HOT WHILE IN OPERATION

DO NOT TOUCH, KEEP

CHILDREN, CLOTHING AND FURNITURE AWAY.

CONTACT MAY CAUSE SKIN BURNS. SEE NAMEPLATE

AND INSTRUCTIONS.

CAUTION:

CHAUD LORS DE

L'OPÉRATION. NE PAS

TOUCHER. GARDEZ LES ENFANTS ET LES

VÊTEMENTS LOIN DE L'ESPACE DÉSIGNÉ DE

L'INSTALLATION. LE CONTACT PEUT CAUSER DES

BRÛLURES À LA PEAU. VOIR L'ÉTIQUETTE ET LES

INSTRUCTIONS.

ATTENTION

:

Listed Solid Fuel Room Heater/Pellet Type. Also suitable for Mobile Home

Installation. This appliance has been tested and listed for use in Manufactured

Homes in accordance with OAR 814-23-9000 through 814-23-909.

Appareil de chauffage de combustible solide/de type de boulettes. Accepté dans

l'installation dans les maisons mobiles. Cet appareil a été testé et enregistré pour

l'usage dans les Maisons Mobiles en accord avec OAR 814-23-9000 jusqu'à

814-23-909.

PREVENT HOUSE FIRES / PRÉVENTION DES FEUX DE MAISON

Install and use only in accordance with manufacturer's installation and operating

instructions. Contact local building or fire officials about restrictions and inspection in

your area.

WARNING - FOR MOBILE HOMES: Do not install appliance in a sleeping room. An

outside combustion air inlet must be provided. The structural integrity of the mobile

home floor, ceiling and walls must be maintained. Refer to manufacturer's

instructions and local codes for precautions required for passing chimney through a

combustible wall or ceiling. Inspect and clean vent system frequently in accordance

with manufacturer's instructions. DO NOT CONNECT THIS UNIT TO A CHIMNEY

SERVING ANOTHER APPLIANCE. Use a 3" or 4" diameter type "L" or "PL" venting

system.

Installez et utilisez en accord avec les instructions d'installation et d'opération du

fabricant. Contactez le bureau de la construction ou le bureau des incendies au sujet

des restrictions et des inspections d'installation dans votre voisinage. Ne pas obstruez

l'espace en dessous de l'appareil.

AVIS - Pour Les Maisons Mobiles: Ne pas installer dans une chambre à coucher. Un

tuyau extérieur de combustion d'air doit être installé et ne doit pas être obstrué

lorsque l'appareil est en usage. La structure intégrale du plancher, du plafond et des

murs de la maison mobile doit être maintenue intacte. Référez vous aux instructions

du fabricant et des codes locaux pour les précautions requises pour passer une

cheminée à travers un mur ou un plafond combustibles, et les compensations

maximums. Inspectez et nettoyez la cheminée fréquemment. Ne pas connecter cet

appareil à une cheminée servant un autre appareil. Utilisez systèm de ventilation "L"

ou "PL" diamètre 76mm ou 102mm

Conforms to ASTM Std E1509. Certified to ULC S627. Room Heating Pellet

BurningType, (UM) 84-HUD FOR USE ONLY WITH PELLETIZED WOOD FUEL. Do

not use any other type of fuel.

Input Rating: 50,775 Btu's/hr. Electrical Rating:115 VAC, 60 Hz, Start 2.9 Amps, Run

2.45 Amps. Route power cord away from unit. Do not route cord under or in front of

appliance. Do not obstruct the space beneath the heater.

DANGER: Risk of electrical shock. Disconnect power supply before servicing.

Replace glass only with 5mm ceramic. To start, turn dial control to desired setting and

set thermostat above room temperature, the stove will light automatically. To

shutdown, turn dial control to OFF or set thermostat below room temperature. For

further instruction refer to owner's manual. Keep viewing doors tightly closed during

operation. Keep viewing and ash removal doors tightly closed during operation.

Conforme à la norme ASTM E1509 Std. Certifié à la norme ULC S627. Room Heating

Pellet Burning Type, (UM) 84-HUD POUR USAGE AVEC LES BOULETTES DE BOIS.

N’utiliser aucun autre genre de combustible.

Puissance de Rendement: 50,775 Btu's/hr. Puissance Électrique: 115 VAC, 60 Hz,

Début 2.9 Amps, Courir 2.45 Amps, Éloignez le fil électrique de l'appareil. Ne pas faire

passer le fil électrique au dessus ou en dessous de l'appareil. Ne pas bloquer

l’espace au dessous de l’appareil.

DANGER: Il y a risque de décharge électrique. Déconnectez le fil électrique de la

prise de contact avant le service. Remplacez la vitre seulement avec une vitre

céramique de 5 mm disponible chez votre fournisseur. Pour commencer, tournez la

molette de réglage à la température désirée et réglez le thermostat au-dessus de la

température ambiante, le poêle s'allumera automatiquement. Pour éteindre, tournez la

molette de réglage sur OFF ou réglez le thermostat dessous de la température

ambiante. Pour des instructions supplémentaires, référez vous au manuel du

propriétaire. Gardez la porte d'ouverture et la porte des cendres fermées

hermétiquement durant l'opération.

