english 13

Trouble shooting

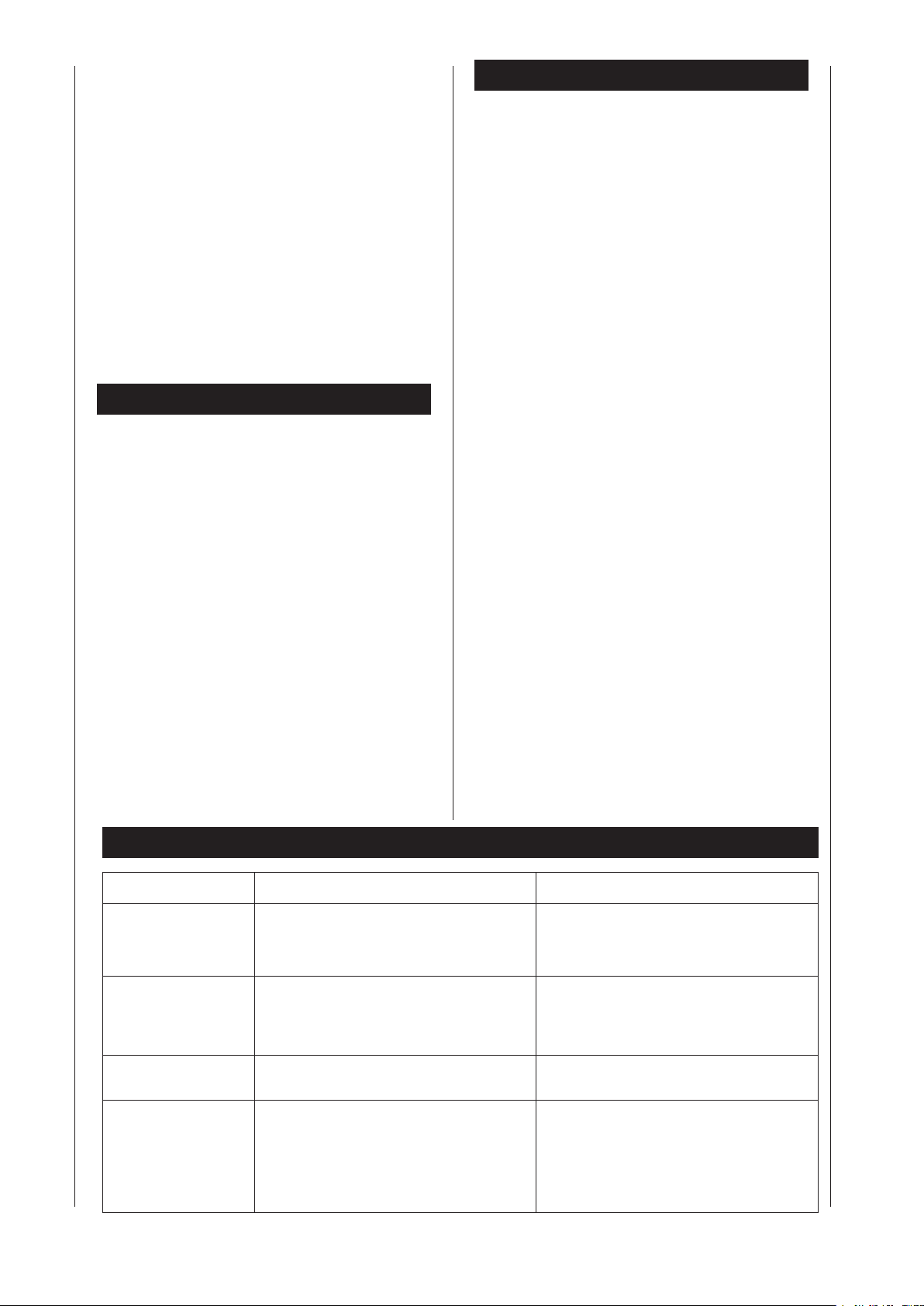

Problem Possible Cause Help

Saw blade gets loose

after turning off the

motor

Fastening nut tightened insufficiently Tighten fastening nut, M20 left-handed

thread

Motor does not start a) Fastening nut tightened insufficiently

b) Extension cable defect

c) Connections on the motor or switch defect

a) Check the mains fuse.

b) See “Electrical Connection” in the

operating manual

c) Have it checked by an electrician

No motor output turns

off automatically

Overload by dull saw blade, thermoprotection

is triggered

Insert a sharpened saw blade; motor can be

turned on again after the cooling period

Burns on the cutting

surface

c) with longitudinal

cuts

d) with cross cuts

a) Fastening nut tightened insufficiently

b) Wrong saw blade

c) Longitudinal stop not parallel

d) Slide carriage not parallel

a) Insert a sharpened saw blade

b) Insert saw blade with 20 or 28 teeth for

longitudinal cuts

c) Exchange the longitudinal stop

Align the slide carriage with the saw blade

AC motor Fig. 10

• The supply voltage must be 230 V / 50 Hz.

• Extension lines up to a length of 25 m must have a cross

section of 1.5 square millimetres. Extension lines with a

length of more than 25 m must have a minimum cross

section of 2.5 square millimetres.

• The mains connection is protected with a delay-action

fuse of 16 A.

If you have further questions, please specify the follow-

ing:

• Motor manufacturer

• Kind of current of the motor

• Data from the machine type plate

• Data from the switch type plate

If you return the motor, always return the complete drive

unit with the switch.

Maintenance

Perform resetting, measuring, and cleaning work exclu-

sively when the motor is turned off. Disconnect the mains

plug, and wait until the rotating tool stands still.

All protection and safety devices must be immediately re-

installed once the repair and maintenance work is com-

pleted.

The built-in ball bearings are maintenance-free.

Recommendations:

• Slightly re-lubricate the slewing segments of the table

and the bend tensioning device.

• Regularly clean the saw band. Wood leaves resin sedi-

ments. We recommend the deresinifying concentrate

Pharmol HEK, item no. 61009700 for the cleaning.

• Regularly check the guiding rollers and the counterpres-

sure bearings. If required, readjust or disassemble them,

and grease or exchange the parts.

• Exchange worn-out table inserts.

• Ensure that the tabletop is always free of resin.

Special Accessories

Artikel Art. No.

Cross cutting jig 7322 0710

Saw bands for wood:

12/0,36/1490 mm, 4 teeth/inch 7322 0701

10/0,36/1490 mm, 14 teeth/inch 7322 0702

6/0,36/1490 mm, 24 teeth/inch 7322 0703

for wood and synthetic materials:

6/0,36/1490 mm, 6 teeth/inch 7322 0704

Turning works with small radius 25 mm

3/0,45/1490 mm, 14 teeth/inch 7322 0705

Precision cutting works