3 Admin Functions ........................................................................................... 3-1

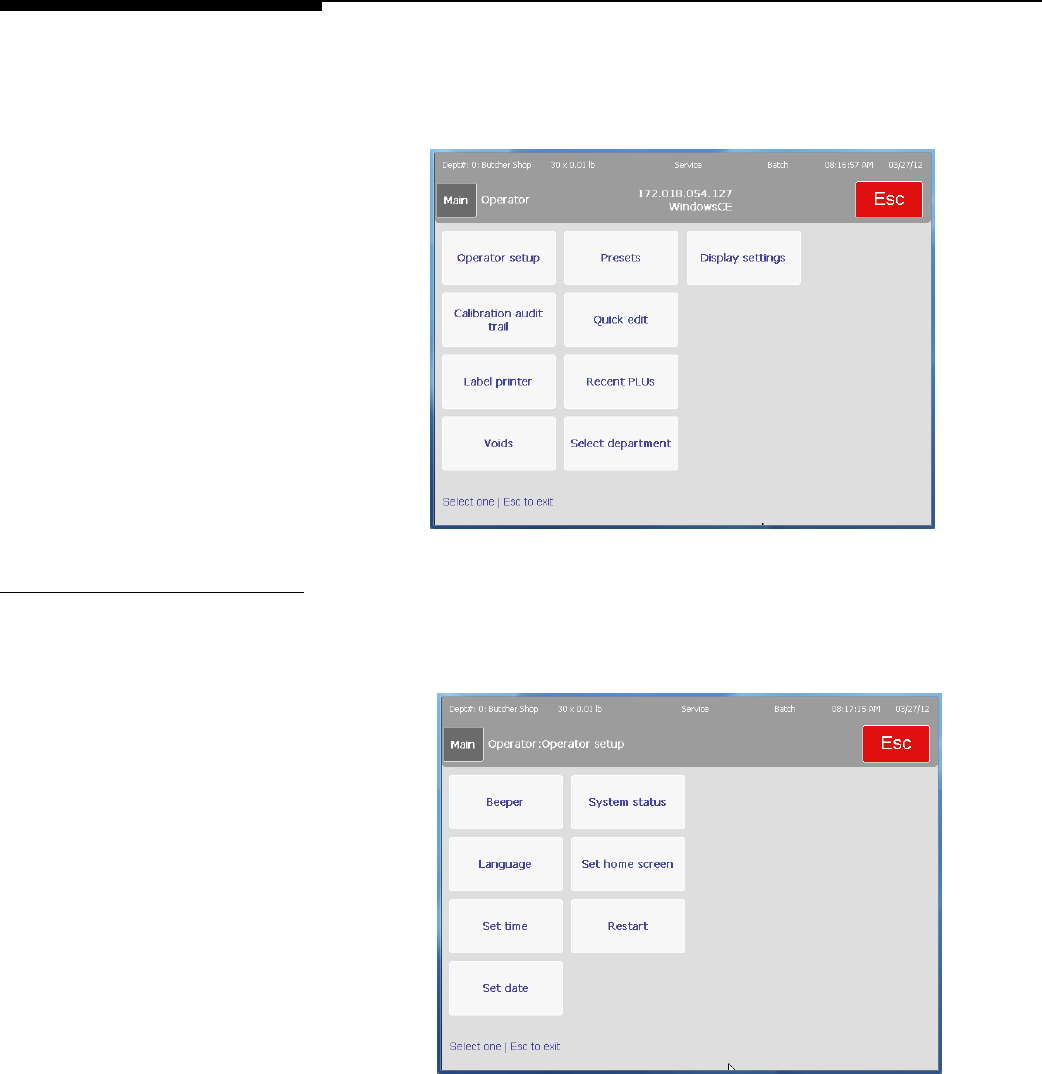

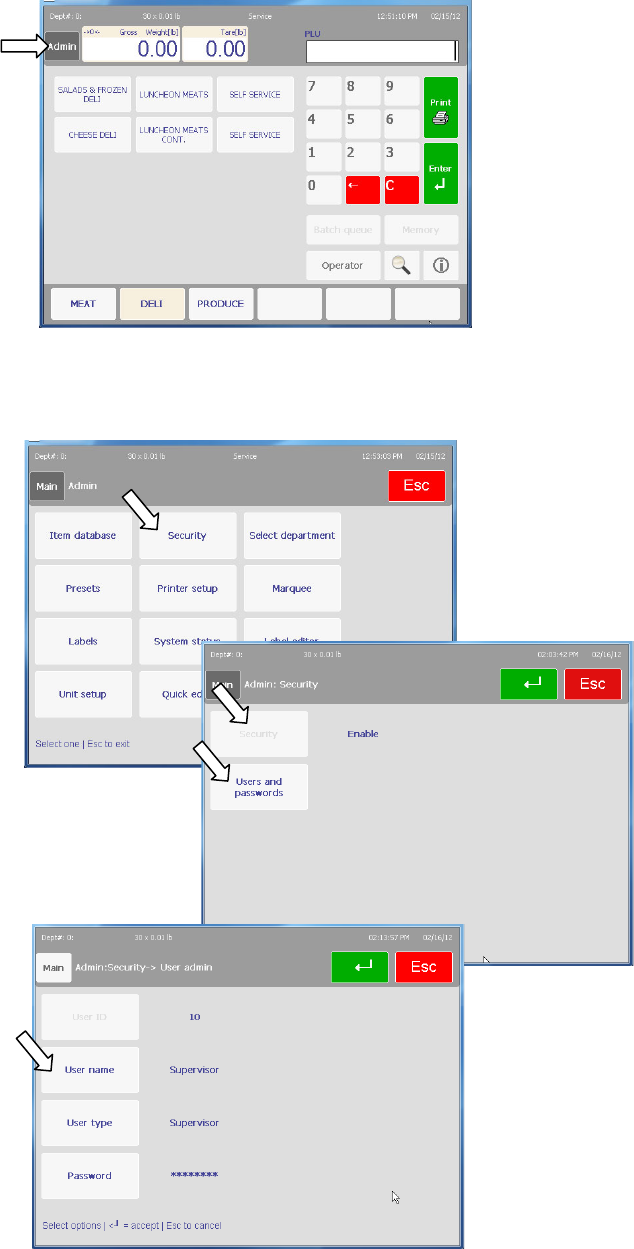

Admin Button ...................................................................................................................... 3-1

Item Database ..................................................................................................................... 3-2

Item Database Editor ............................................................................................................. 3-2

REM Master Editor ................................................................................................................ 3-3

