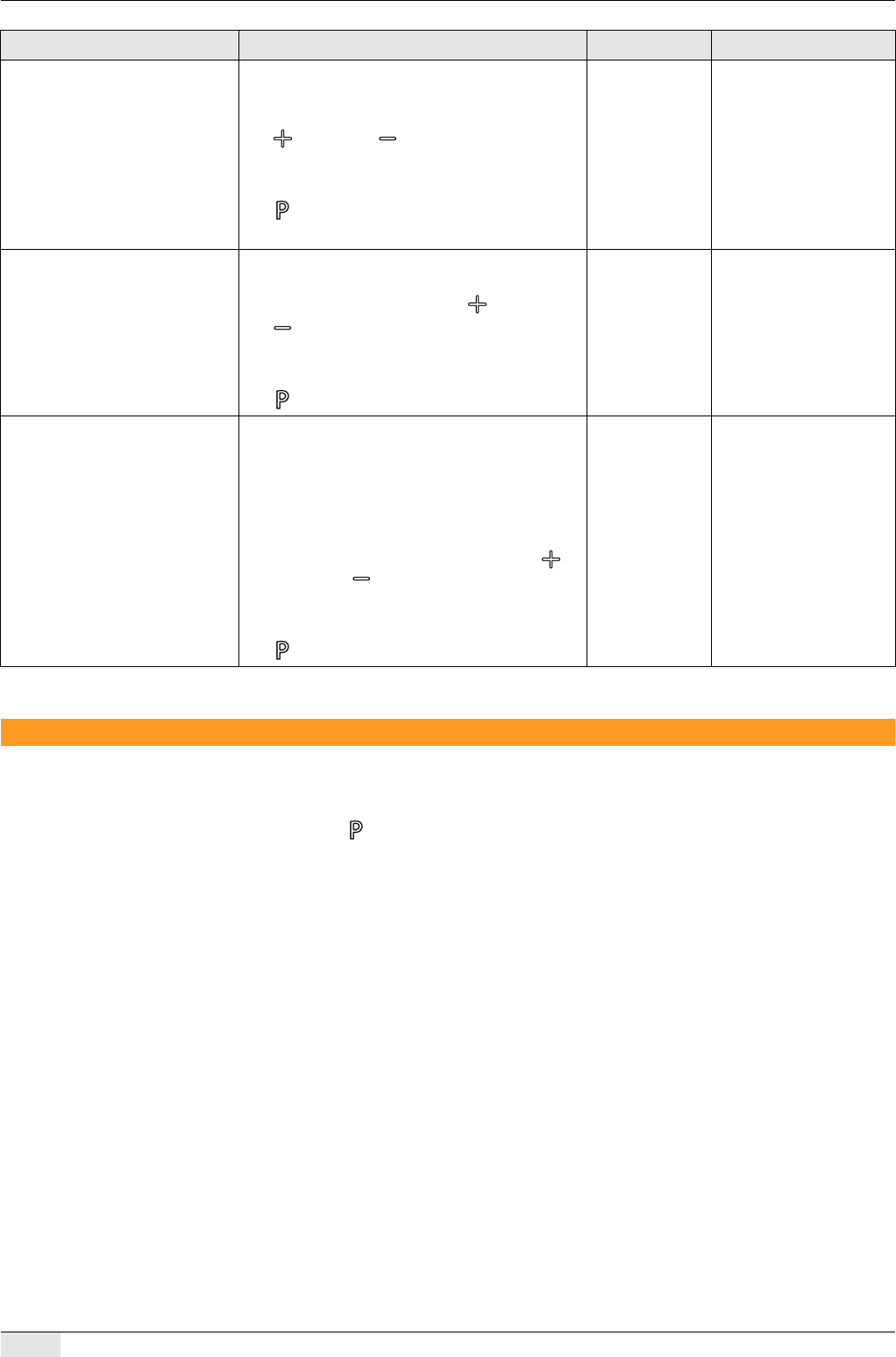

-

Hoe zet je deze machine terug in fabrieksinstellingen? Gesteld op 8-1-2025 om 12:40

Reageer op deze vraag Misbruik melden -

Onze machine geeft maar twee van de vijf mogelijkheden weer.

Reageer op deze vraag Misbruik melden

Hoe krijg ik ze alle 5 in werking? Gesteld op 8-1-2025 om 12:36 -

Onze machine blijft hangen in de opwarmfase omdat er telkens de melding 'Doorstroming gestopt' verschijnt. Alles al geprobeerd. Het lijkt alsof alle leidingen prima doorstroming hebben en af en toe geeft het pijpje voor heet water een stoomwolk en wat gepruttel, maar geen vast water. Omdat de opwarmfase nooit voorbij gaat kunnen we verder ook niets met het bedieningspaneel doen.... Wie weet raad? Gesteld op 29-2-2024 om 14:27

Reageer op deze vraag Misbruik melden-

Check de handleiding pagina 40. Klik op deze LINK Geantwoord op 1-3-2024 om 09:28

Waardeer dit antwoord Misbruik melden

-

-

Het ontkalkinsprogramma blijft hangen op 1 minuut en gaat niet verder. Weet iemand hoe ik dit kan onderbreken?

