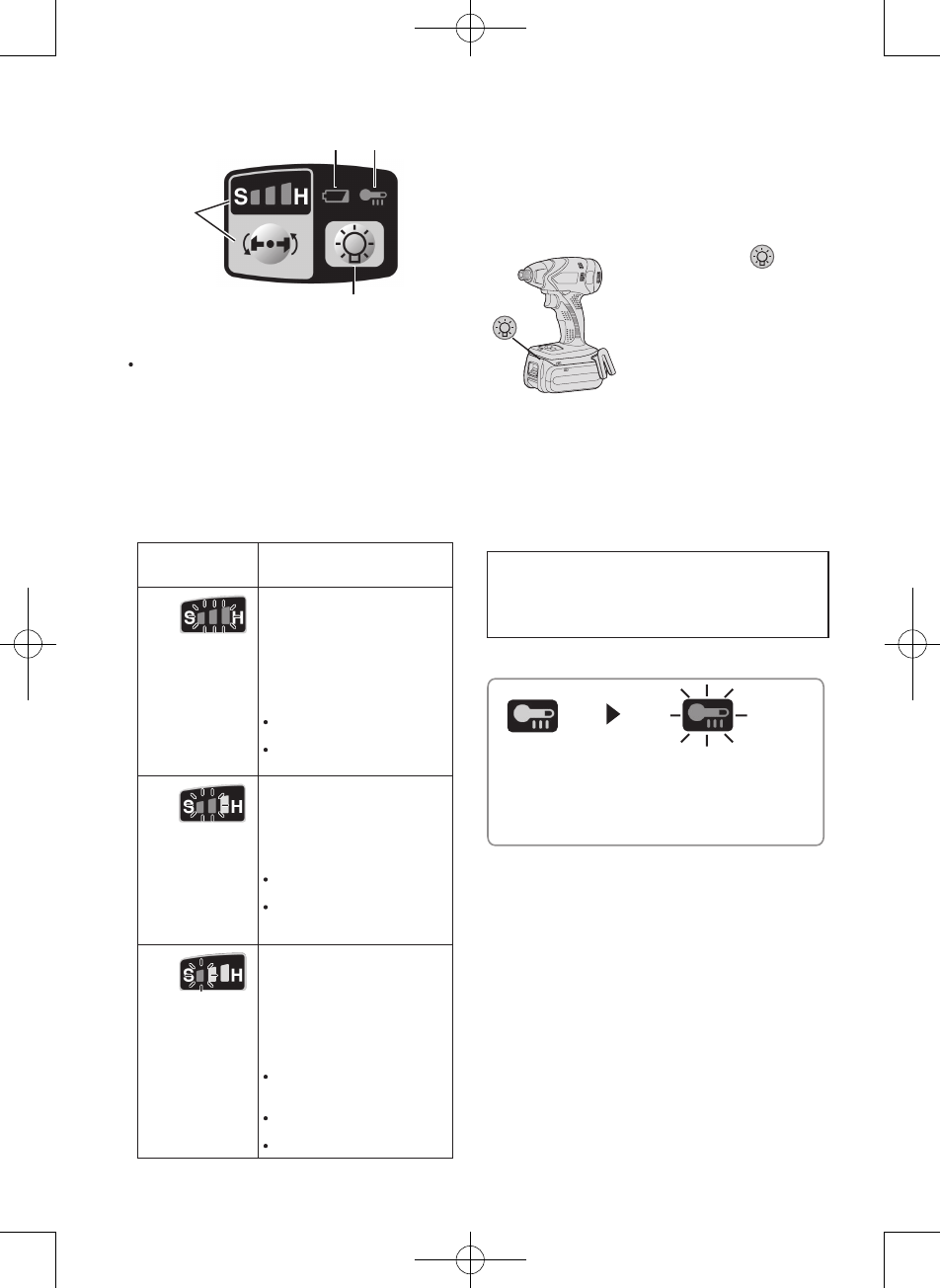

Control Panel

(1)

(4) (3)

(2)

(1) Impact Power Mode Select

Selecting the impact power among 3

modes (Soft, Medium, Hard).

Press the impact power mode button to set

it. The mode changes to hard, medium, or

soft each time the button is pressed.

The driver is preset to “hard” impact mode

setting when shipped from the manufac-

turer.

Recommended work guideline table

Impact

Power mode

Display

Recommended Application

H

Jobs requiring a high level

of torque where there is

no possibility of the bolts

or screw breaking, its top

shearing off, or the bit coming

loose. (This setting provides

maximum torque.) Suitable

applications include:

Tightening M8 and larger

bolts

Tightening long screws

during interior finishing work

0 – 2300 r.p.m./

0 – 2500 r.p.m.

and

0 – 3000 i.p.m./

0 – 3300 i.p.m./

0 – 3500 i.p.m.

M

Jobs requiring limited torque

where there is a possibility of

the screw breaking or its top

shearing off. (This setting limits

torque.) Suitable applications

include:

Tightening bolts with

smaller diameters (M6)

Tightening metalwork

screws when installing

fixtures

0 – 1400 r.p.m.

and

0 – 2800 i.p.m.

S

Jobs requiring limited torque

where there is a possibility

of the screw breaking, its

top shearing off, or the bit

coming loose and damaging

a nished exterior surface.

(This setting limits torque.)

Suitable applications include:

Tightening bolts smaller

than M6 that may shear

easily

Tightening screws into

molded plastic

Installing gypsum wallboard

0 – 1000 r.p.m.

and

0 – 2000 i.p.m.

* i.p.m. = Impact per minute.

Avoid repeatedly depressing the switch

when the bolts and screws are securely

fastened.

Not doing so may cause a delay in

rotation starting, or the Impact Power

mode display to flash and prevent rotation

from starting for circuit protection.

(2) LED light

Pressing the but ton

tog gles the LED light on

and off.

The light illuminates with

very low current, and

it does not adversely

affect the performance

of the

driver during use

or its battery capacity.

CAUTION:

• The built-in LED light is designed to illu-

minate the small work area temporarily.

•

Do not use it as a substitute for a regu-

lar

flashlight, since it does not have

enough brightness

.

Caution : DO NOT STARE INTO BEAM.

Use of controls or adjustments or performance

of procedures other than those specied herein

may result in hazardous radiation exposure.

(3) Overheat warning lamp

Off (normal

operation)

Flashing: Overheat

Indicates operation has

been halted due to motor

or battery overheating.

The overheating protection feature halts

driver operation to protect the motor and

battery pack in the event of overheating.

The overheat warning lamp on the control

panel flashes when this feature is active.

• If the overheating protection feature acti-

vates, allow the driver to cool thoroughly

(at least 30 minutes). The driver is ready

for use when the overheat warning lamp

goes out.

• Avoid using the driver in a way that

causes the overheating protection fea-

ture to activate repeatedly.