-

Ik heb deze naaimachine van m'n schoonmoeder geërfd, heb geen handleiding en hier vind ik ze enkel in het Duits of Engels. Kan iemand mij helpen aub. Gesteld op 8-2-2021 om 18:13

Reageer op deze vraag Misbruik melden-

Heeft u het al gevonden ik beb ook opzoek naar de Nederlandse handleiding Geantwoord op 19-1-2022 om 14:22

Waardeer dit antwoord (5) Misbruik melden

-

-

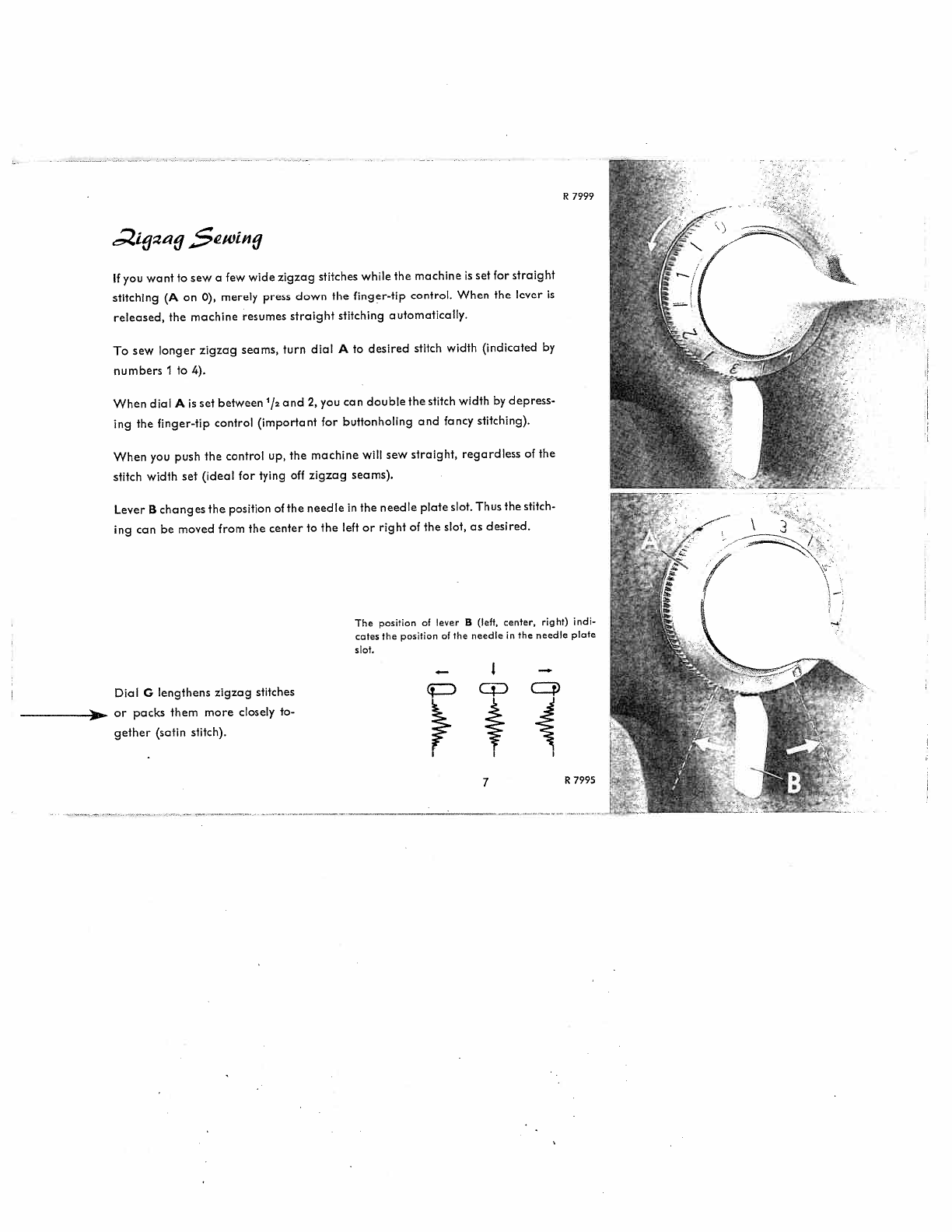

Hallo mijn toestel wil niet meer zig zag kan iemand mij raad geven alvast bedankt Gesteld op 14-10-2020 om 12:25

Reageer op deze vraag Misbruik melden-

Hallo, kan je de knop nog bewegen om zig zag in te stellen? Of zit tie vast? Zo ja, beetje wd40 er tussen spuiten, tussen knop en machine en dan draait hij wel weer! Succes! Geantwoord op 14-10-2020 om 12:45