Reageer op deze vraag Misbruik melden

Gesteld op 25-1-2024 om 22:22-

Hier ook last van. Iemand al een oplossing

Waardeer dit antwoord Misbruik melden

Geantwoord op 27-11-2024 om 16:43

-

-

De espressomachine JOY loopt slecht door en geeft geen crema Gesteld op 25-1-2024 om 06:03

Reageer op deze vraag Misbruik melden -

Mijn Schaerer joy heeft de knoppen voor melk en cappuccino geblokkeerd. Hoe kan ik die weer 'enablen" Gesteld op 24-12-2023 om 16:06

Reageer op deze vraag Misbruik melden-

Check vraag van Gesteld op 27-10-2021 om 22:20 hieronder. Geantwoord op 31-12-2023 om 15:08

Waardeer dit antwoord (5) Misbruik melden

-

-

Kaffee joy geeft doorstroming gestopt.Alles in de handleiding gedaan.Storing blijft zich voordoen,behalve bij caffee crème.Deze doet het lang goed.Denk dat het voorzetten oftewel padjes voor bevochtigen stopt of niet goed wordt uitgevoerd omdat de gemalen koffie bonen droog worden afgevoerd.Wie weet er raad,?

Reageer op deze vraag Misbruik melden

groet rene Gesteld op 29-5-2023 om 13:09-

Wij hebben ook dit probleem, al een oplossing gehad?

Waardeer dit antwoord Misbruik melden

Geantwoord op 14-8-2023 om 08:47

-

-

apparaat is naar de kringloop Geantwoord op 14-8-2023 om 10:09

Waardeer dit antwoord Misbruik melden -

Mijn machine geeft time-out niveau aan. Wat moet ik doen. Of wat is er dan aan de hand met deze machine. Gesteld op 28-4-2023 om 21:45

Reageer op deze vraag Misbruik melden -

Goedemiddag

Reageer op deze vraag Misbruik melden

Mijn vraag is:apparaat geeft aan molen blokkeert; hoe los ik dit op? Gesteld op 26-4-2023 om 17:46 -

Foutmelding drankkeuze geblokeerd zeteenh.eindschak wat kan dat wezen Gesteld op 14-12-2022 om 10:35

Reageer op deze vraag Misbruik melden-

brewer verwijderen en kijken onderaan in toestel, zit waarschijnlijk vol koffiedras waardoor brewer niet meer naar home posistie kan gaan Geantwoord op 9-4-2023 om 13:39

Waardeer dit antwoord (5) Misbruik melden

-

-

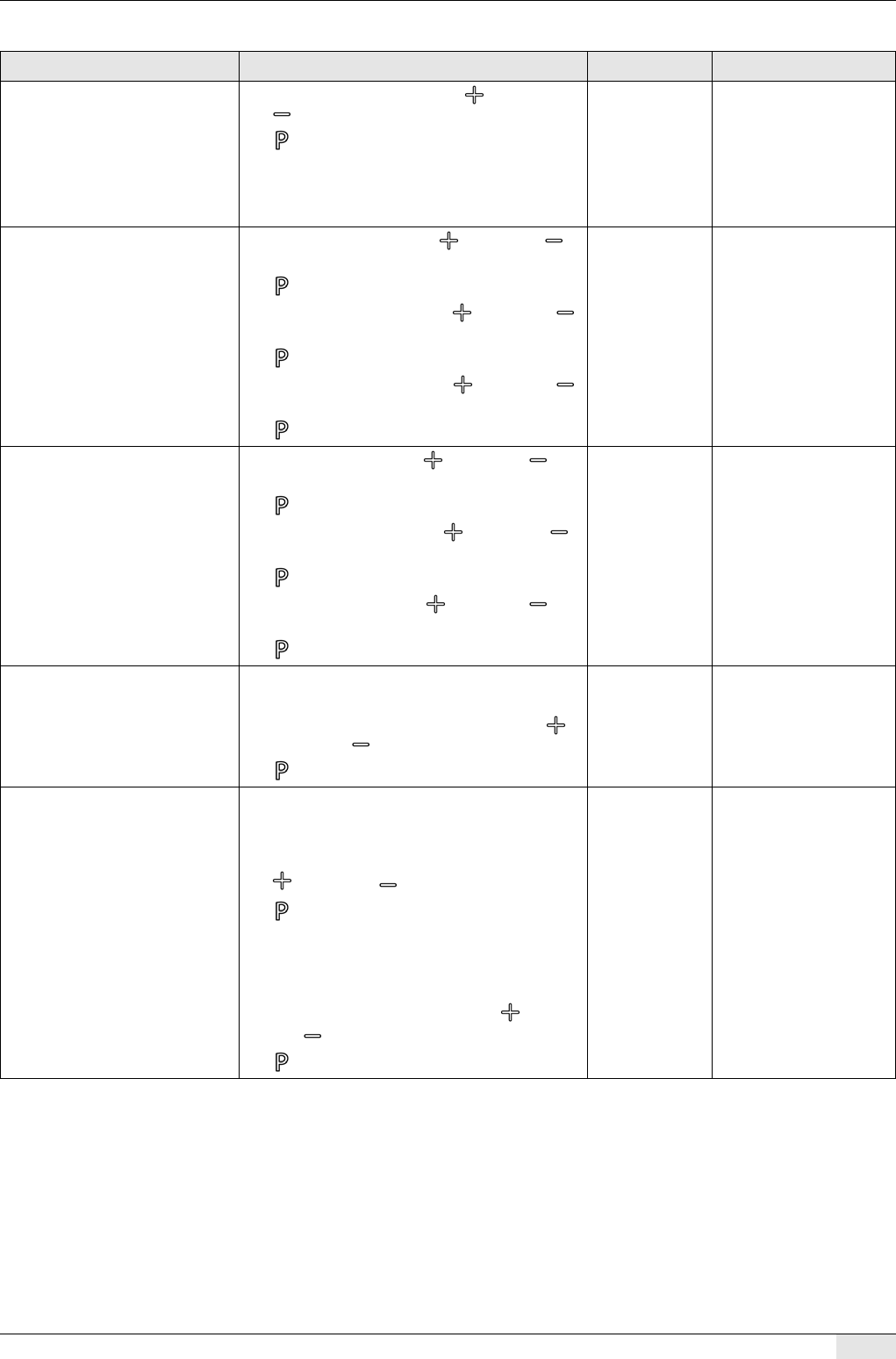

Goedendag,

Reageer op deze vraag Misbruik melden

Mijn Schaerer Coffee apparaat geeft de melding 'brewer verstopt'. Nu heb ik de brewer verwijderd, schoongemaakt en afgespoeld maar het probleem blijft. Weet iemand op dit forum wat ik nog meer kan doen om dit te verhelpen?

