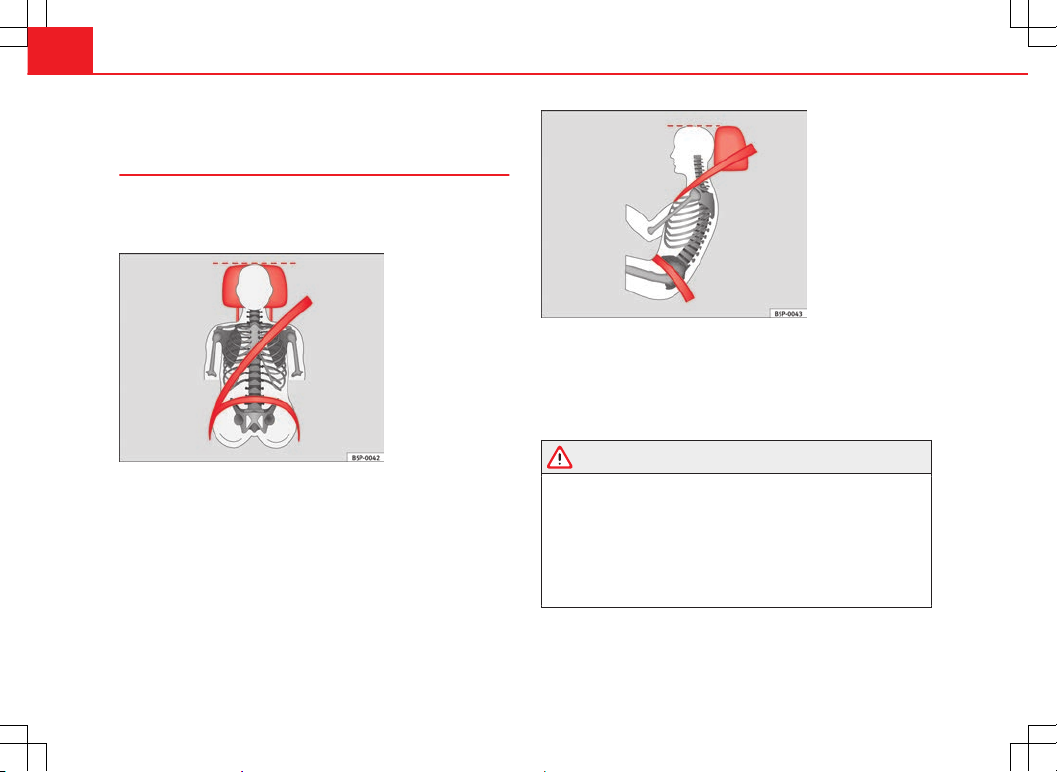

Proper sitting position for occupants . . . . . . . . . 10

Pedal area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Storing objects . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

