12

GB/IE/

CY

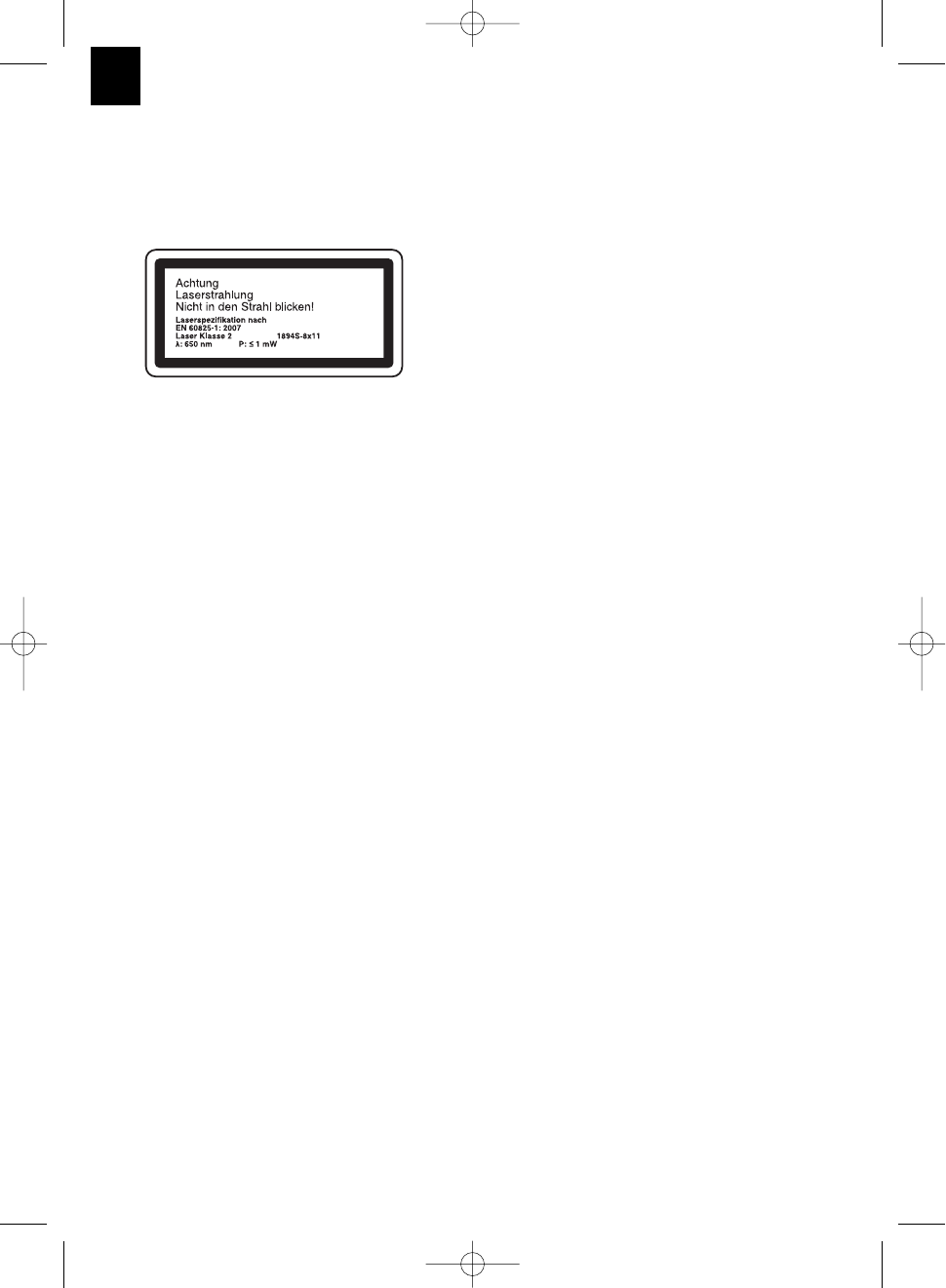

2. Safety information on the laser

Important:

Laser radiation

Do not look into the beam

Laser class 2

Protect yourself and your environment from

accidents by taking the appropriate

precautionary measures.

Do not look directly into the laser beam with

the naked eye.

Never look directly into the laser path.

Never direct the laser beam at reflecting

surfaces, persons or animals. Even a low

output laser beam can inflict injury on the

eye.

Caution: It is vital to follow the work

procedures described in these instructions.

Using the equipment in any other way may

result in hazardous exposure to laser

radiation.

Never open laser module.

When the laser is not going to be used for

an extended period of time, the batteries

should be removed.

Never use an optical instrument (for

example magnifying glass) to view the laser

beam.

Check the laser for damage on a regular

basis and always before use. To protect

yourself against injury, never use the

equipment if it is damaged.

Defective lasers have to be repaired by a

customer service workshop.

3. Safety information on the batteries

Never recharge the batteries. Danger of

explosion.

Keep batteries out of the reach of children.

Do not throw batteries into the fire, short-

circuit or take them apart.

If necessary clean the contacts on the

batteries and equipment before inserting the

batteries.

Remove flat batteries immediately from the

equipment. Risk of leakage!

Always replace all batteries in one go. Only

use new batteries of the same make.

Avoid contact with skin, eyes and mucous

membranes. If you come into contact with

battery acid, rinse the affected pars at once

with plenty of clear water and seek

immediate medical assistance.

Do not expose batteries to extreme

conditions, e.g. do not place on heaters or in

direct sunshine. Increased risk of leakage.

4. Maintenance and service

The following conditions can have an

influence on noise impact on the operator:

- Type of saw blade (e.g. saw blades

designed to reduce noise development)

- Material of the workpiece

- The force with which the workpiece is

pushed against the saw blade

Faults on the machine or its guards, safety

devices and blade must be reported to the

person in charge as soon as they are

discovered.

5. Safe operation

Use a suitable blade for the material you

wish to saw.

Never use the drag, crosscut and miter saw

to cut any materials other than those

specified by the manufacturer.

Use only the transport devices to move the

equipment. Never use the guards for

handling or moving the equipment.

Use the saw only if it is in perfect condition

and properly maintained and only if the

guards are correctly positioned.

When cutting miters, make sure that the

device for swiveling the arm is fastened

securely.

The floor around the machine must be level,

clean and free of loose particles, such as

chips and cutting residues.

The operator must receive proper training in

the use, adjustment and operation of the

machine.

Only use properly sharpened saw blades.