Met vriendelijke groeten,

Frits

Gesteld op 13-7-2022 om 15:53 -

bij ons geeft de machine steeds time out rechterkant aan... vanalles geprobeerd maar doet het nog steeds niet wie weet een oplossing Gesteld op 20-4-2022 om 11:15

Reageer op deze vraag Misbruik melden

-

Wat betekent bij de schaerer coffee joy de tekst

Reageer op deze vraag Misbruik melden

opwarmen time-out niveau

Gesteld op 6-3-2022 om 09:51 -

Ik zoek een lekbak voor de Schaerer Coffee Joy. Het lipje wat de aanwezigheid van de bak moet aangeven is afgebroken. Wie kan me daar aan helpen? Gesteld op 8-11-2021 om 11:07

Reageer op deze vraag Misbruik melden-

Goede middag. Wij hebben nog een nette gebruikte onderbak liggen. Als u interesse heeft kunt u mij bereiken via Koffieservice Flakkee Geantwoord op 20-11-2021 om 00:43

Waardeer dit antwoord Misbruik melden

-

-

Ik heb n schroefje op deze plek van binnenuit naar buiten gedraaid. En de afstand zo aangepast dat de machine weer de lekvak herkent. Het werkt perfect Geantwoord op 14-11-2024 om 14:02