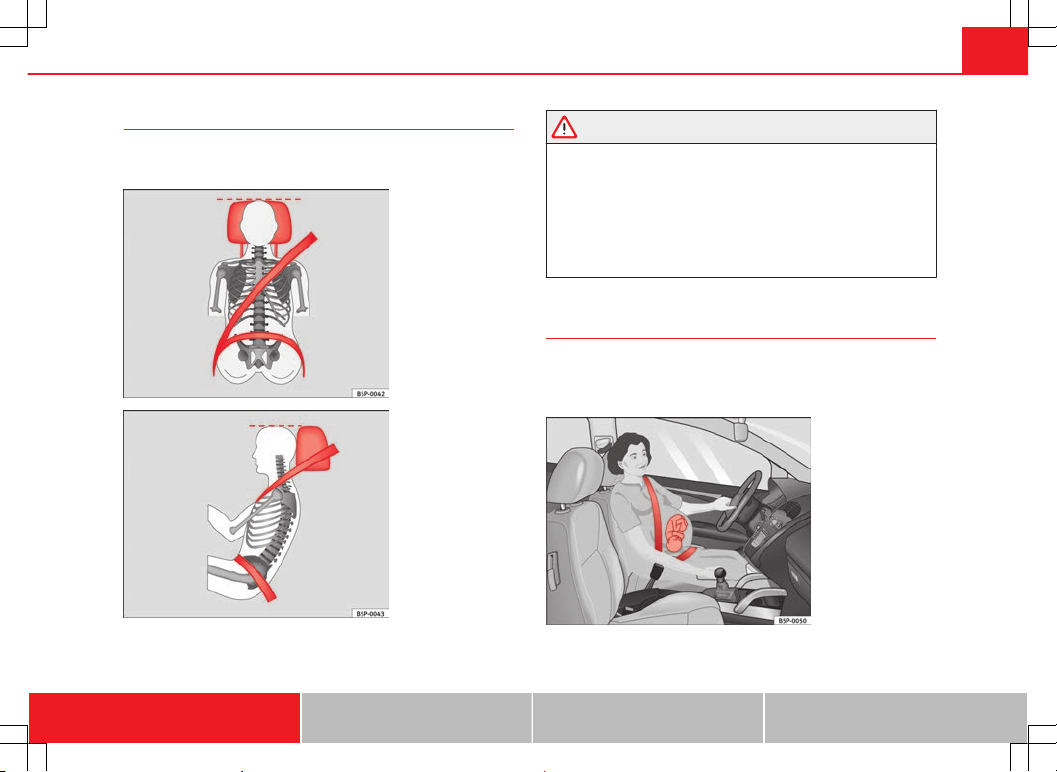

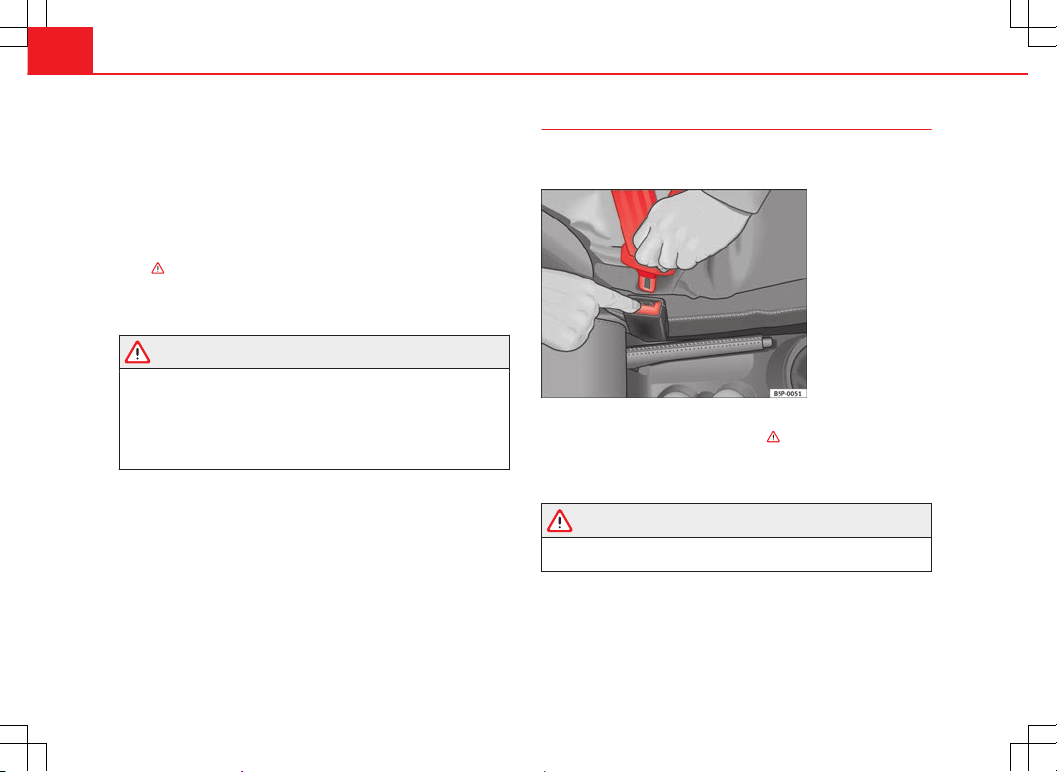

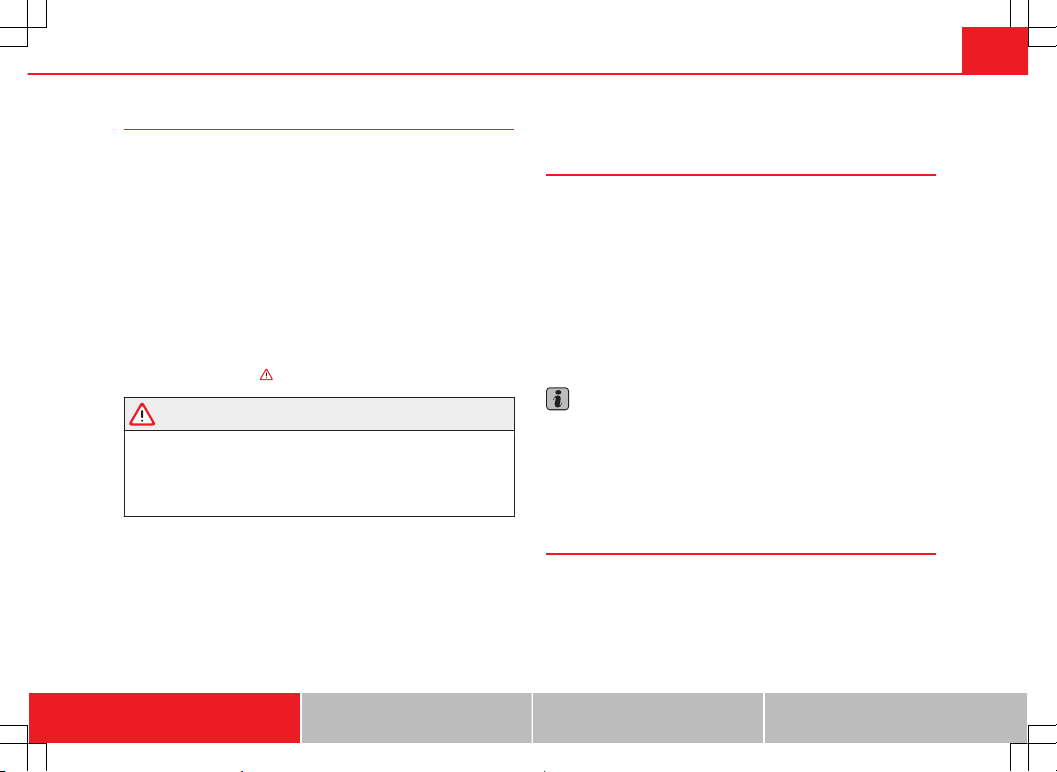

Seat belts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

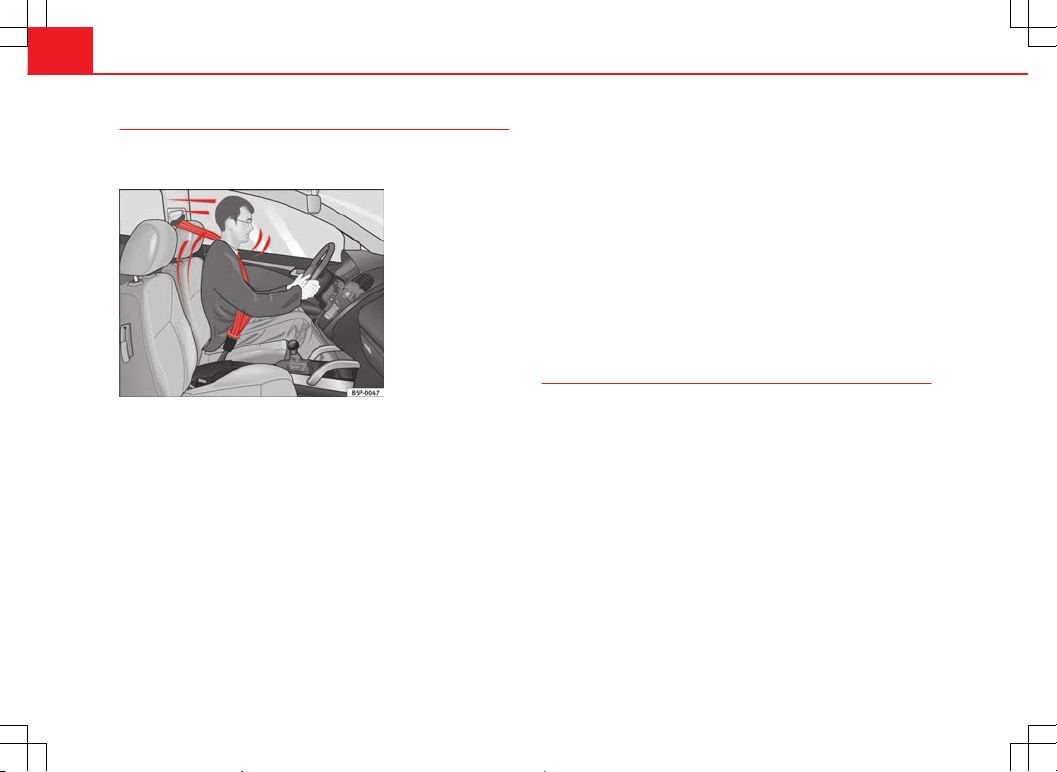

Brief introduction . . . . . . . . . . . . . . . . . . . . . . . . . 18

Why wear seat belts? . . . . . . . . . . . . . . . . . . . . . . 20

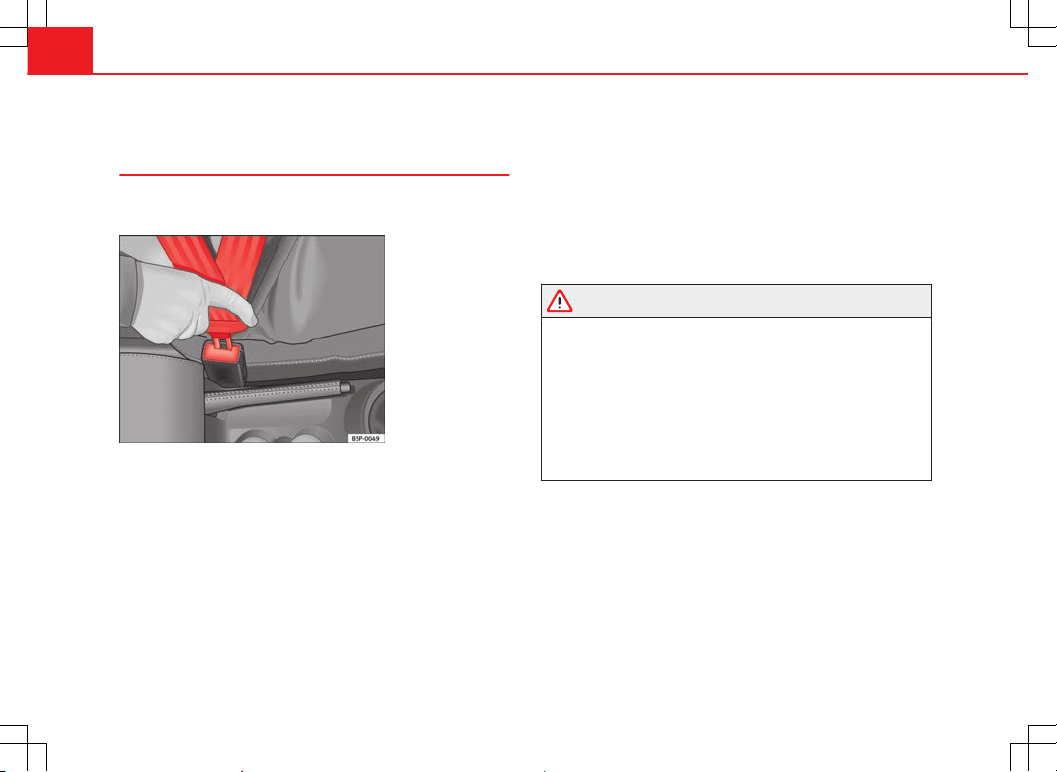

Seat belts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

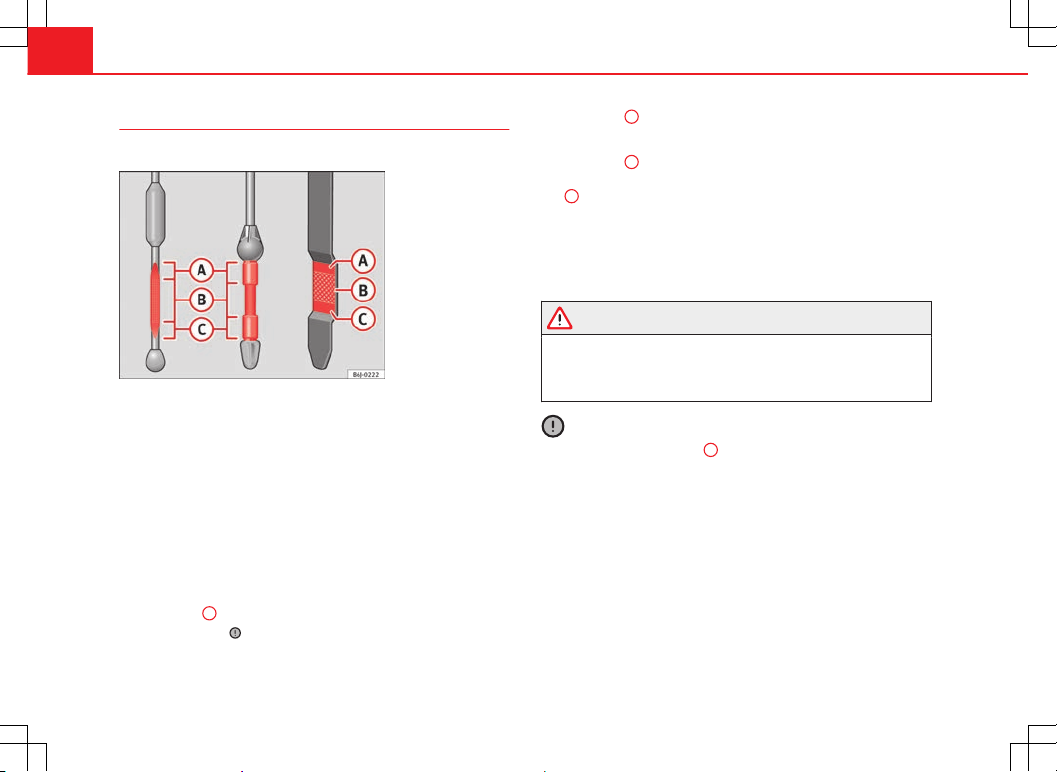

Seat belt tensioners* . . . . . . . . . . . . . . . . . . . . . . 27

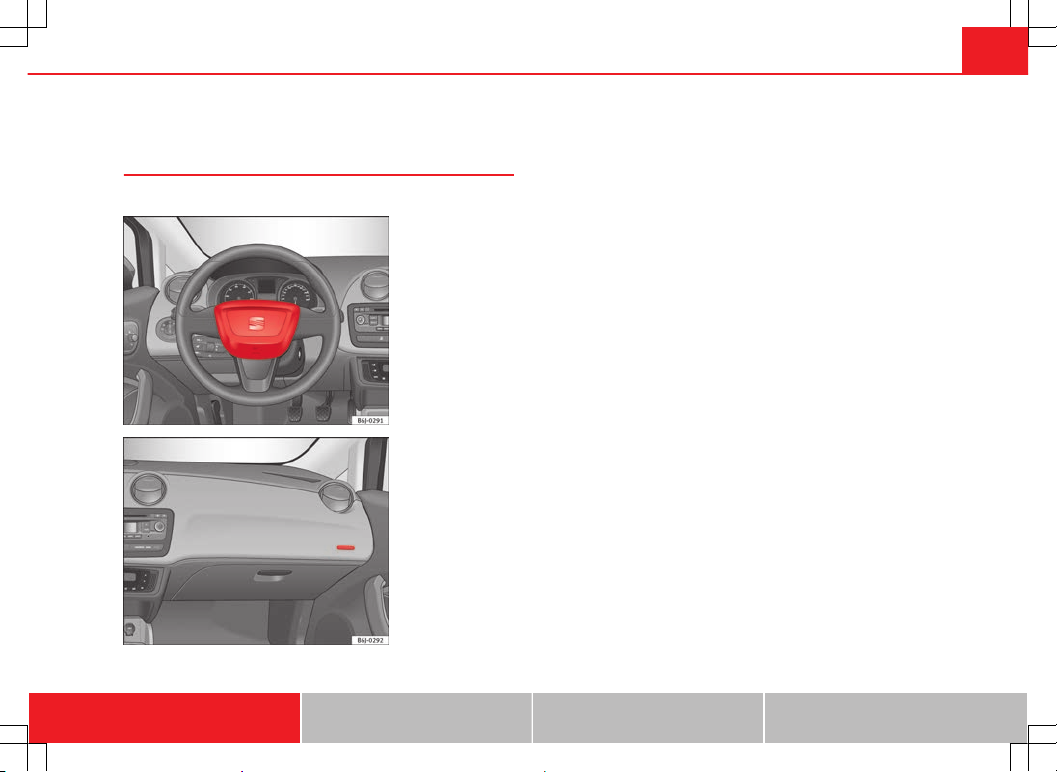

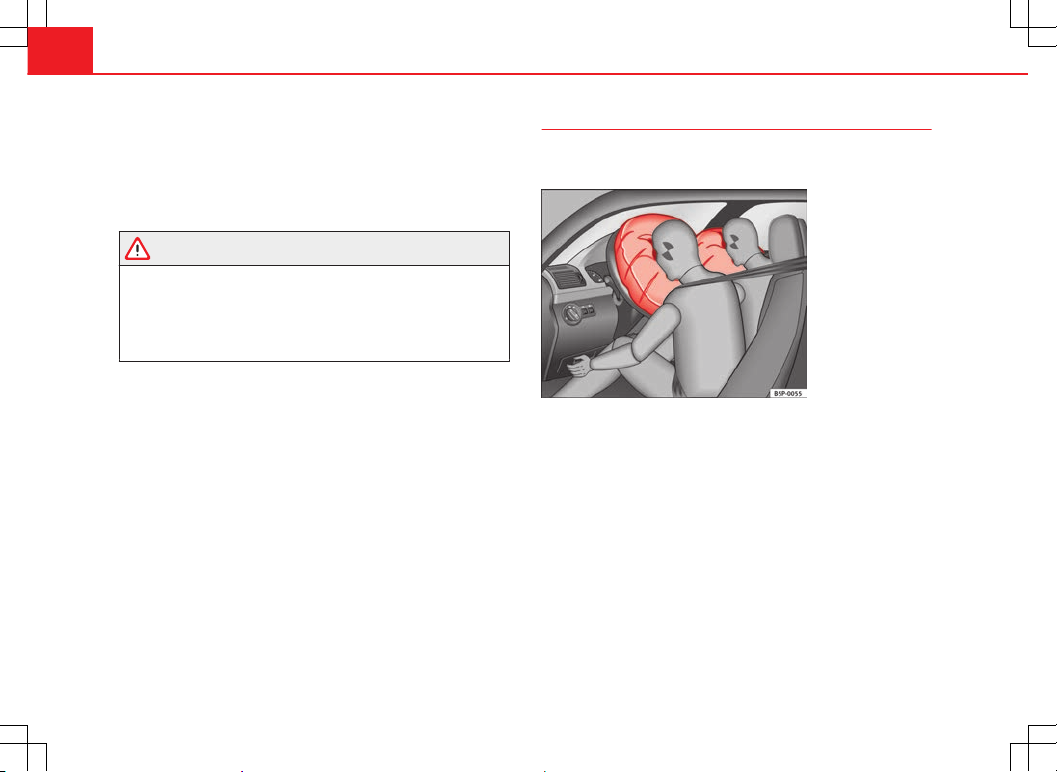

Airbag system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

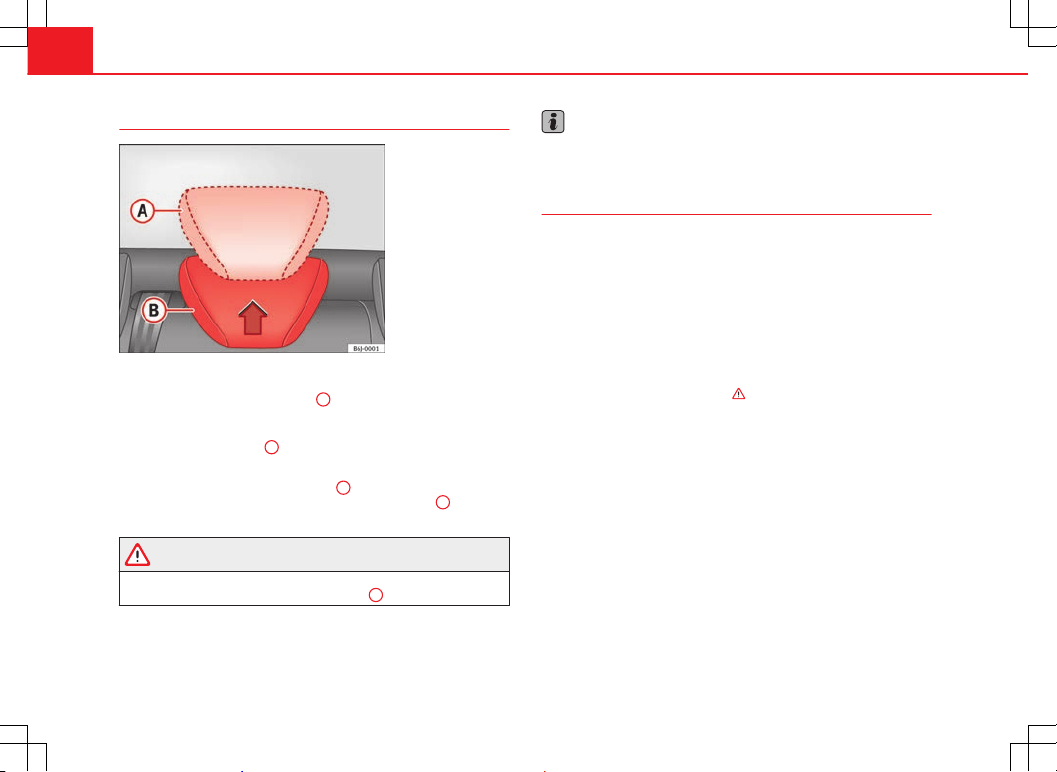

Brief introduction . . . . . . . . . . . . . . . . . . . . . . . . . 29

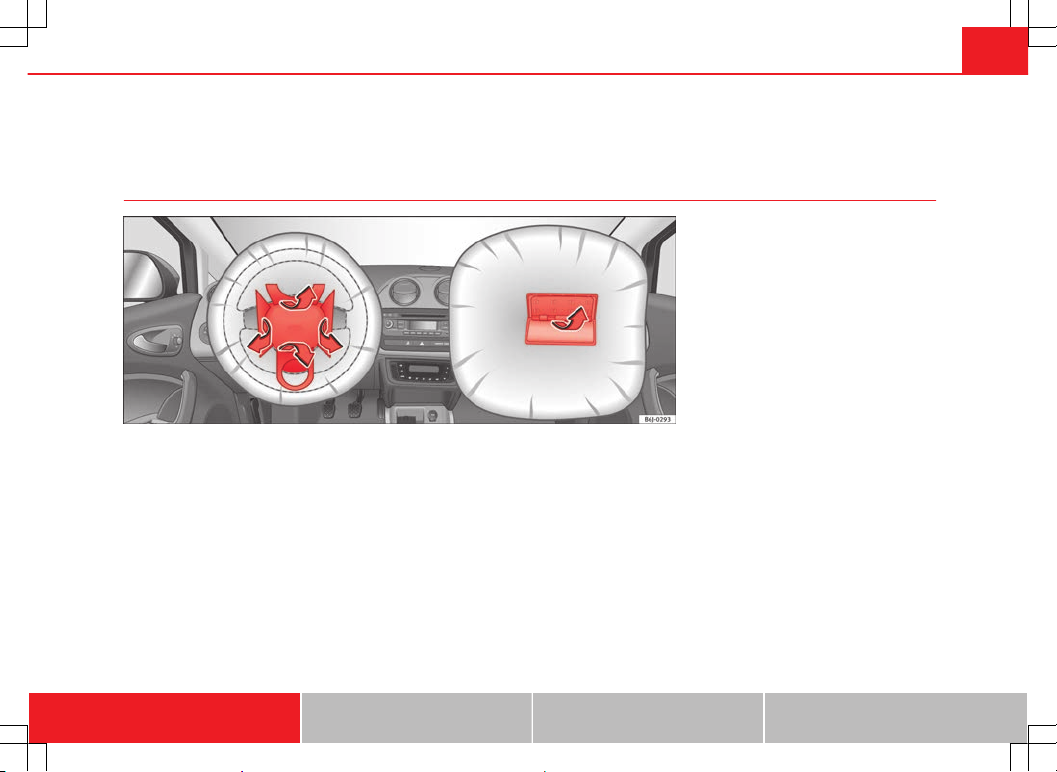

Front airbags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

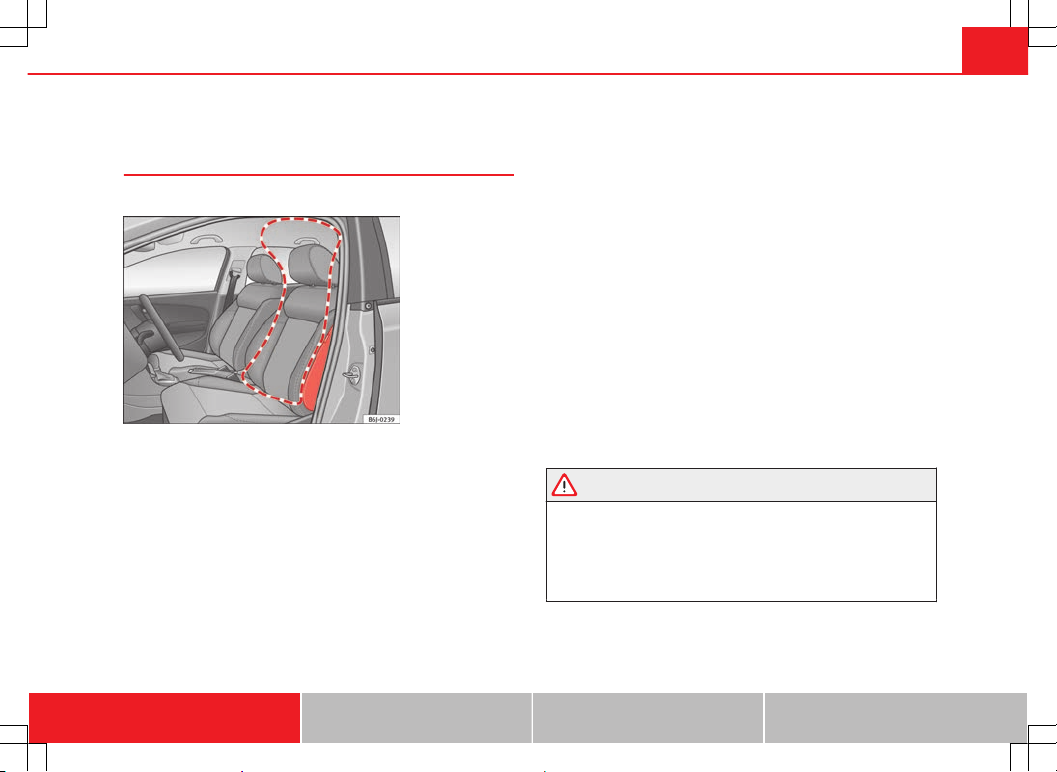

Side airbags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

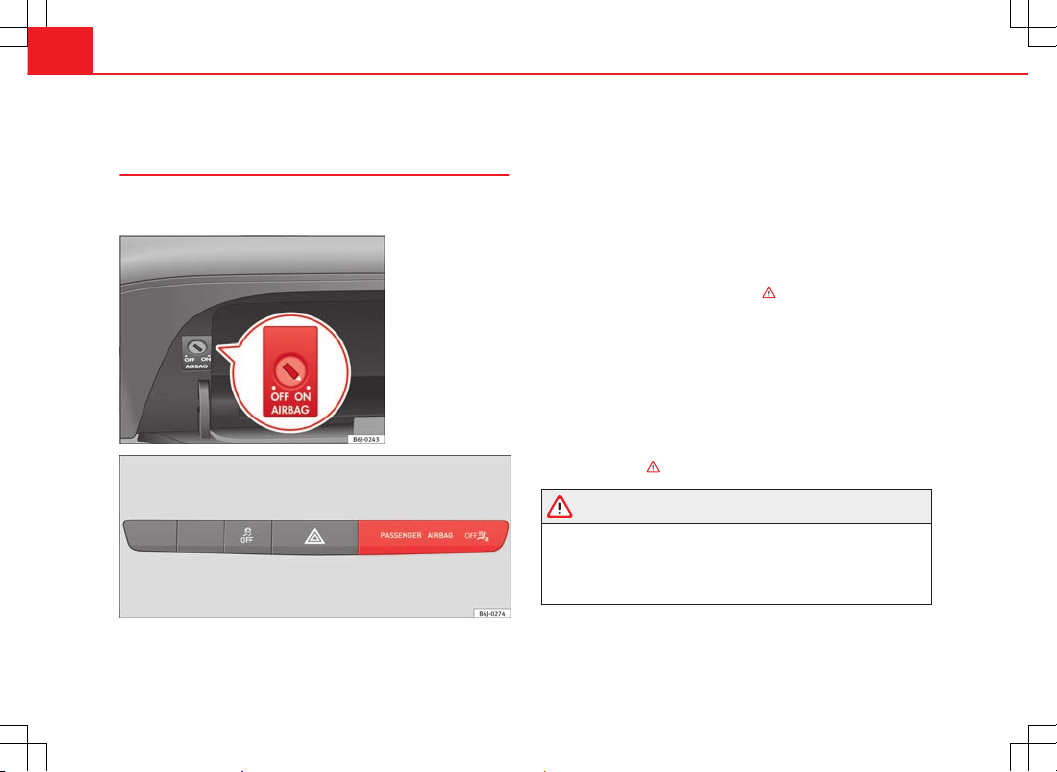

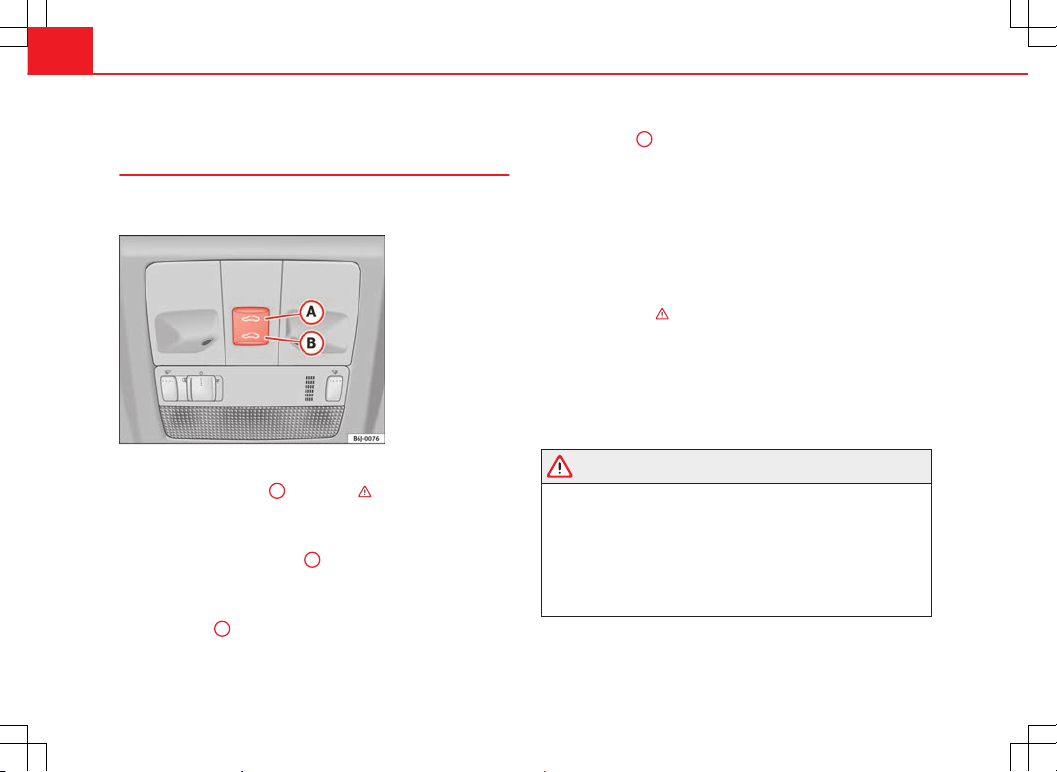

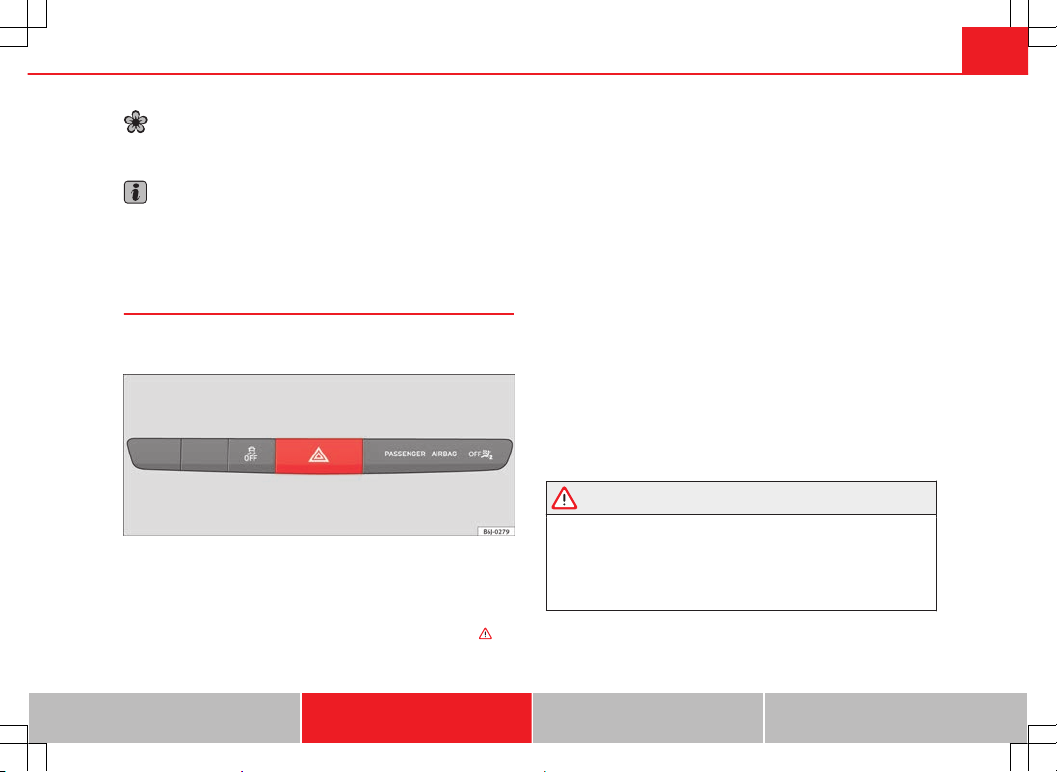

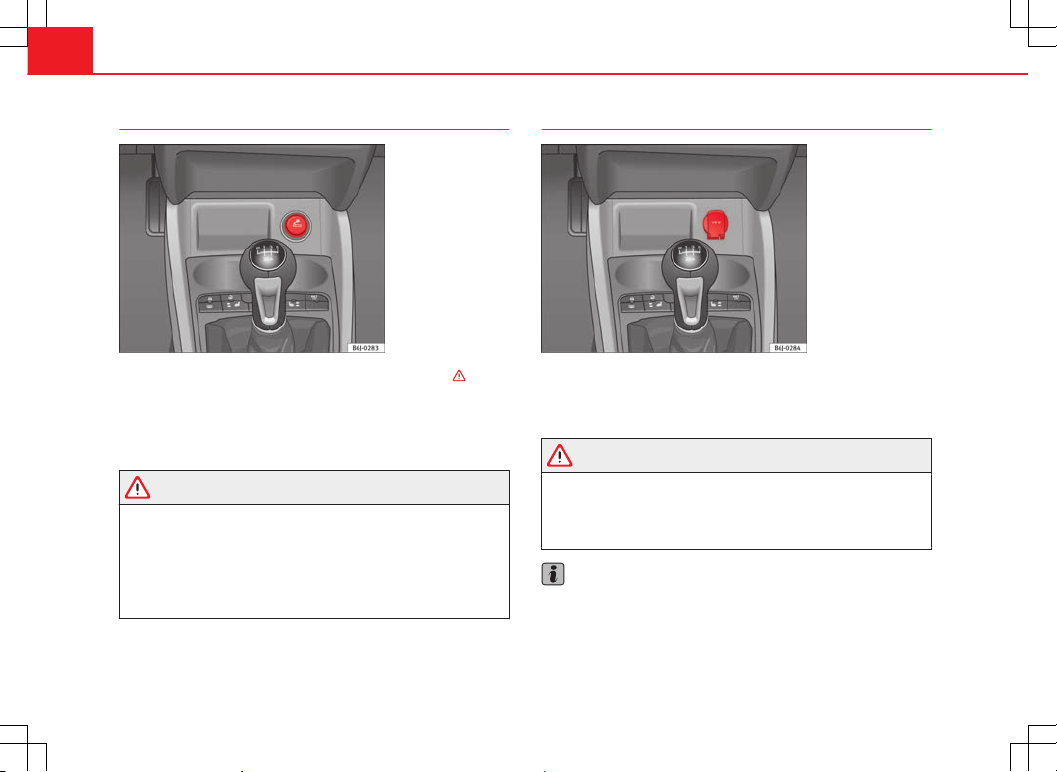

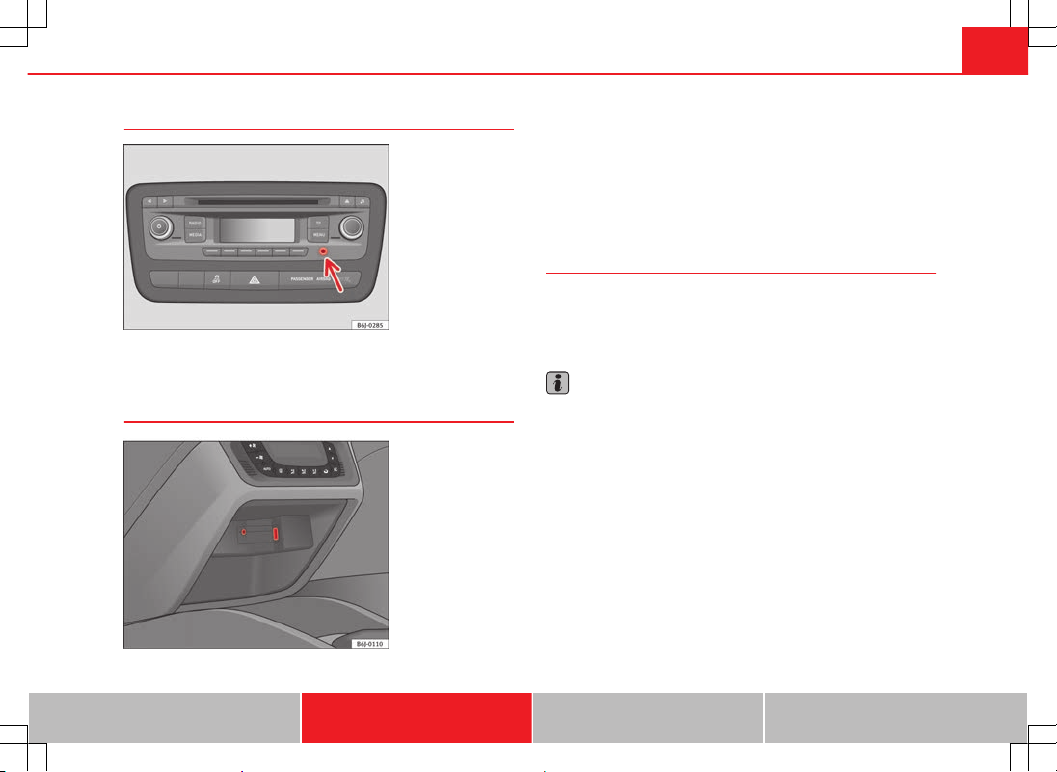

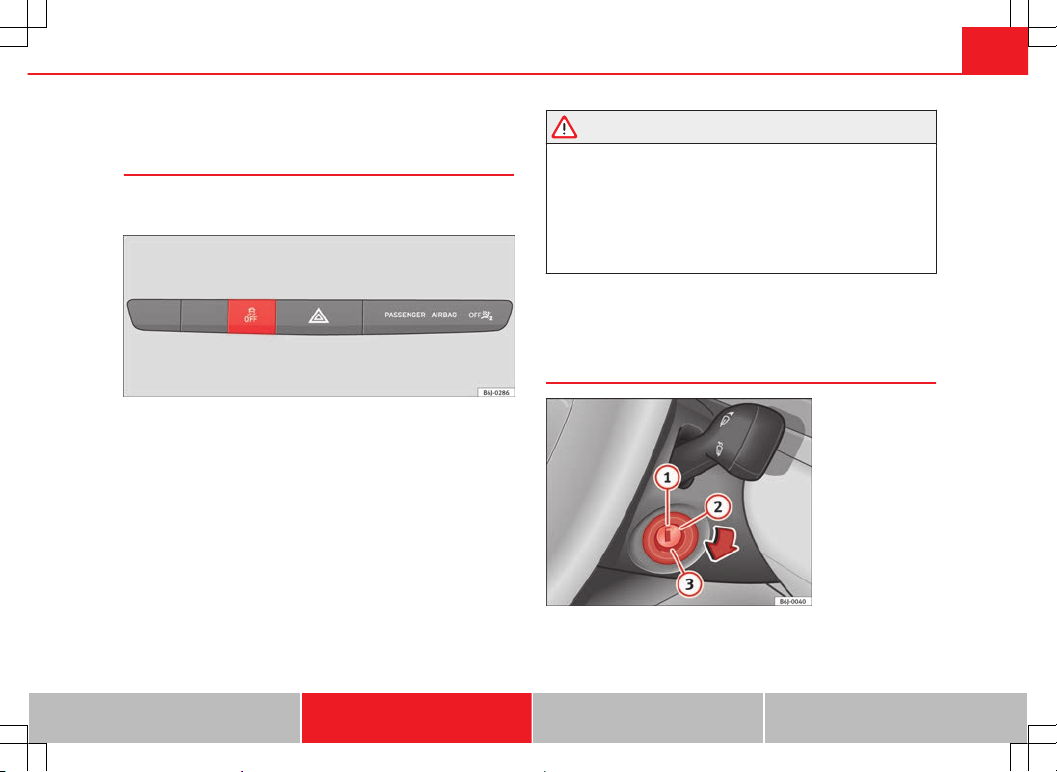

Deactivating airbags* . . . . . . . . . . . . . . . . . . . . . . 40

Child safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Brief introduction . . . . . . . . . . . . . . . . . . . . . . . . . 42