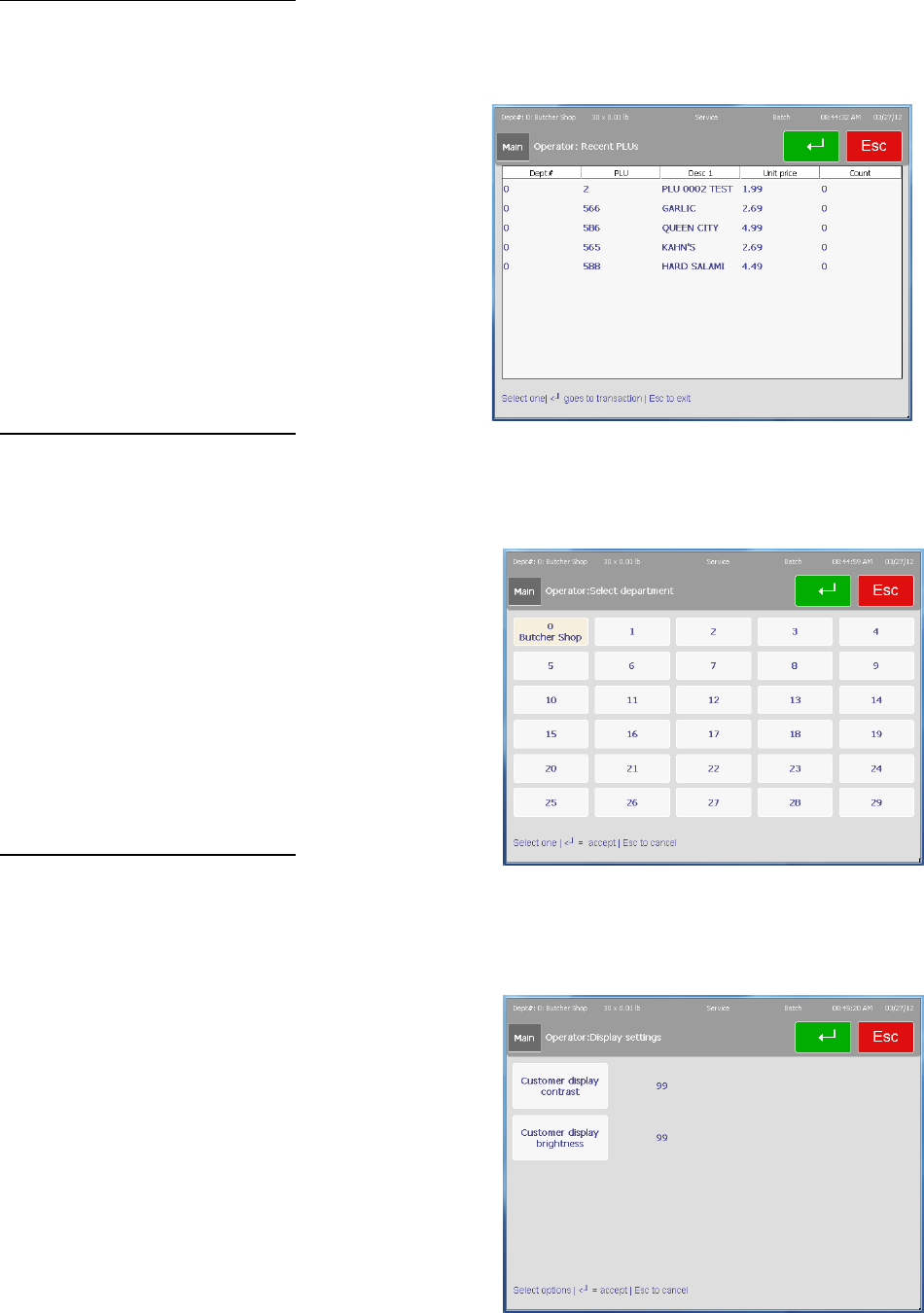

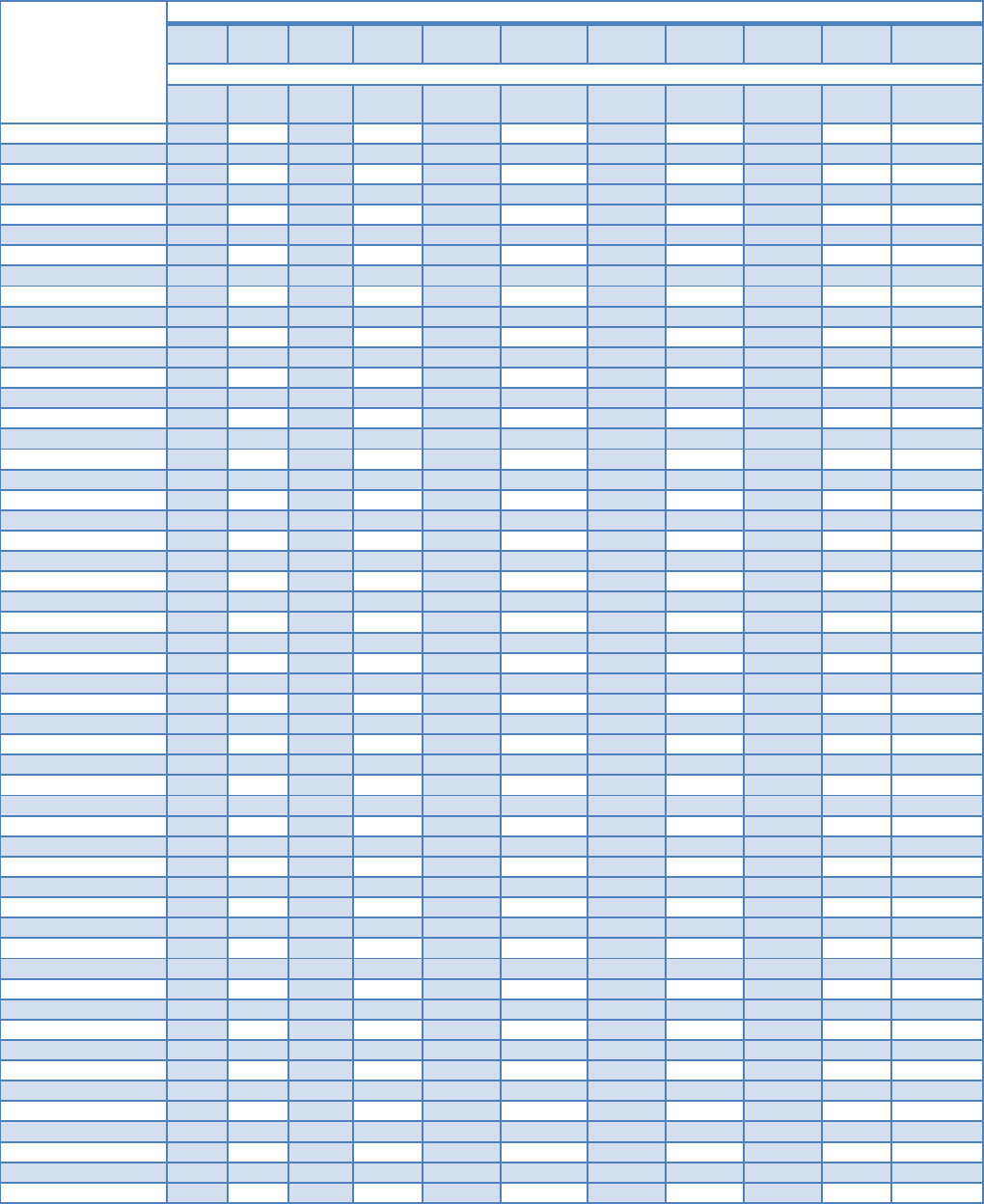

PLUs .................................................................................................................................. 3-3

Extra Text ............................................................................................................................ 3-7

Nutrifacts............................................................................................................................. 3-7

COOL .................................................................................................................................. 3-9

Create/Edit COOL Text .............................................................................................................. 3-10

Tracking or Lot Numbers .......................................................................................................... 3-12

COOL Records and Lists .......................................................................................................... 3-13

COOL Setup ............................................................................................................................ 3-19

Label Formats ........................................................................................................................ 3-20

Using COOL ........................................................................................................................... 3-21

Accumulators ..................................................................................................................... 3-22

Reports ............................................................................................................................. 3-23

Clear ................................................................................................................................ 3-23

Action Code ....................................................................................................................... 3-24

Grade ............................................................................................................................... 3-25

Group ............................................................................................................................... 3-26

