Table of Contents

SMA Solar Technology AG

Operating manualSTP3-6-3AV-40-BE-en-124

7 Commissioning ......................................................................... 37

7.1 Commissioning Procedure ......................................................................................... 37

7.2 Commissioning the Inverter........................................................................................ 37

7.3 Selecting a configuration option............................................................................... 39

7.4 Starting the Self-Test (for Italy and Dubai)................................................................ 41

8 Operation ................................................................................. 43

8.1 Establishing a connection to the user interface ........................................................ 43

8.1.1 Establishing a Direct Connection via Ethernet ...................................... 43

8.1.2 Establishing a direct connection via WLAN ......................................... 43

8.1.3 Establishing a Connection via Ethernet in the local network ............... 45

8.1.4 Establishing a Connection via WLAN in the Local Network ............... 46

8.2 Logging In and Out of the User Interface................................................................. 47

8.3 Start Page Design of the User Interface.................................................................... 49

8.4 Activating the Smart Inverter Screen......................................................................... 51

8.5 Starting the Installation Assistant............................................................................... 52

8.6 Activate WPS Function............................................................................................... 53

8.7 Switching WLAN On and Off................................................................................... 53

8.8 Switching the Dynamic Power Display Off............................................................... 54

8.9 Changing the Password............................................................................................. 55

8.10 Changing Operating Parameters.............................................................................. 55

8.11 Configuring the Country Data Set............................................................................. 56

8.12 Configuring Feed-In Management............................................................................ 57

8.13 Configuring the Modbus Function............................................................................. 58

8.14 Activating the Receipt of Control Signals (Only for Italy)........................................ 59

8.15 Deactivating Grounding Conductor Monitoring...................................................... 59

8.16 Setting the Tripping Threshold of the Residual-Current Device................................ 60

8.17 Saving the Configuration in a File............................................................................. 60

8.18 Adopting a Configuration from a File....................................................................... 60

8.19 Updating the Firmware.............................................................................................. 61

