POWX0614 EN

Copyright © 2019 VARO p a g e | 7 www.varo.com

You must keep the spindle lock pressed while you change the wheel !

For grinding wheels up to approx. 3 mm thick, screw on the flange nut with the flat side facing

the grinding wheel.

7.4 Switching on / off (Fig. 6)

Before working with the angle grinder, check that the voltage shown on the

machine’s model plate is the same as the mains voltage being used.

Before engage the ON/OFF switch trigger, check that the grinding disc is

properly fitted and run smoothly, the outer flange is well tightened.

To switch on the angle grinder, press the safety lock-off button (6) downward and squeeze the

ON/OFF switch trigger (5).

When you release the switch trigger, the tool turns off.

Do not let go of grinder until it has stopped running.

The wheel continues to rotate after the tool is switched off.

8 OPERATON MODES

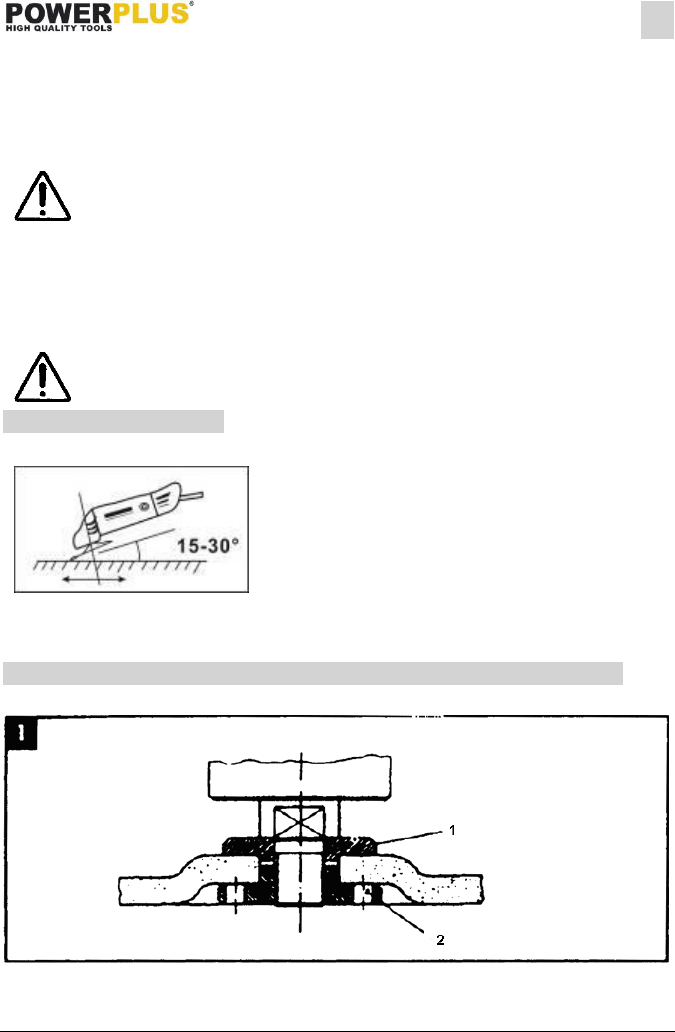

8.1 Grinding

Hold the handle (4) and auxiliary handle (7) firmly and

switch on. Avoid blocking the ventilation slots with your

hand, as this may cause the grinder to overheat. Let the

disc reach full speed. Apply the grinder to the item.

Maximum effect is achieved when the grinder is held at

an angle of 15-30°in relation to the item. Move the

grinder gently along the item. Give the grinder time to

work. It is rarely necessary to press the disc hard against the surface to be worked. Sparks

can occur in the motor compartment during use. This is normal and does not mean the grinder

is defective. Switch off the grinder after use.

9 FLANGE ARRANGEMENTS WHEN USING GRINDING WHEELS

9.1 Flange arrangements when using a depressed centre or straight grinding wheel

1 Clamping flange

2 Flange nut