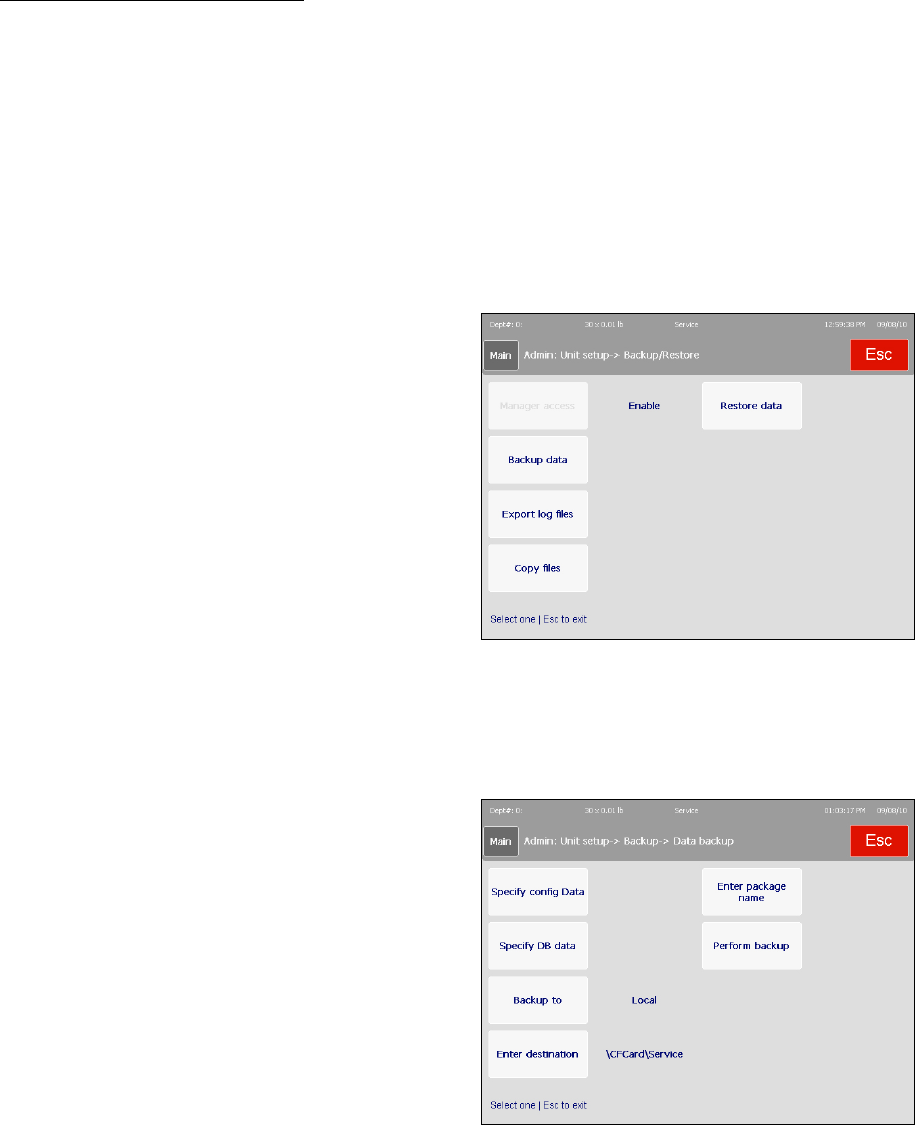

Department Settings ............................................................................................................ 3-27

Edit ....................................................................................................................................... 3-27

Clear ..................................................................................................................................... 3-28

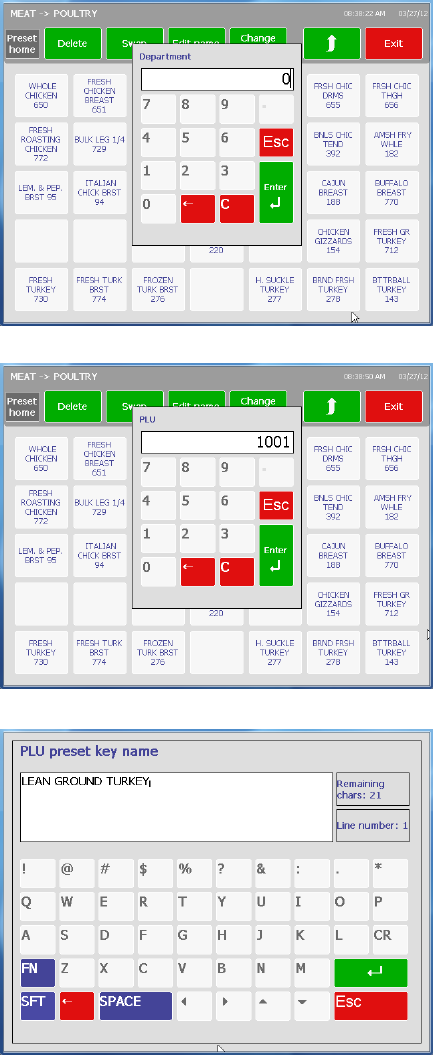

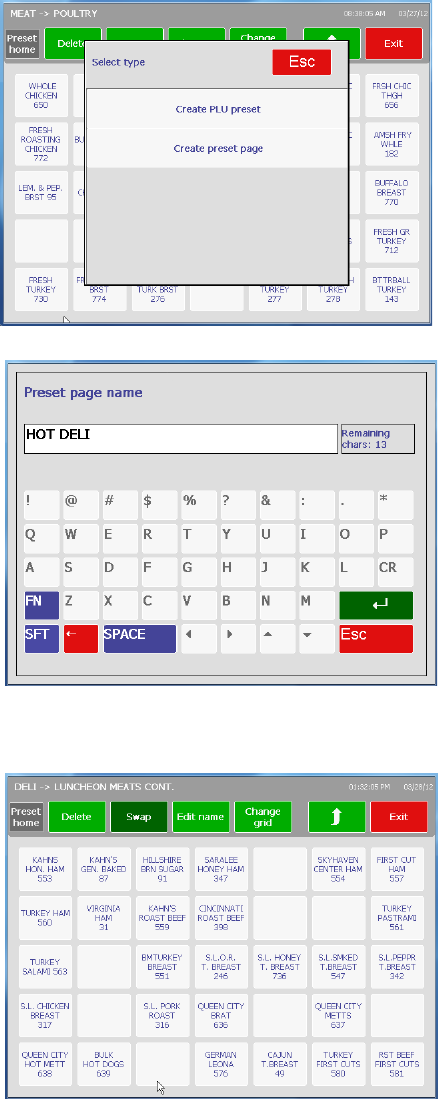

Presets ............................................................................................................................. 3-29

