48

12-5. In Case of Compressor Malfunction

12-5-1. Procedure for replacing compressor

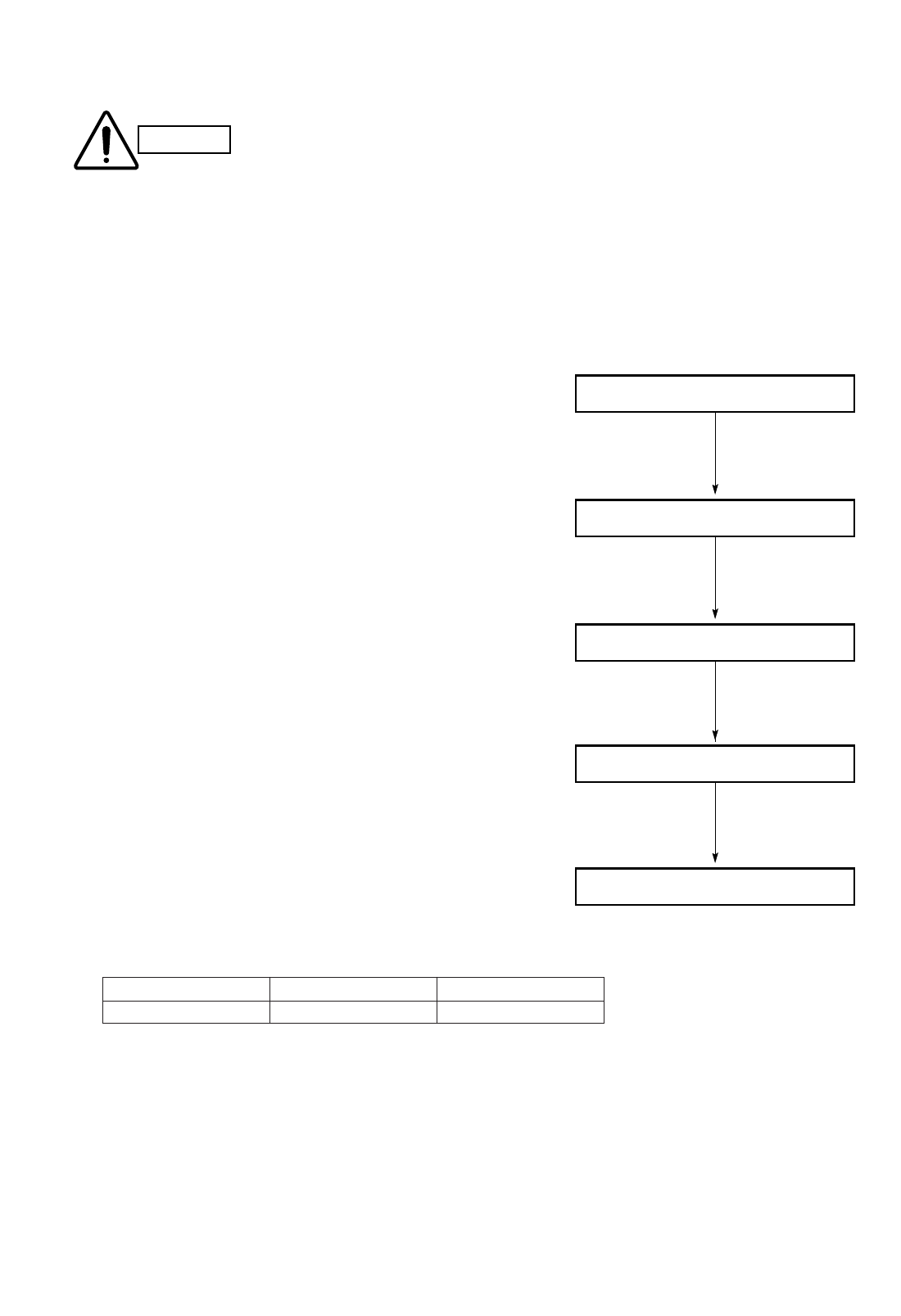

(1) Recovering refrigerant

● Any remaining refrigerant inside the unit should not be

released to the atmosphere, but recovered using the

refrigerant recovery unit for R410A.

● Do not reuse the recovered refrigerant, since it will

contain impurities.

(2) Replacing Compressor

● Soon after removing seals of both discharge and suc-

tion tubes of the new compressor, replace it quickly.

(3) Checking for sealing

● Use nitrogen gas for the pressurized gas, and never

use a refrigerant other than R410A. Also do not use

oxygen or any flammable gas.

(4) Evacuation

●

Use a solenoid valve-installed vacuum pump

so

that even if power is cut off in the middle of evacuation

of air due to a power interruption, the valve will pre-

vent the pump oil from flowing back.

● The equipment may be damaged if moisture remains

in the tubing, thus carry out the evacuation thoroughly.

● When using a vacuum pump with exhaust air volume

more than 25L/min. and ultimate vacuum pressure

rate of 0.05Torr:

Standard time for evacuation

●

Should the compressor malfunction, be sure to make the switch to a replacement

compressor as quickly as possible.

●

Use only the tools indicated exclusively for R410A.

➞

See “12-3. Tools

Specifically for R410A.”