0

OPERATING INSTRUCTIONS

9

Volts Cord length Amps Gauge needed Amps Gauge needed

115/120V 25 ft 0 - 6 18 10 - 12 16

6 - 10 18 12 - 16 14

115/120V 50 ft 0 - 6 18 10 - 12 16

6 - 10 18 12 - 16 14

115/120V 100 ft 0 - 6 16 10 - 12 14

6 - 10 14 12 - 16 not recommended

115/120V 150 ft 0 - 6 14 10 - 12 12

6 - 10 12 12 - 16 not recommended

220/240V 50 ft 0 - 6 16 10 - 12 16

6 - 10 16 12 - 16 12

220/240V 100 ft 0 - 6 16 10 - 12 16

6 - 10 16 12 - 16 12

220/240V 200 ft 0 - 6 16 10 - 12 14

6 - 10 14 12 - 16 not recommended

220/240V 300 ft 0 - 6 14 10 - 12 12

6 - 10 12 12 - 16 not recommended

Table 1

Inspecting the Chain

Always inspect an incoming cutting chain and review any

problems with owner or user. Always check for proper

installation of tie straps and/or reversed drive links.

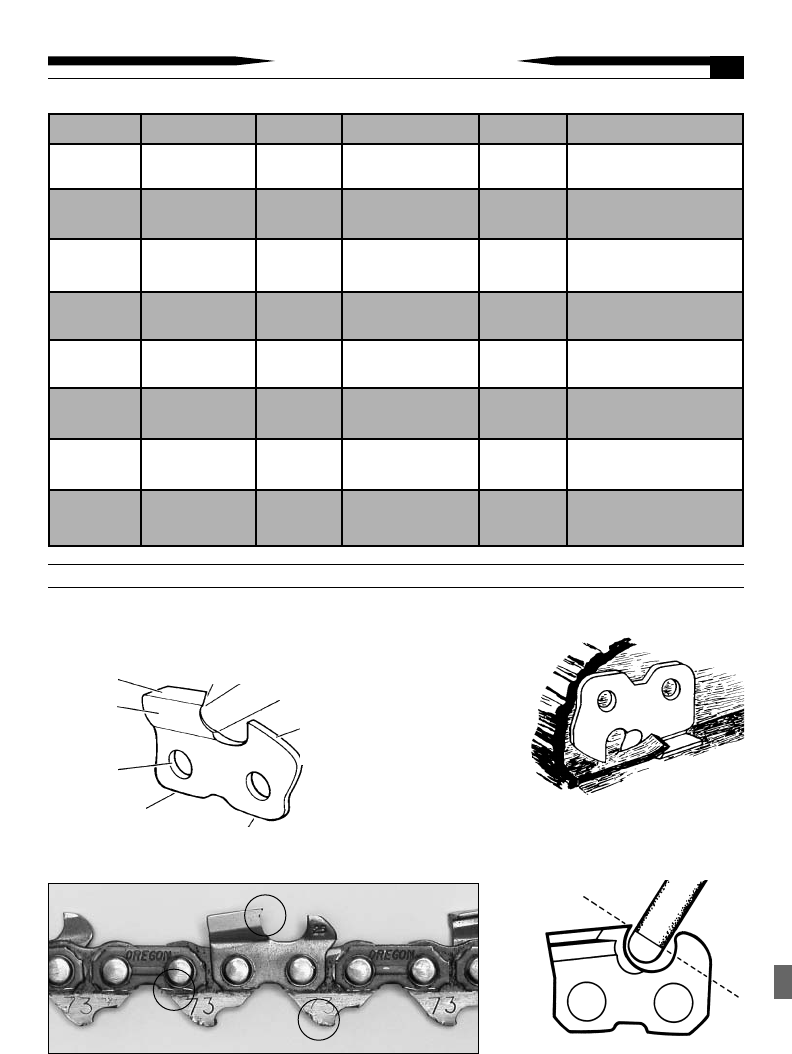

How a Cutter Works

A. Depth gauge

(controls bite of

the cutter).

B. Working corner

(slices the cross

grain – does most

the work).

C. Top plate edge (lifts out chips after cross grain

has been cut).

D. + E. Heel and toe (support cutter while working).

Top Plate

Side Plate

Rivet Hole

D. Heel

E. Toe

C. Top Plate

Edge

B. Working Corner

A. Depth

Gauge

Parts of a Cutter

Gullet

Note: For proper side plate angle,

do not grind the gullet deeper

than where the grinding wheels’

radius meets the flat of the wheel.

(see Illustration).

Grinding A Chain