A

B

CD

D

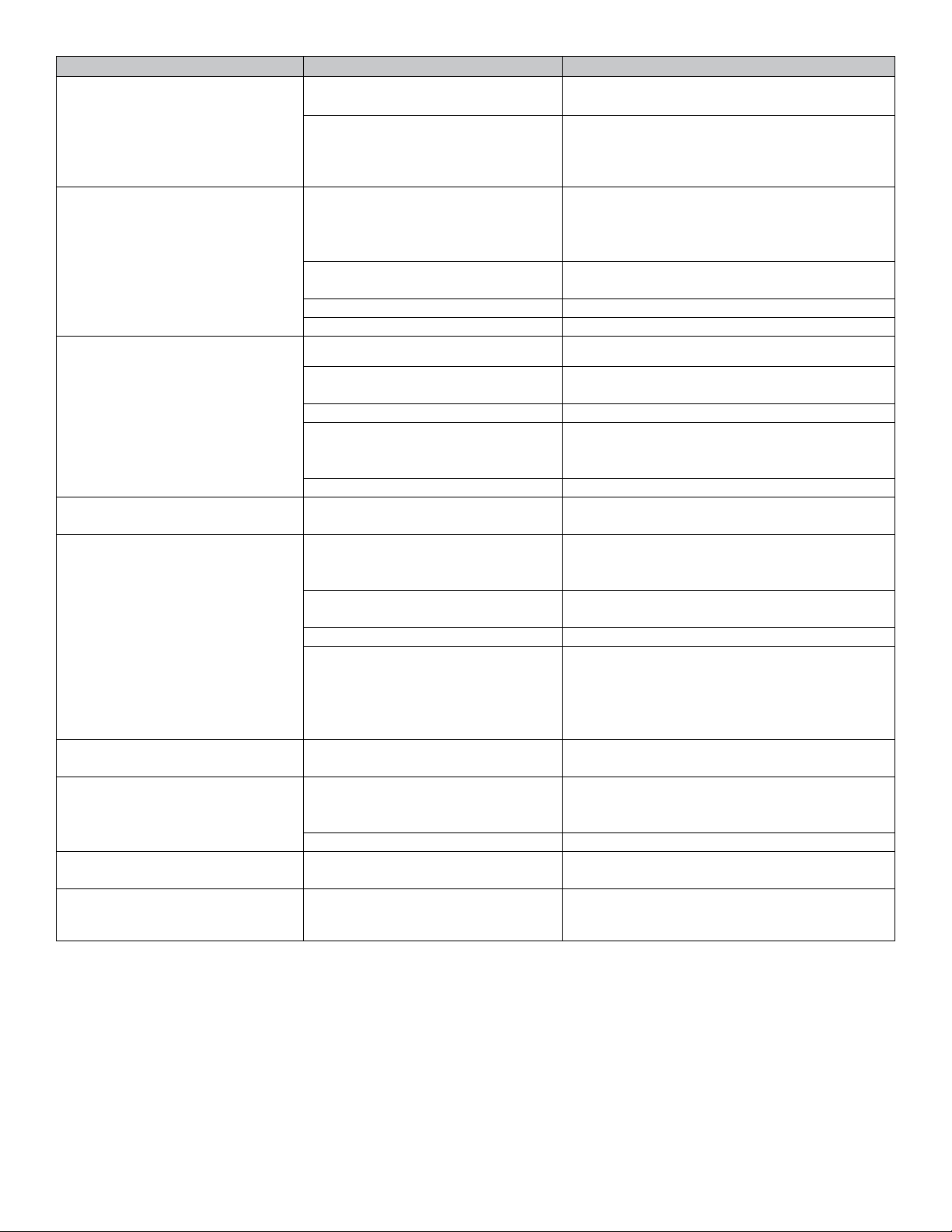

MINIMUM CLEARANCES TO COMBUSTIBLE MATERIALS

ESPACES LIBRES MINIMUM DES MATÉRIAUX

A Back Wall / Mur Arrière 2 in [51 mm]

B Side Wall / Mur De Côté 6 in [152 mm]

C “L” or “PL” Pipe to Back Wall / “L” ou “PL” Un Tuyau Mur Arrière 1 in [25 mm]

D Side Wall / Mur De Côté 2 in [51 mm]

FLOOR PROTECTION / PROTECTION DU SOL

Floor protector must be non-combustible

material, extending beneath heater and to

the front/sides/rear as indicated. Measure

front distance (I) from the surface of the

glass door.

Le poêle doit être placé sur une assise non

combustible s’étendant tout autour de lui,

comme les schémas l’indiquent. Mesurez la

distance du devant (I) de la surface de la

porte vitrée.

*Non-combustible floor protection must extend 2 inches

(51mm) beneath the flue pipe when installed with horizontal

venting or under the Top Vent Adapter with vertical installation.

