10

Prior to installation

For optimum extractor hood efficiency:

❑

Short, smooth air exhaust pipe.

❑

As few bends in the pipe as possible.

❑

Diameter of pipe to be as large as

possible and no tight bends in pipe.

If long, rough exhaust-air pipes,

many pipe bends or smaller pipe

diameters are used, the air extraction

rate will no longer be at an optimum

level and there will be an increase in

noise.

❑

Round pipes:

We recommend

Internal diameter: 150 mm (at least

120 mm).

❑

Flat ducts must have an internal cross-

section that equates to that of round

pipes.

There should be no sharp bends.

l 120 mm approx. 113 cm

2

l 150 mm approx. 177 cm

2

❑

If pipes have different diameters:

Insert sealing strip.

❑

For exhaust-air mode, ensure that

there is an adequate supply of fresh air.

Connecting a l 150 mm exhaust-air

pipe:

❑

Mount the pipe directly onto the air

outlet on the hood.

Connecting a l 120 mm exhaust-air

pipe:

❑ Place the reducing connecting piece

onto the air connecting piece – Fig. 3 –

and fasten the exhaust pipe to it.

❑ Attach the exhaust-air pipe to the

reducing connector.

Circulating-air mode Fig. 4

❑ With activated carbon filter if exhaust-air

mode is not possible.

ṇIf the extractor hood is suitable for

circulating-air mode, you can purchase the

complete installation set at specialist

outlets.

Preparing the ceiling

❑

The ceiling must be flat and horizontal.

❑

Ensure that the ceiling is capable of

providing a firm hold for mounting

screws and plugs. The enclosed plugs

are suitable for concrete and stonework.

If the ceiling is made of any other

material, use appropriate mounting

components.

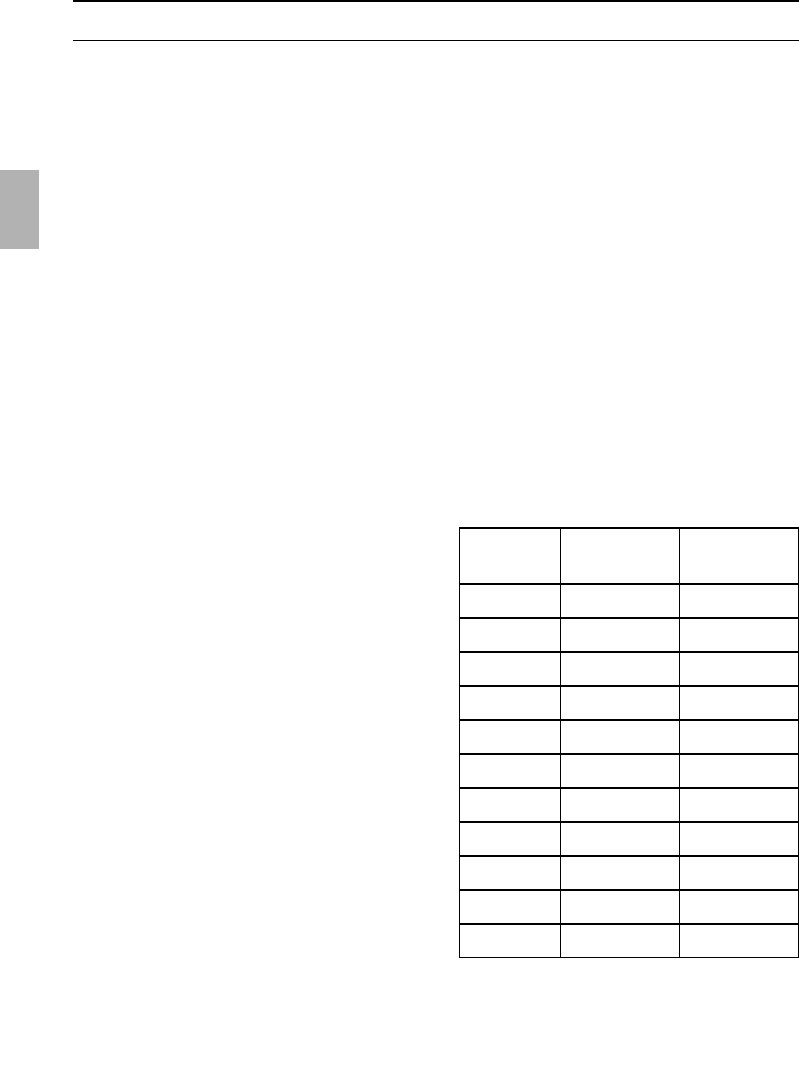

Weight in kg:

We reserve the right to construction changes within the

context of technical development.

Exhaust

air

Recircula-

ting air

3432

DIE975A

5048

DIE995F

4341

DIE945E

4341

LC91150

4341

LC97050

3432

LC95950

3735

LC95150

4341

LC92950

3129

D8150N1

3129

D8150N2

4341

D91E1N0