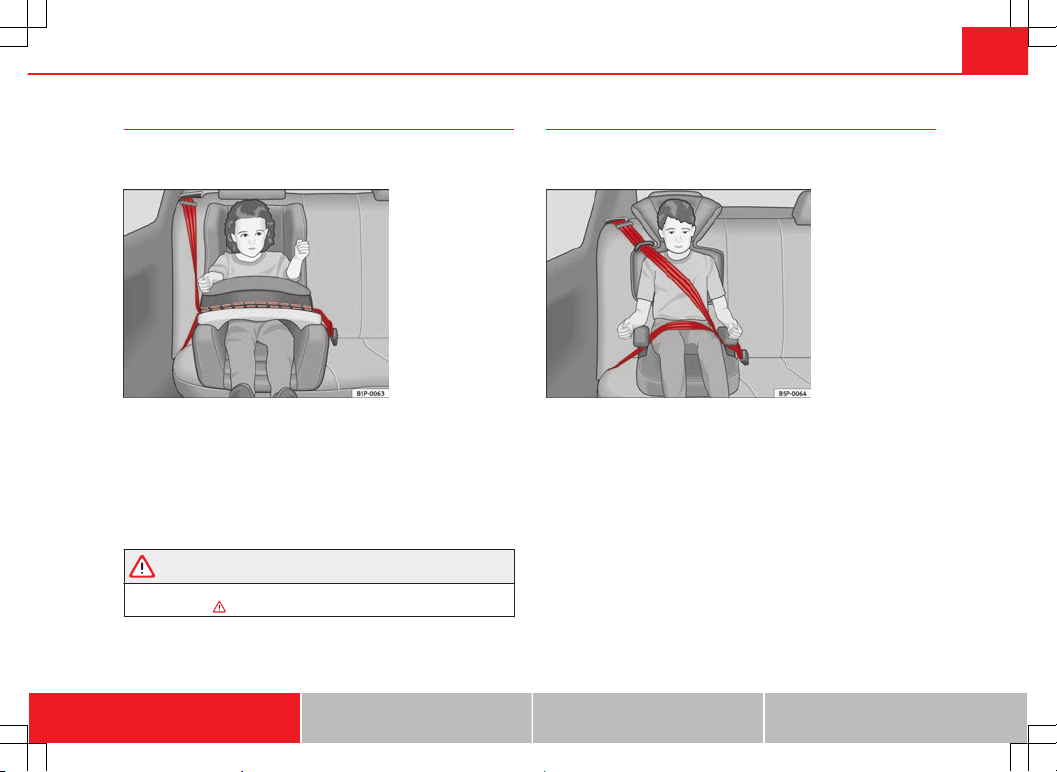

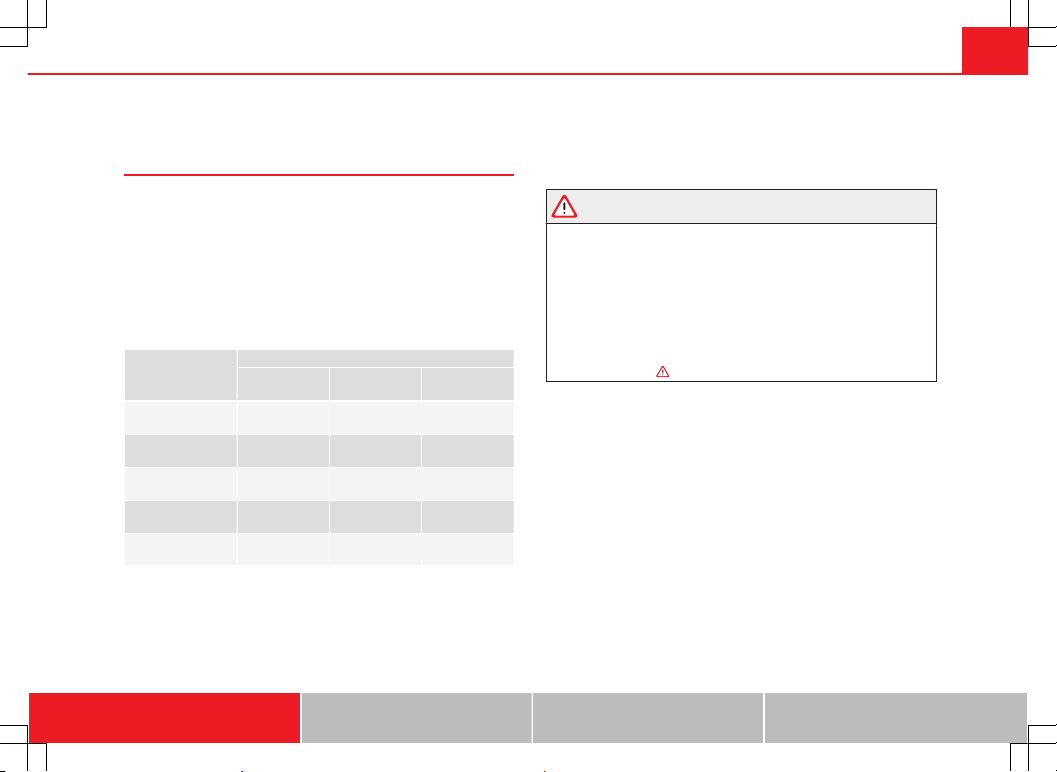

Child seats . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

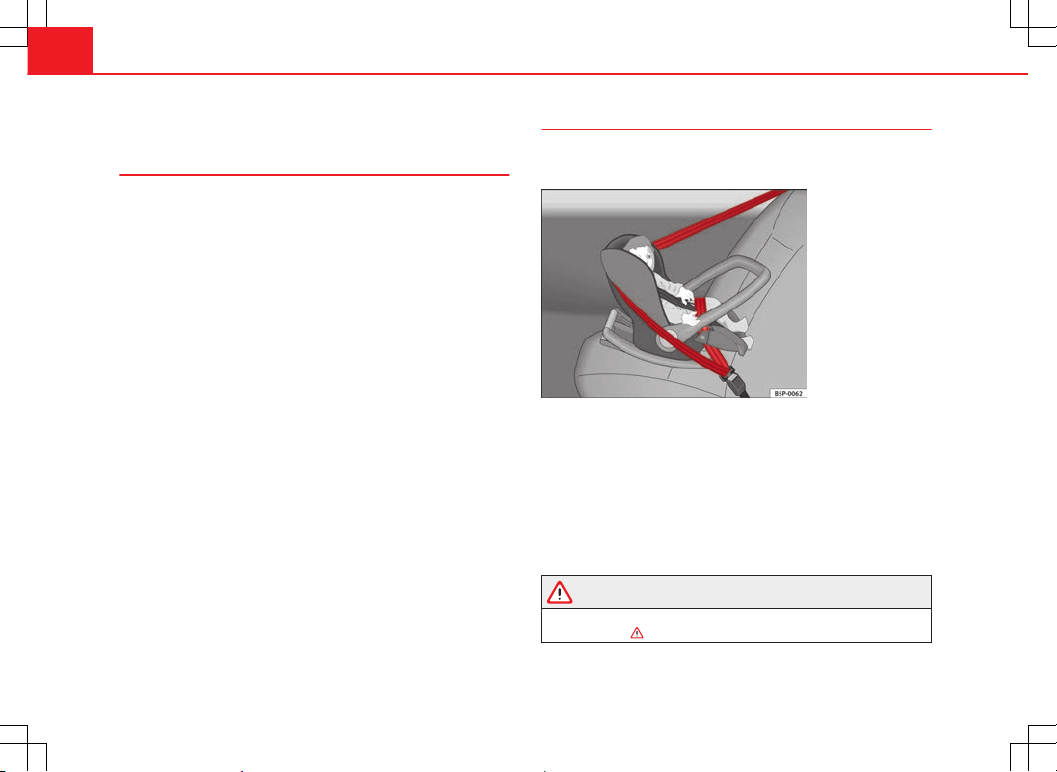

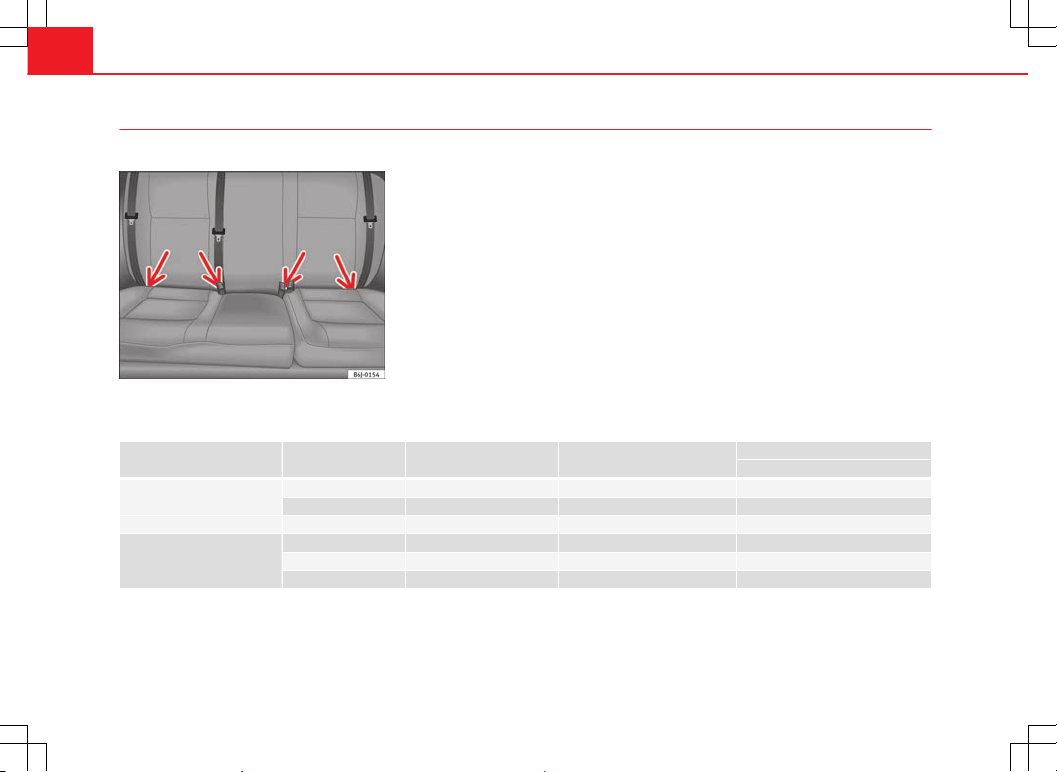

Securing child seats . . . . . . . . . . . . . . . . . . . . . . . 47

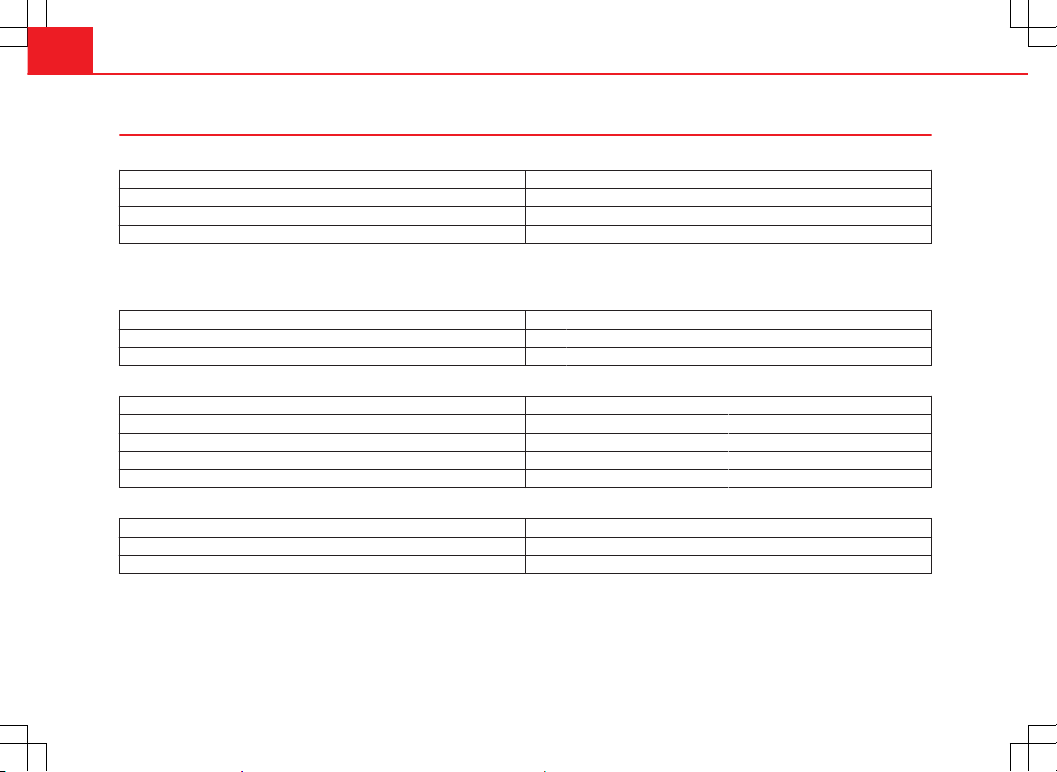

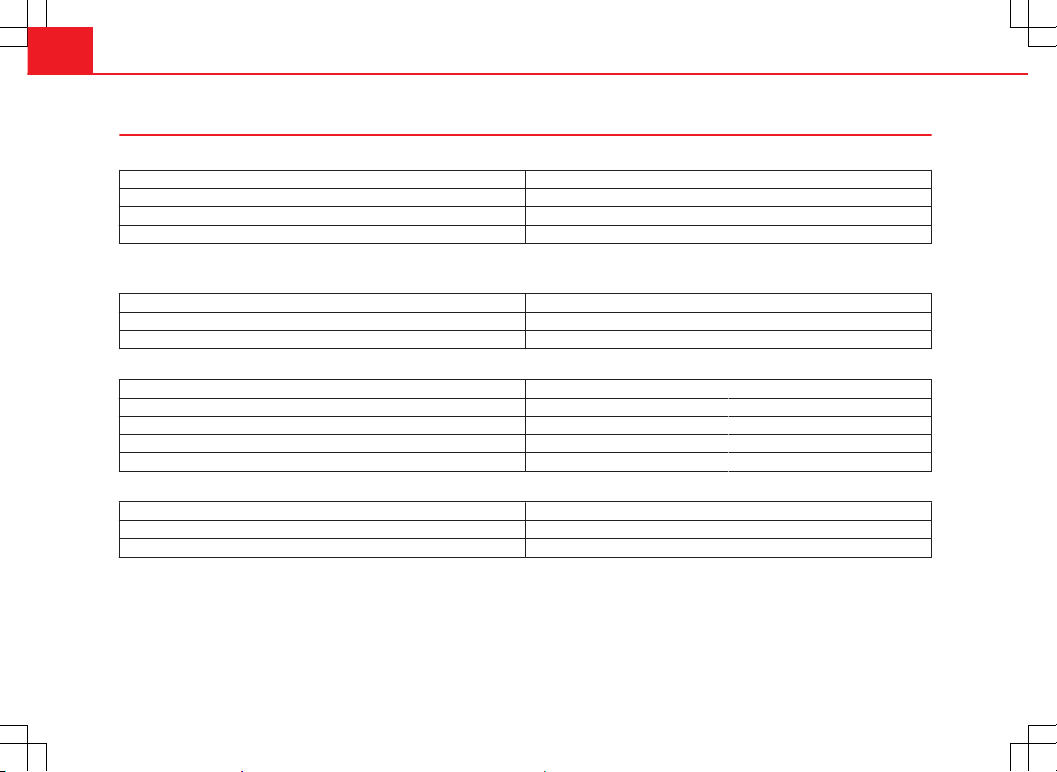

Operating Instructions . . . . . . . . . . . . . 53

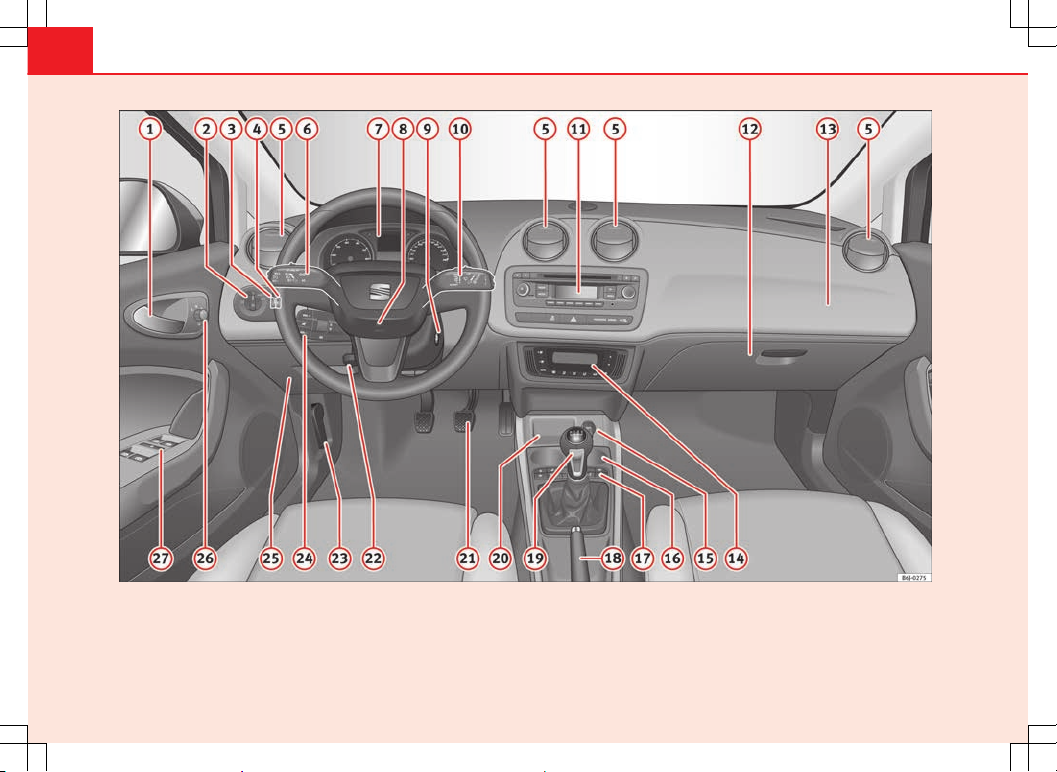

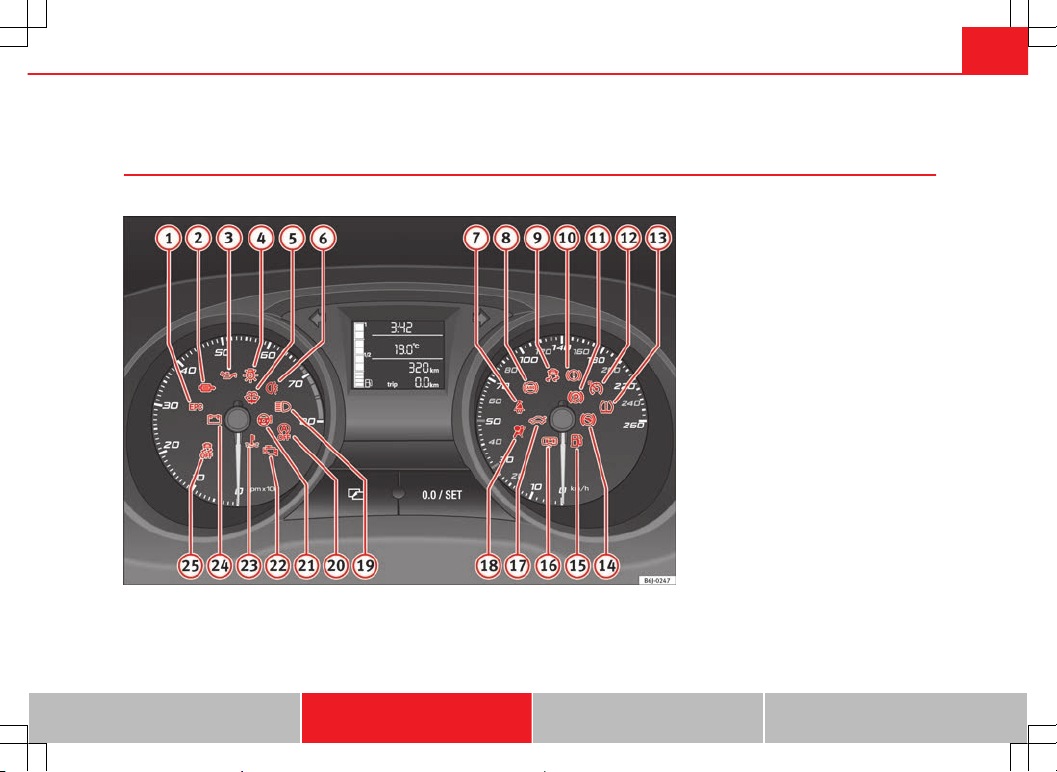

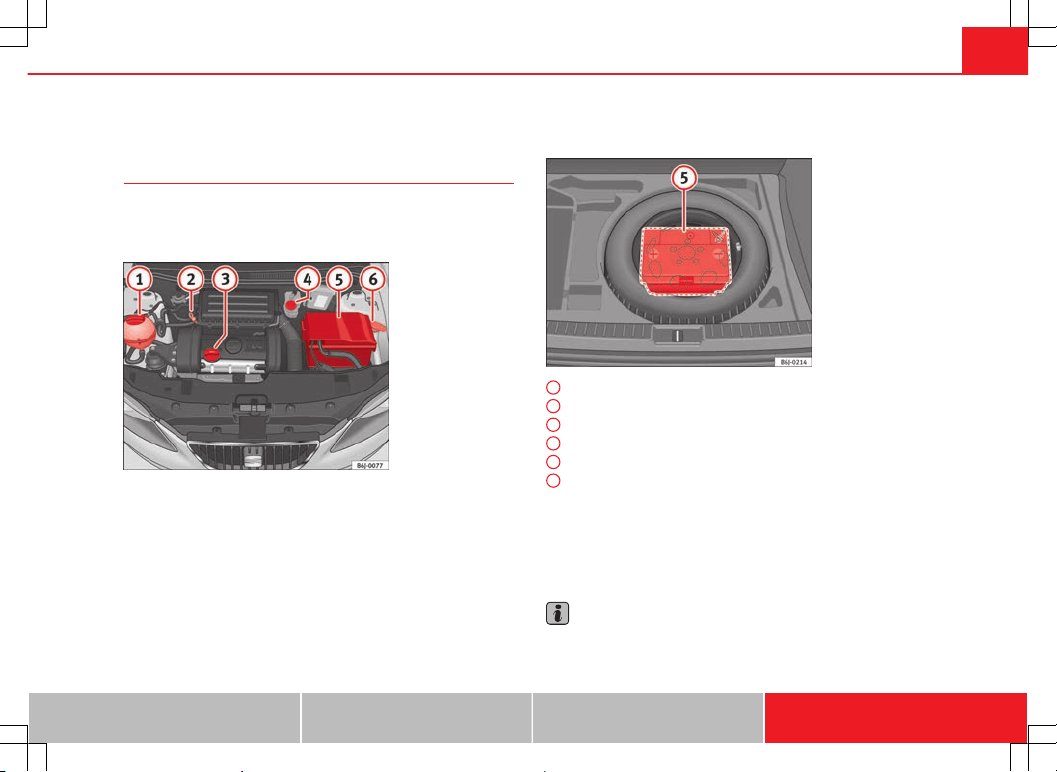

Cockpit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

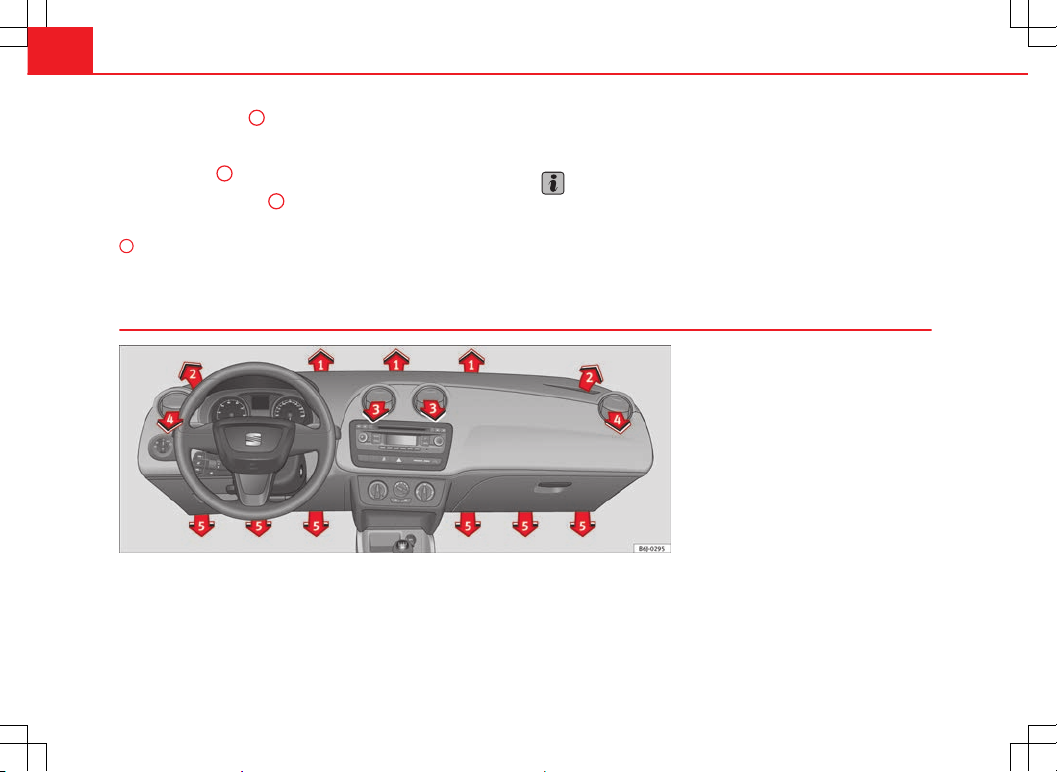

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

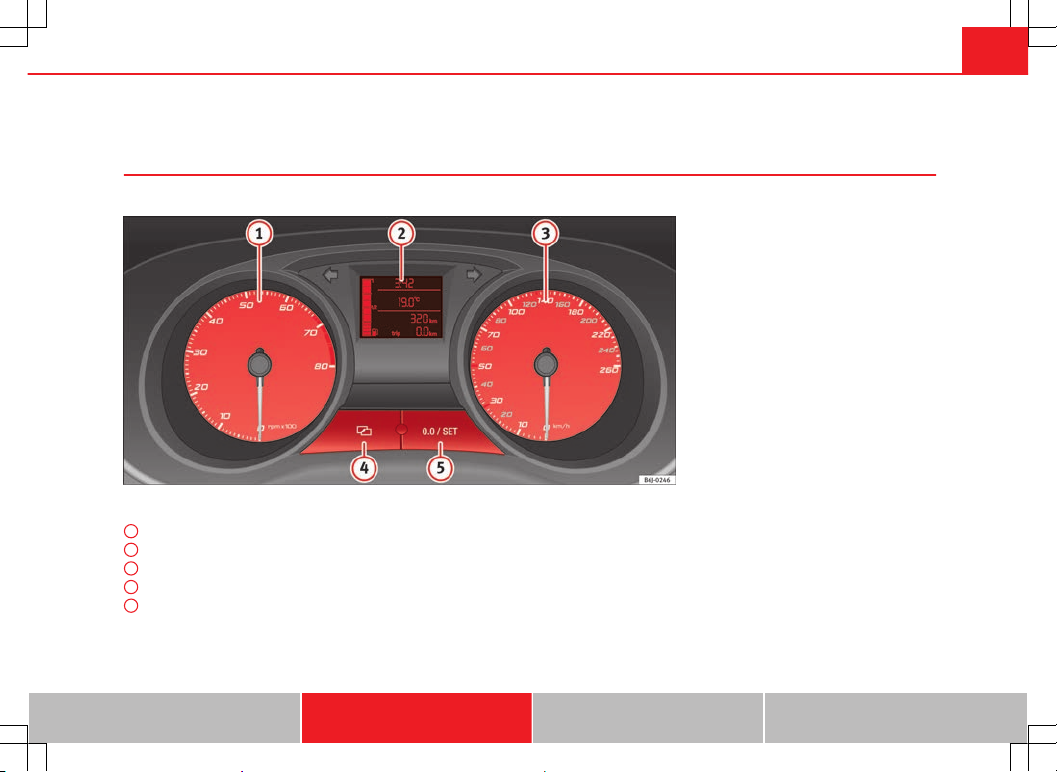

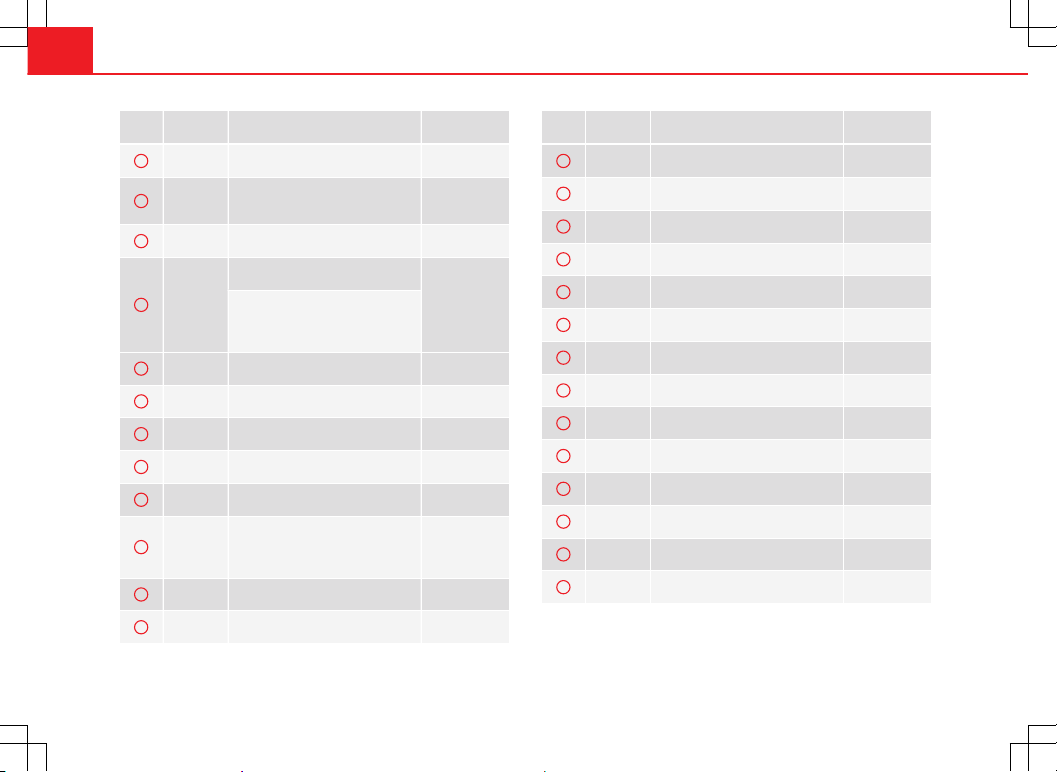

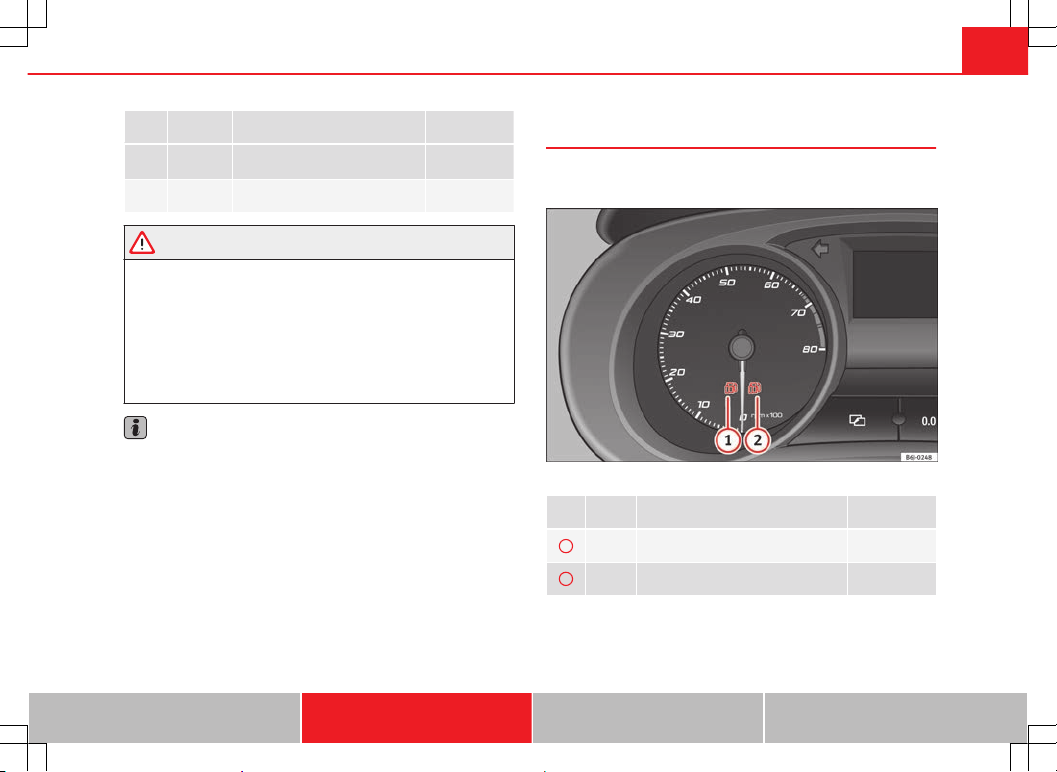

Instruments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

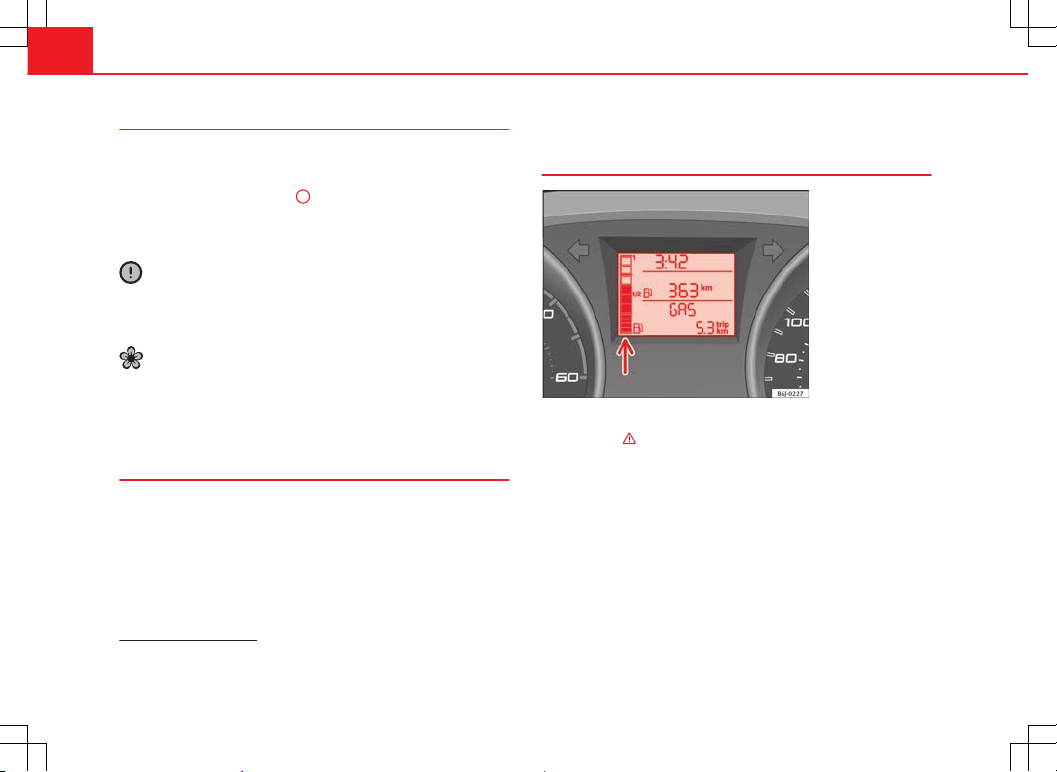

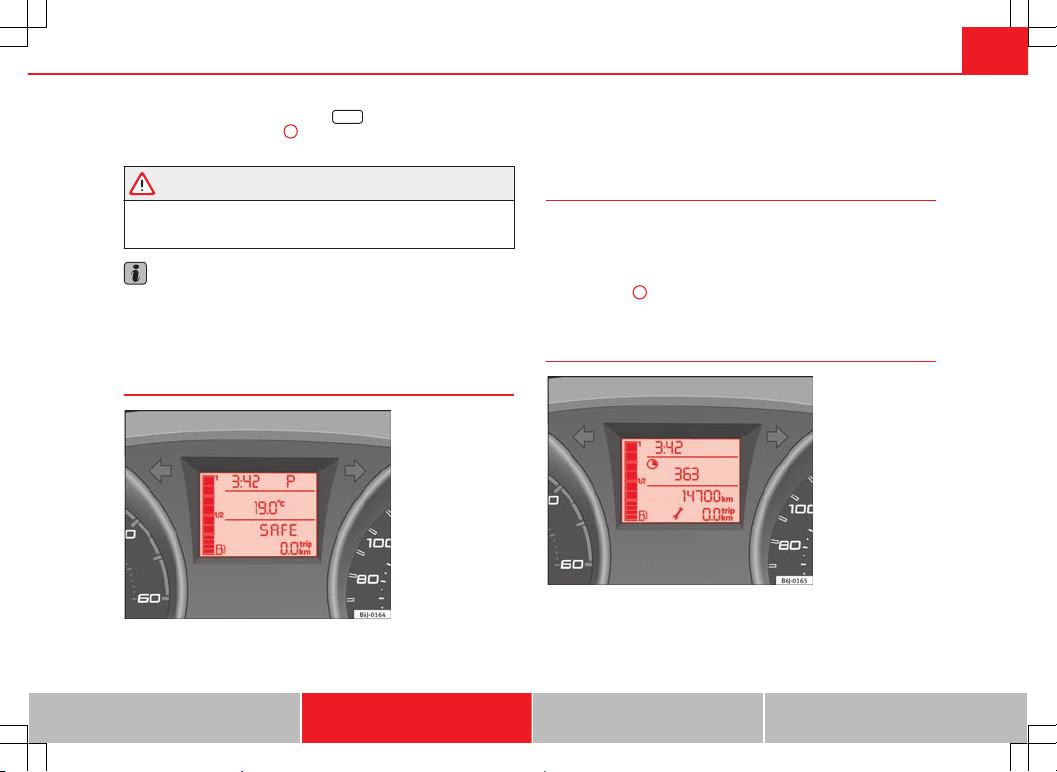

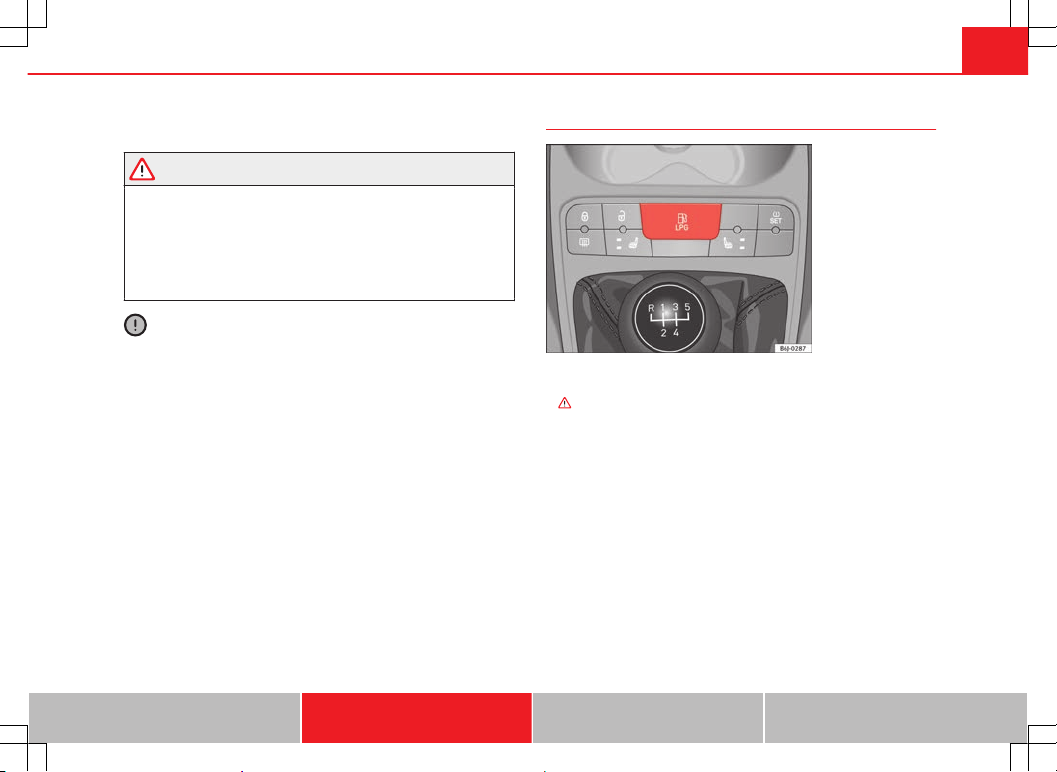

LPG system* . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