Waardeer dit antwoord Misbruik melden -

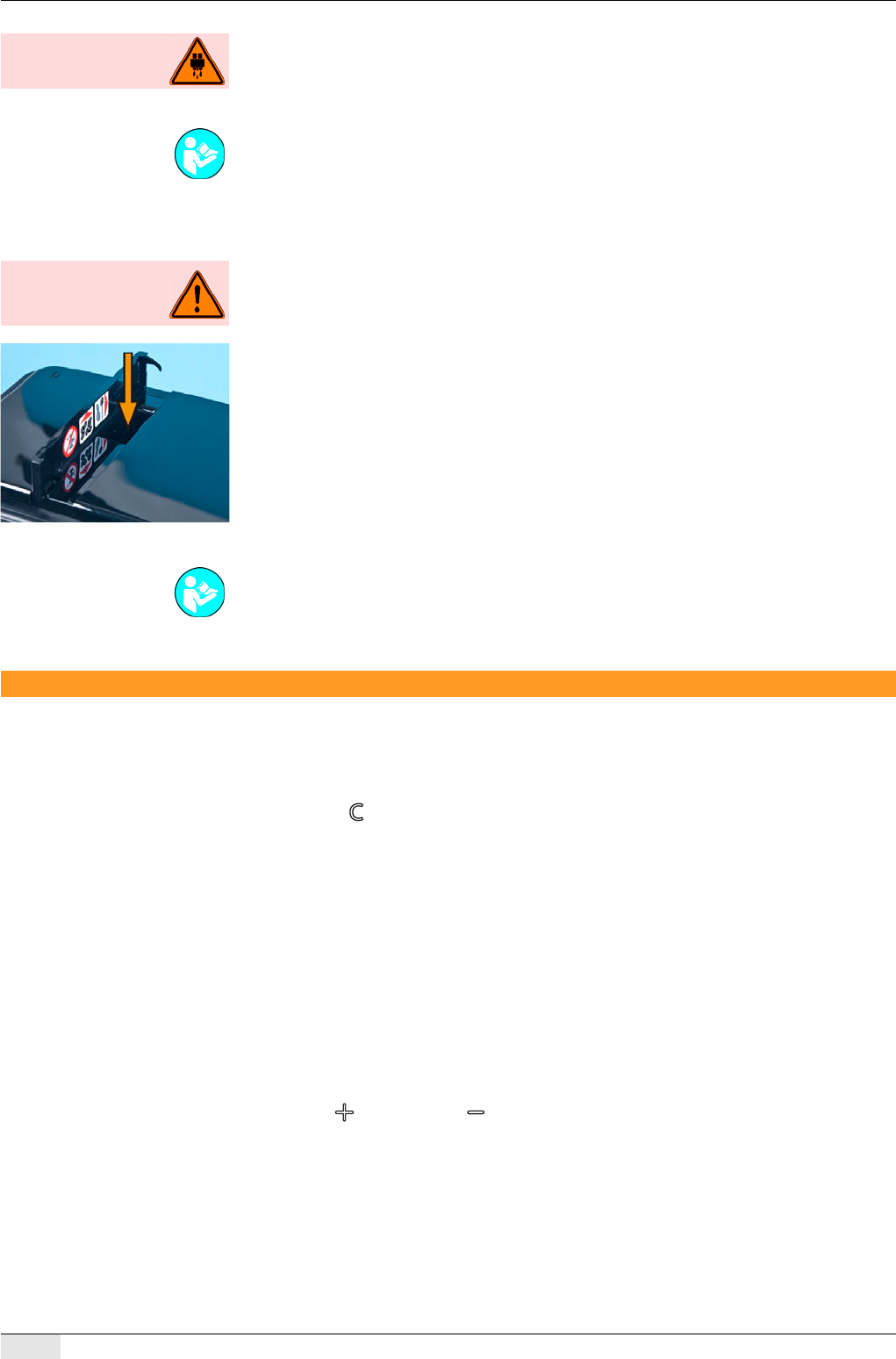

Ik heb een machine van mijn schoonzoon hier staan maar daar kan ik niet voor latte of cappuccino kiezen omdat deze knoppen niet oplichten..... dit is waarschijnlijk een keer uitgezet door een service monteur omdat deze machine in een supermarkt stond. Nu wil hij hem thuis gebruiken maar hoe zet ik deze functies weer aan? Gesteld op 27-10-2021 om 22:20

Reageer op deze vraag Misbruik melden-

Machine herstellen naar standaard fabrieksinstellingen, daarna moet het weer werken Geantwoord op 25-12-2021 om 14:57

Waardeer dit antwoord Misbruik melden

-

-

Of via de service software Geantwoord op 13-5-2022 om 11:35

Waardeer dit antwoord Misbruik melden -

dient via laptop en programma aangepast te worden Geantwoord op 9-4-2023 om 13:41

Waardeer dit antwoord Misbruik melden -

Wij hebben een koffiemachine joy, maar als je koffie wil zetten blijft het water maar opwarmen en komt er stoom uit. Weet jij de reden Gesteld op 10-4-2021 om 16:53

Reageer op deze vraag Misbruik melden -

Ik heb een Schaerer Joy staan en blijft de melding opwarmen geven, en als je op een knop drukt geeft hij de melding drankkeuze geblokkeerd bedieningspaneel reinigen. Maar je hoort hem wel opwarmen als je hem aan zet, je kan ook niet in programma komen. Maar het paneel is inmiddels brandschoon. Er zitten wel een paar stickers op maar die zitten er al jaren op omdat de machine op een locatie staat voor verstandelijk beperkten. Gesteld op 19-3-2021 om 20:23

Reageer op deze vraag Misbruik melden-

Wij hebben precies dezelfde melding op onze machine. Heeft U ondertussen al een oplossing hiervoor gevonden ? Geantwoord op 19-1-2022 om 09:29

Waardeer dit antwoord (15) Misbruik melden

-

-

rectificatie: .... die na 30 JAAR nog steeds werken ... Gesteld op 15-1-2021 om 07:43

Reageer op deze vraag Misbruik melden

-

Wij hebben in 2015 de schaerer coffee joy gekocht.

Reageer op deze vraag Misbruik melden

Sinds juli 2020 lekt de machine water dat ergens onderuit de machine loopt.

De zet-groep/Brewer-groep er uit gehaald en schoongemaakt zoals ik dat overigens altijd ook al volgens het wekelijkse Schaerer onderhoudsschema deed (wekelijkse Brewer cleaning).

Een paar probleem kenmerken van onze machine:

- er lekt dus koffie water onderuit de machine op het keukenblad;

- de koffie droes in de opvangbak is niet droog maar nat;

- de persunit waar de gemalen koffie in gaat en waar het 'hete water' onder 'druk' doorheen geperst

wordt, hoort normaal leeg te zijn, maar daar blijft nu water in staan;

- geeft tevens e.o.a. foutmelding op het display;

Ik heb deze machine altijd volgens het standaard bijgeleverde 'Schaerer schema' gereinigd en de machine ziet er nog als nieuw uit en is alleem bij ons thuis gebruikt en niet op het kantoor (waar deze machine volgens Schaerer) geschikt is.

Wij balen er van dat een erg dure machine van dit merk, dat alleen maar particulier gebruikt wordt, zo snel al 'verstek' laat gaan. Ik heb hier thuis nog een koffiemachine van Philips (koffiemaal met filter doorloop) machines, die na 3 jaar nog steeds werken en in vergelijk, maar een fractie van de prijs kosten.....

Onderdelen schijnen nog al moeilijk verkrijgbaar te zijn en ontzettend duur.

Is er iemand die een idee heeft wat hiermee aan de hand kan zijn? Gesteld op 15-1-2021 om 07:39-

Wij hebben hetzelfde probleem. Hoe heeft u dit probleem opgelost? Geantwoord op 9-6-2021 om 11:50

Waardeer dit antwoord Misbruik melden

-

-

Het water wat onder de machine ligt komt waarschijnlijk door een versleten o-ring bij de aansluiting van de watertank, als je de watertank verwijderd zie je hem vanzelf.

Waardeer dit antwoord (4) Misbruik melden

Ook kan het zijn dat de lekbak wat achterover hangt, zodat het overloopje in het midden vooraan het water achter het lekbakje eruit gooit, oplossing 2 stukjes vilt(wat ook onder stoelen wordt geplakt) onder het lekbakje plakken zodat hij weer recht en goed aansluit Geantwoord op 14-11-2021 om 13:08 -

koffieventiel sluit niet meer en brewerkamer loopt hierdoor vol Geantwoord op 9-4-2023 om 13:43