Waardeer dit antwoord Misbruik melden

-

-

Mijn machine wil niet van zigzag af

Waardeer dit antwoord Misbruik melden

Geantwoord op 6-2-2025 om 19:21 -

wat als de steekinstellingsknop niet reageert (dus blijft altijd sttaan op dezelfde steekgrootte Gesteld op 20-8-2020 om 22:58

Reageer op deze vraag Misbruik melden -

Weet iemand als deze machine geschikt voor lederen handtassen te maken? Gesteld op 17-6-2020 om 18:38

Reageer op deze vraag Misbruik melden-

Hoi, voor zover ik weet kan je hier wel leernaalden in gebruiken, maar voor dik stug leer zou ik het niet aanraden....de machine is niet zwaar genoeg denk ik! Dan heen je meer iets nodig wat een schoenmaker gebruikt! Geantwoord op 18-6-2020 om 23:17

Waardeer dit antwoord (1) Misbruik melden

-

-

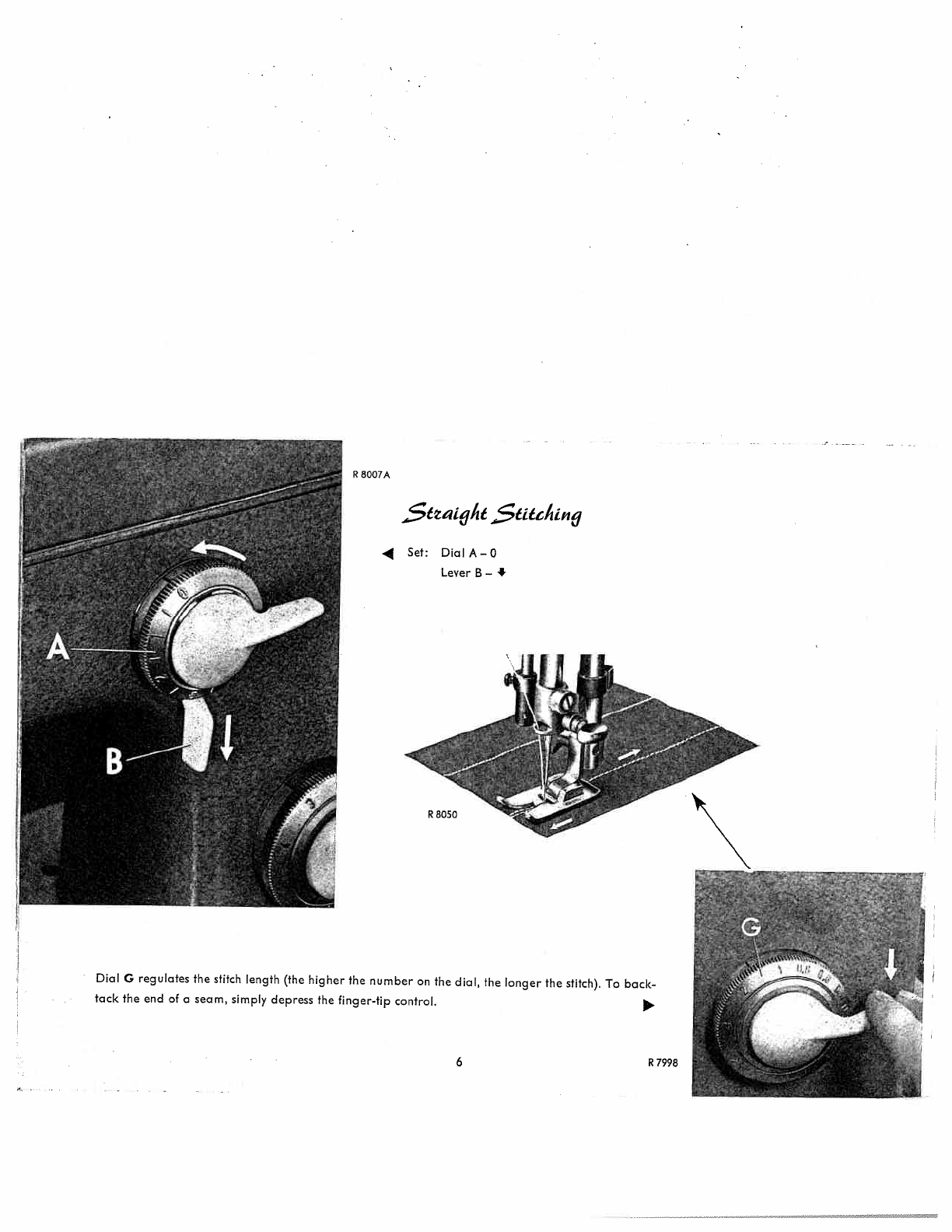

ik kan de zigzag niet verwijderen om trug recht te stikken hoe kot dit?? dank u Gesteld op 29-4-2020 om 10:53