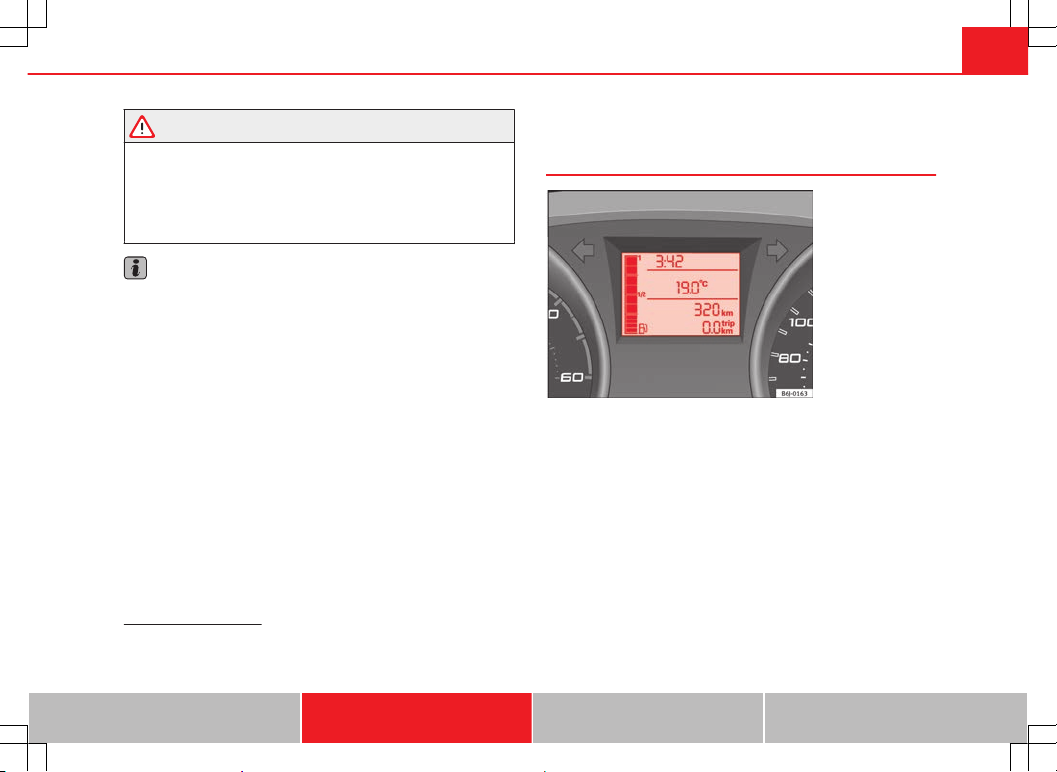

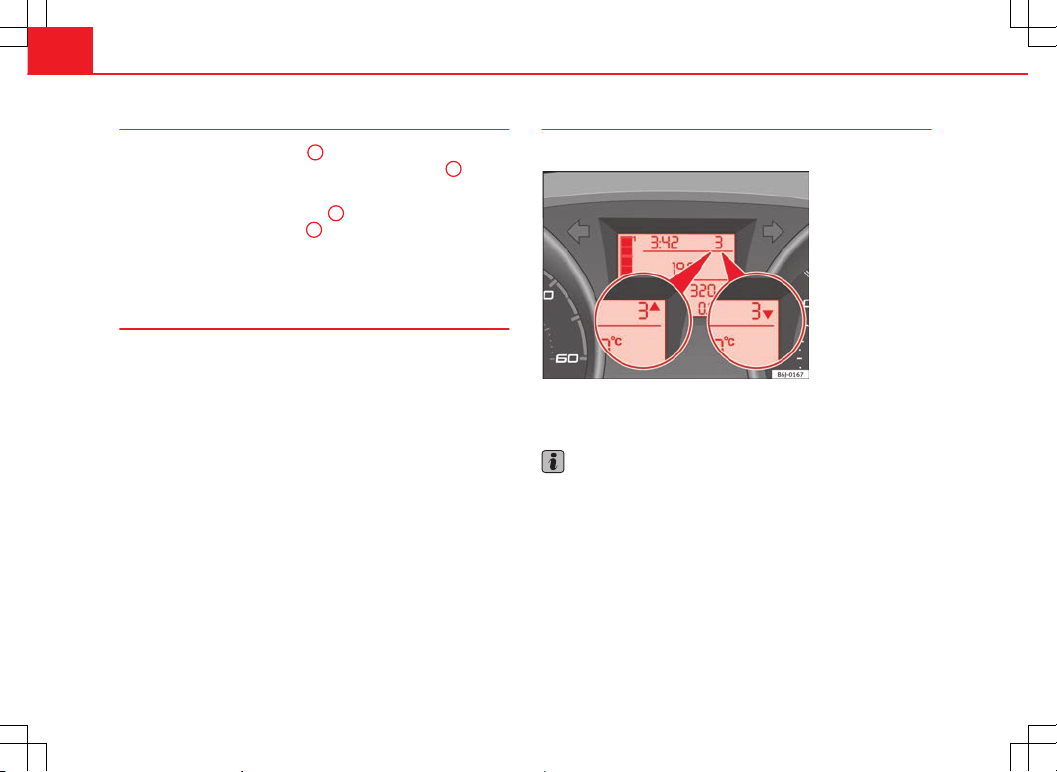

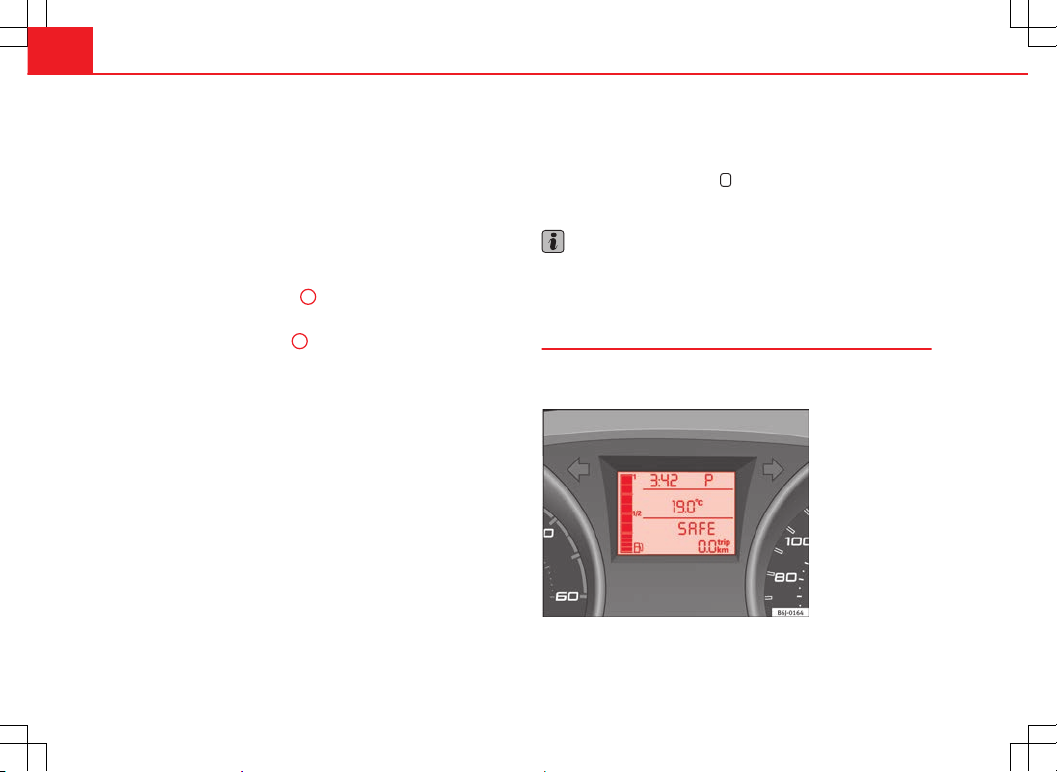

Digital instrument panel display . . . . . . . . . . . . . 57

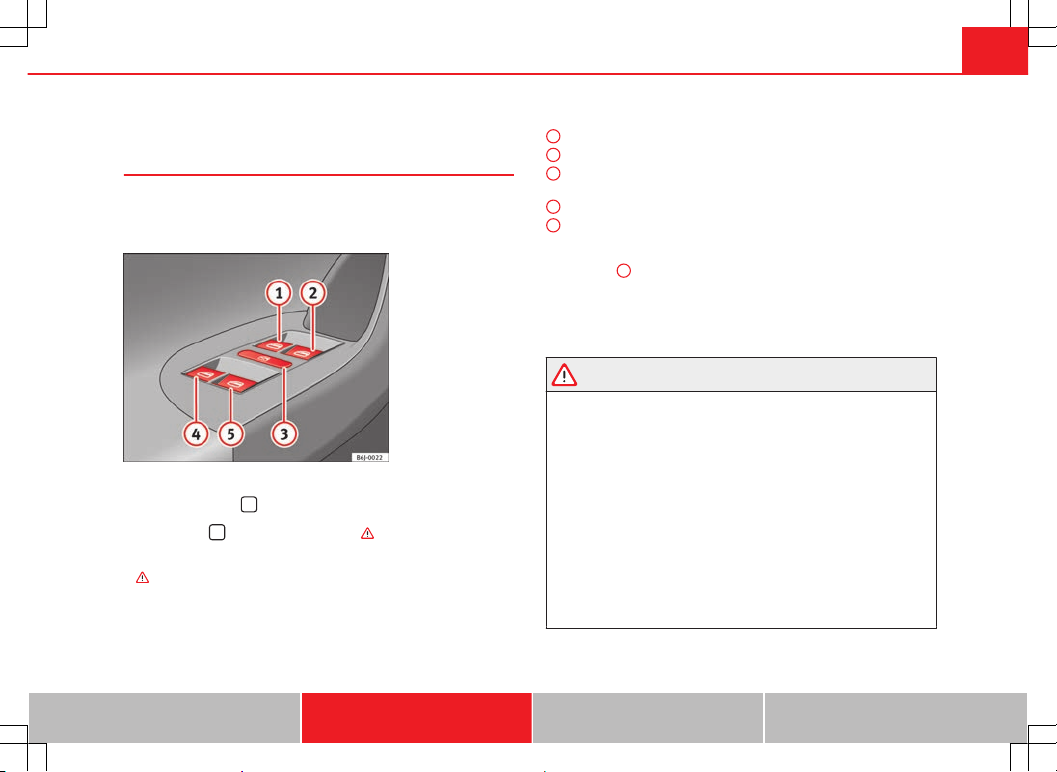

Warning lamps . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

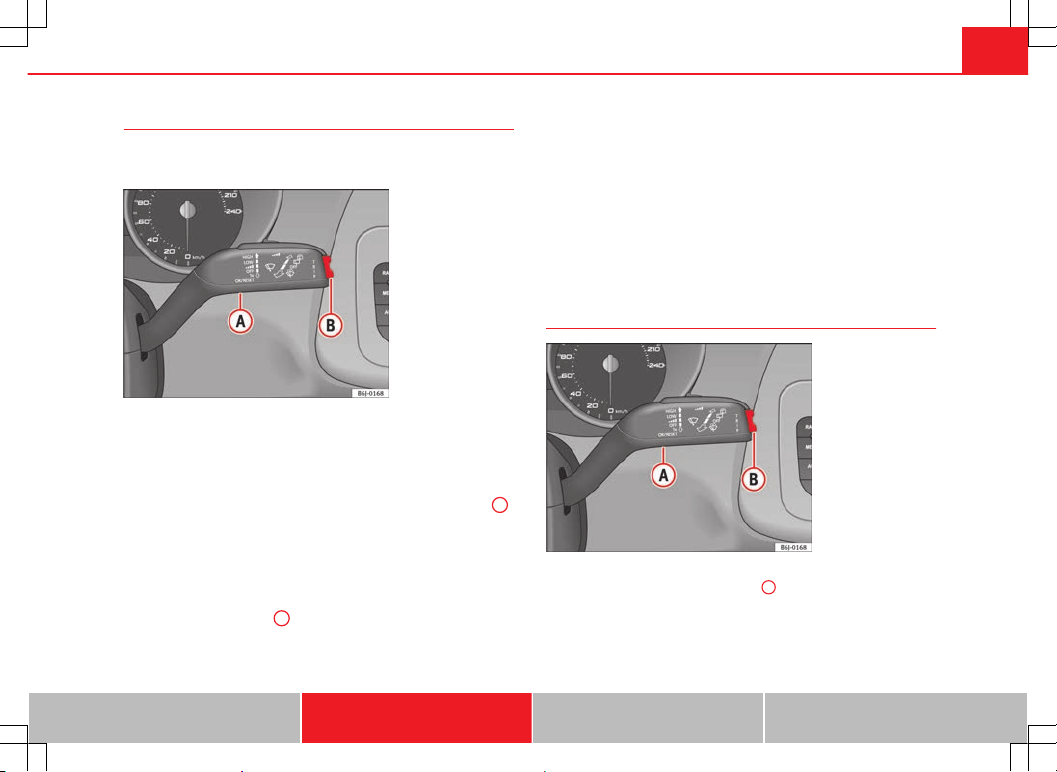

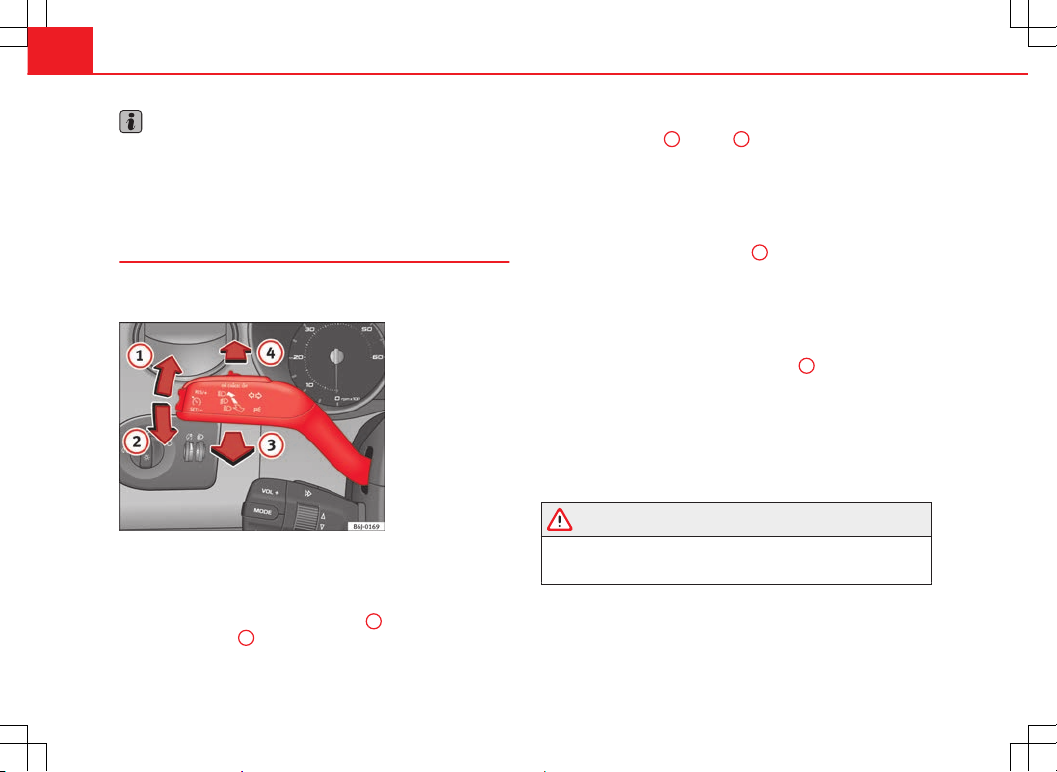

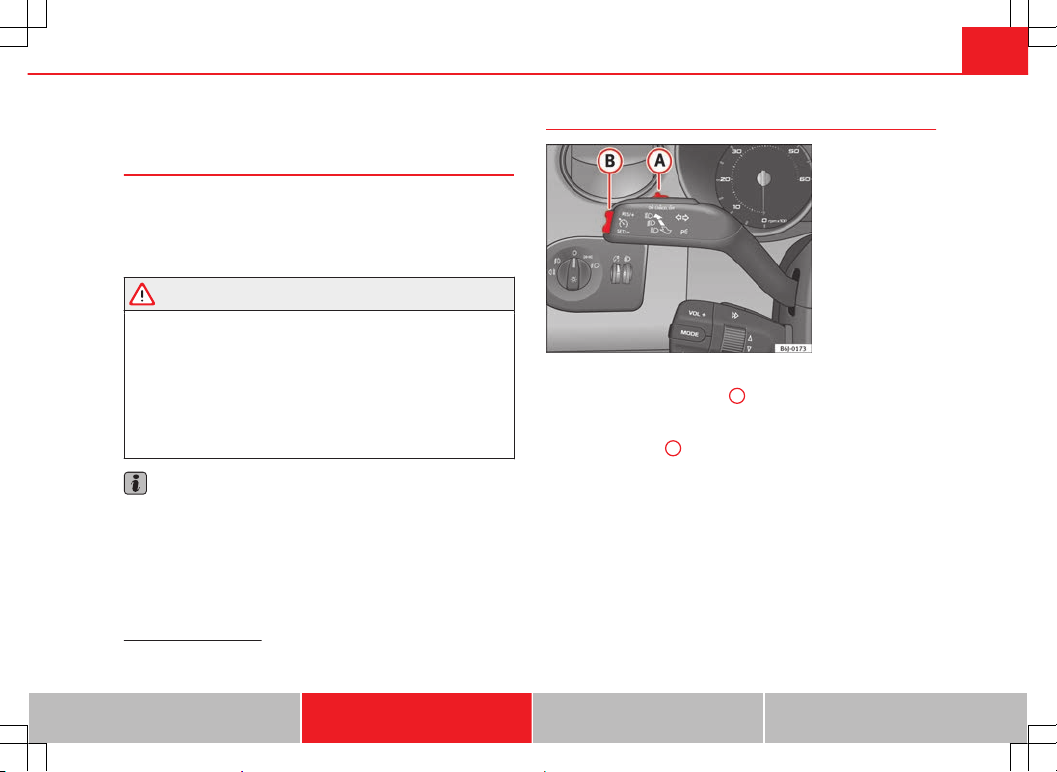

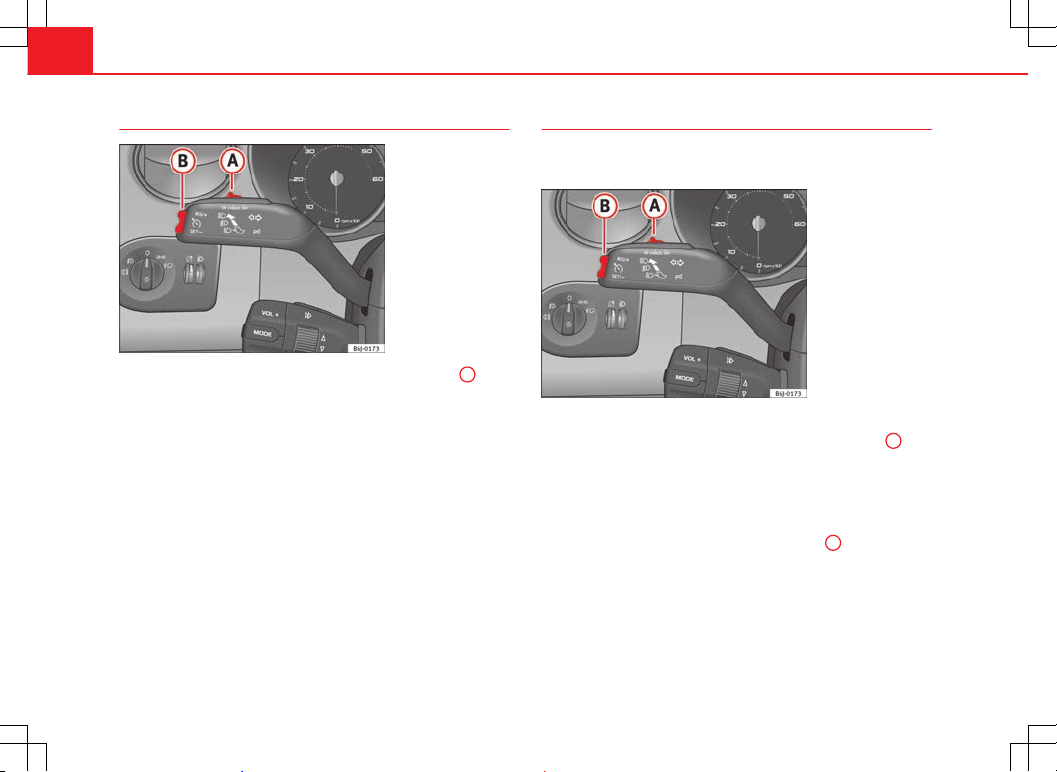

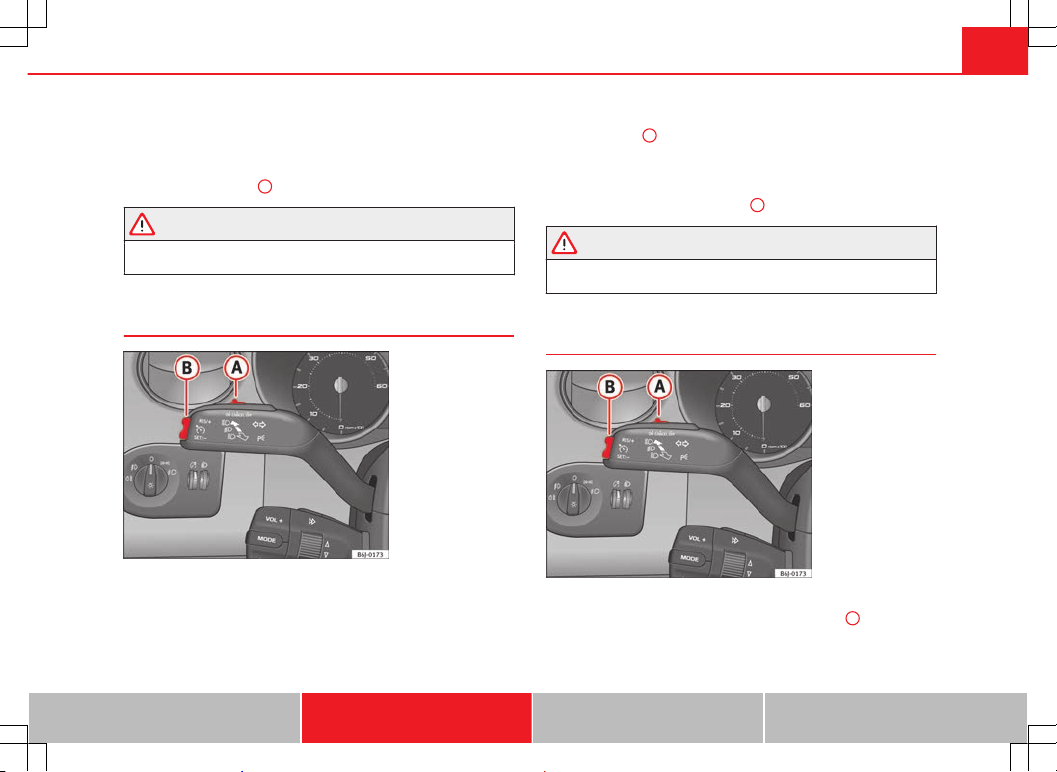

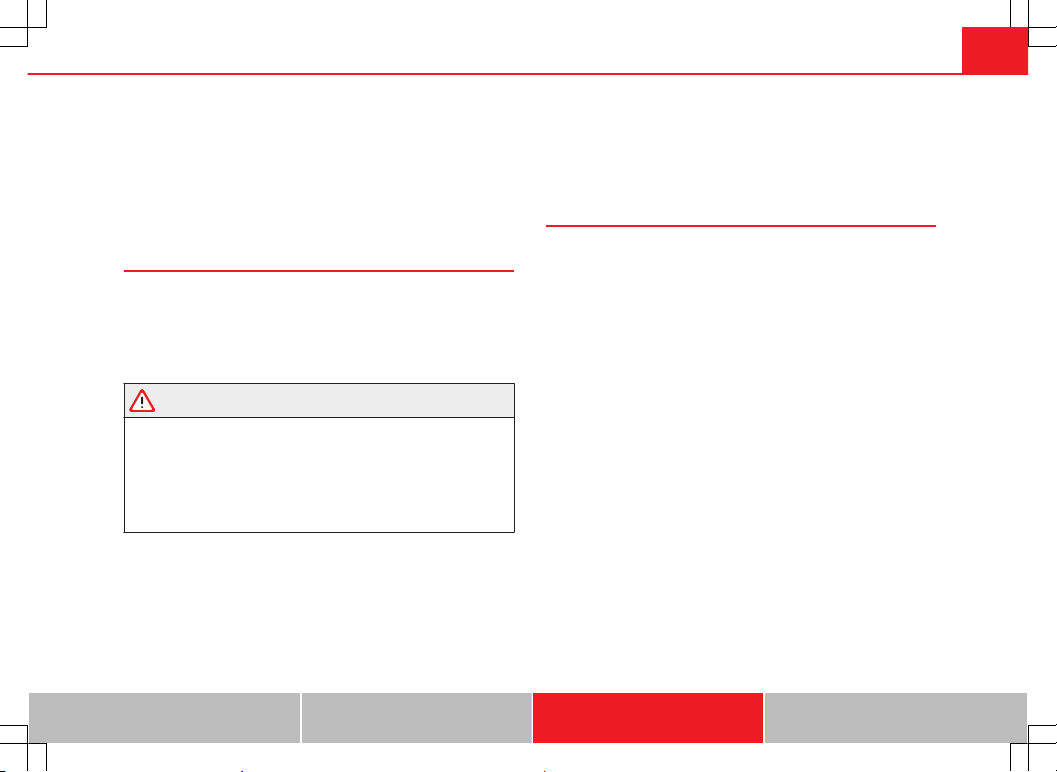

Steering column controls* . . . . . . . . . . . . . . . . . 76

General information . . . . . . . . . . . . . . . . . . . . . . . 76

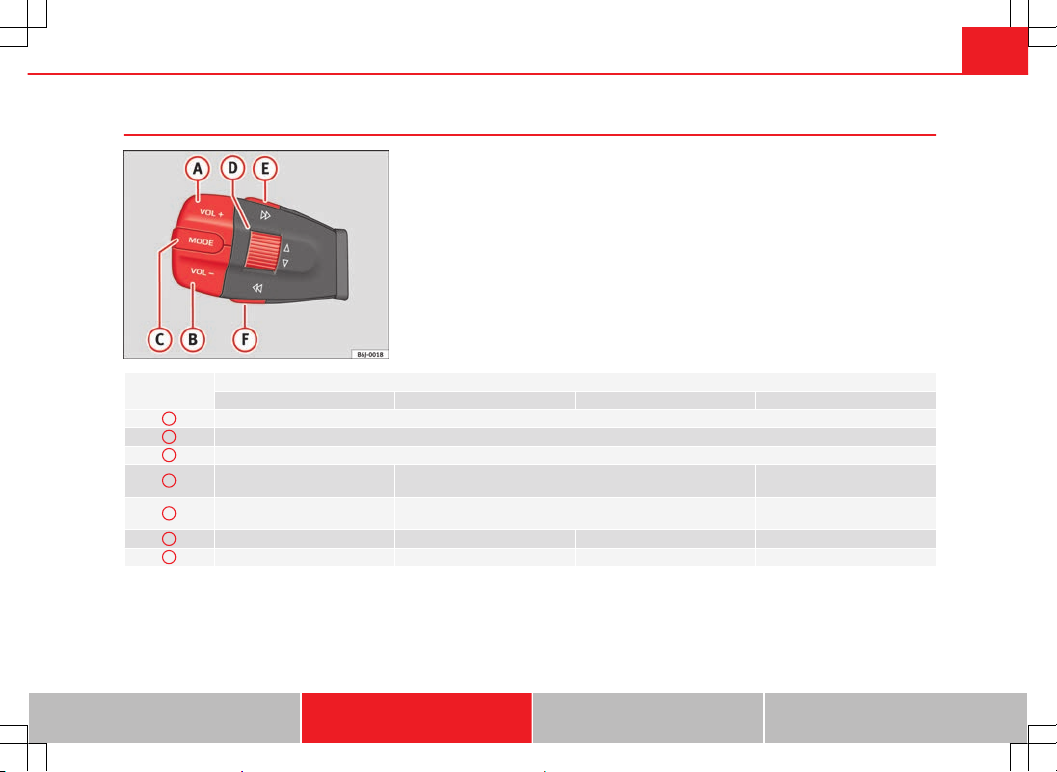

Audio Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

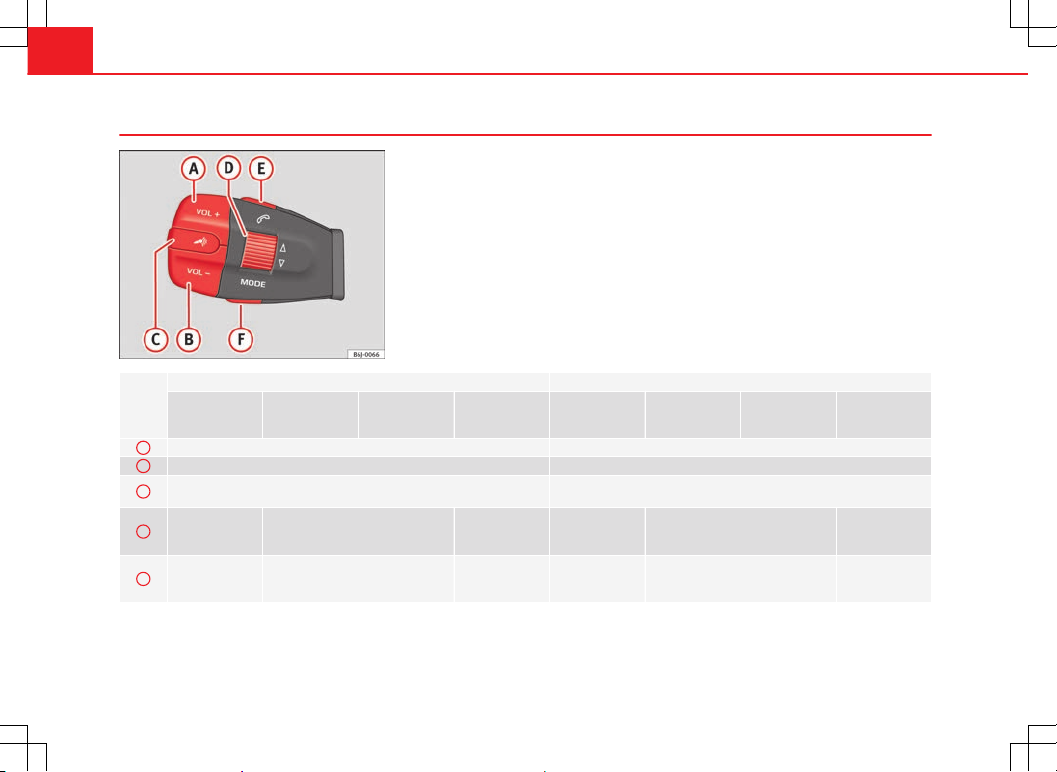

Audio + Telephone Control . . . . . . . . . . . . . . . . . . 78

Opening and closing . . . . . . . . . . . . . . . . . . . . . . 80

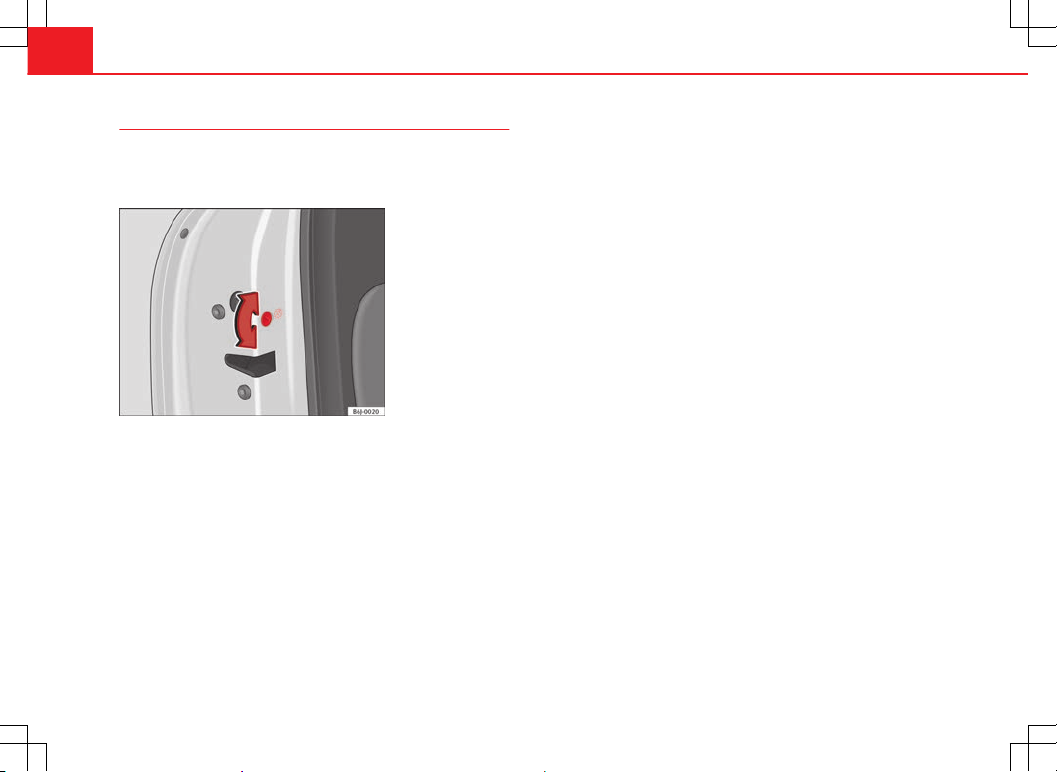

Central locking . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