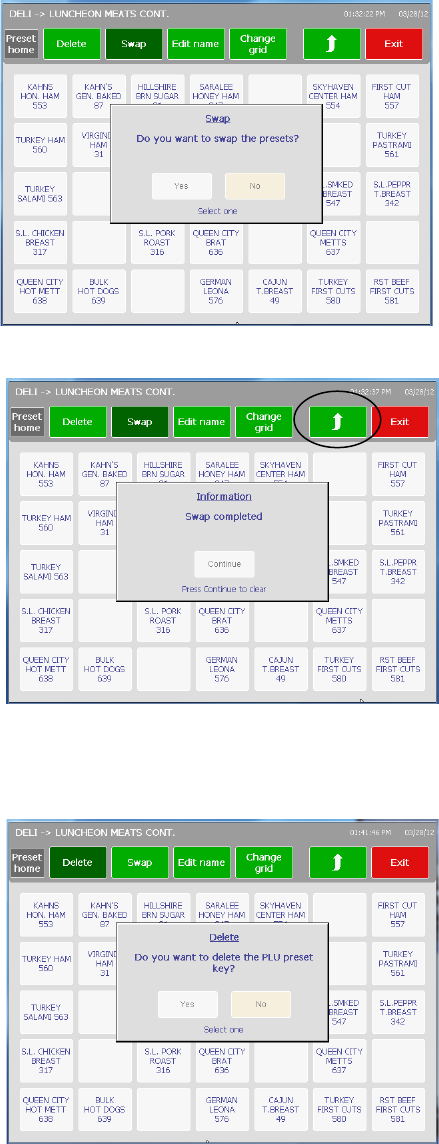

Delete ............................................................................................................................... 3-29

Swap Pages ...................................................................................................................... 3-29

Edit Name ......................................................................................................................... 3-30

Change Grid ...................................................................................................................... 3-30

Programming Presets ......................................................................................................... 3-30

