2

Table of Contents

(

Page

1. Introduction ................................................................................................................................................................................................... 3

2. Explanation of Symbols ...............................................................................................................................................................................

4

3. Intended Use .................................................................................................................................................................................................

4

4. Safety Information ........................................................................................................................................................................................

4

5. Features .....................................................................................................................................................................................................

6

6. Working Principle of the 3D Printer ..........................................................................................................................................................

6

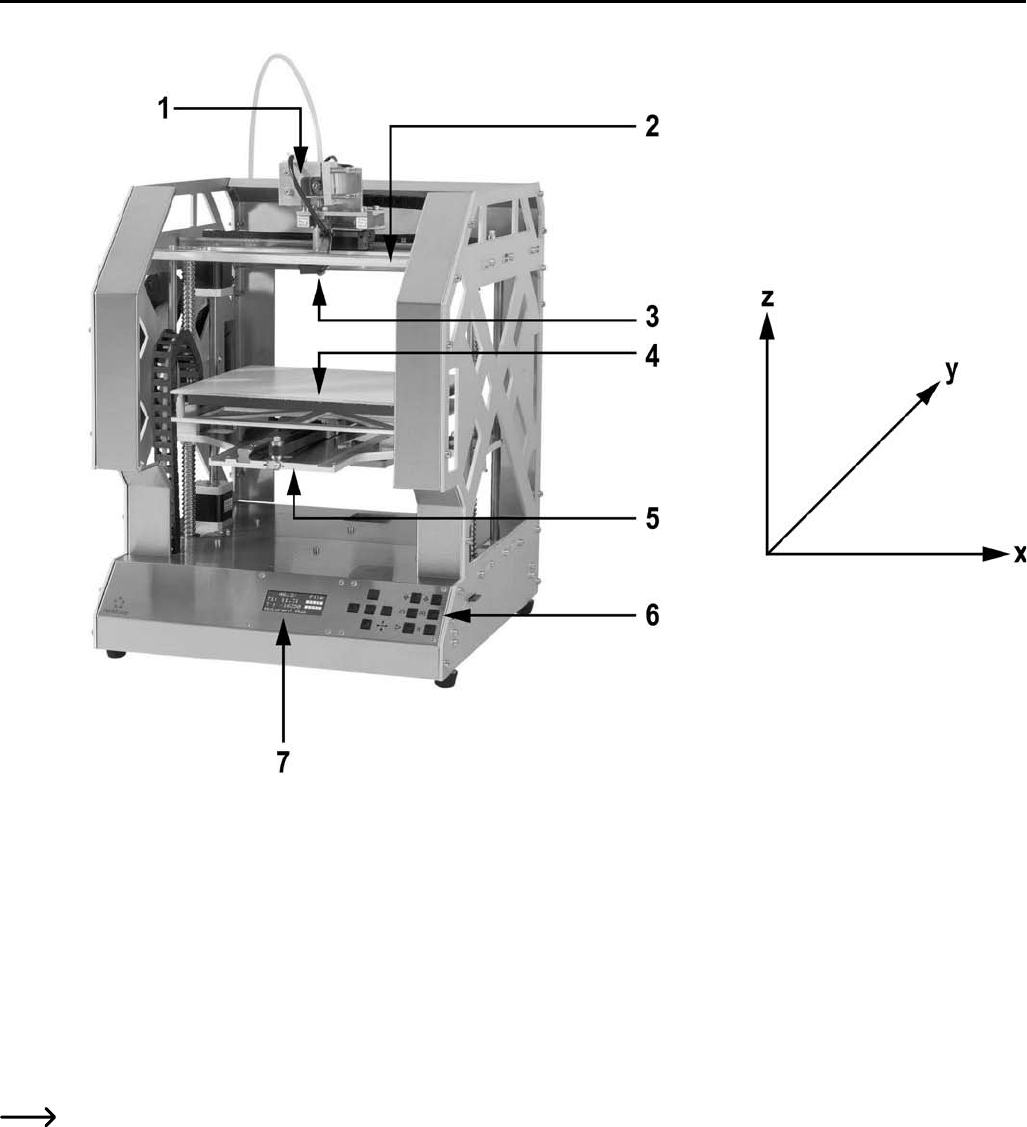

7. Overview of the Most Important Parts .....................................................................................................................................................

7

8. Required Tools and Material ......................................................................................................................................................................

8

9. Assembly of the Mechanical Parts ...........................................................................................................................................................

8

a) General .................................................................................................................................................................................................... 8

b) Assembly of the Components .............................................................................................................................................................

9

10. Wiring of the Electrical Components ......................................................................................................................................................

40

a) General .................................................................................................................................................................................................. 40

b) Wiring of the Components ..................................................................................................................................................................

41

c) Installation of the PCBs ......................................................................................................................................................................

49

11. Final Work ....................................................................................................................................................................................................

54

12. Initial Commissioning .................................................................................................................................................................................

57

a) Assembly of the Filament Holder and the Filament Hose .............................................................................................................

57

b) Insertion of the Filament .....................................................................................................................................................................

58

c) Setup and Transport ............................................................................................................................................................................

59

d) Mains Connection and First Activation ............................................................................................................................................

59

e) Calibration ............................................................................................................................................................................................. 60

f) First Print of an Example Object from the SD Card ........................................................................................................................

63

13. Operation at the Printer .............................................................................................................................................................................

65

a) Menu Overview ....................................................................................................................................................................................

65

b) Functions of the Individual Menu Items ...........................................................................................................................................

67

14. General Notes on 3D Printing ...................................................................................................................................................................

69

15. Software “Repetier Host” .........................................................................................................................................................................

70

a) General Notes on Software ...............................................................................................................................................................

70

b) Installation ............................................................................................................................................................................................ 70

c) Connection of the Connected Printer ...............................................................................................................................................

71

d) Manual Operation via the Software .................................................................................................................................................

73

e) Placement of a printing Object in the Software .............................................................................................................................

74

f) Preparation for Print ............................................................................................................................................................................

76

g) Printing .................................................................................................................................................................................................. 78

h) More Detailed Description of the Slicer Functions ........................................................................................................................

80

16. Software “Cura” .........................................................................................................................................................................................

86

a) General Notes on Software ...............................................................................................................................................................

86

b) Installation ............................................................................................................................................................................................ 86

c) Setup of the Software .........................................................................................................................................................................

87

d) Use of the Software in the Quickprint Mode ...................................................................................................................................

91

e) Use of the Software in the Expert Mode ..........................................................................................................................................

92

17. Filament Change .........................................................................................................................................................................................

94

18. Firmware Update ........................................................................................................................................................................................

95