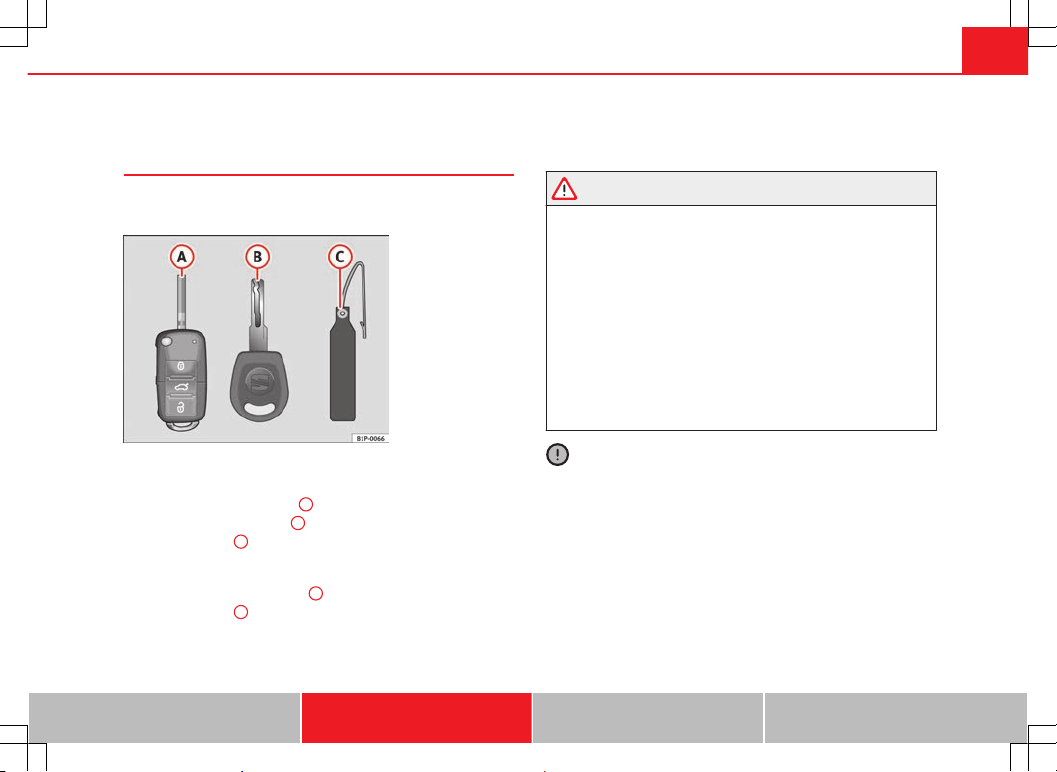

Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

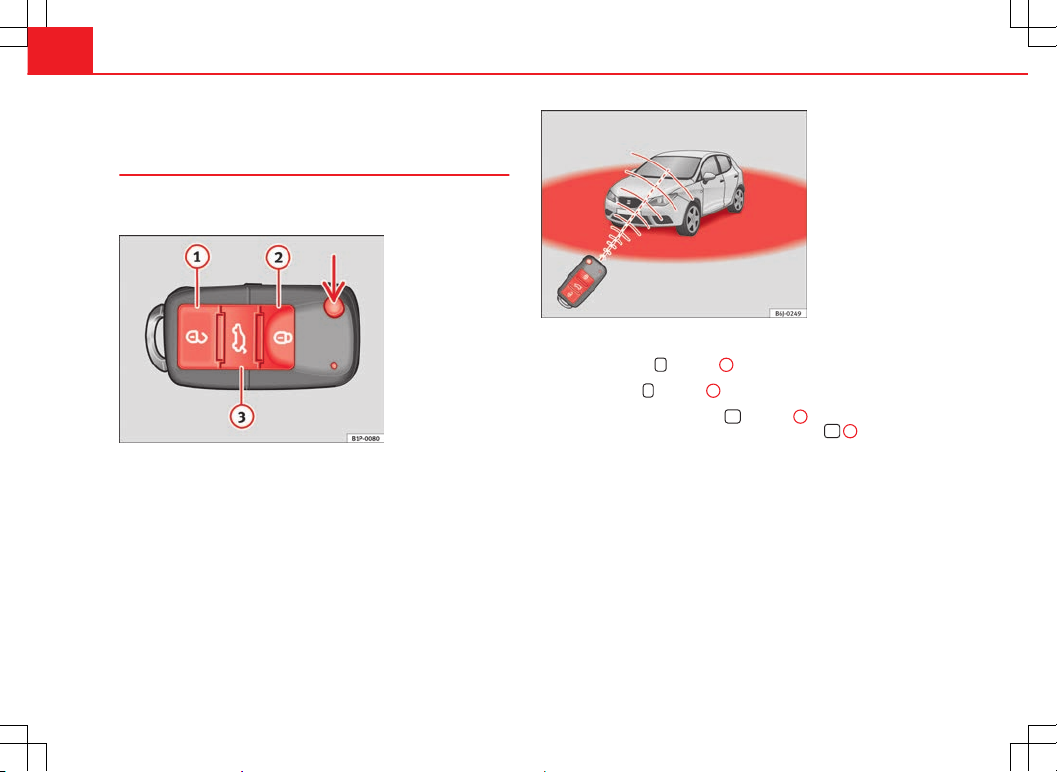

Radio frequency remote control* . . . . . . . . . . . . . 86

Anti-theft alarm system* . . . . . . . . . . . . . . . . . . . 88

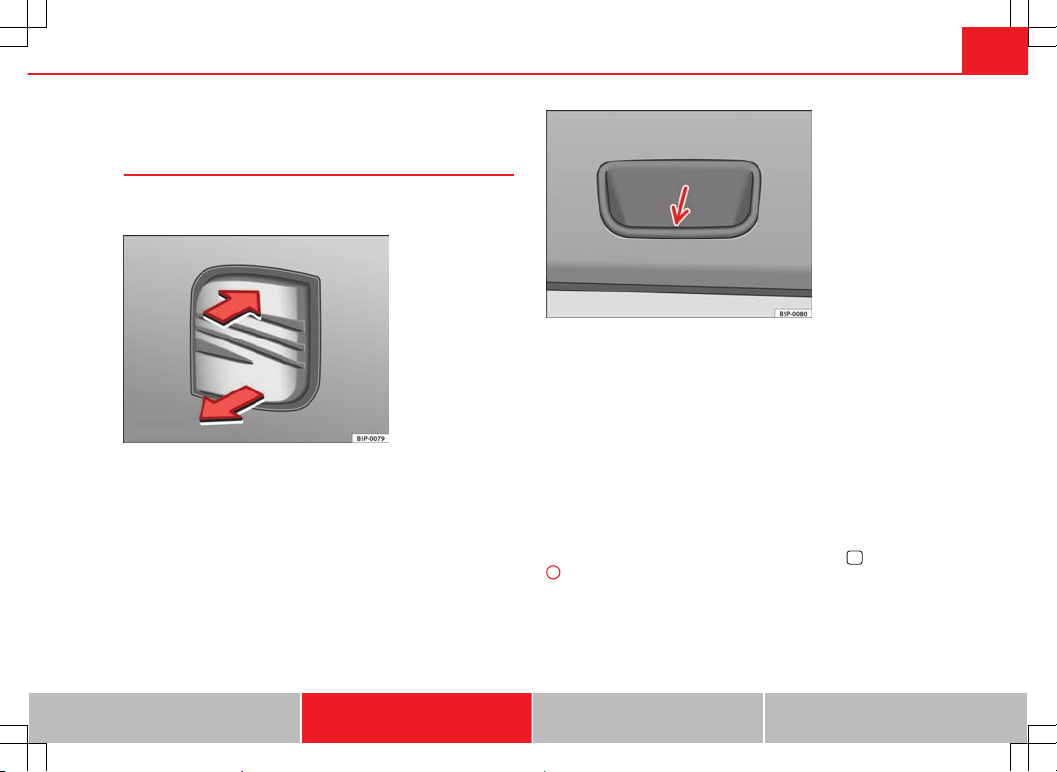

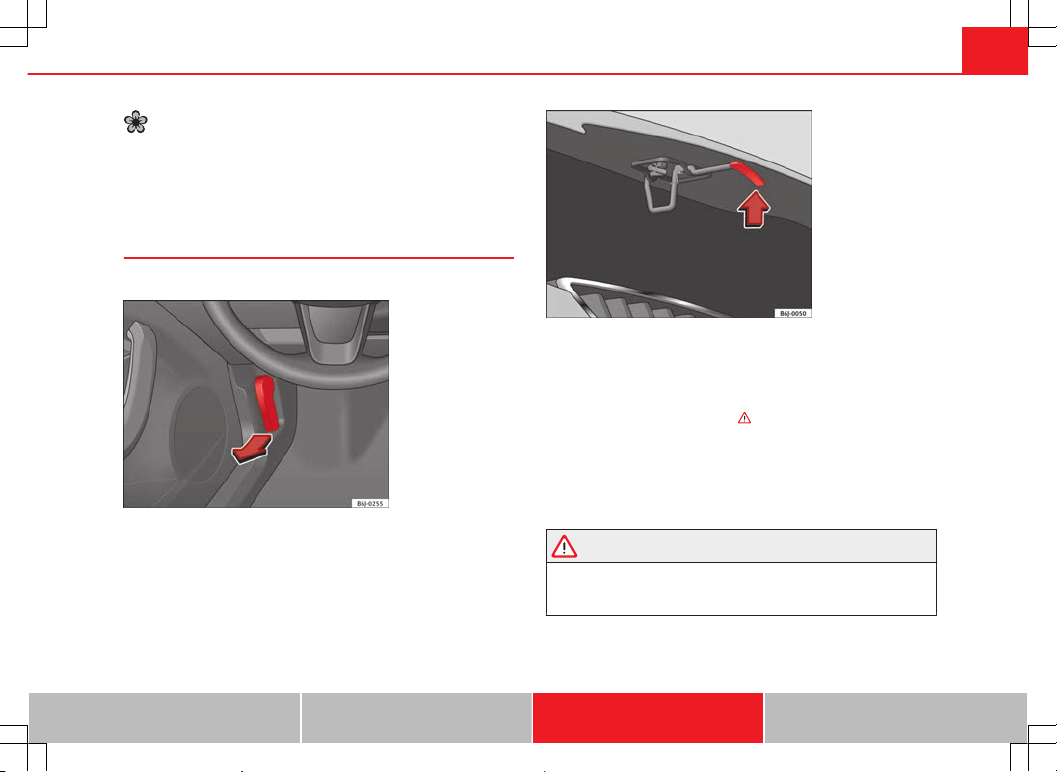

Rear lid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Windows . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

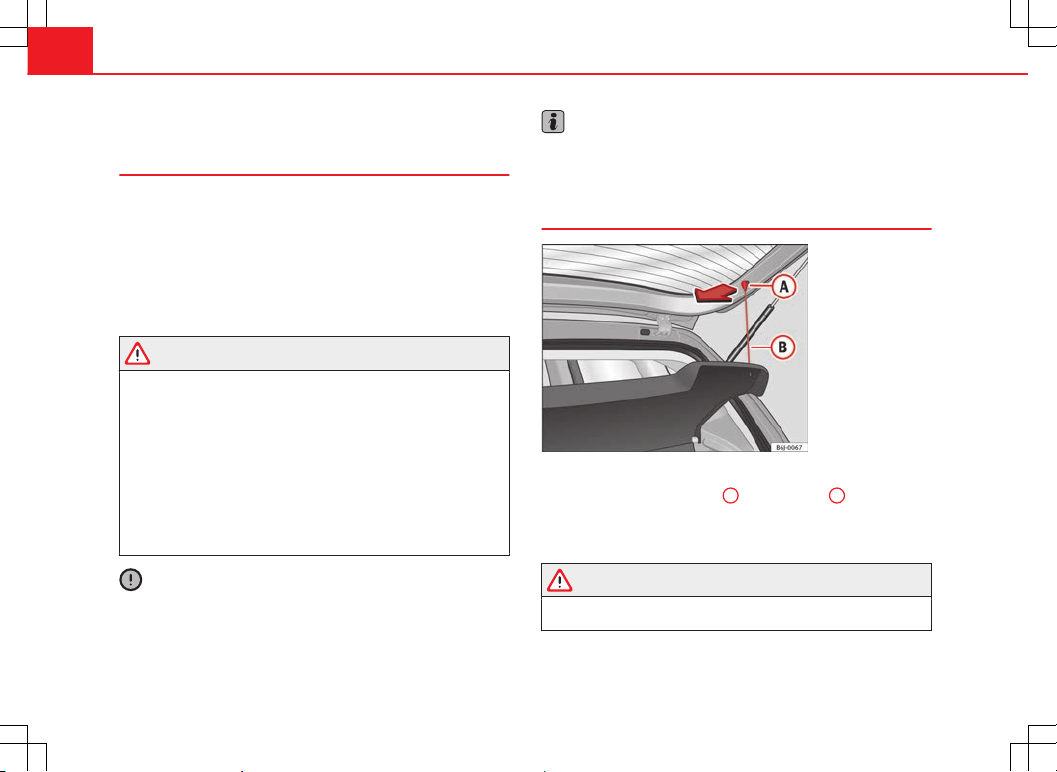

Panoramic tilting sunroof* . . . . . . . . . . . . . . . . . . 96

Lights and visibility . . . . . . . . . . . . . . . . . . . . . . . . 98

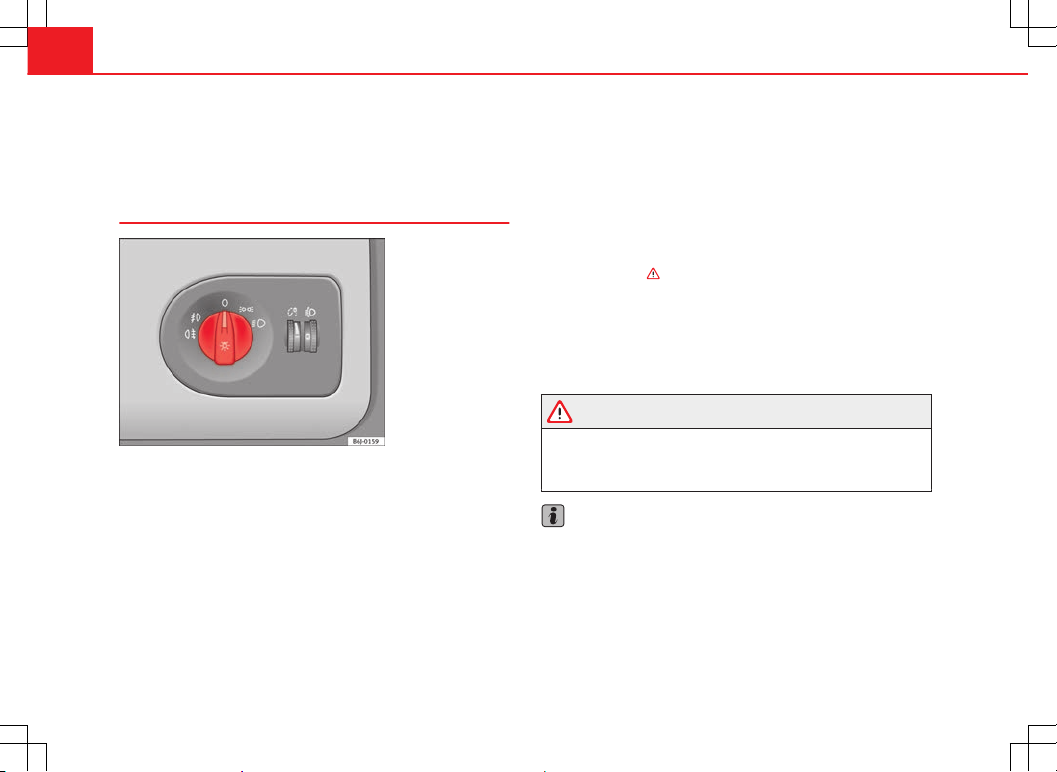

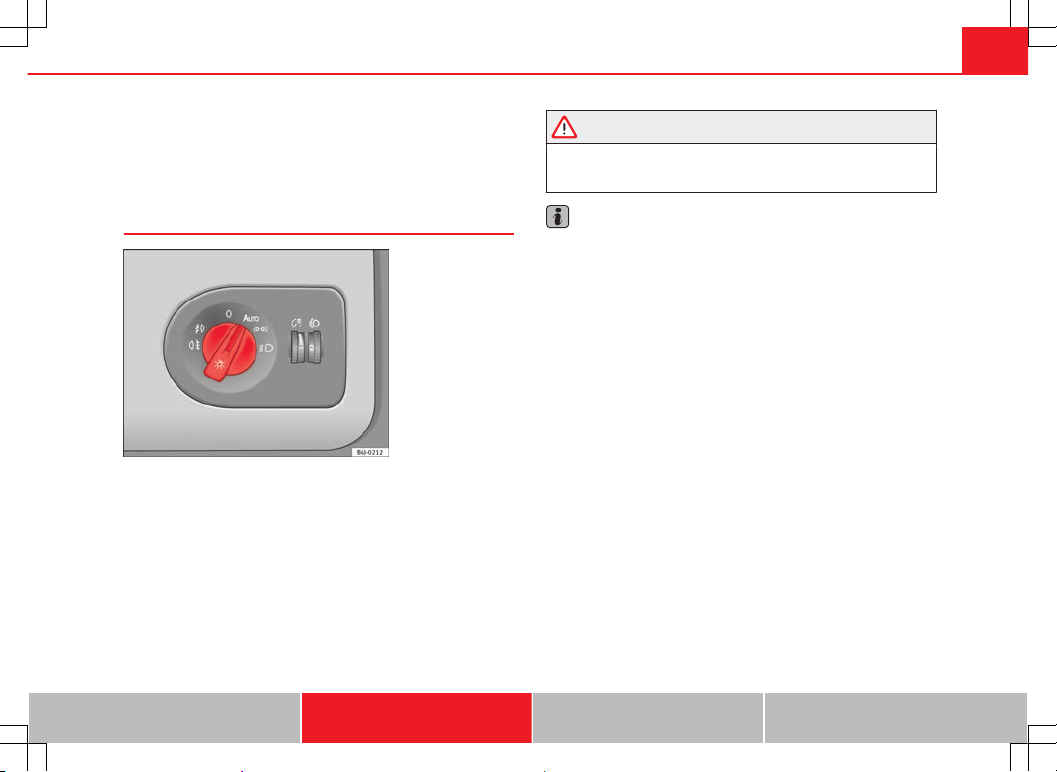

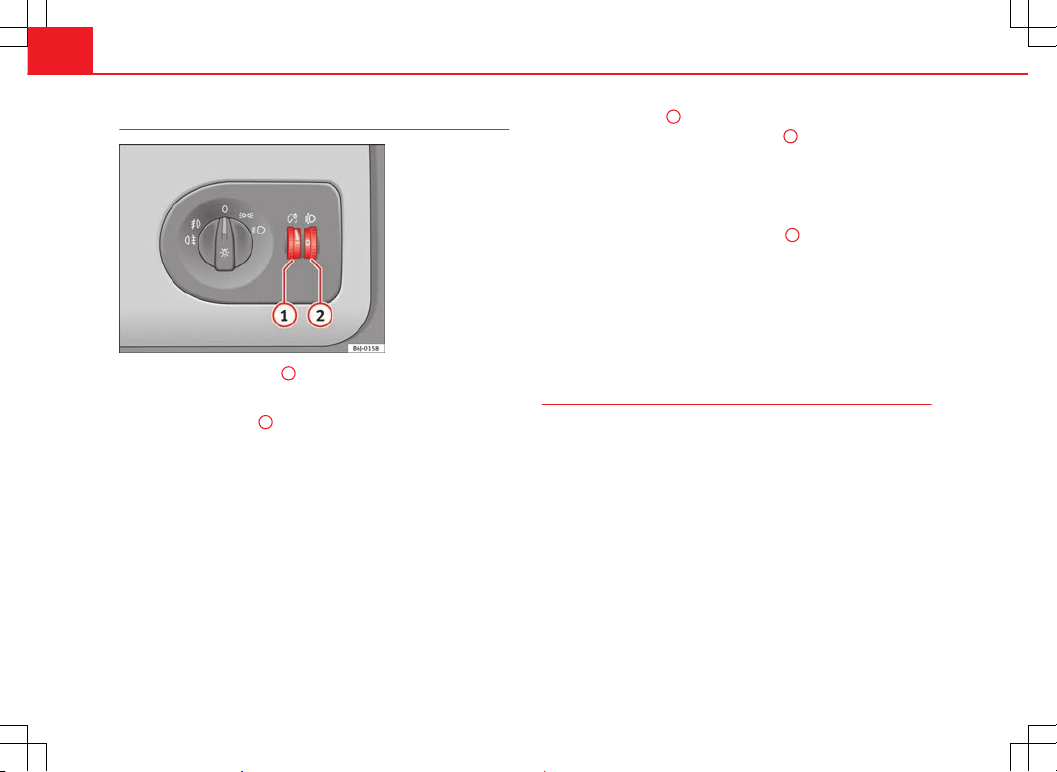

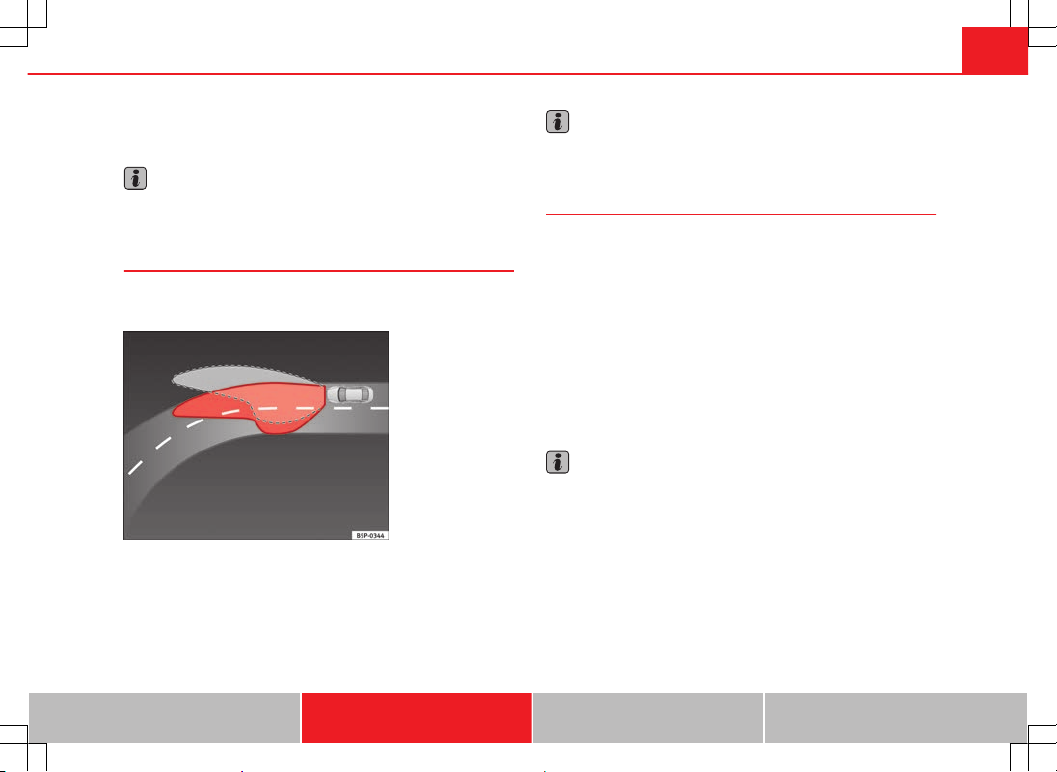

Lights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

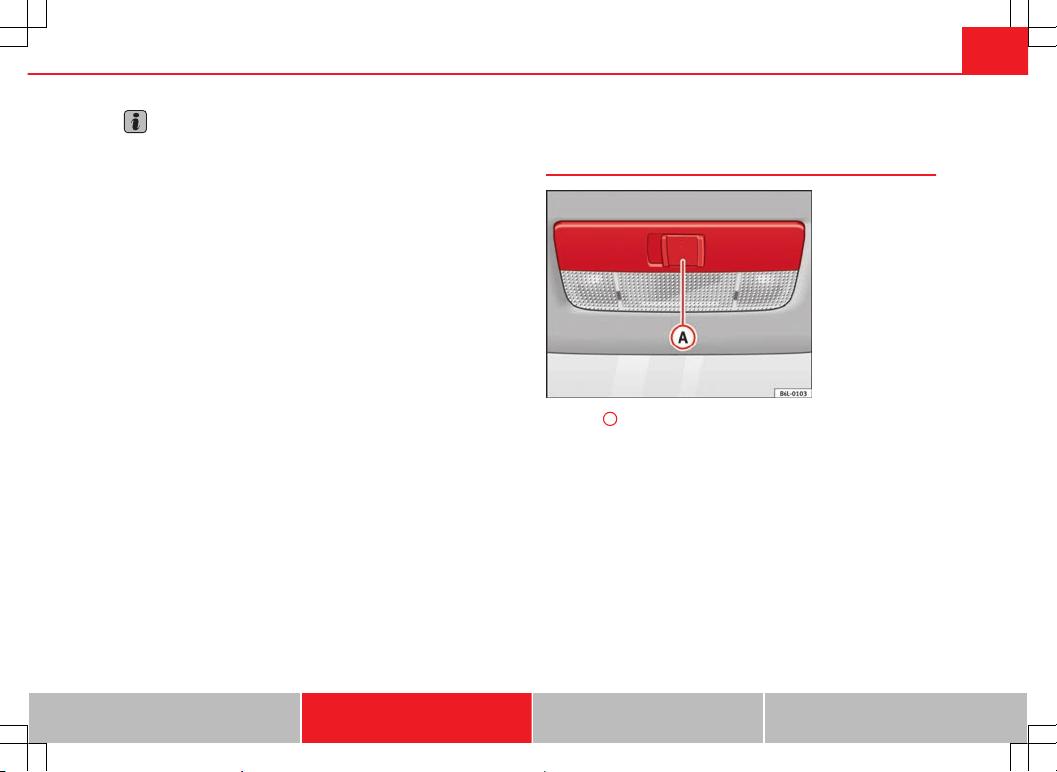

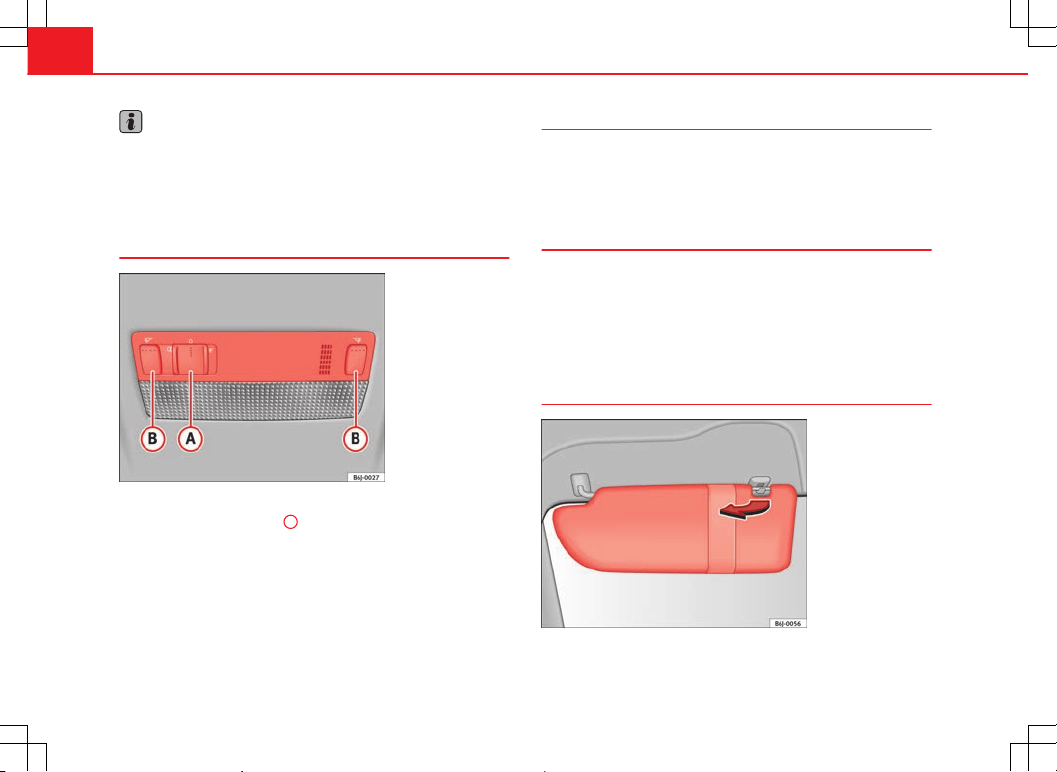

Interior lights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Visibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