Waardeer dit antwoord (2) Misbruik melden -

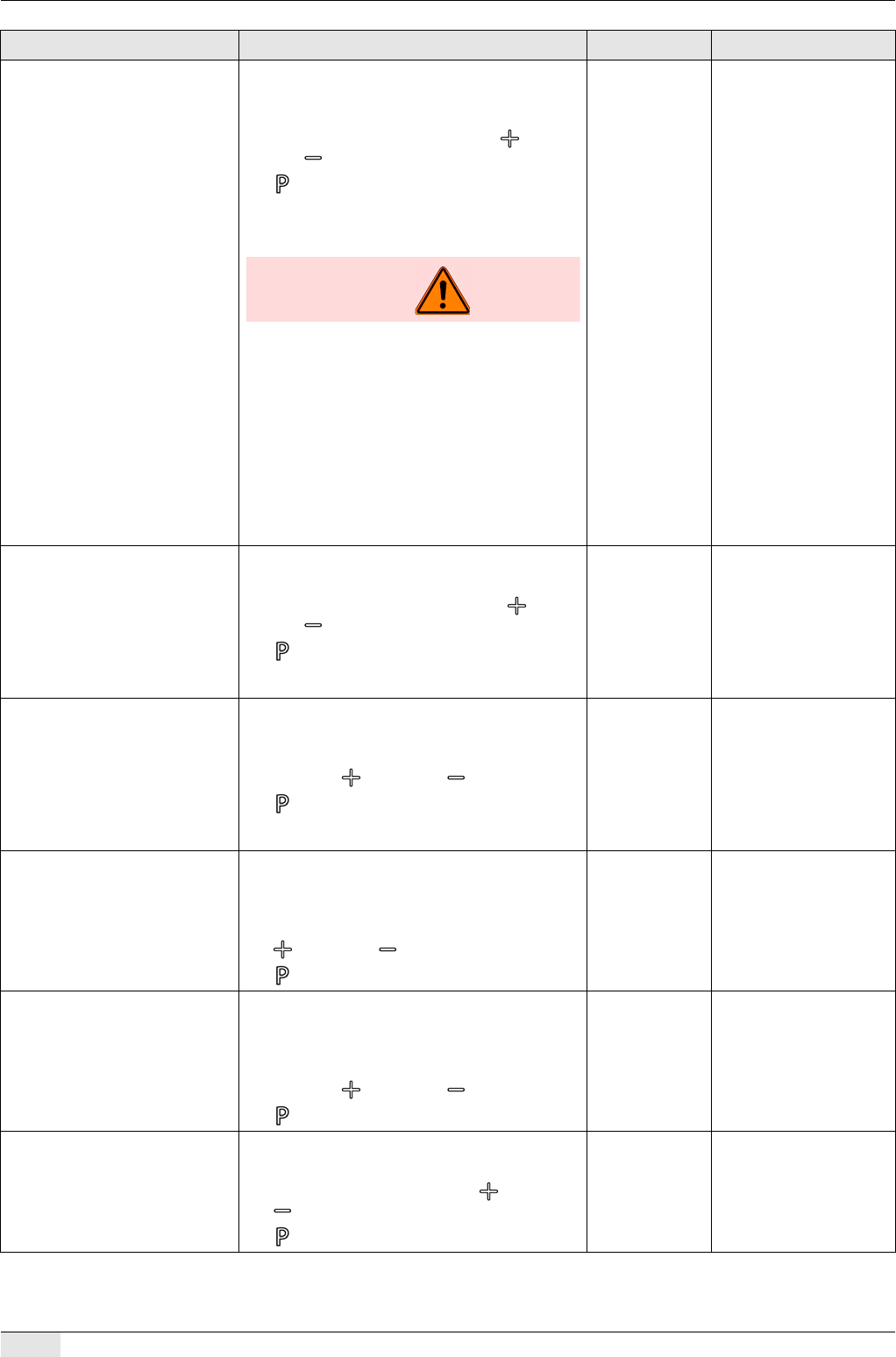

SCJoy is vastegelopen. Op display : zeteenheid eindschak.....

Reageer op deze vraag Misbruik melden

Hoe kan ik dit oplossen? Gesteld op 21-12-2020 om 20:49 -

Op de display staat:

Reageer op deze vraag Misbruik melden

Opwarmen

Zeteenh. eindschak

Wat betekend dit en hoe los ik dit op? Gesteld op 23-11-2020 om 16:47-

De bovenste of onderste positie van de zetgroep wordt niet gehaald. Misschien koffie prut waar hij op klem loopt? Of er is een reedswitch defect die ziet of de brewer in een van die twee posities staat. In dat geval ga je zelf niets oplossen. Wordt reparatie. Geantwoord op 10-12-2020 om 20:51

Waardeer dit antwoord (16) Misbruik melden

-

-

Wij hebben al een aantal jaren de coffee jou en hij doet het prima en nog steeds, vroeg ons eigen af of de mesjes wel eens vervangen moeten worden die de bonen vermalen

Reageer op deze vraag Misbruik melden

Mvg

Peter Gesteld op 22-11-2020 om 09:33-

Kan, maar ze kunnen wel 35000-40000 koffie consumpties mee. Als je slappe koffie hebt, fijner afstellen helpt niet meer dan wordt het tijd. Geantwoord op 10-12-2020 om 20:54

Waardeer dit antwoord (3) Misbruik melden

-

-

steeds gemalen koffie inwerpen maar ik wil geen gemalen koffie Gesteld op 3-11-2020 om 20:19

Reageer op deze vraag Misbruik melden-

Als je deksel er af tilt. Zodat je bij de zetgroep kan komen. Dan zitten er in het midden, boven aan, bij de achterwand, 2kleine schakelaars. Een van 2 is van het decafklepje/ tablet inworp klepje. Daar gaat het fout. Of je pinnetje van het klepje is afgebroken. Geantwoord op 10-12-2020 om 20:58