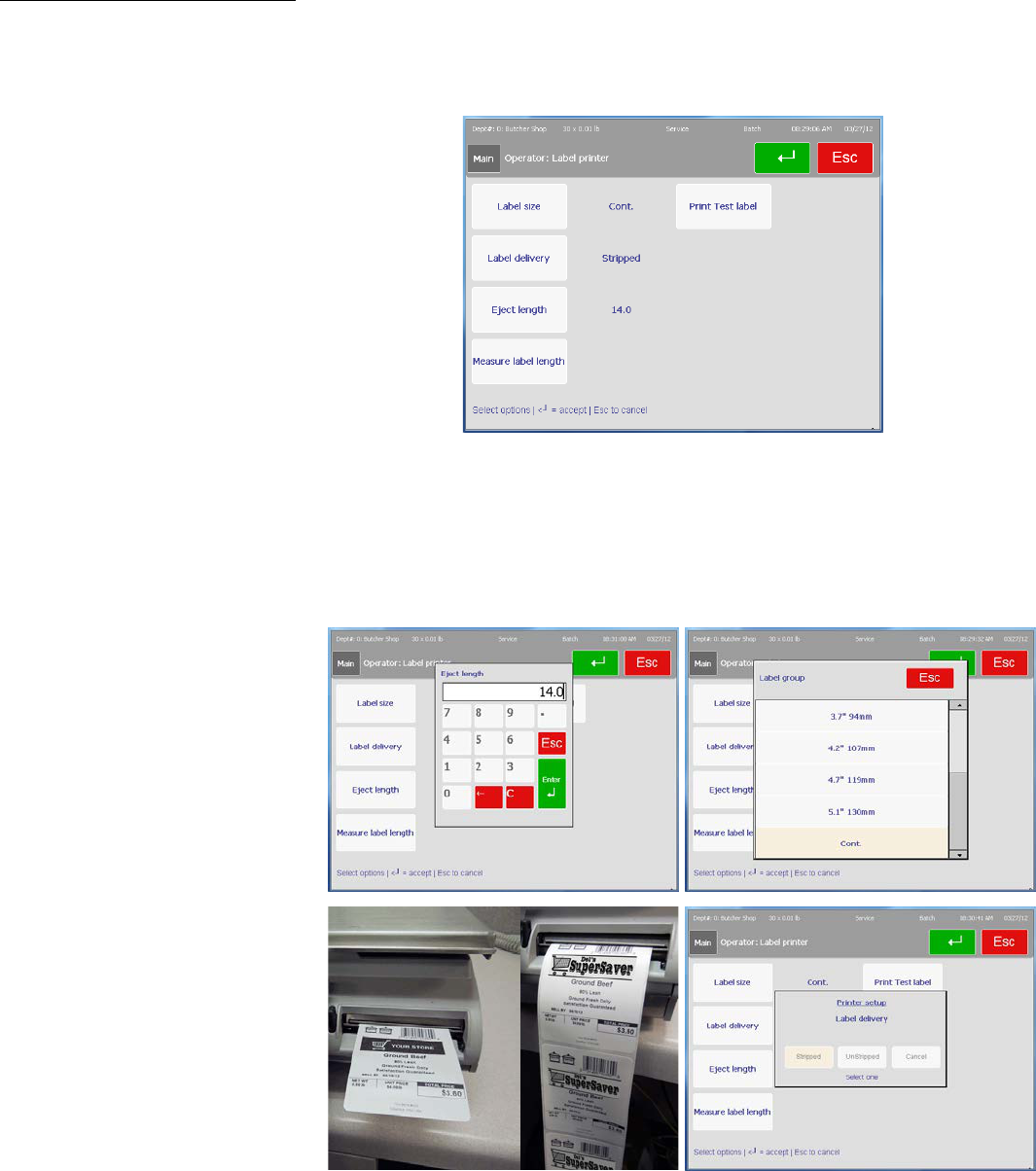

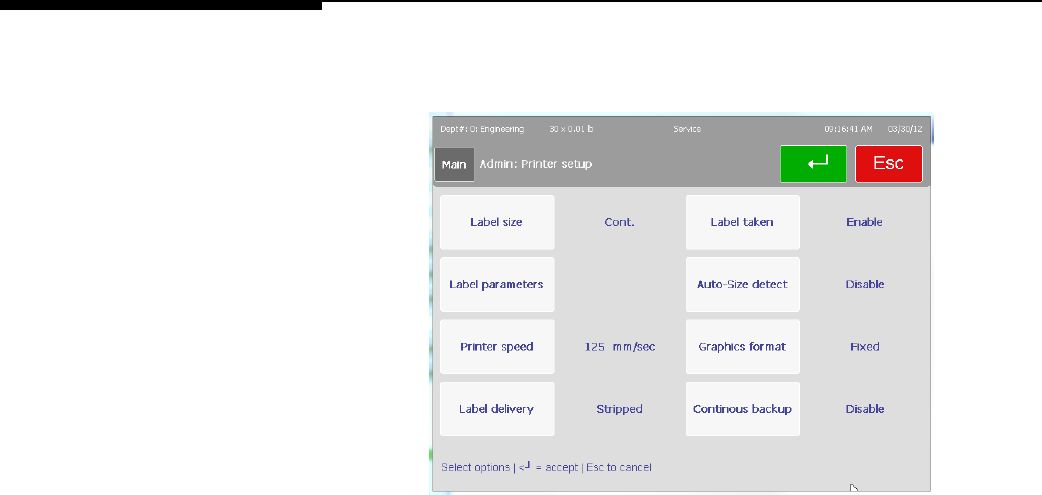

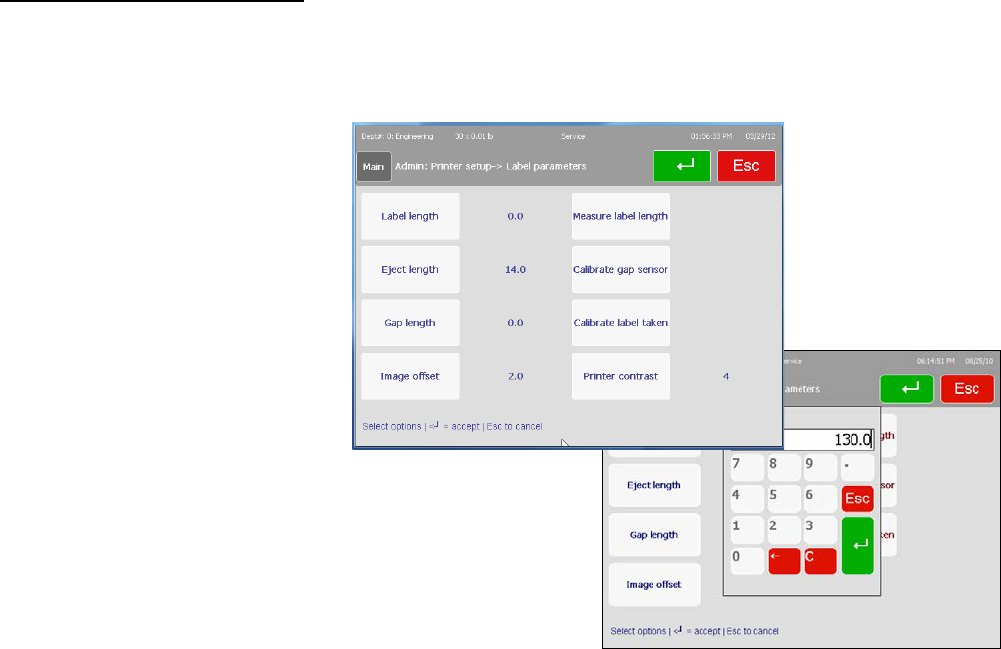

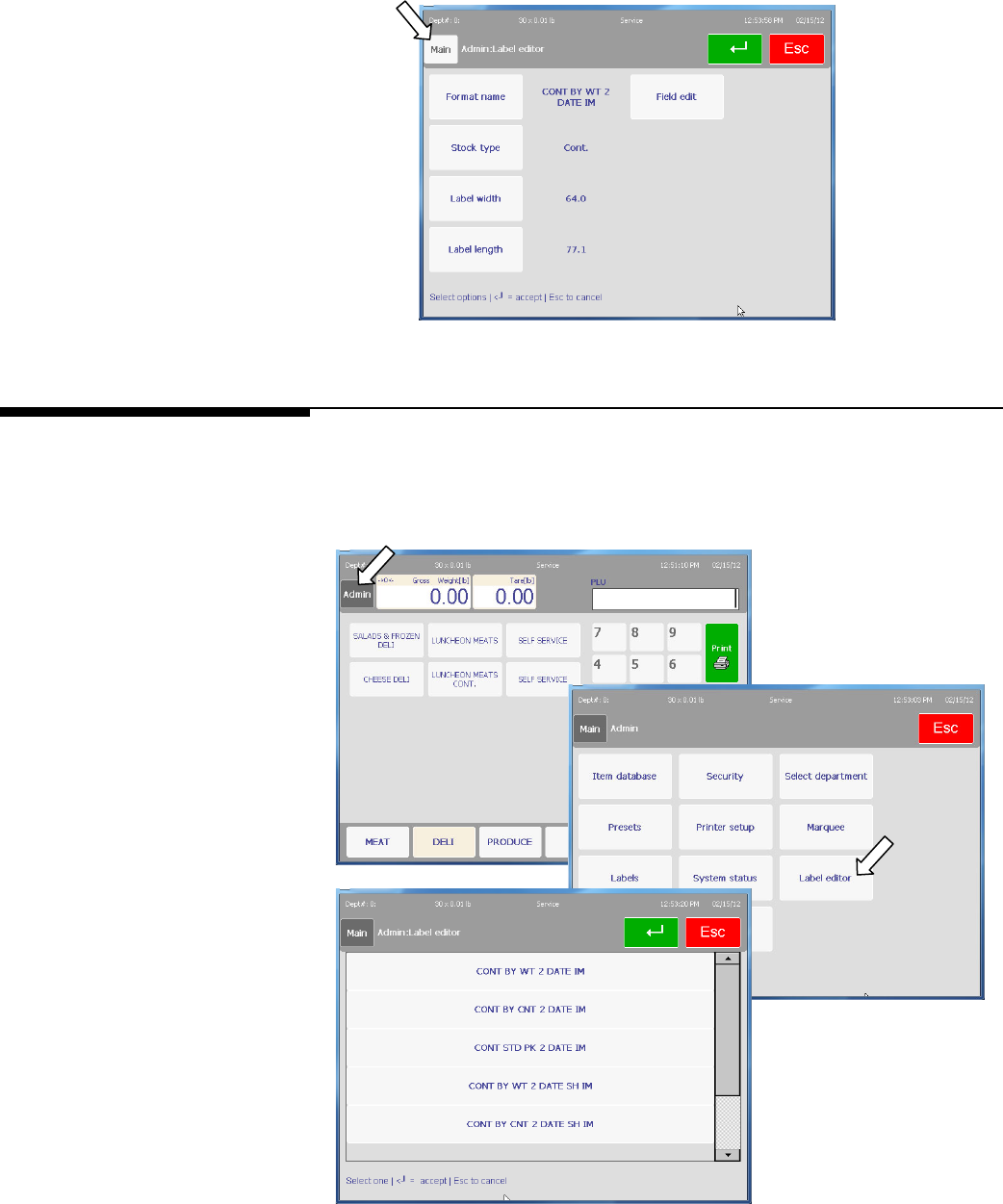

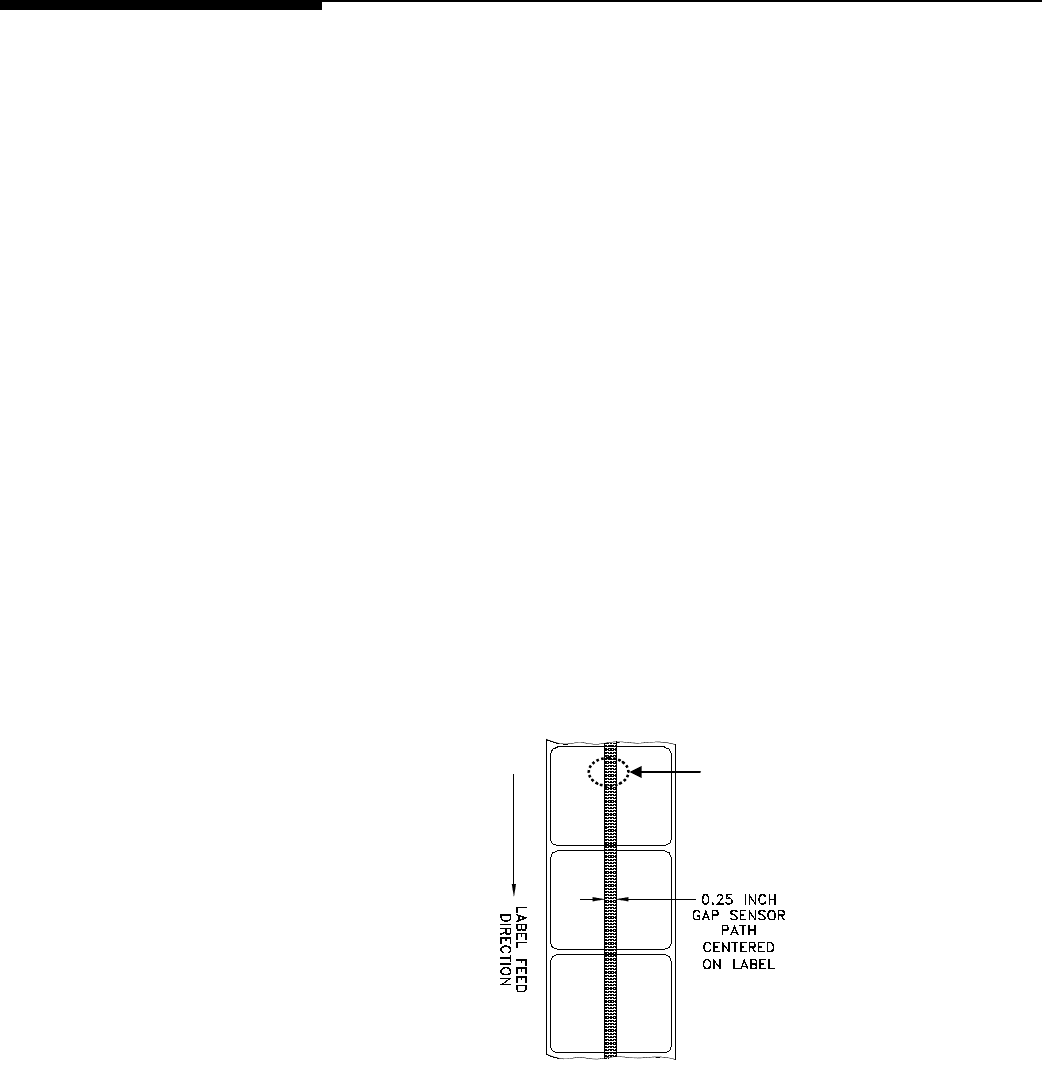

Labels .............................................................................................................................. 3-32

Label Styles ..............