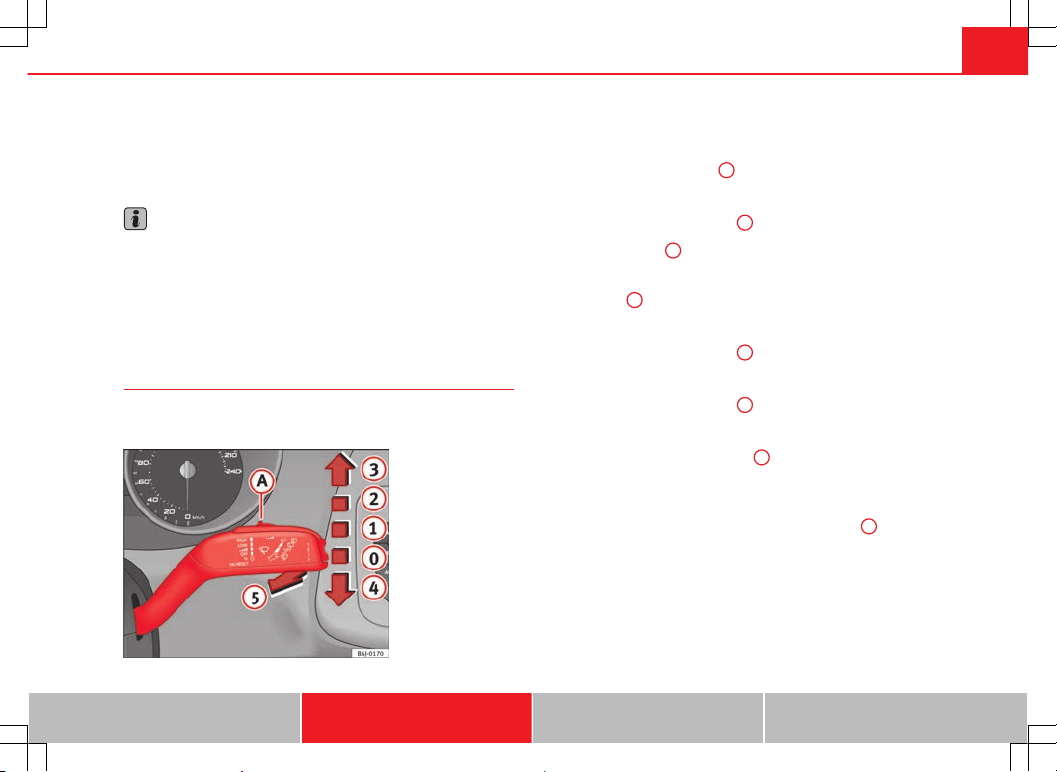

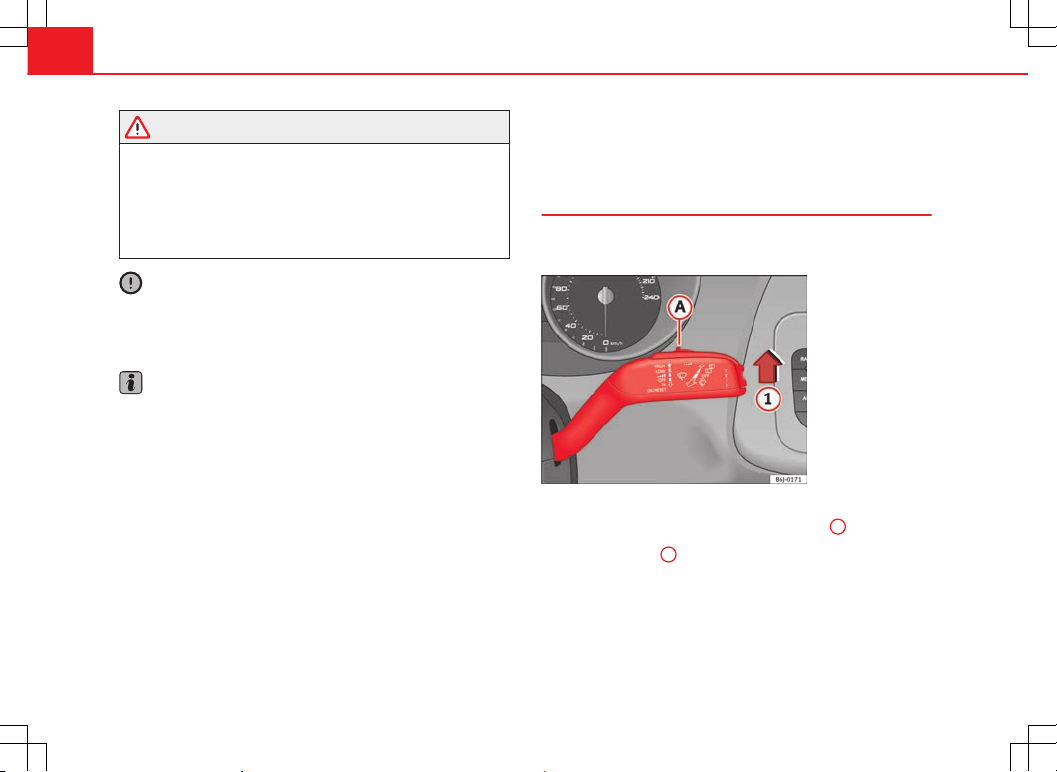

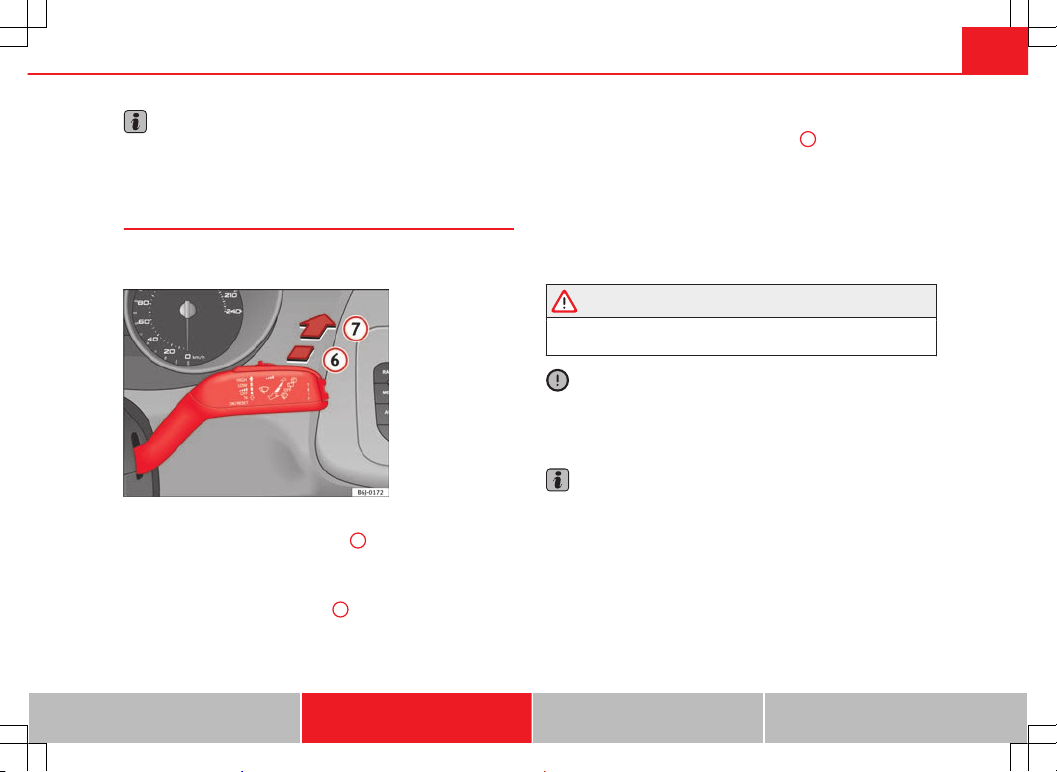

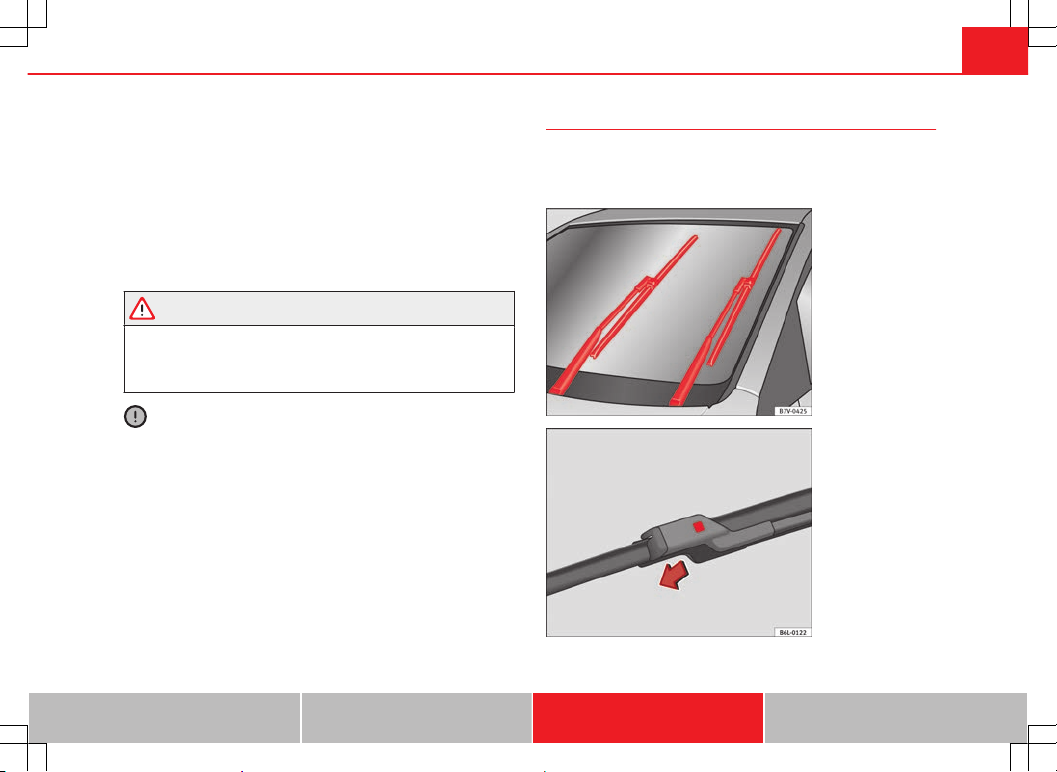

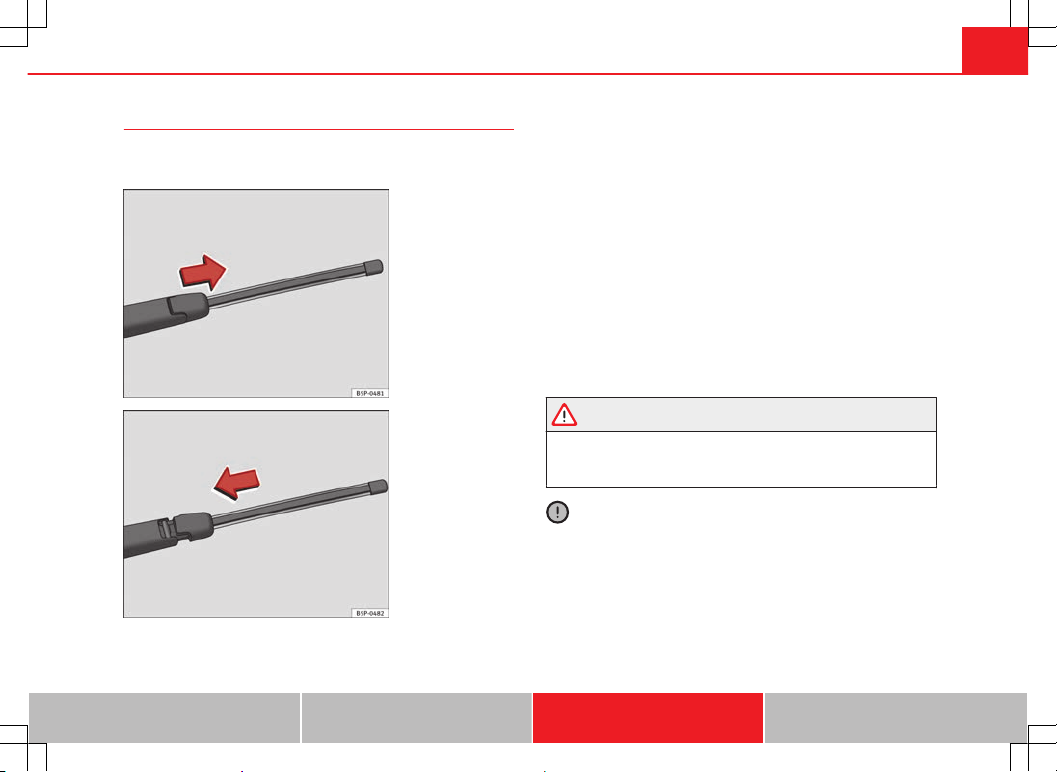

Windscreen wipers . . . . . . . . . . . . . . . . . . . . . . . . 107

Rear view mirrors . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Seats and storage compartments . . . . . . . . . . 113