Waardeer dit antwoord (3) Misbruik melden

-

-

Op de display op de machine wordt vermeld: "Opwarmen Timeout niveau" wat houdt dit in, lijkt er op dat de koffiemachine niets doet Gesteld op 21-10-2020 om 10:43

Reageer op deze vraag Misbruik melden-

geeft een Timeout niveau wat moet ik doen Geantwoord op 23-3-2021 om 19:50

Waardeer dit antwoord (41) Misbruik melden

-

-

Mijn koffie apparaat doet het niet meer er staat opwarmen Temp. Sensor stoom

Reageer op deze vraag Misbruik melden

Wat kan ik doen Gesteld op 29-8-2020 om 10:42-

Temp sensor stoomboiler kapot. Wordt nieuwe boiler, of je moet een boiler hebben waar de tempsensor los in kan worden geschoven. Dan kun je die vervangen. De oudere types kunnen dat niet. Geantwoord op 10-12-2020 om 21:00

Waardeer dit antwoord Misbruik melden

-

-

Wij hebben de watertoevoer rechtstreeks vanuit de waterleiding in de koffiemachine. Bij reiniging moet het waterreservoir gevuld worden. Hoe doe ik dit? Waar zit dit reservoir? Rechts, maar hoe kan ik hier bij komen? Gesteld op 12-2-2020 om 10:01

Reageer op deze vraag Misbruik melden-

wij hebben ook rechtstreeks aangesloten op de waterleiding. maar ik hoef voor het reinigen van de machine niet het waterreservoir gevuld te hebben. Geantwoord op 13-2-2020 om 09:44

Waardeer dit antwoord Misbruik melden

-

-

Dat komt omdat die vastwater kit die ke er bij hebt, een slechte oplossing is. In die zwarte box die er bij zit, zit een klep die steeds open en dicht gestuurd wordt als er water nodig is. Maar de diameter van die klep is vrij kritiek, om binnen een "X" tijd die de machine stelt, op het benodigde waterniveau te komen. De ene kit doet het zonder problemen en de andere mauwt er steeds over. Maar als het goed is moet de reiniging wel lukken. Alleen met wat meer pauzes/ onderbrekingen. Geantwoord op 10-12-2020 om 21:07

Waardeer dit antwoord Misbruik melden -

Waar kan ik onderdelen kopen voor de zetgroep van de Coffee joy? Gesteld op 8-2-2020 om 13:37

Reageer op deze vraag Misbruik melden-

Ik heb nog een compleet aparaat staan voor onderdelen is nog helemaal compleet geeft alleen storing aan stoomcensor seteenheid is nog helemaal top in orde Geantwoord op 26-11-2020 om 16:27

Waardeer dit antwoord (10) Misbruik melden

-

-

Mijn email is c.roozenburg@ xs4all.nl voor vragen mail mij even Geantwoord op 26-11-2020 om 16:28

Waardeer dit antwoord (5) Misbruik melden -

Koffiemachine heeft water onder zich liggen, ligt ook soms natte koffiegruis achter waterreservoir, al meerdere malen grondig gereinigd maar nog steeds probleem. Wat kan dit zijn Gesteld op 1-2-2020 om 13:03

Reageer op deze vraag Misbruik melden -

Ik ben de machine aan het reinigen maar in de display blijft de melding Tablet inwerpen in handinworp Gesteld op 18-1-2020 om 13:12

Reageer op deze vraag Misbruik melden -

drankkeuze geblokkeerd timeout niveau

Reageer op deze vraag Misbruik melden

wat is er dan defect? Gesteld op 9-8-2019 om 08:59-

Ik heb hetzelfde probleem. Was het je al gelukt wat het probleem was? Geantwoord op 9-10-2019 om 09:45

Waardeer dit antwoord (54) Misbruik melden

-

-

onder schoon maken gaat hij niet verder en geeft waterreservoir vullen aan Gesteld op 11-11-2018 om 13:21