Reageer op deze vraag Misbruik melden-

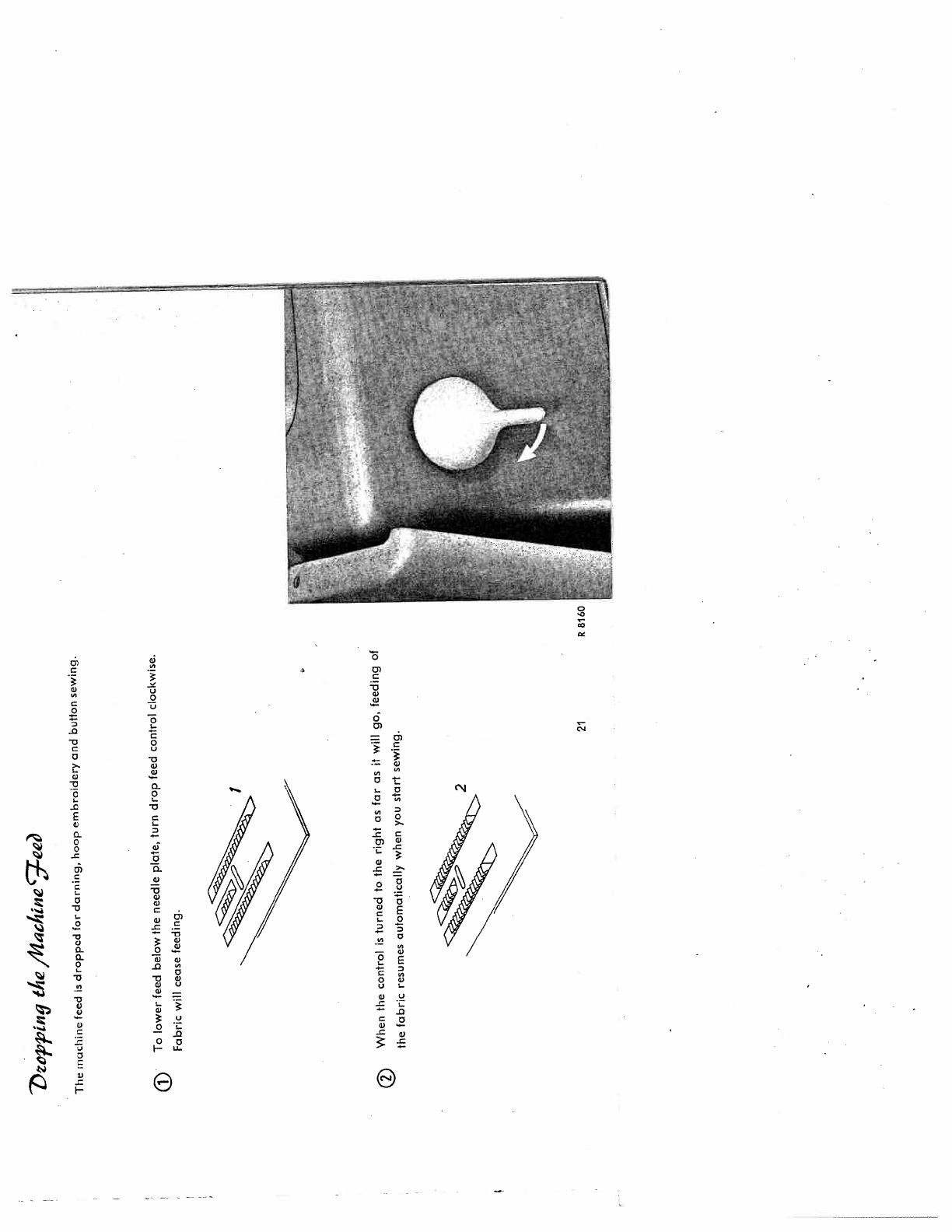

Hallo, er zit een grote knop rechts op de machine met een witte hendel eraan. Deze moet je links of rechtsom draaien en dan komt het goed. Je ziet het vanzelf aan het stiksel.

Waardeer dit antwoord Misbruik melden

Groet René Geantwoord op 29-4-2020 om 11:08

-

-

Maar de hendel zit los ,hoe krijg ik die vast? Geantwoord op 12-1-2022 om 09:05

Waardeer dit antwoord Misbruik melden -

Kan iemand mij de handleiding voor naaimachine phaff 360 automatic bezorgen aub heb dit toestel geerfd zonder handleiding .

Reageer op deze vraag Misbruik melden

Mvg

Marc Gesteld op 2-9-2019 om 13:48-

ik heb hetzelfde probleem, geërfd, geen handleiding, en hier vind ik enkel de Duitse of Engelse handleiding. Heeft u inmiddels een handleiding gevonden mijnheer ? Geantwoord op 8-2-2021 om 18:09

Waardeer dit antwoord Misbruik melden

-