......................................................................................................... 3-32

Print Test Label .................................................................................................................. 3-33

Verify Labels ...................................................................................................................... 3-33

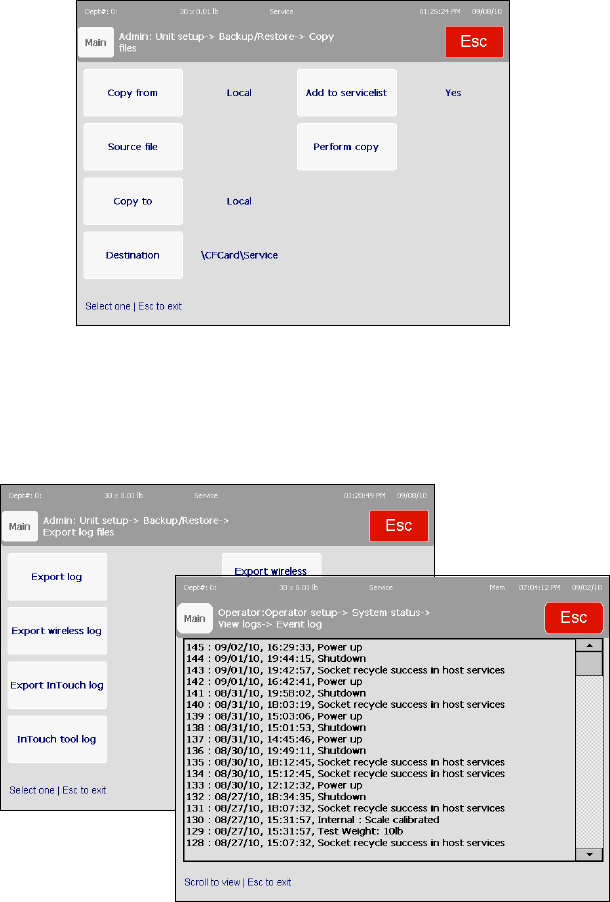

