Replace the nozzle and o-ring C (see Figure 6.2 Gas changeover 5. → 51) with those

of the diameter suited to the new type of gas (see Table 6.2 Gas nozzles and con-

tent of CO2 → 51). The nozzle code is stamped on the nozzle itself.

Check that the o-ring B is fitted.6.

Reassemble the gas valve to the blower with the 4 bolts G taking care that the red 7.

silicon hose between the venturi tube and the gas valve (see detail F of Figure 6.2

Gas changeover → 51) is correctly installed.

Replace the white gasket between the blower and the burner.8.

Reinstall the blower/gas valve assembly to the burner with the 4 bolts E, taking 9.

care not to damage the white gasket.

Reconnect the gas pipe to the gas valve.10.

Replace the sticker indicating the type of gas for which the appliance was set up 11.

with one that indicates the new type of gas used.

Check the tightness of the installation as follows:12.

Connect a manometer to the gas intake D (Figure 6.1 Gas valve • → 49).

Open the gas valve.•

Close the gas cock and check that the mains pressure has not dropped.•

If there is no gas leak, supply gas and electricity to the appliance and restart it.13.

complete the change of gas type by checking that all gas connections are sealed, 14.

including those not directly affected by this operation (using soapy water or an-

other suitable method).

Now check and adjust the combustion parameters as indicated in the respective 15.

paragraph.

Table 6.2 – Gas nozzles and content of CO2

Gas type G20 G25 G25.1 G27 G2.350 G30 G31

Nozzle code 180 181 181 187 184 182 183

Nozzle diameter 4,7 5,2 5,2 5,4 5,9 3,4 3,6

Content CO2 with MAX modulation 9,1% 9,2% 10,1% 9,0% 9,0% 10,4% 9,8%

Delta CO2 between Max and Min potential 0,4 0,6 0,8 0,5 0,5 0,5 0,4

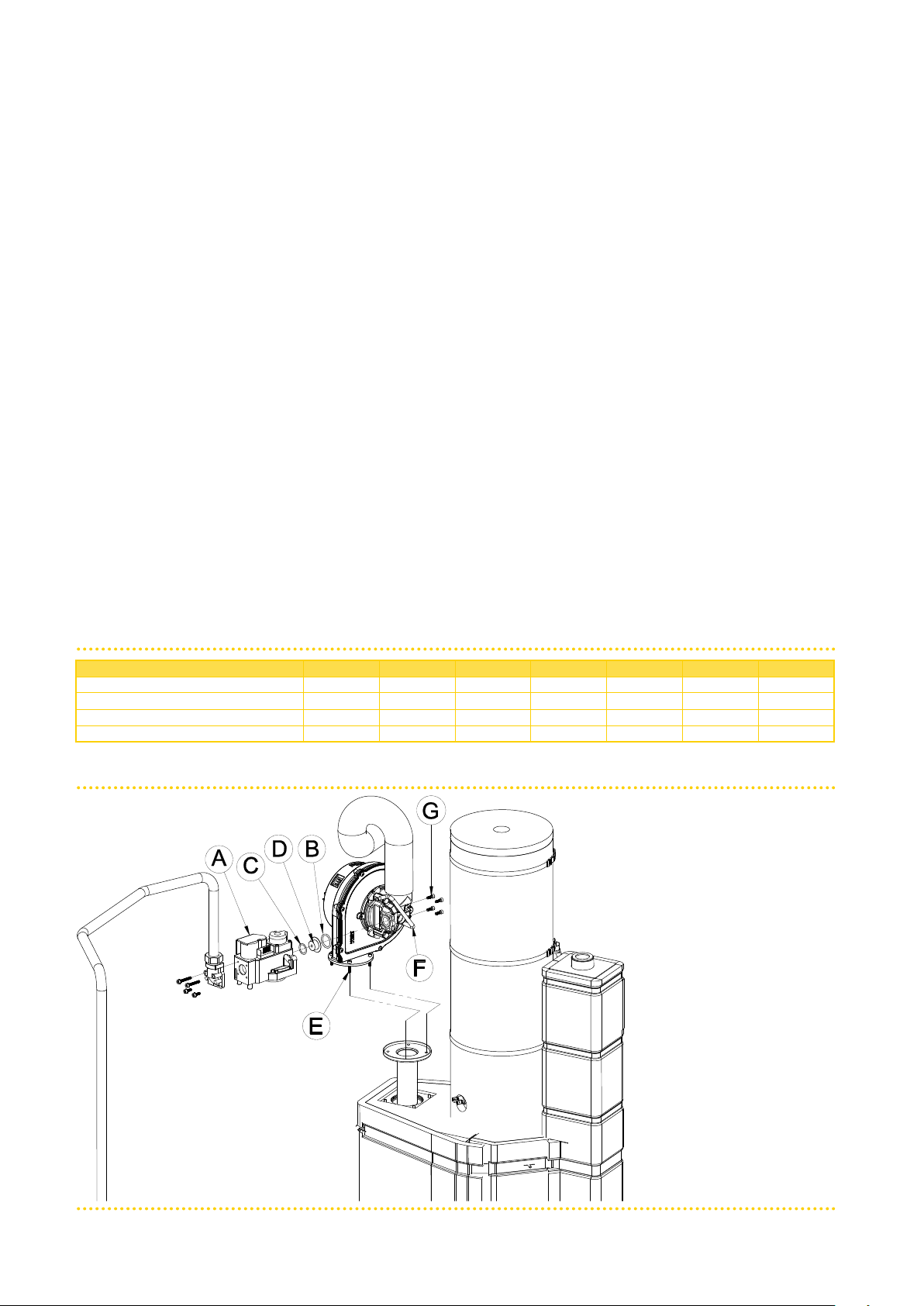

Figure 6.2 – Gas changeover

Gas changeover

LEGEND

A Gas valve

B O-ring

C O-ring

D Gas nozzle

E Fixing screws

F Red silicon pipe

G Fixing screws

H Manual reset fumes thermostat