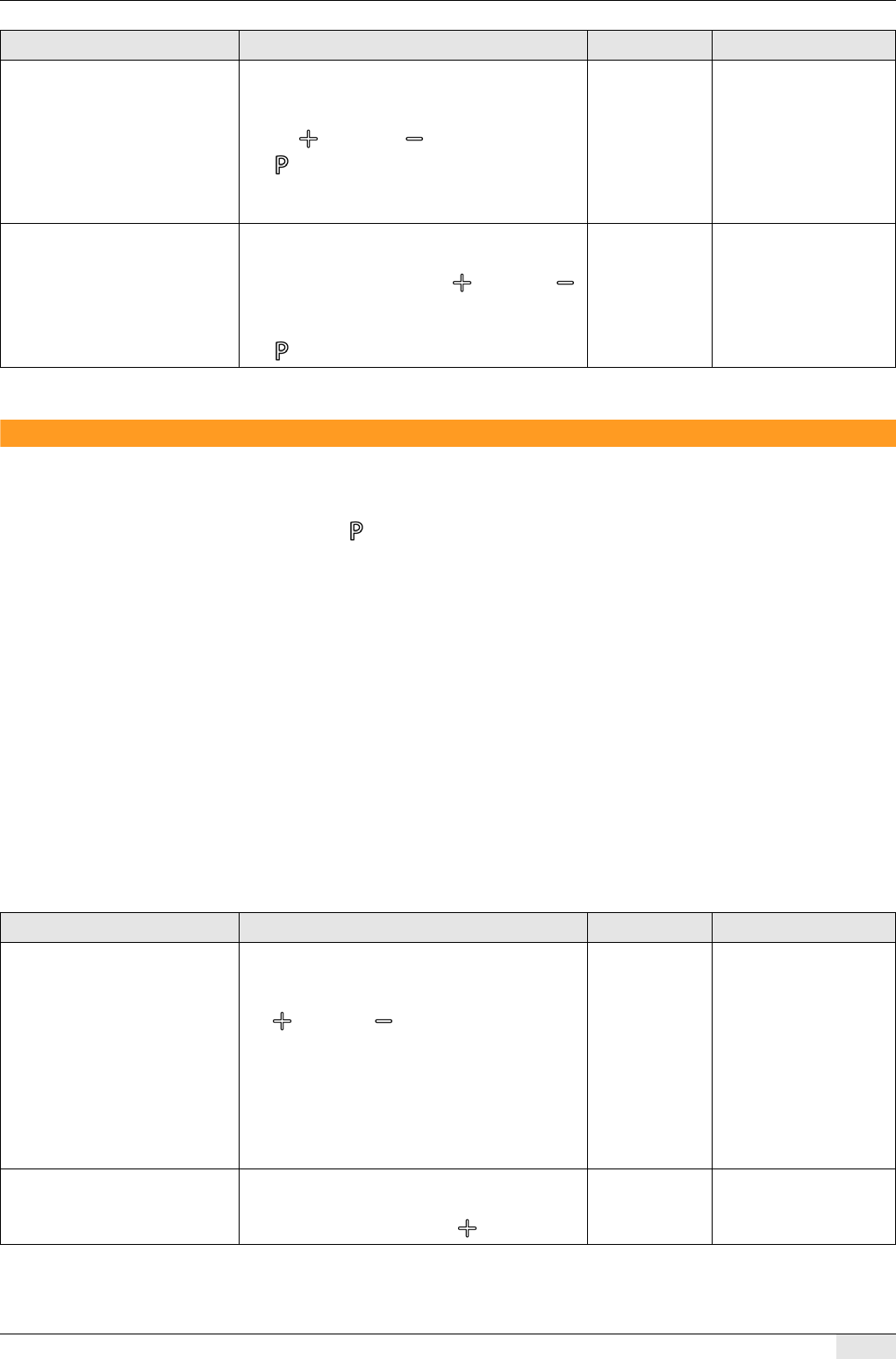

Reageer op deze vraag Misbruik melden-

Weet u het antwoord al wij hebben hetzelfde probleem Geantwoord op 8-12-2018 om 21:56

Waardeer dit antwoord Misbruik melden

-

-

ik heb het water resevoir gewoon zelf gevuld met een kannetje en daarna terug geplaatst nu doet die het gewoon goed Geantwoord op 8-12-2018 om 22:04

Waardeer dit antwoord Misbruik melden -

Display geeft deze melding aan; brewereindsch.

Reageer op deze vraag Misbruik melden

Iemand een idee?

Schoongemaakt, teruggeplaatst maar melding blijft, melding alleen een servicemonteur kan dit probleem oplossen.. Gesteld op 22-10-2018 om 22:18-

handmatig de het zwarte tandwiel verdraaien van de zeteenheid. Geantwoord op 10-3-2019 om 08:33

Waardeer dit antwoord Misbruik melden

-

-

mijn schaerer lekt aan de onderkant, weet iemand wat er mis kan zijn? Gesteld op 29-4-2018 om 16:20

Reageer op deze vraag Misbruik melden-

heeft u de oplossing al van dat water lekken Geantwoord op 15-11-2018 om 15:05

Waardeer dit antwoord (22) Misbruik melden

-

-

De flush slang die in de lekbak uit komt is dan los, machine open maken en de slang weer vast zetten Geantwoord op 12-10-2020 om 13:11

Waardeer dit antwoord (6) Misbruik melden -

Dezevraag werd al eerder gesteld maar geen duidelijk antwoord. Ook ik wordt helemaal gek van dat apparaat.hij lekt water aan de onderkant.en ik krijg hele lichte koffie. Als je de brewer eruit haalt ligt er steeds gemalen koffie naast. De koffie uitworp lijkt niet in de cup voor de persing te vallen of maar heel weinig waardoor er nauwelijks koffie in een gezet kopje zit.

Reageer op deze vraag Misbruik melden

Wie kent het probleem en weet de oplossing? Gesteld op 31-7-2017 om 16:41-

Dat probleem heb ik ook met de brewer hier onder in de antwoorden zeg iemand dat je 4 klepjes moet schoonmaken ga ff bekijken of ik ze vinden kan

Waardeer dit antwoord (15) Misbruik melden

Geantwoord op 3-12-2017 om 15:08

-

-

gemal koffie inwerpen geeft het apparaat aan terwijl er bonen inzitten Gesteld op 16-1-2017 om 10:54

Reageer op deze vraag Misbruik melden-

Hoi ik ben alleen gebruiker van de zelfde machine en heb deze melding opgelost door machine uit te schakelen, alle bonen er uit halen laatste reste lukt helaas alleen met een stofzuiger.