The importance of correct seat adjustment . . . . . 113

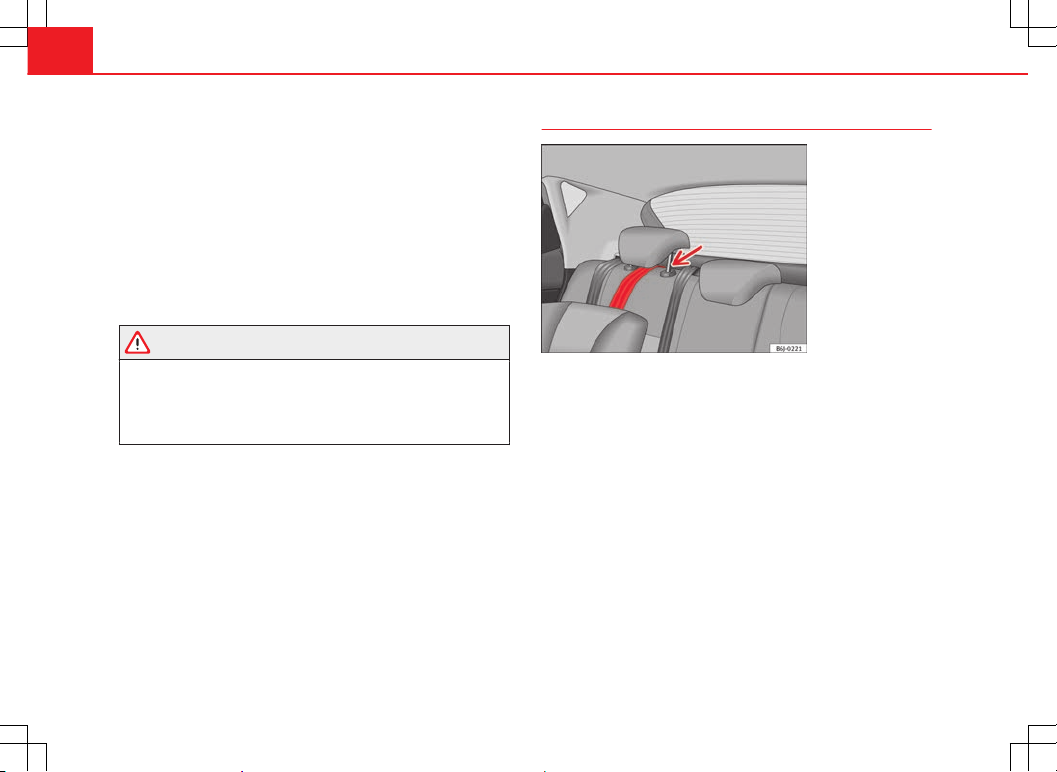

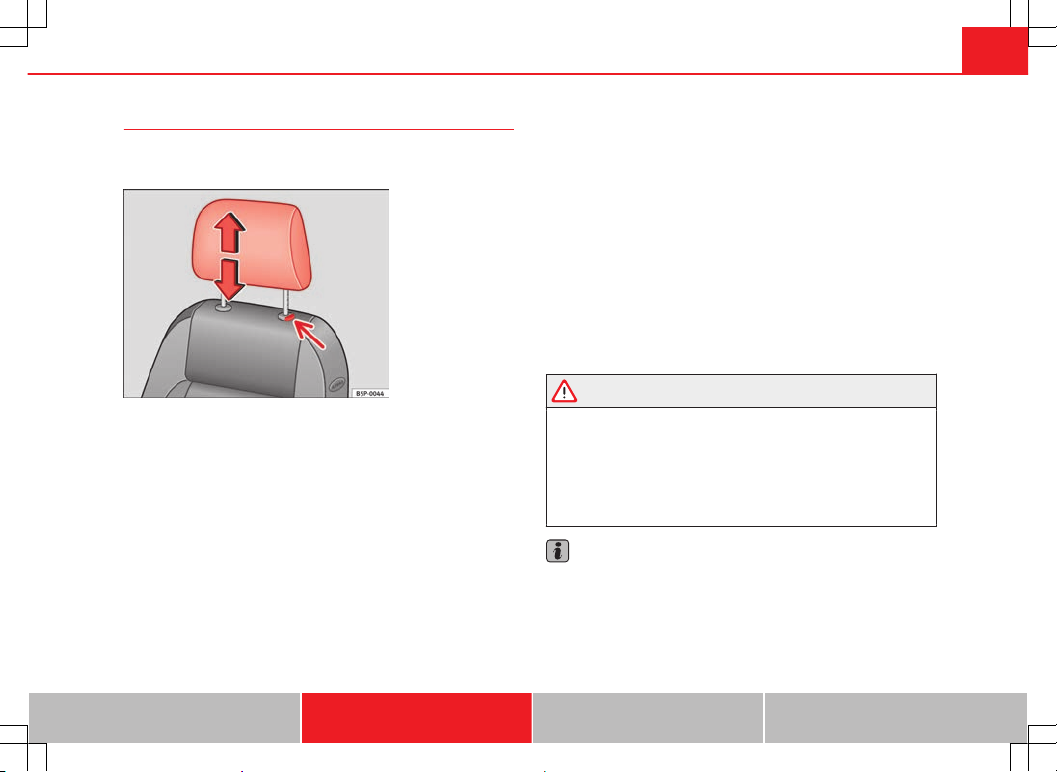

Head restraints . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

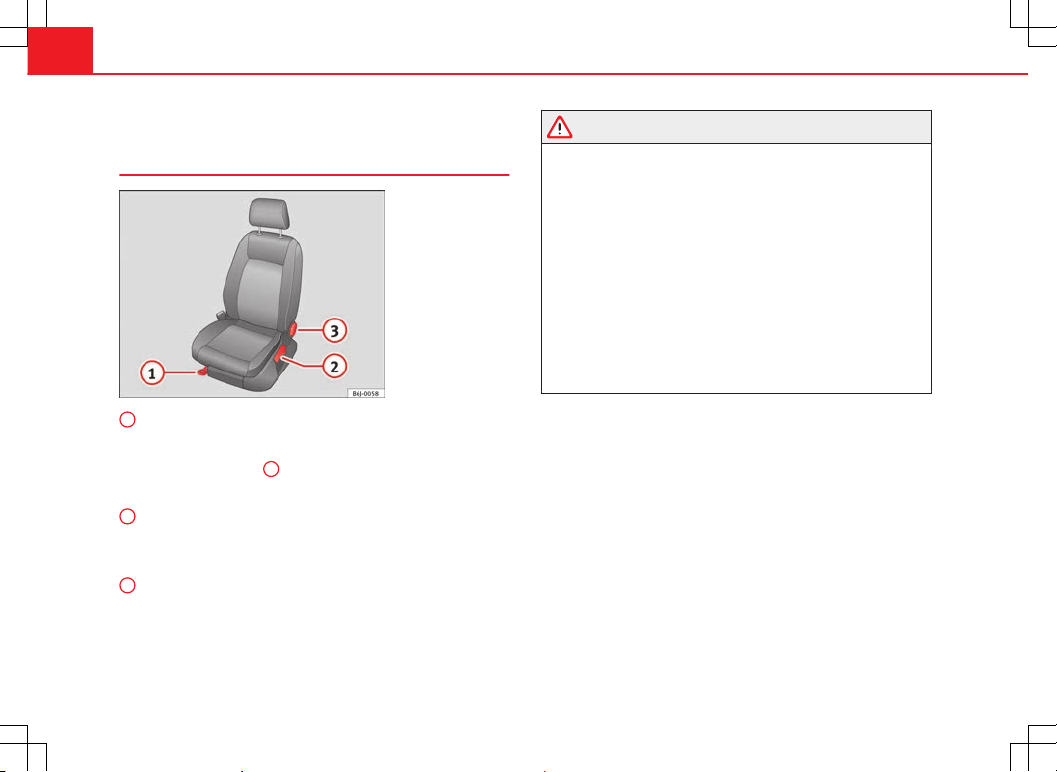

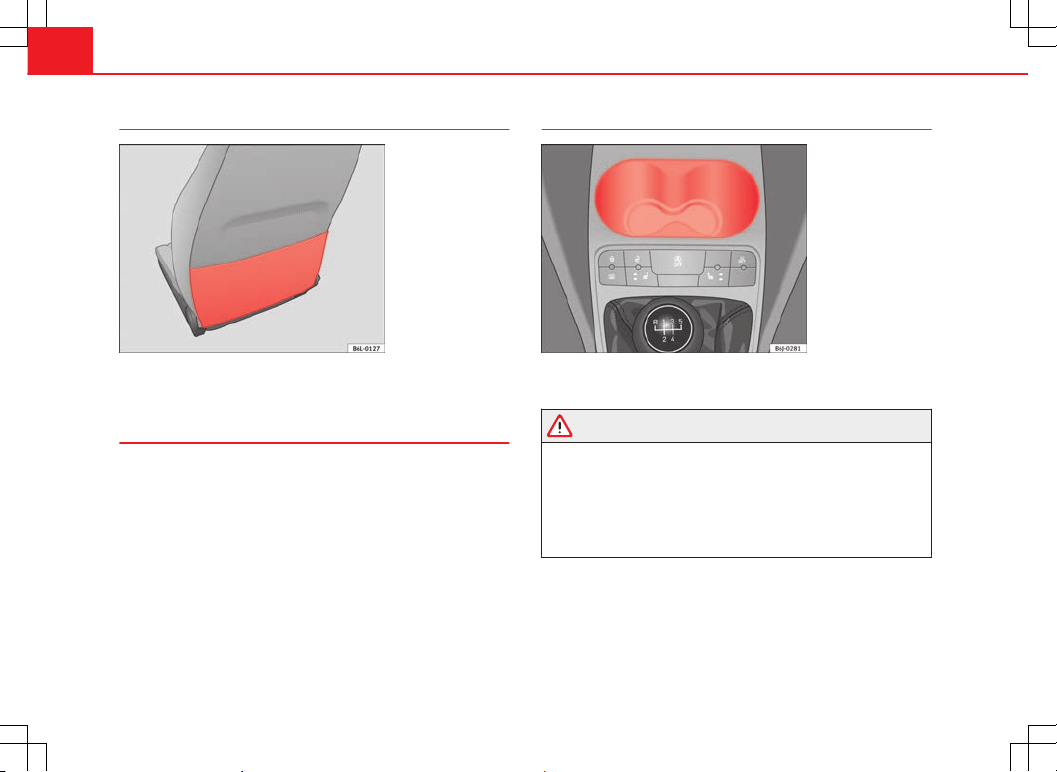

Front seats . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

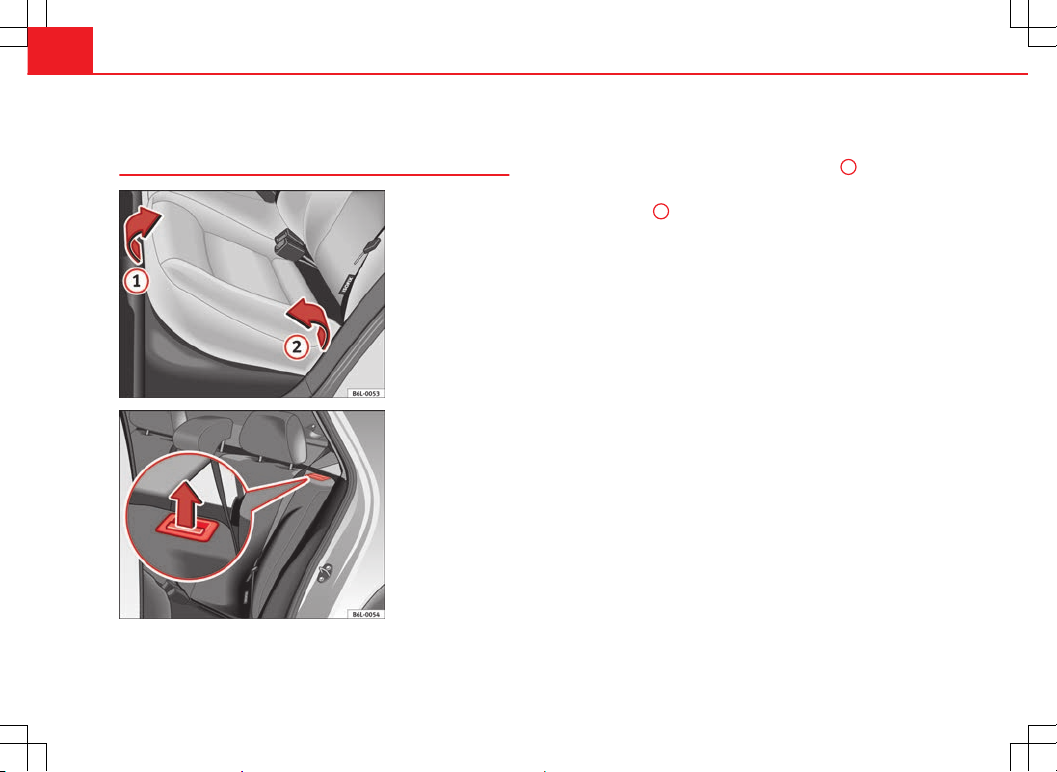

Rear seats . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

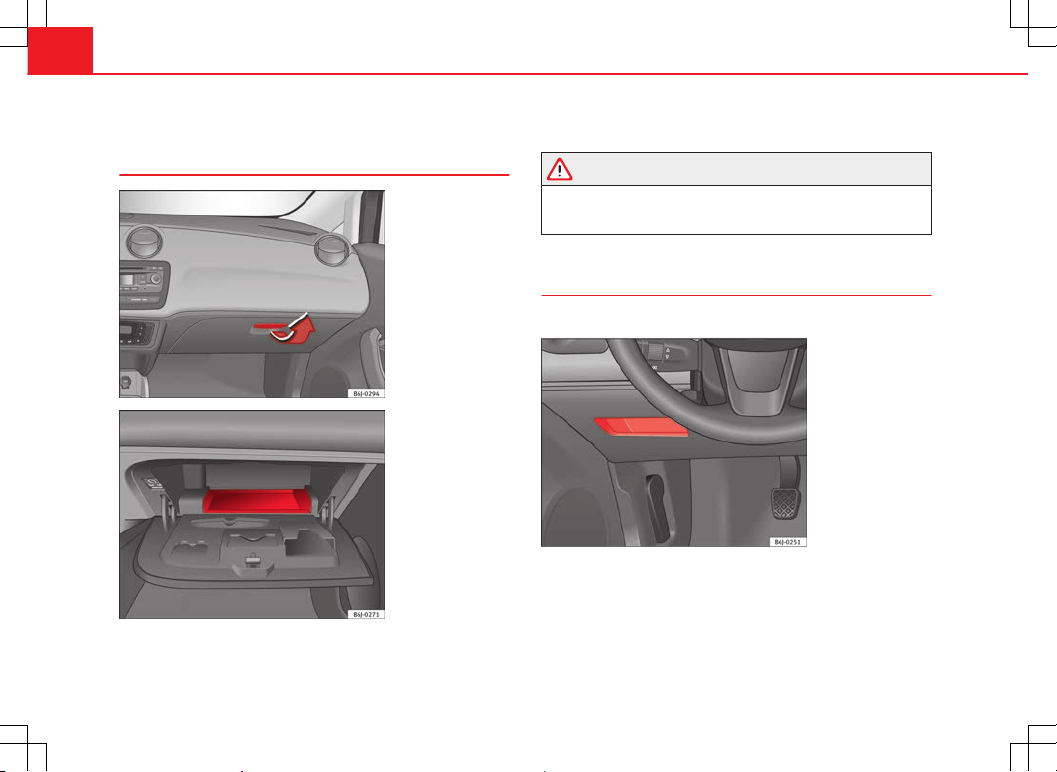

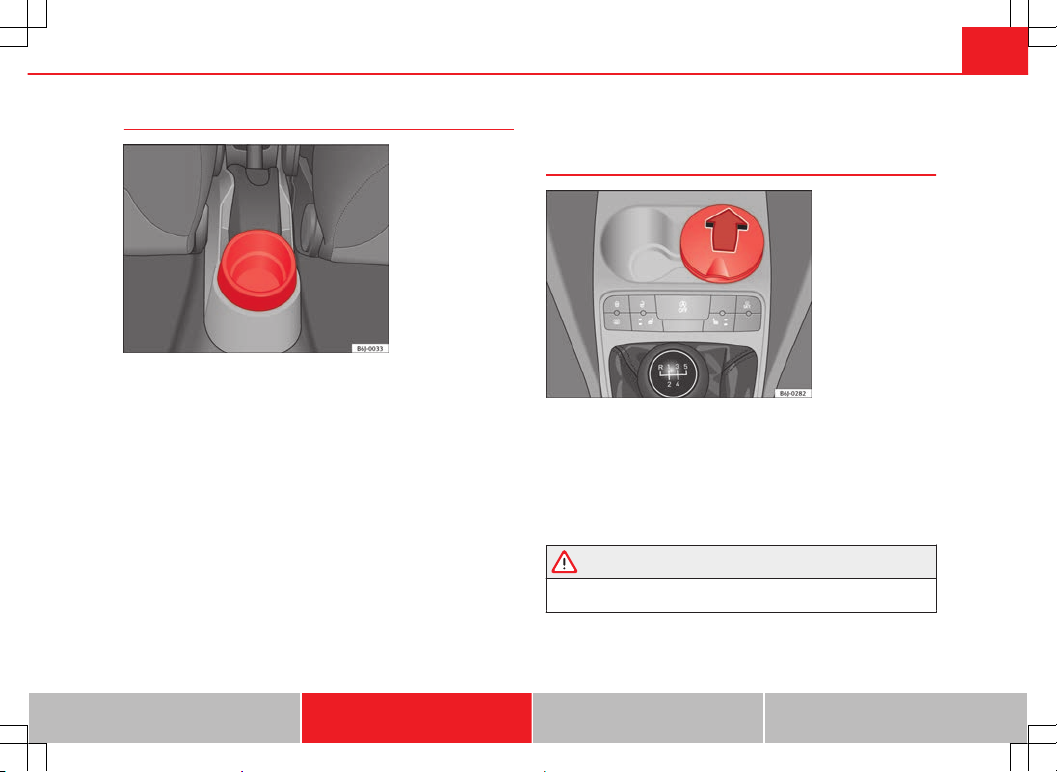

Storage compartment . . . . . . . . . . . . . . . . . . . . . . 120

Ashtrays, cigarette lighter and power socket . . . 123

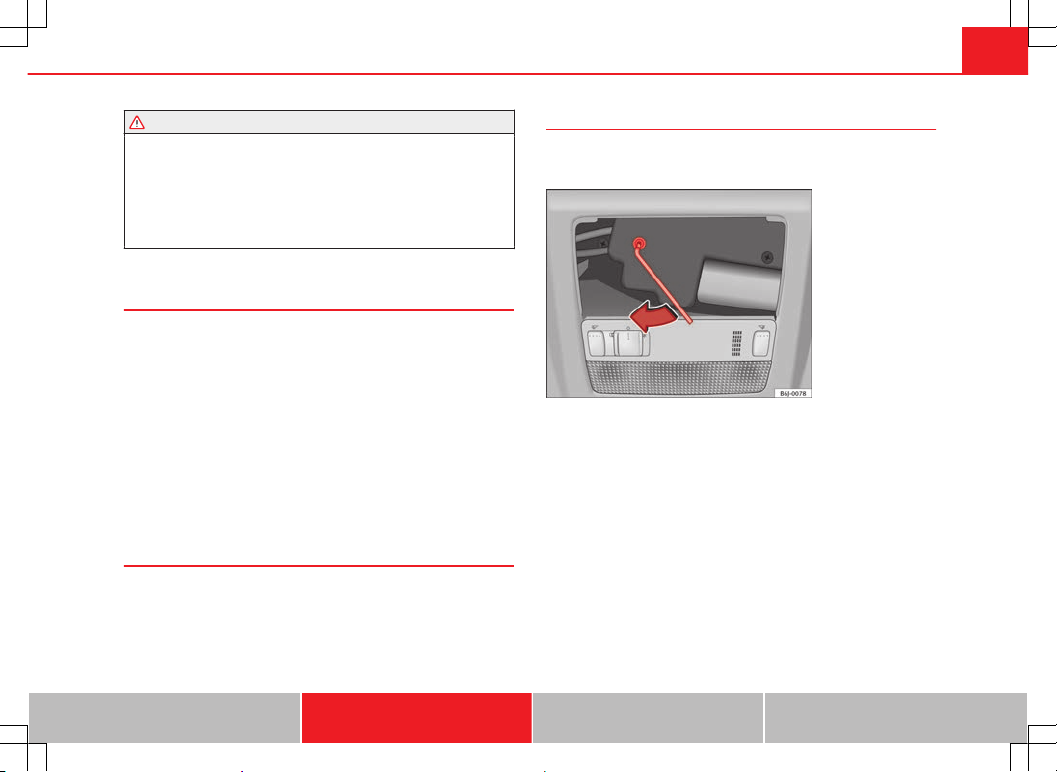

First-aid kit, warning triangle, fire extinguisher* 125

Luggage compartment . . . . . . . . . . . . . . . . . . . . . 126

Air conditioning . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

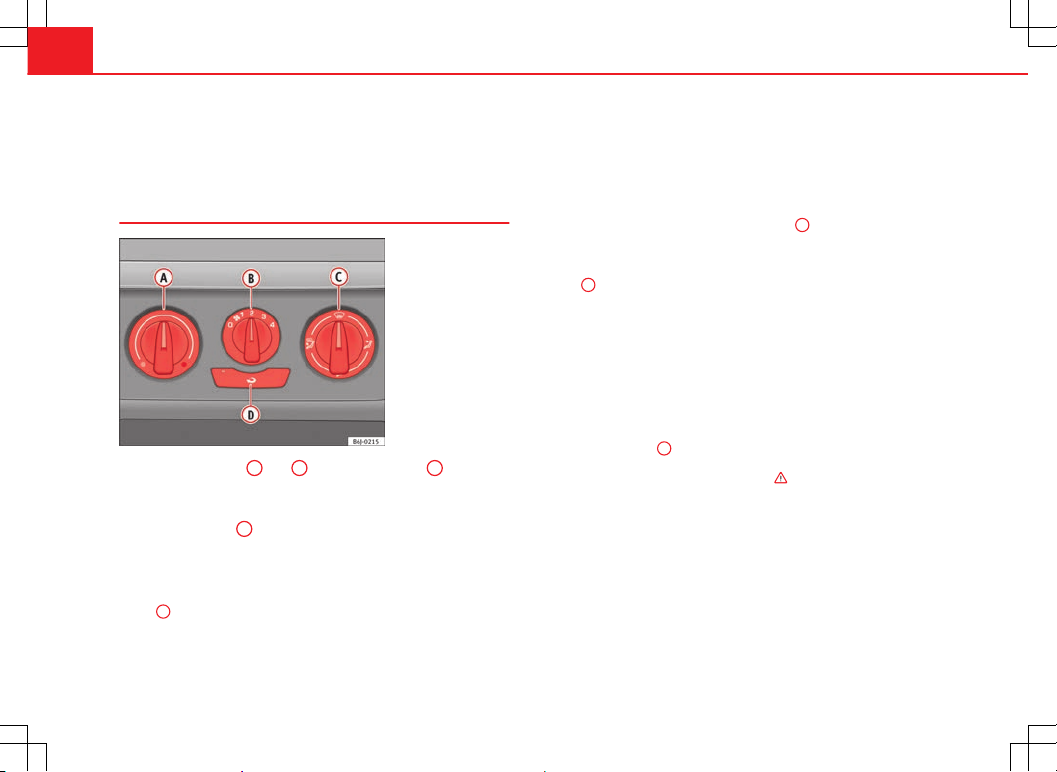

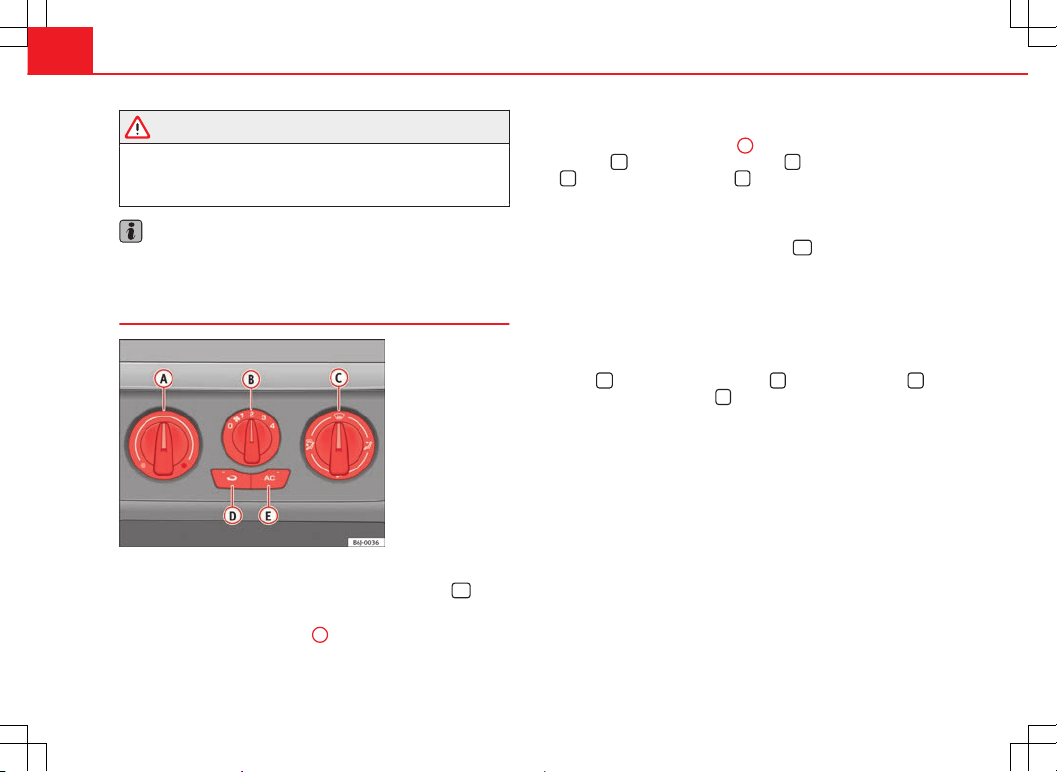

Heating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

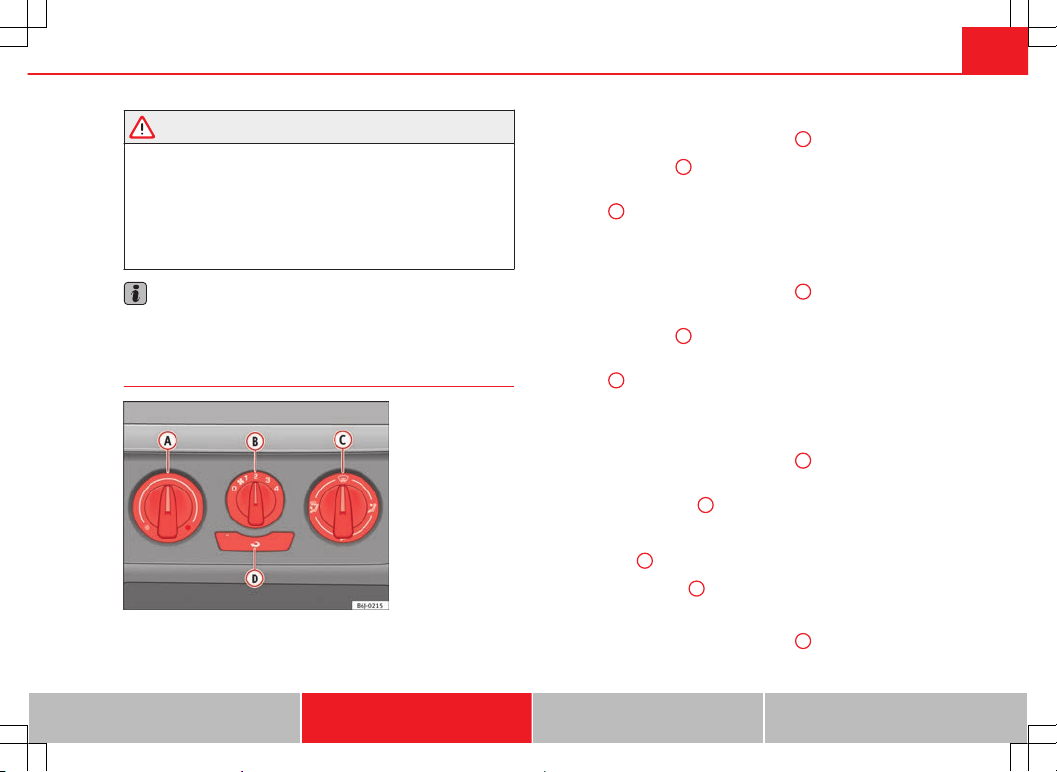

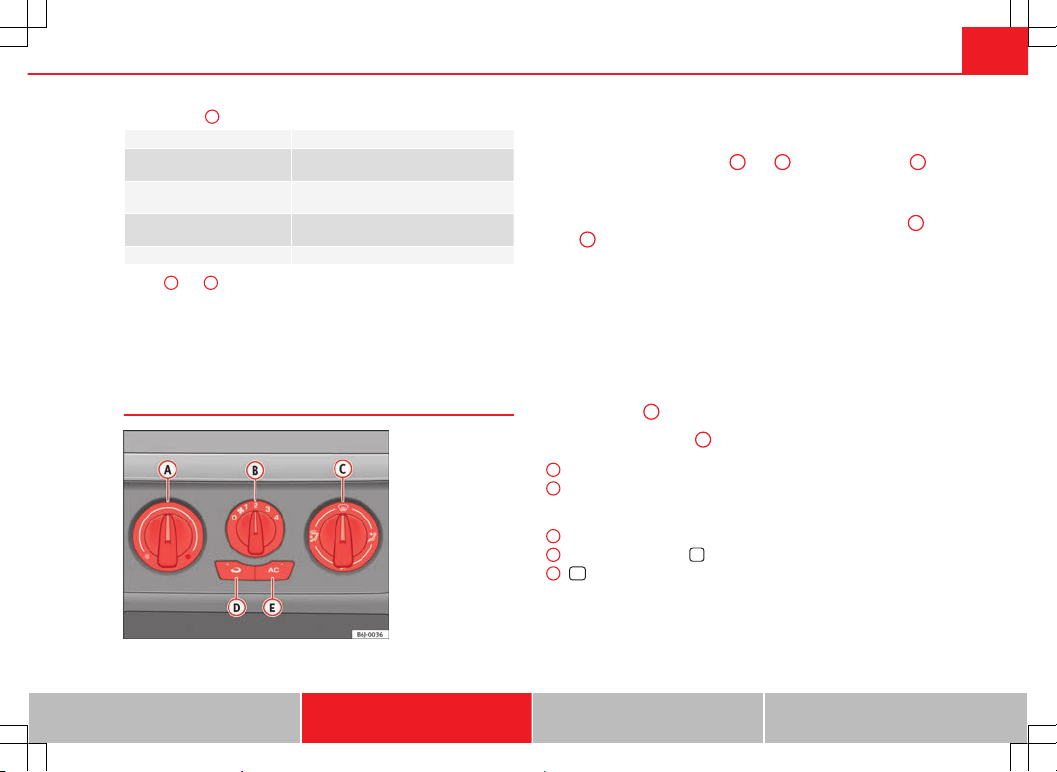

Air conditioning* . . . . . . . . . . . . . . . . . . . . . . . . . . 131

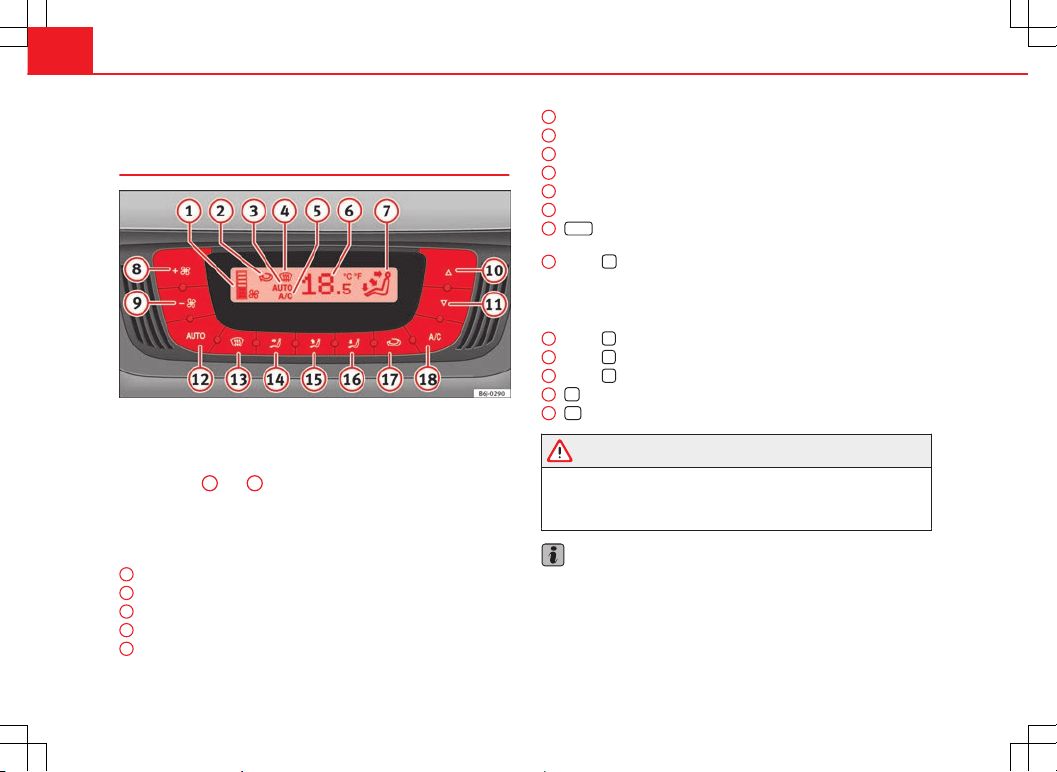

Climatronic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

General notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

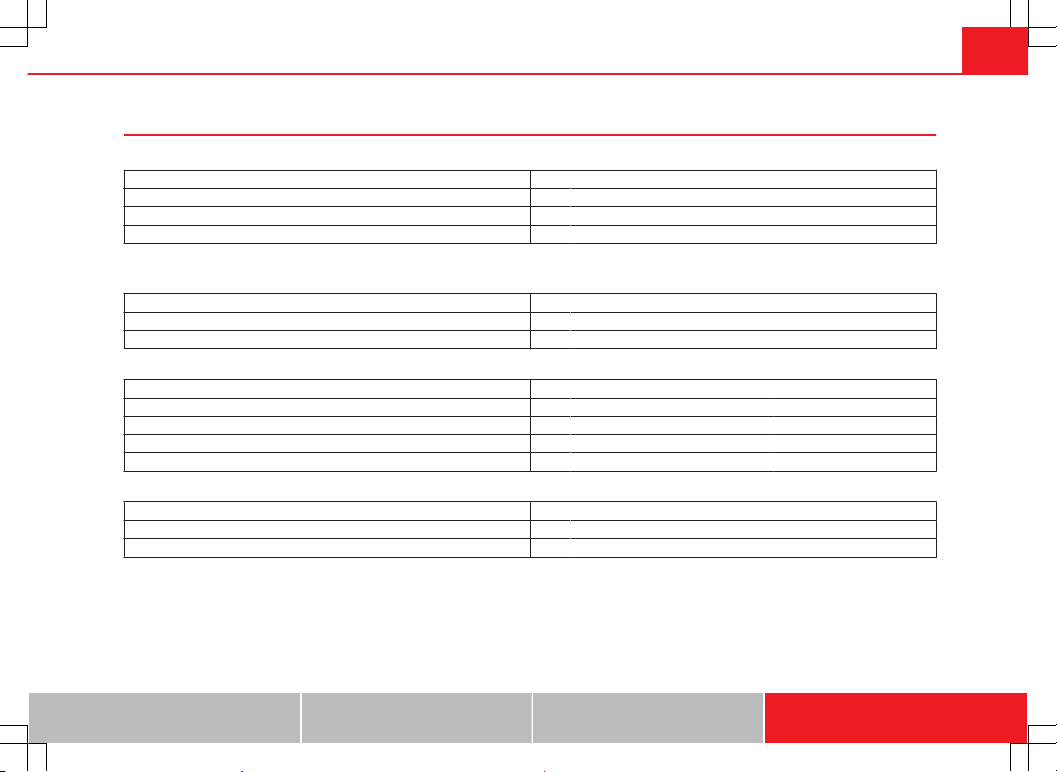

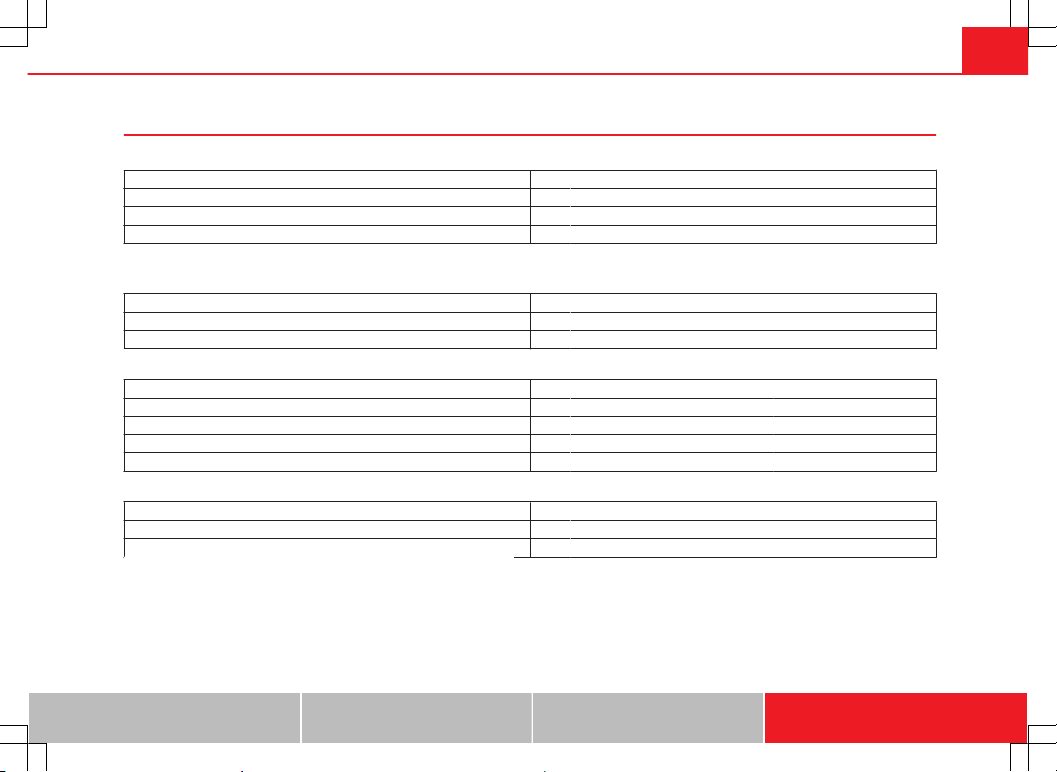

Driving . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

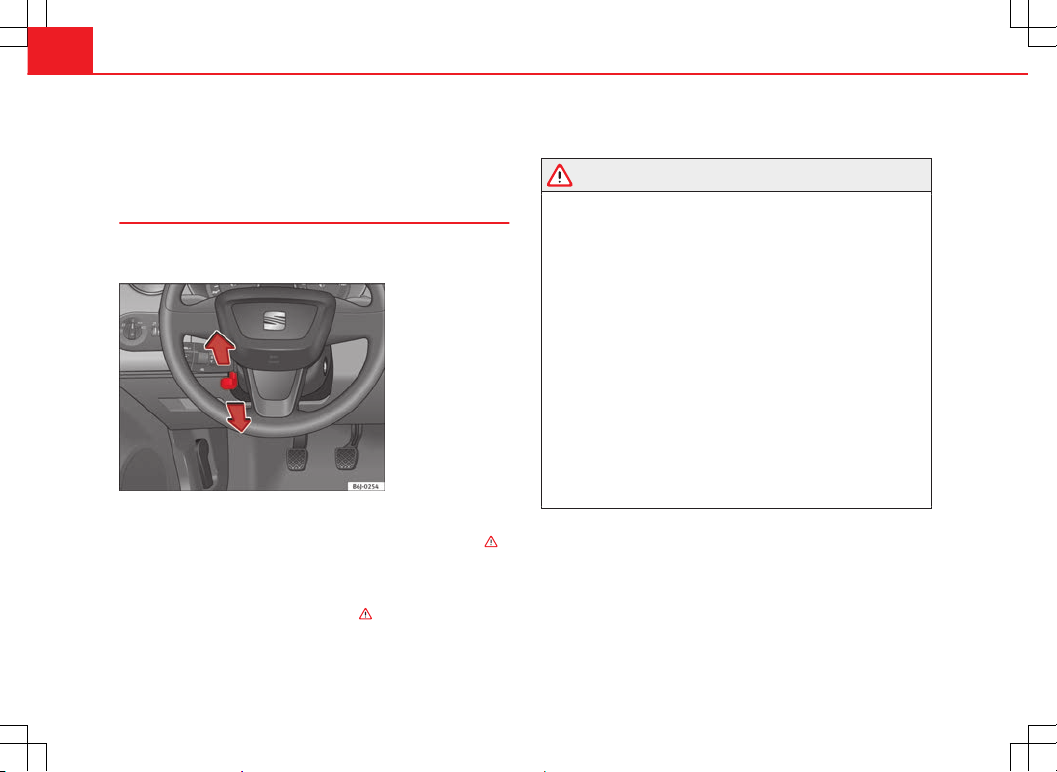

Steering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

Ignition lock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

Starting and stopping the engine . . . . . . . . . . . . 141

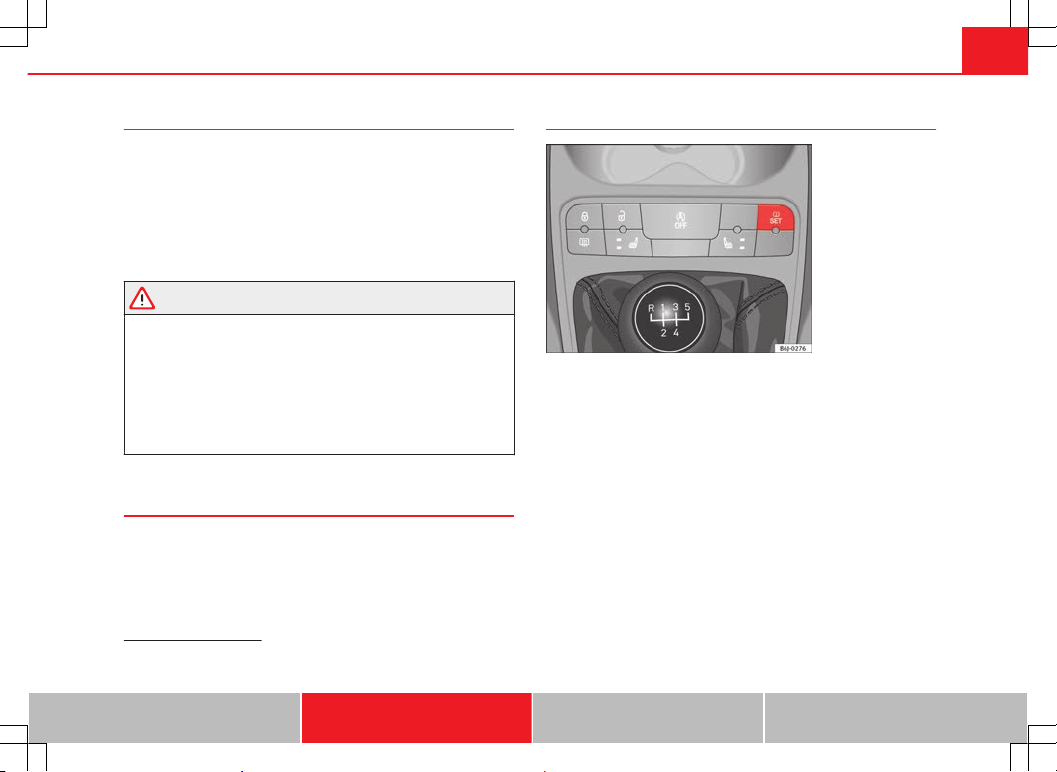

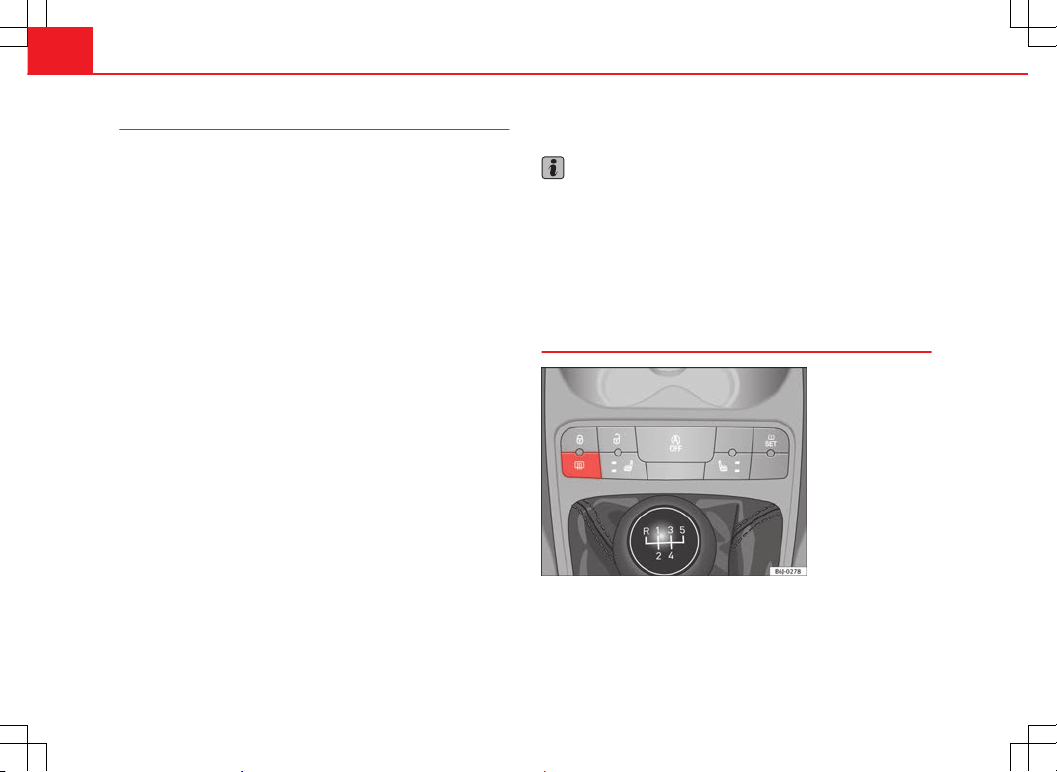

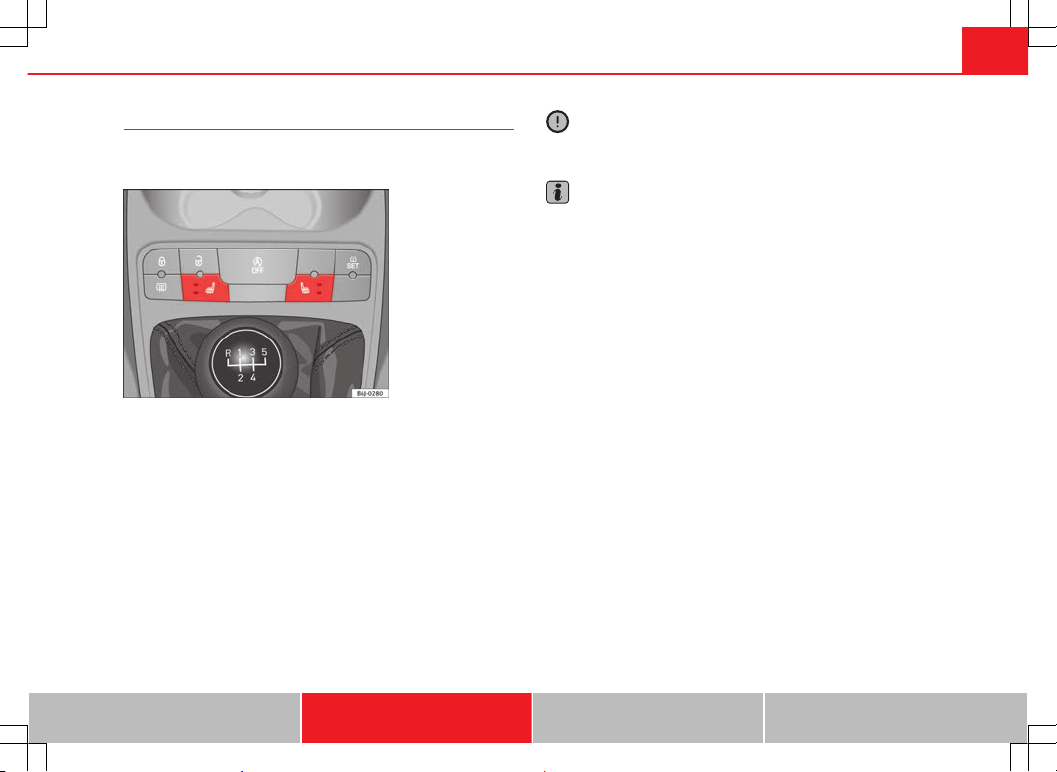

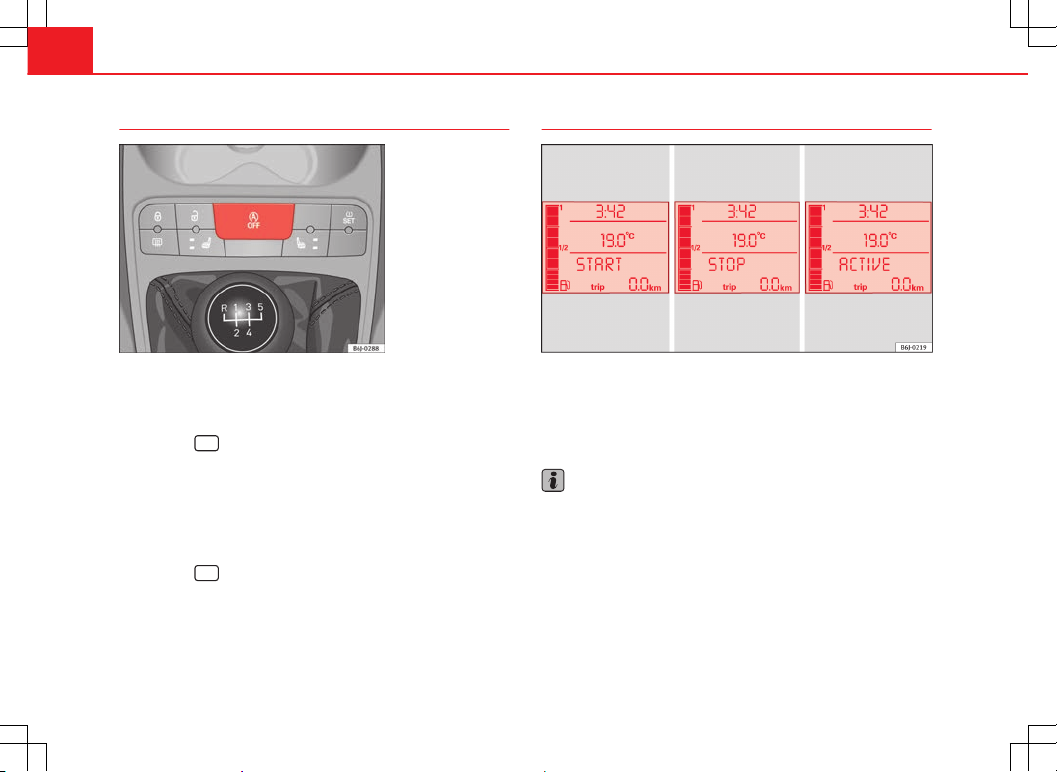