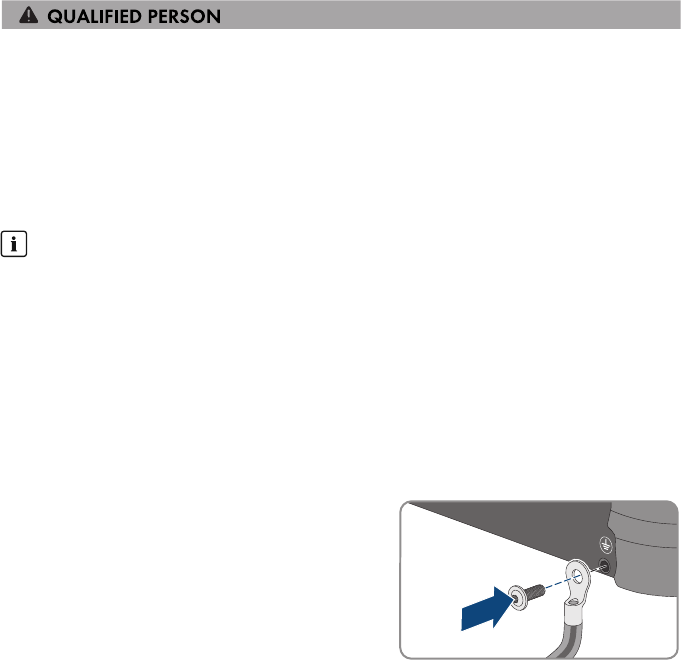

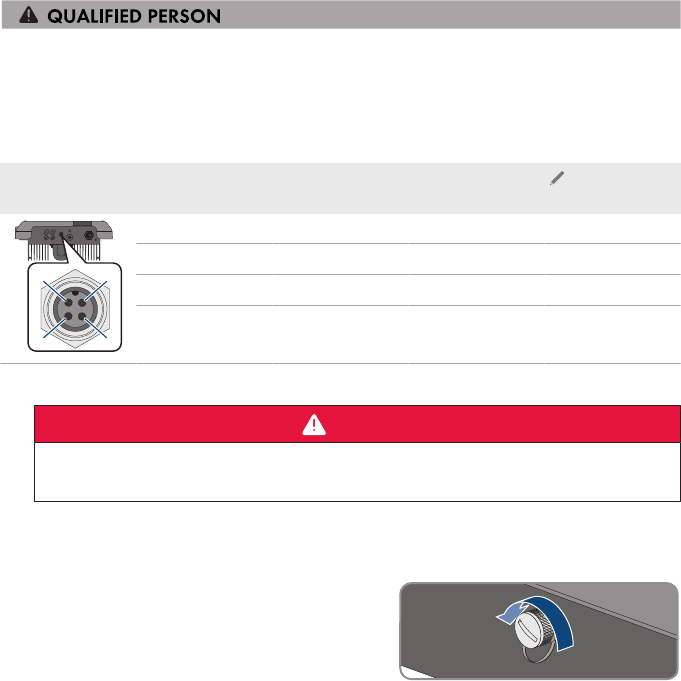

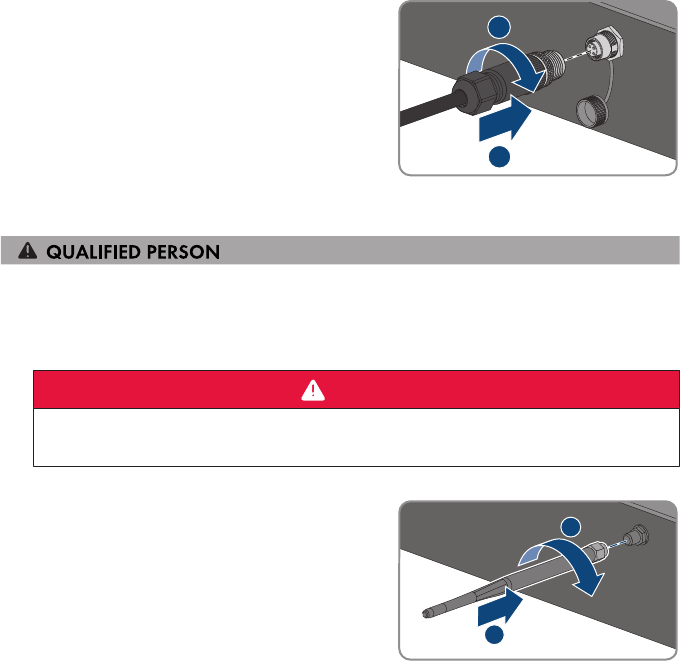

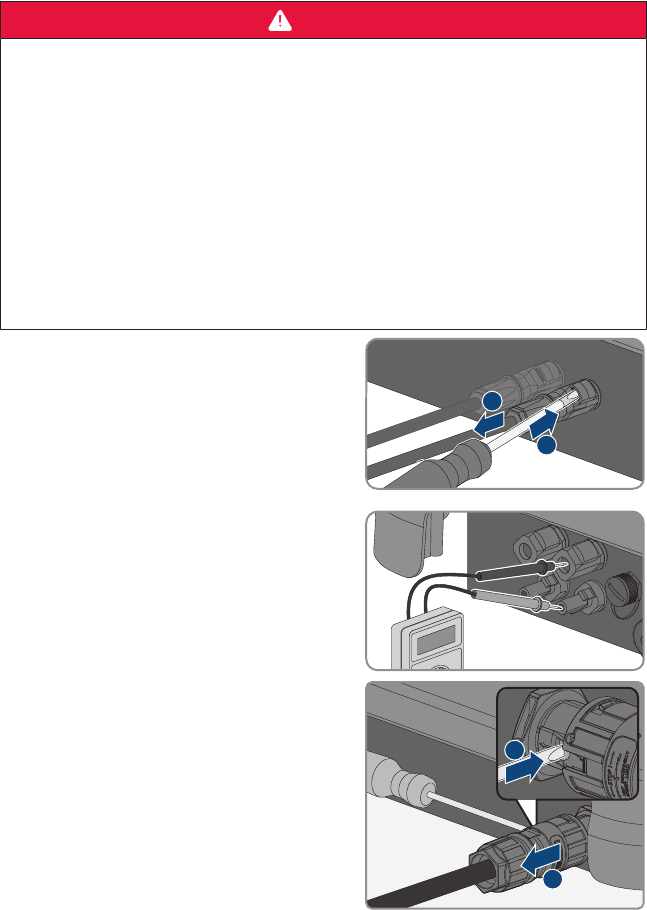

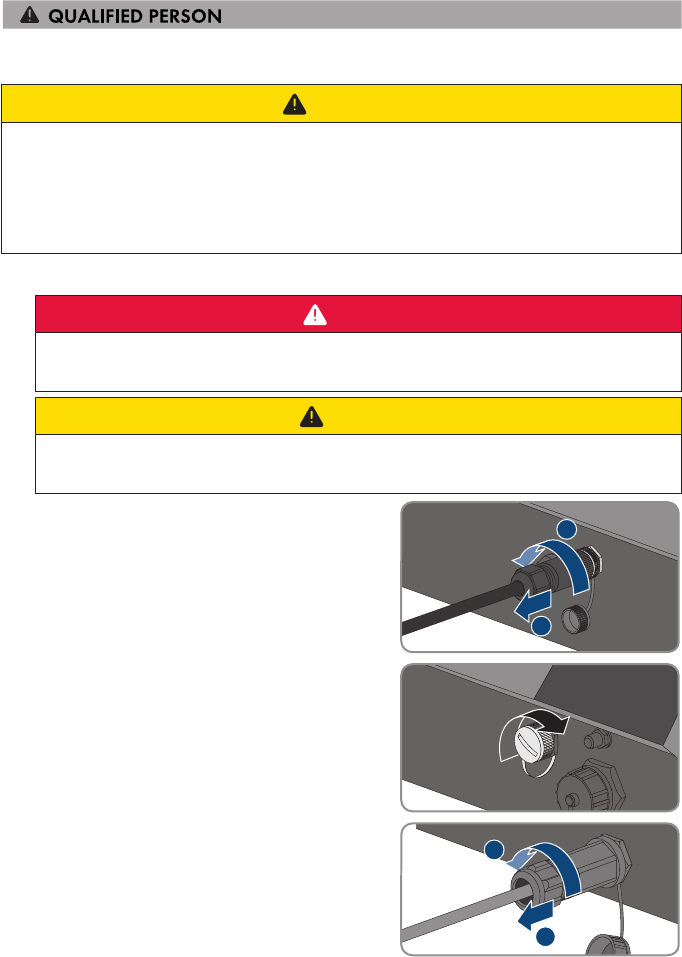

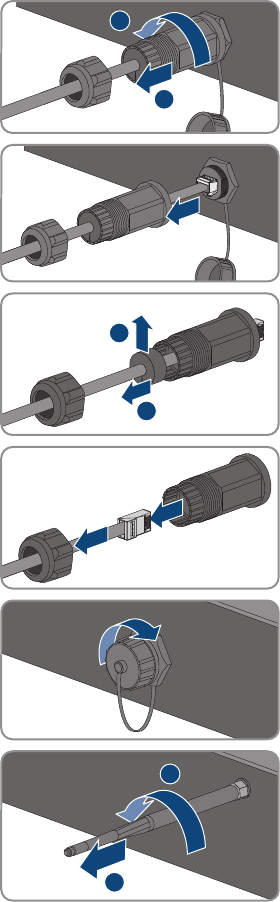

9 Disconnecting the Inverter from Voltage Sources ................. 62

10 Cleaning the Inverter ............................................................... 64

11 Troubleshooting........................................................................ 65

11.1 Forgotten Password.................................................................................................... 65

11.2 Event Messages ......................................................................................................... 66

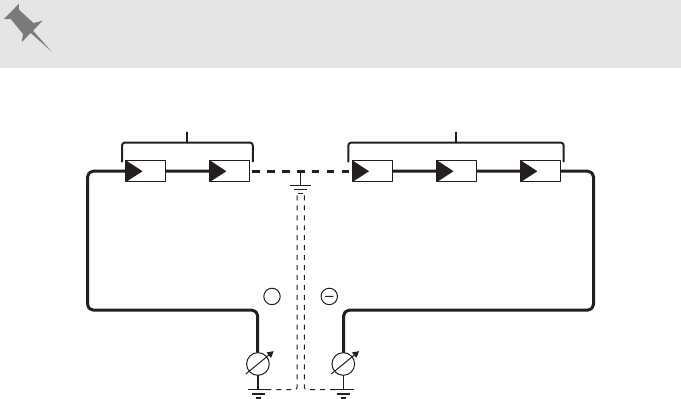

11.3 Checking the PV System for Ground Faults.............................................................. 82

12 Decommissioning the Inverter................................................. 86