-

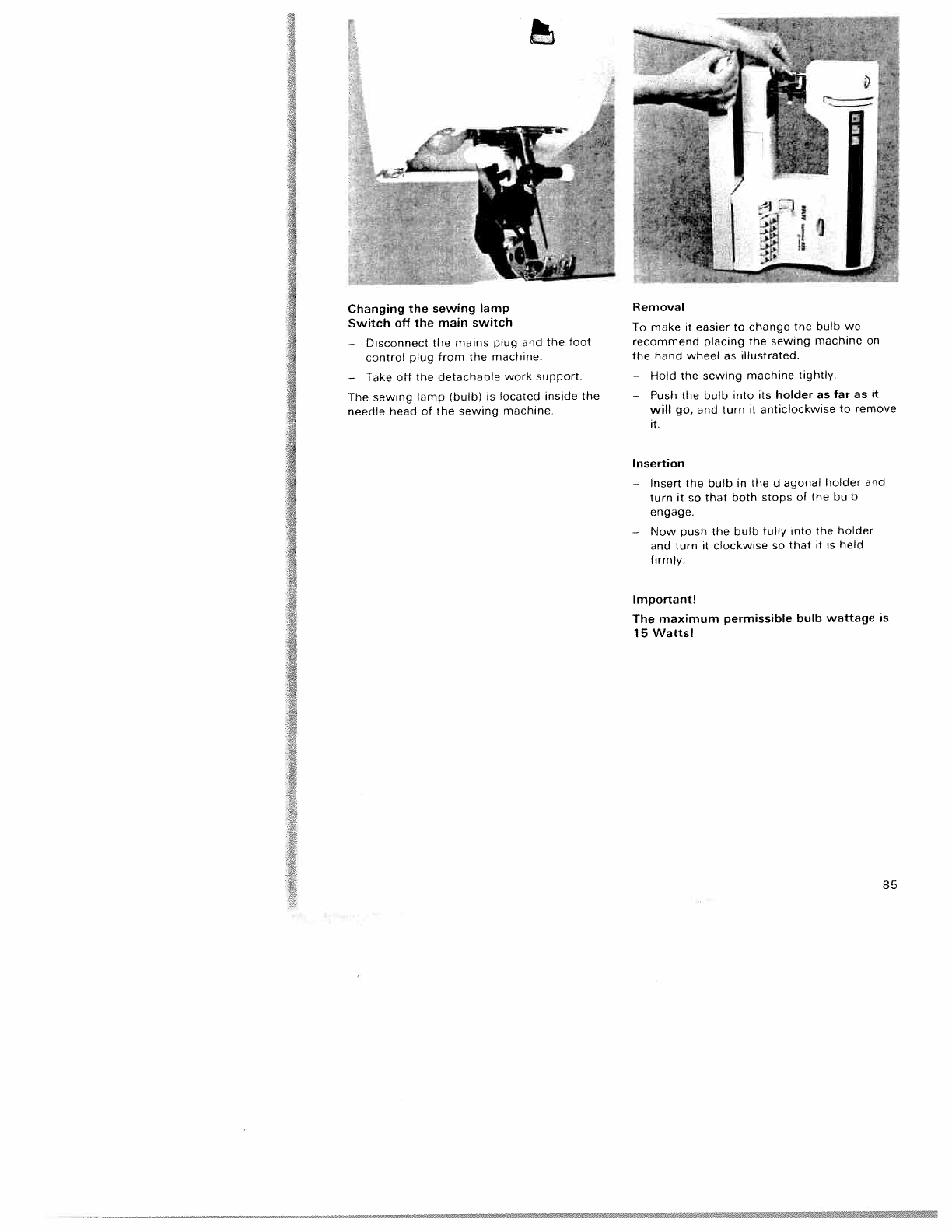

hoe vervang ik het lampje van mijn naaimachine pfaff 6120 Gesteld op 23-8-2023 om 15:44

Reageer op deze vraag Misbruik melden -

Ik weet niet wat ik los moet schroeven om het lampje te verwisselen Gesteld op 27-10-2021 om 16:11