Waardeer dit antwoord (14) Misbruik melden

Dan zie je een zwart dopje met een schroefje erin als je die losmaakt en nogmaals de stofzuiger erin zet is ook het molentje leeg nu kun je kijken of er wellicht een boontje dwars zit en de molen blokkeert.Bij mij was het toen opgelost hoop dat je er wat aan hebt. Geantwoord op 17-1-2017 om 15:52

-

-

Oplossing is heel makkelijk. Zorg dat de drie klepjes bovenop goed gesloten zitten. vooral de middelste waar het tabletje ingaat. Dan is het euvel als het goed is verholpen. Geantwoord op 27-2-2017 om 10:04

Waardeer dit antwoord (6) Misbruik melden -

"Zeteenheid eindschak" geeft de machine aan......hoe kan ik dit oplossen? Gesteld op 28-12-2016 om 08:53

Reageer op deze vraag Misbruik melden-

we hebben hier ook dit rampzalige probleem los het aub ook voor mij op ik ga dood van de slaap aanvallen. Geantwoord op 15-6-2019 om 16:12

Waardeer dit antwoord (13) Misbruik melden

-

-

Machiné geeft foutmelding temperatuur sensor stoom. Doet niets. Zie ook de andere meldingen zie geen antwoord

Reageer op deze vraag Misbruik melden

Janetdejongh@hotmail.com Gesteld op 20-7-2016 om 18:48-

heeft u al antwoord gekregen op uw vraag? Wij hebben het zelfde probleem Geantwoord op 20-10-2016 om 10:21

Waardeer dit antwoord (24) Misbruik melden

-

-

Ik heb hetzelfde probleem. Na het open vijzen van de machine heb ik nog niets kunnen vinden. Iemand tips? Geantwoord op 14-5-2022 om 21:18

Waardeer dit antwoord (2) Misbruik melden -

de koffiezetapparaat zegt temperatuur senor stoom. Wat te doen? Hebben al de stekker eruit gedaan en even uit laten staan. Gesteld op 14-6-2016 om 09:32

Reageer op deze vraag Misbruik melden-

Bij onze machine het zelfde vandaag, en warmt niet meer op Geantwoord op 14-6-2016 om 10:56

Waardeer dit antwoord (11) Misbruik melden

-

-

hebben jullie al antwoord gekregen op jullie vraag. Of weten jullie al wat je met deze foutmelding moet doen?? Geantwoord op 20-10-2016 om 10:23

Waardeer dit antwoord (1) Misbruik melden -

Het water lekt er van onderen uit. Ook ligt er koffieprut achter het waterreservoir en de residubak. Wat zou ik kunnen doen? Gesteld op 24-5-2016 om 15:02

Reageer op deze vraag Misbruik melden-

Hoi, mijn apparaat lekt ook water van onder? Weet u al wat het is?

Waardeer dit antwoord (20) Misbruik melden

Gr.sid Geantwoord op 30-12-2016 om 20:14

-

-

Heeft iemand al een verklaring voor dit probleem, water onder machine, volgens mij niet vanuit machine zelf.

Waardeer dit antwoord (10) Misbruik melden

Mvg Toon Geantwoord op 31-1-2017 om 12:26 -

Na ontkalkingsprogramma gisteren, blijft hij hierop staan. Kunnen alleen steeds weer het ontkalkingsprogramma uitvoeren Gesteld op 26-11-2015 om 09:24

Reageer op deze vraag Misbruik melden-

Goedemorgen, al een oplossing bij ons ook alleen maar ontkalkingsprogramma Geantwoord op 27-2-2017 om 09:41

Waardeer dit antwoord Misbruik melden

-

-

Hier ook dit pobleem. Servicemonteur komt er ook niet uit Geantwoord op 13-10-2020 om 07:34

Waardeer dit antwoord Misbruik melden -

Goedemiddag,

Reageer op deze vraag Misbruik melden

Ons koffiezetapparaat geeft de melding "temperatuursensor stoom"

Het apparaat heeft de hele nacht uitgestaan en is dus niet oververhit

Enig idee wat dit kan zijn en hoe op te lossen?

Met vr Gr

Jaap Spithost

Zandvoort 2 Norg

06-55892995

Berrinaspithost@planet.nl

Gesteld op 15-10-2015 om 12:41-

Goedemorgen,

Waardeer dit antwoord (8) Misbruik melden

Ik heb ook dezelfde melding op mijn machine, enig idee. Ik zie namelijk nog geen reacties.

Mvg,

Frank

Geantwoord op 31-10-2015 om 09:35

-

-

zelde probleem, iemand al een oplossing

Waardeer dit antwoord (2) Misbruik melden

Gr Ron Geantwoord op 28-4-2018 om 20:25 -

wordt helemaal gek van dat apparaat.hij lekt water aan de onderkant.en krijg hele licht koffie is net melkwater. ook als ik dat ding er boven uithaal is die helemaal volgelopen met koffie en als ik de residu eruit haal ligt er ook een hoop koffie naast weet niet meer wat ik er aan kan doen Gesteld op 13-10-2014 om 13:21

Reageer op deze vraag Misbruik melden-

er zitten 4 klepjes in uit elkaar halen en schoonmaken Geantwoord op 5-3-2016 om 09:17

Waardeer dit antwoord (16) Misbruik melden

-

-

Kunt u mij zeggen waar die klepjes zitten heb t zelfde probleem.

Waardeer dit antwoord Misbruik melden

Bedankt

Twan Geantwoord op 13-7-2018 om 14:29 -

Geeft in disply deur open Gesteld op 24-5-2013 om 09:25

Reageer op deze vraag Misbruik melden-

geen idee Geantwoord op 24-5-2013 om 09:28

Waardeer dit antwoord Misbruik melden

-

-

de melk schuimt niet meer Gesteld op 10-1-2013 om 09:54

Reageer op deze vraag Misbruik melden-

Het apparaat goed reinigen en de uitloop helemaal schoonmaken, de reden waarom het melk niet meer schuimt is omdat de uitloop vervuilt is. Geantwoord op 23-5-2013 om 10:46

Waardeer dit antwoord (14) Misbruik melden

-