RECOMMENDED IN USA; REQUIRED IN CANADA.

*Un protecteur incombustible de plancher doit s'étendre 2

inches (51mm) sous le conduit de cheminée pour une

installation de ventilation horizontale ou sous un adapteur de

ventilation de dessus pour une installation verticale.

RECOMMANDÉ AUX ÉTATS-UNIS; NÉCESSAIRE AU

CANADA.

USA

G = 2 in

H* = 2 in

I = 6 in

CANADA

G = 200 mm

H* = 200 mm

I = 450 mm

G

H

I

G

7080-164G

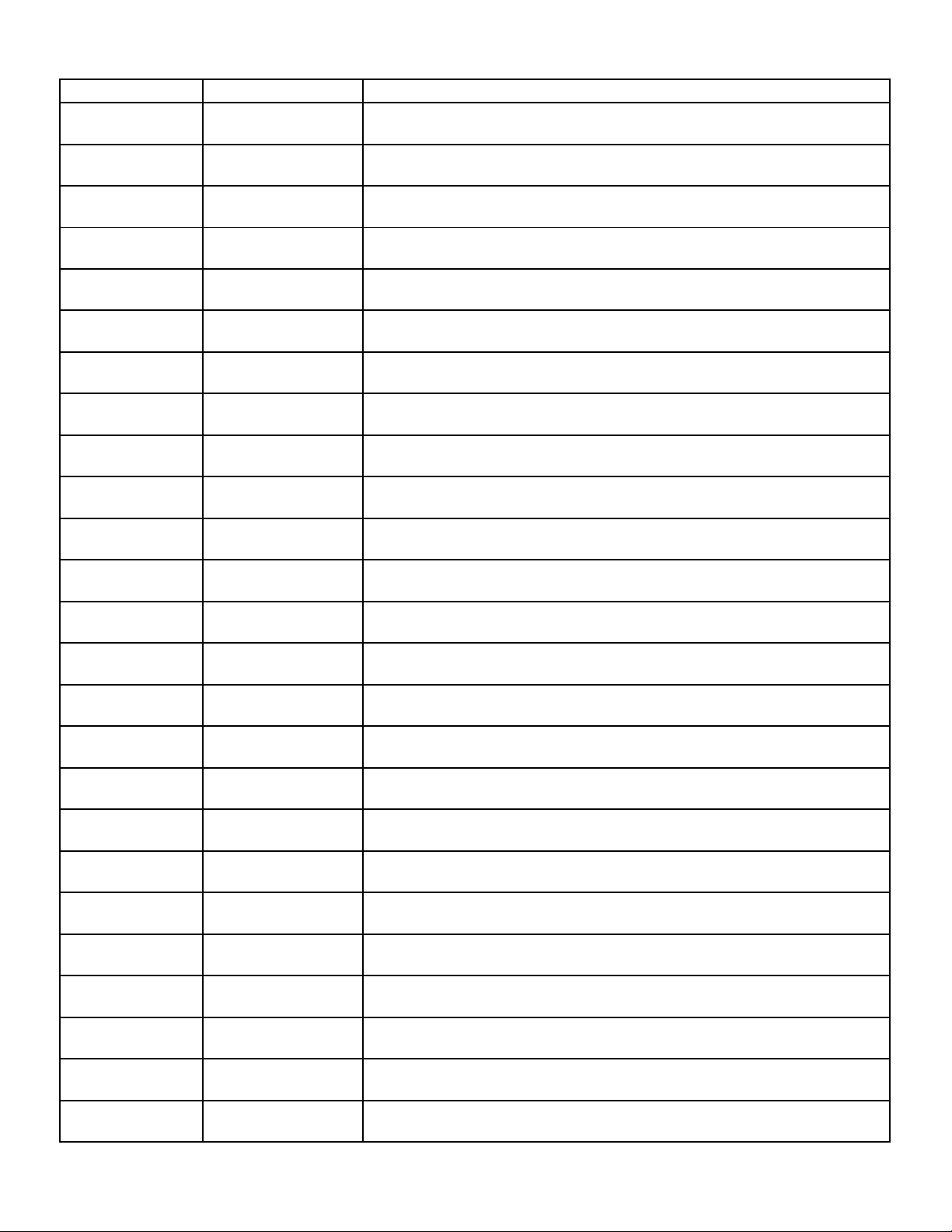

U.S. ENVIRONMENTAL PROTECTION AGENCY

Certified to comply with 2020 particulate standards at

0.74 G/HR. Tested under ASTM E2515, ASTM E2779,

and CSA B415.1-10

DO NOT REMOVE THIS LABEL / NE PAS ENLEVER L'ÉTIQUETTE

Made in U.S.A. of US and imported parts.

Fabriqué aux États-Unis-d’Amérique par des pièces d’origine américaine et pièces importées.

A. Sample of Serial Number / Safety Label

Serial No.

Report No.

Mfg. Date