Start-Stop function* . . . . . . . . . . . . . . . . . . . . . . . 144

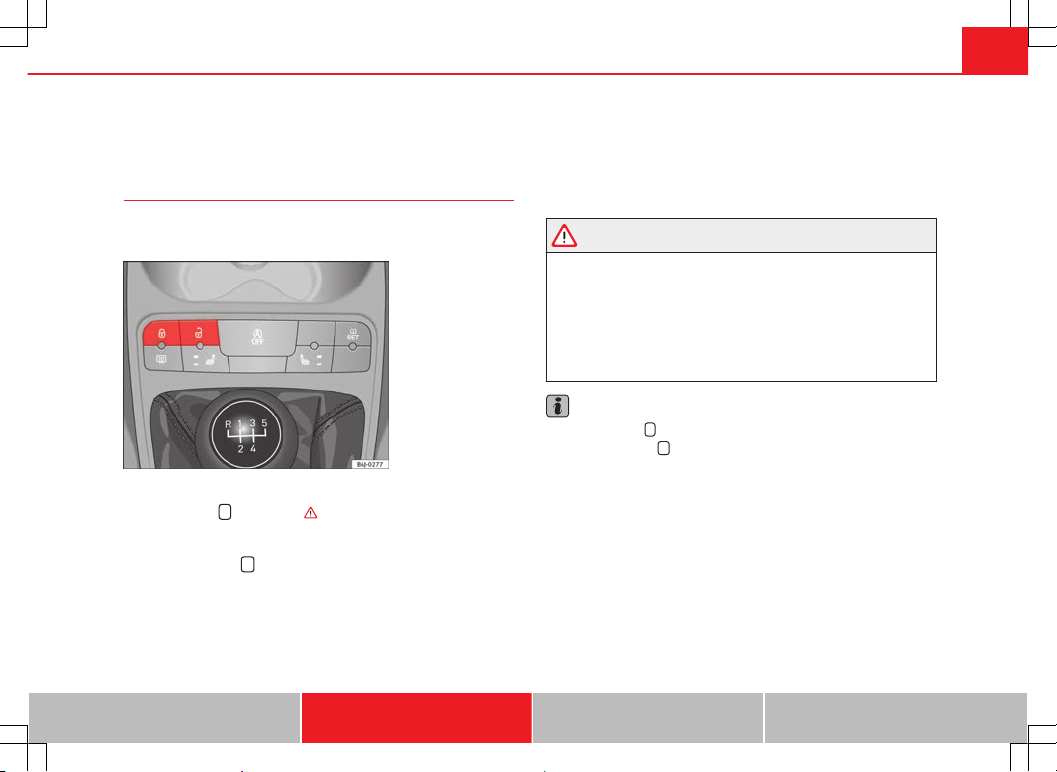

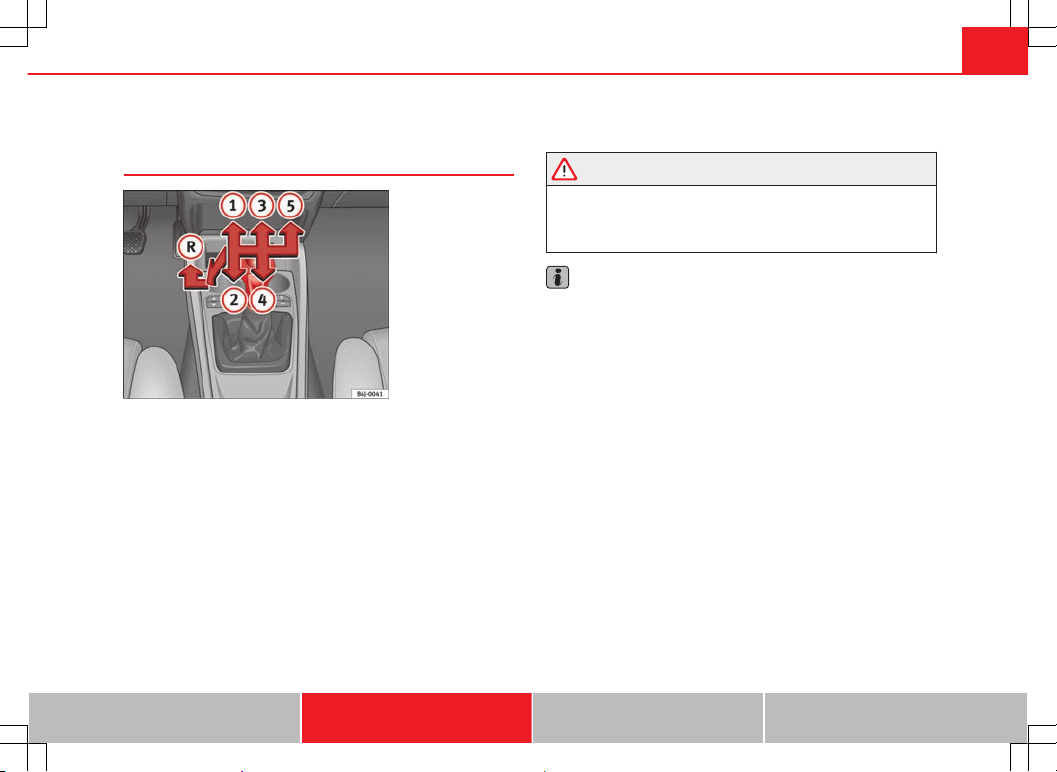

Manual gearbox . . . . . . . . . . . . . . . . . . . . . . . . . . 147

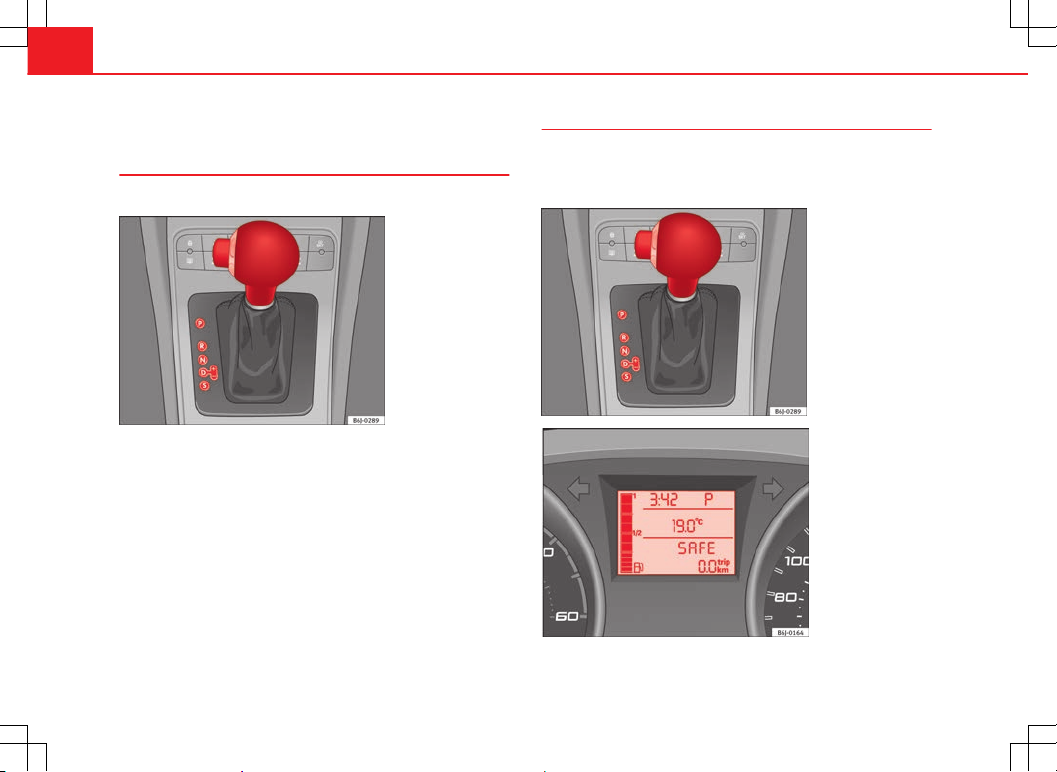

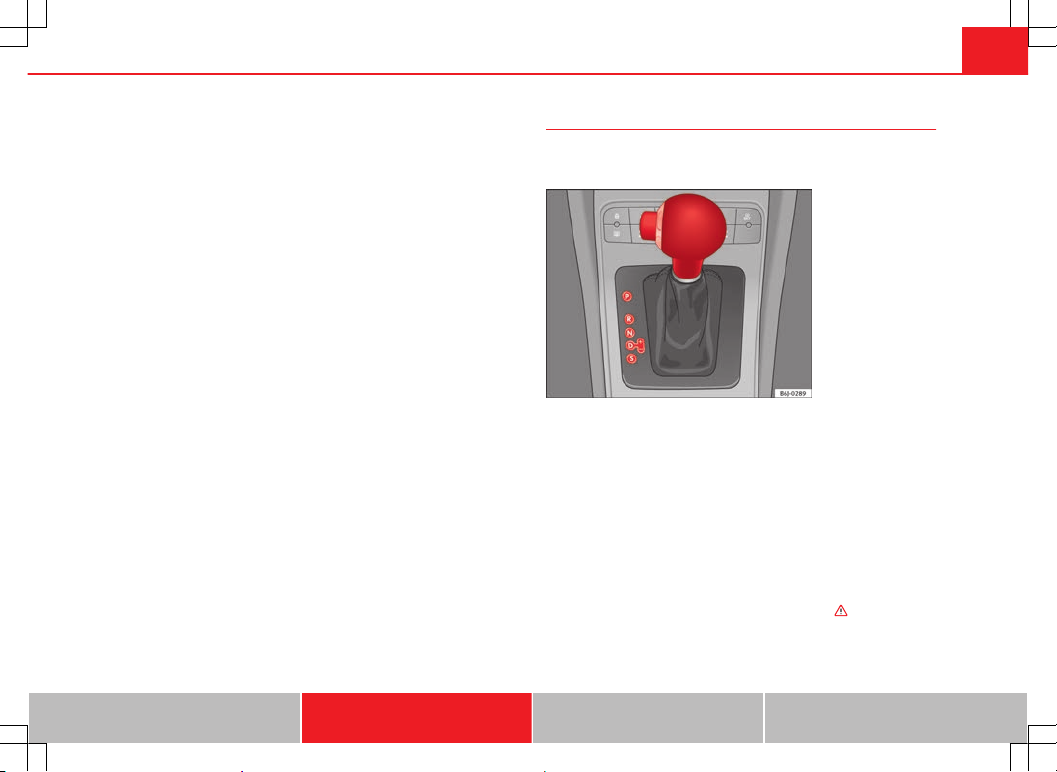

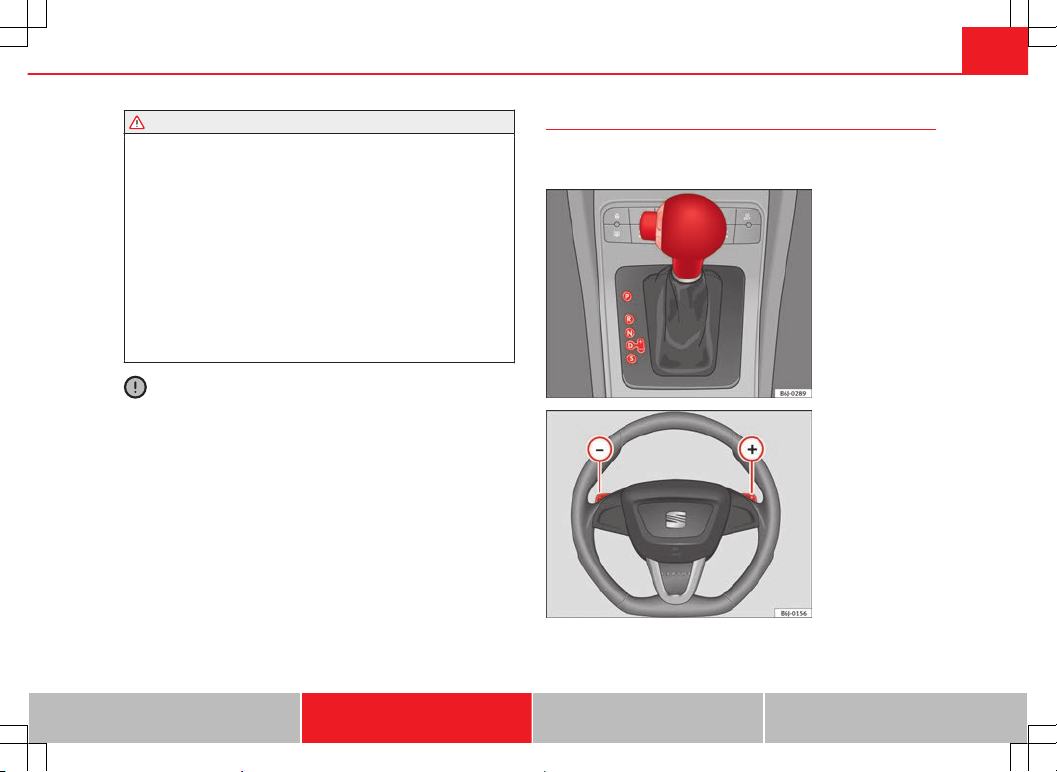

Automatic gearbox* . . . . . . . . . . . . . . . . . . . . . . . 148

Handbrake . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

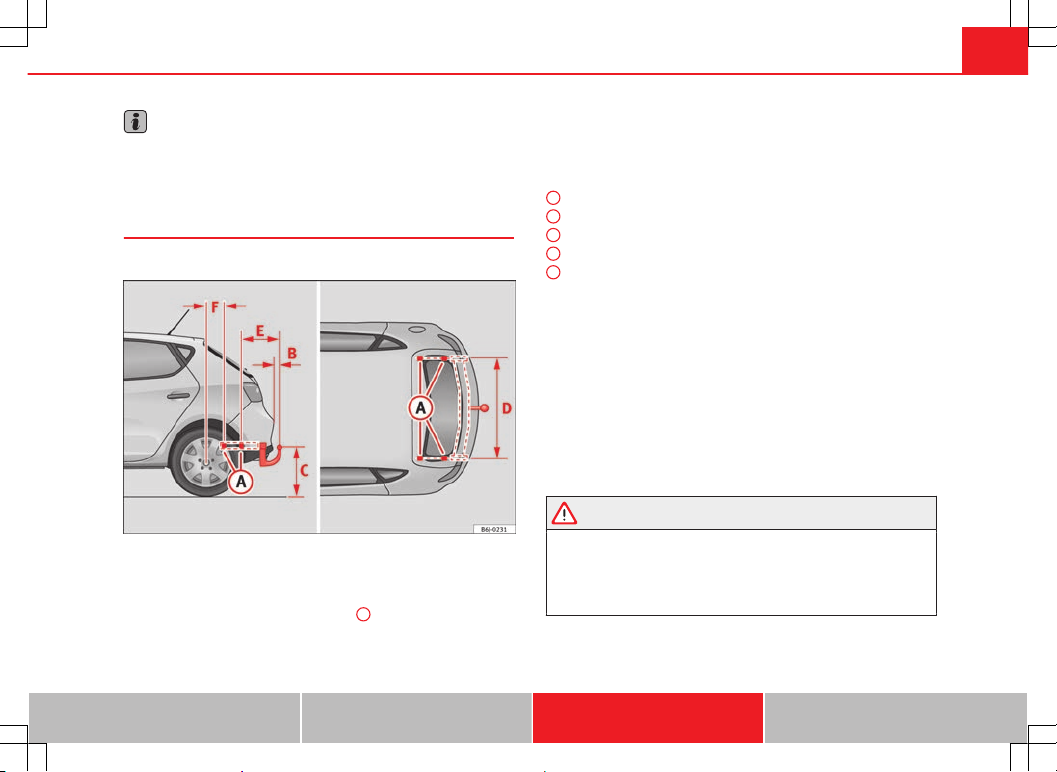

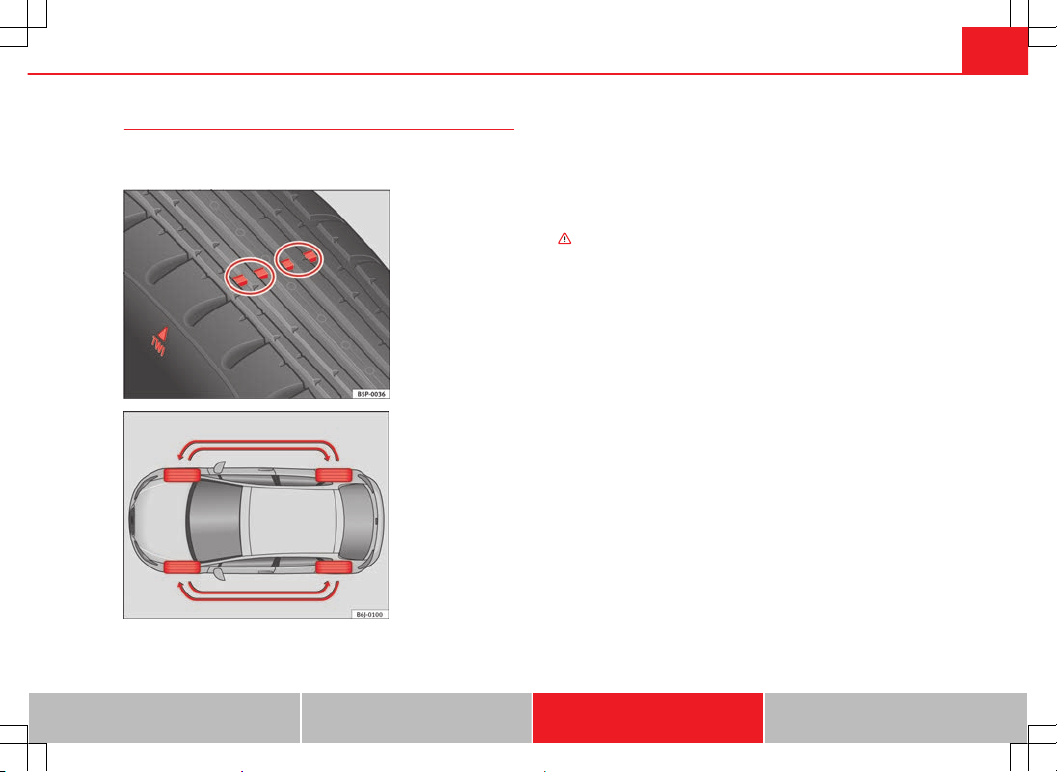

Acoustic parking aid system* . . . . . . . . . . . . . . . 157

Cruise speed* (Cruise control system) . . . . . . . . 159

Practical Tips . . . . . . . . . . . . . . . . . . . . . . . . . 163

Intelligent technology . . . . . . . . . . . . . . . . . . . . . 163

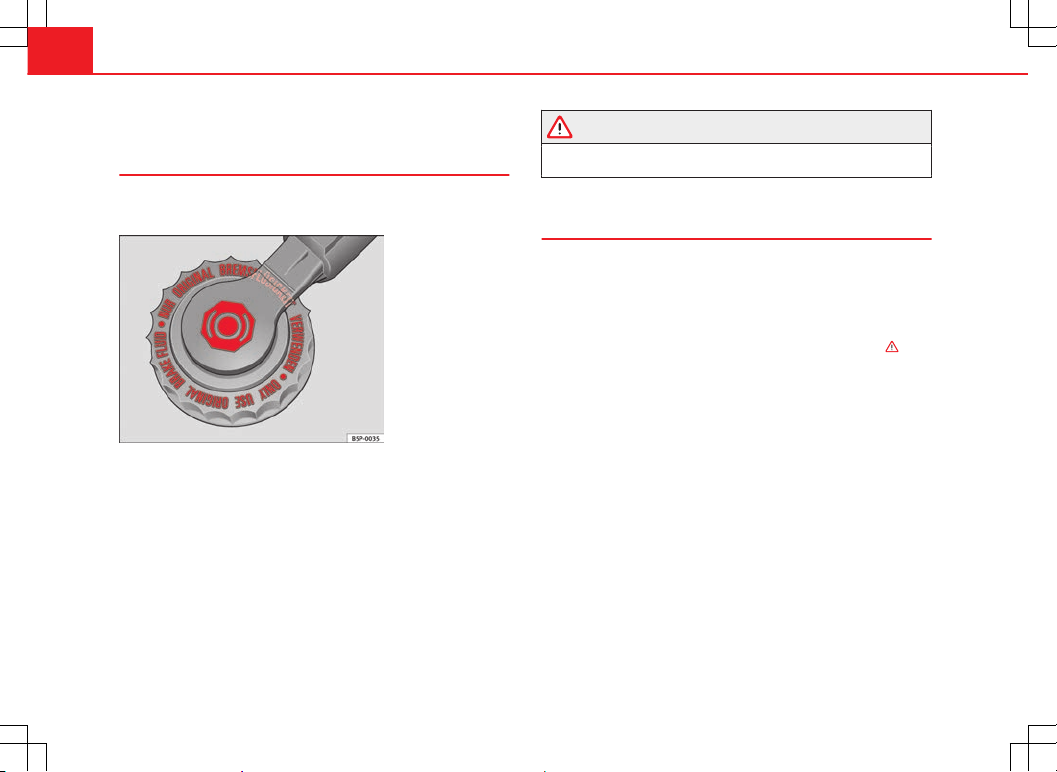

Brakes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

Anti-lock brake system and traction control ABS 164

Electronic Stability Control (ESC)* . . . . . . . . . . . . 165

Driving and the environment . . . . . . . . . . . . . . . 168

Running-in . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 168

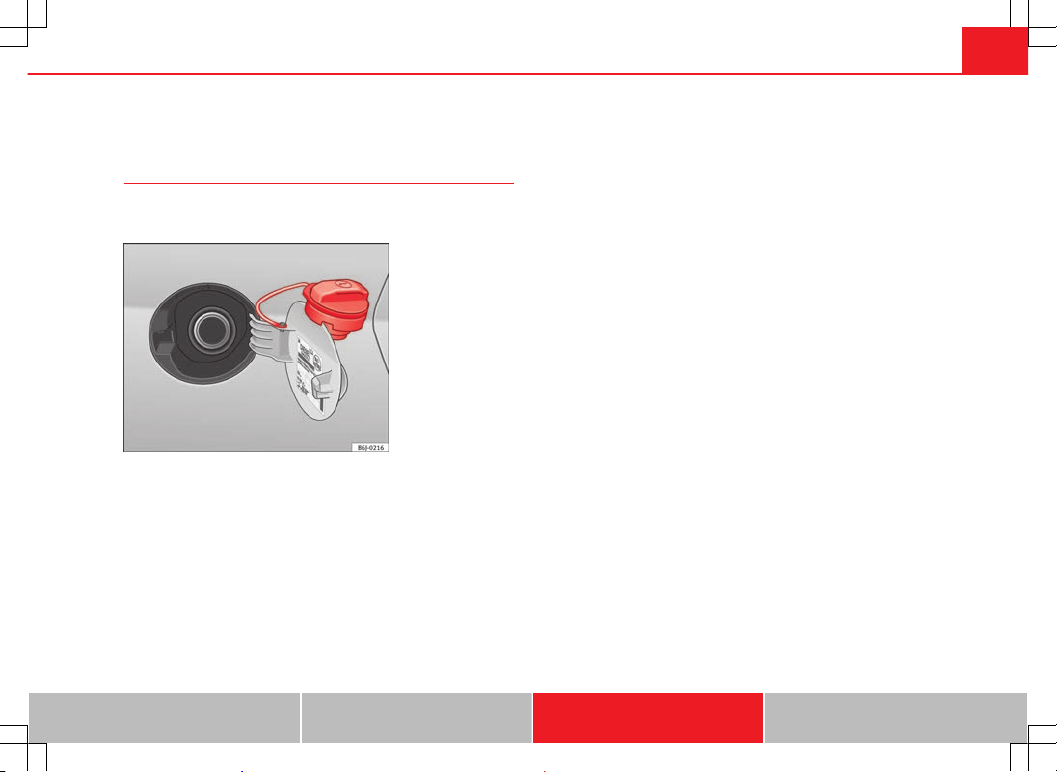

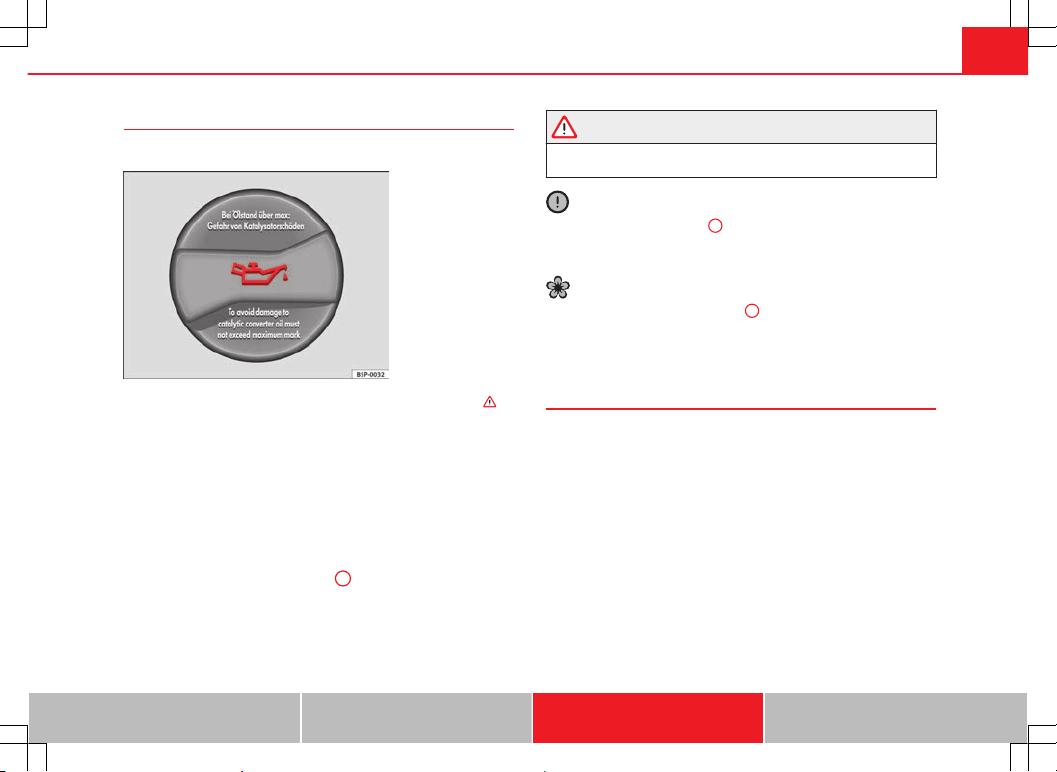

Exhaust gas purification system . . . . . . . . . . . . . 169

Economical and environmentally friendly driving 171

Driving abroad . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

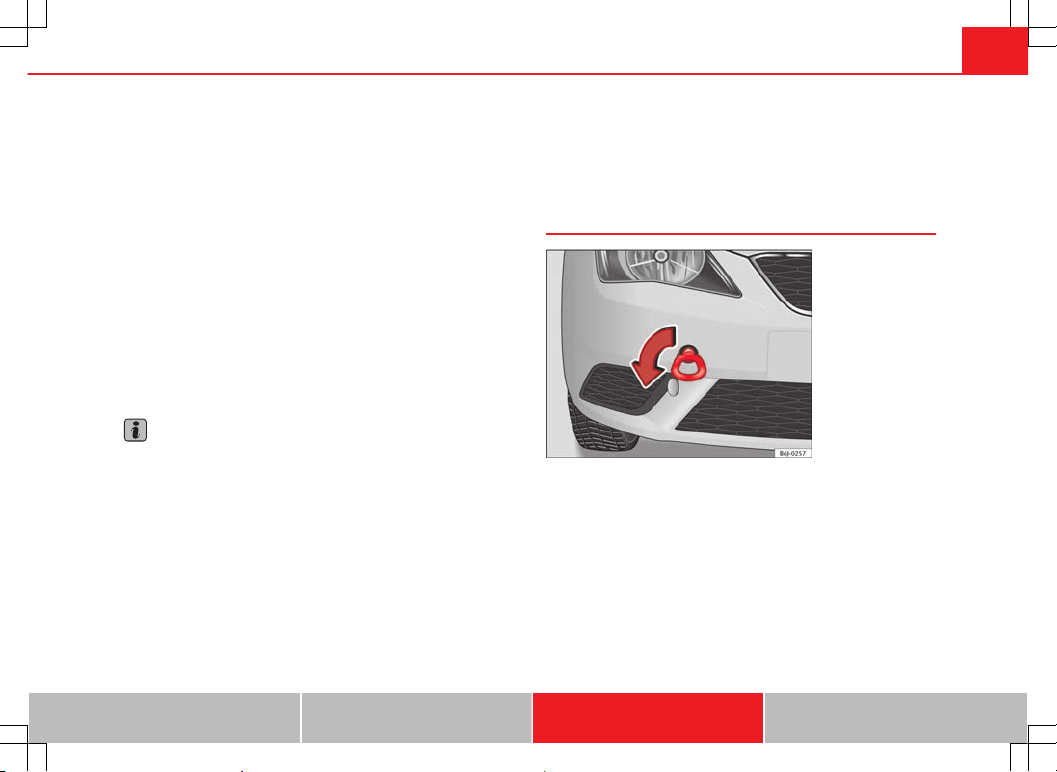

Trailer towing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

Vehicle maintenance and cleaning . . . . . . . . . 176

General notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . 176

Care of the vehicle exterior . . . . . . . . . . . . . . . . . . 177

Vehicle interior maintenance . . . . . . . . . . . . . . . . 182

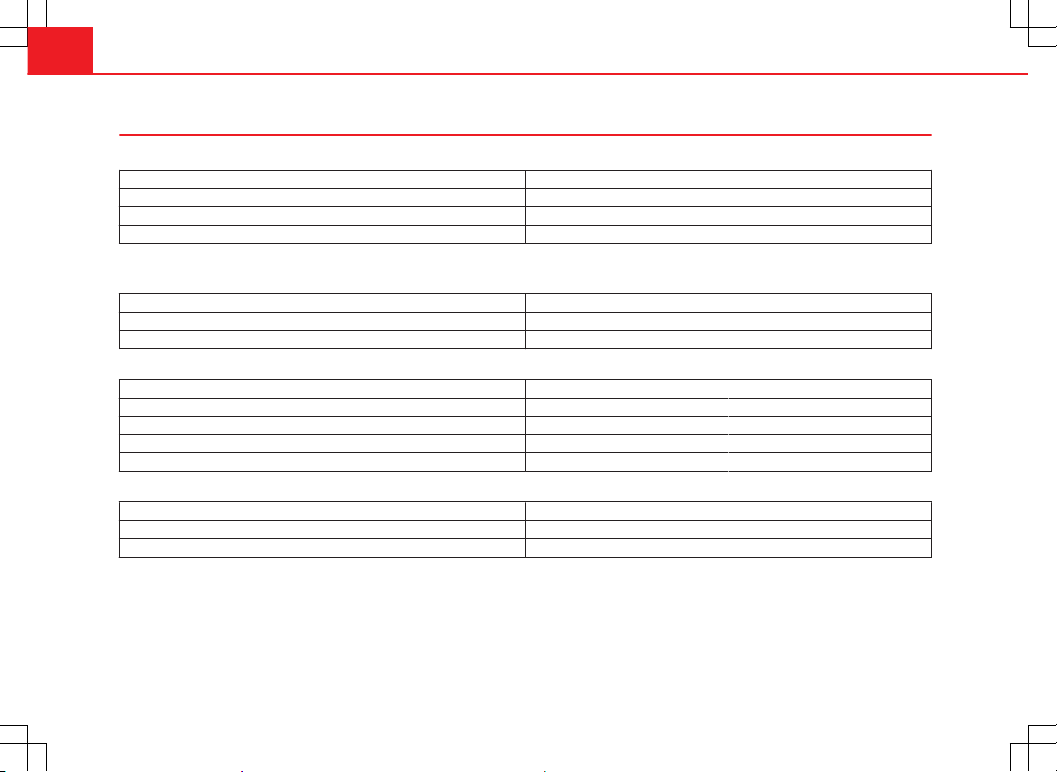

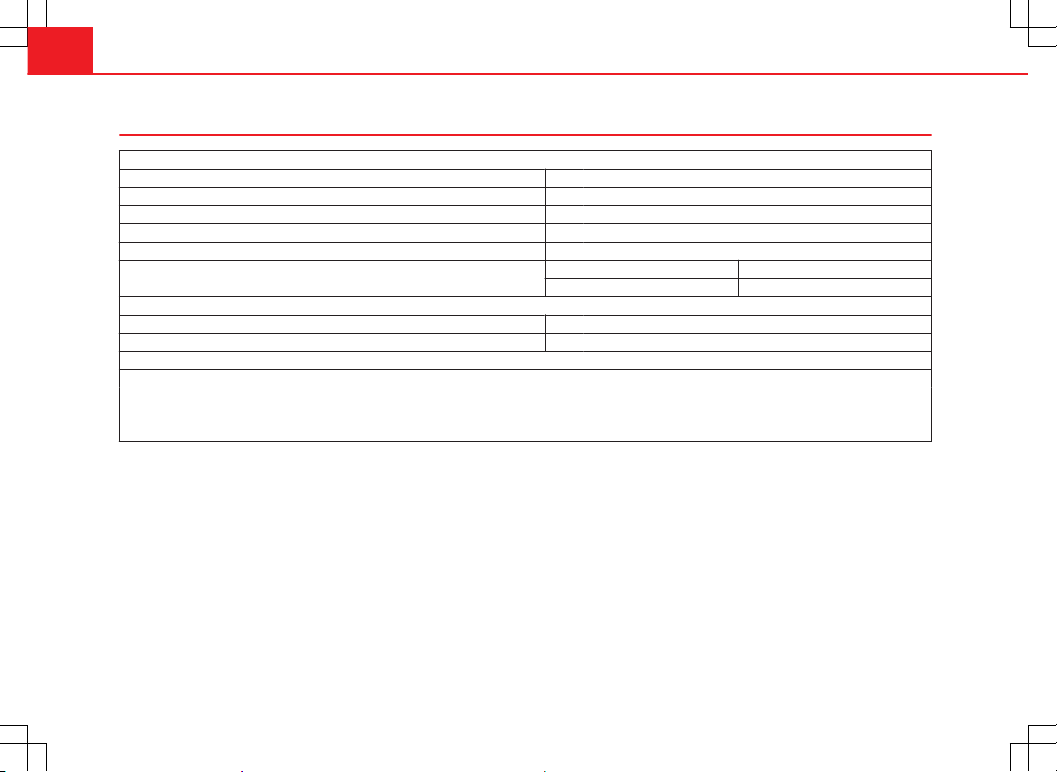

3Table of Contents