Reageer op deze vraag Misbruik melden -

ik wil graag een handleiding van de Pfaff tipatic naaimachine

Reageer op deze vraag Misbruik melden

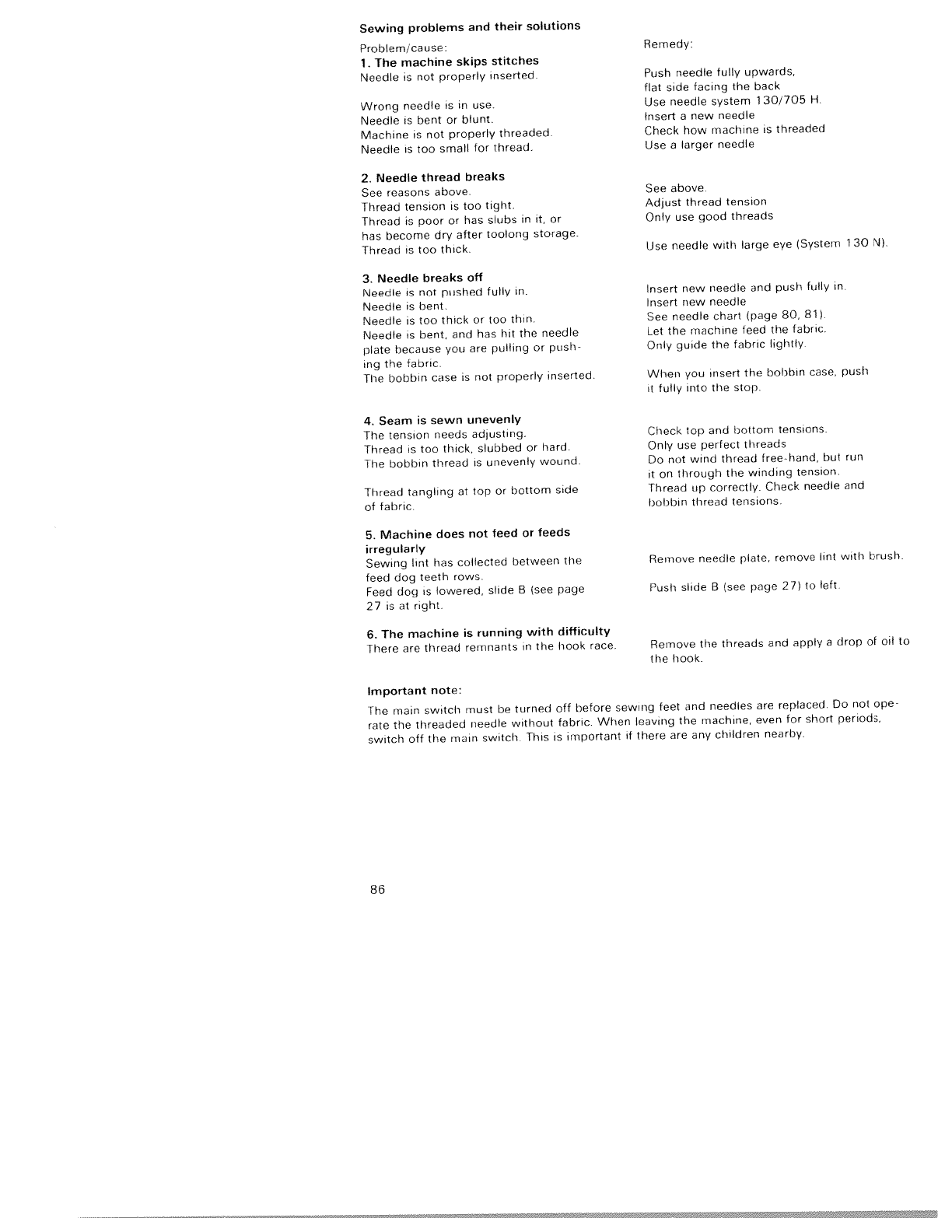

ik weet niet meer hoe ik de draad moet spannen. de boven draad breekt nu telkens Gesteld op 21-12-2020 om 14:30 -

Goedenavond.

Reageer op deze vraag Misbruik melden

Ben door verhuis mijn handleiding van mijn naaimachine Pfaff tipmatic 6120 verloren

Kan er mijn iemand mij deze in de Nederlandse taal bezorgen

Ik betaal de kosten Gesteld op 6-8-2020 om 21:09