Unit Setup ......................................................................................................................... 3-34

Time & Date ...................................................................................................................... 3-35

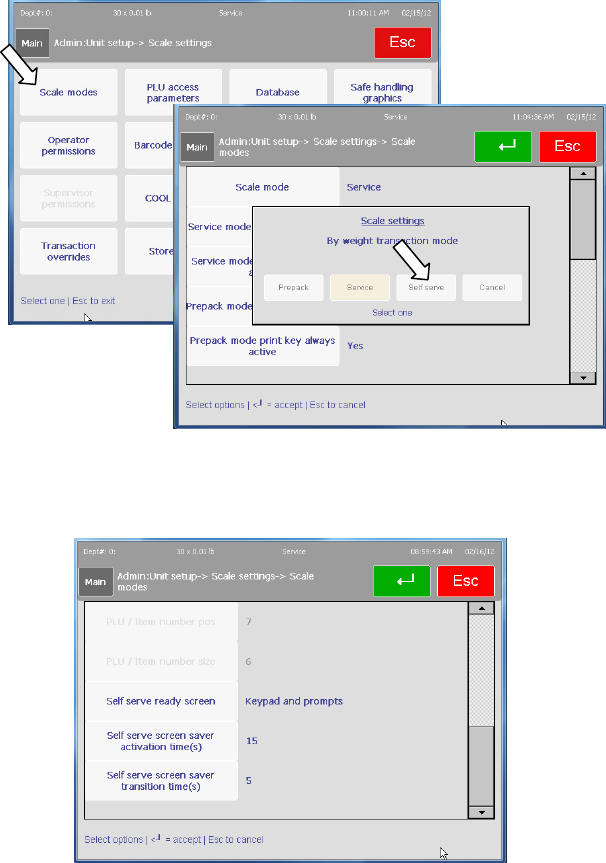

Scale Settings .................................................................................................................... 3-36

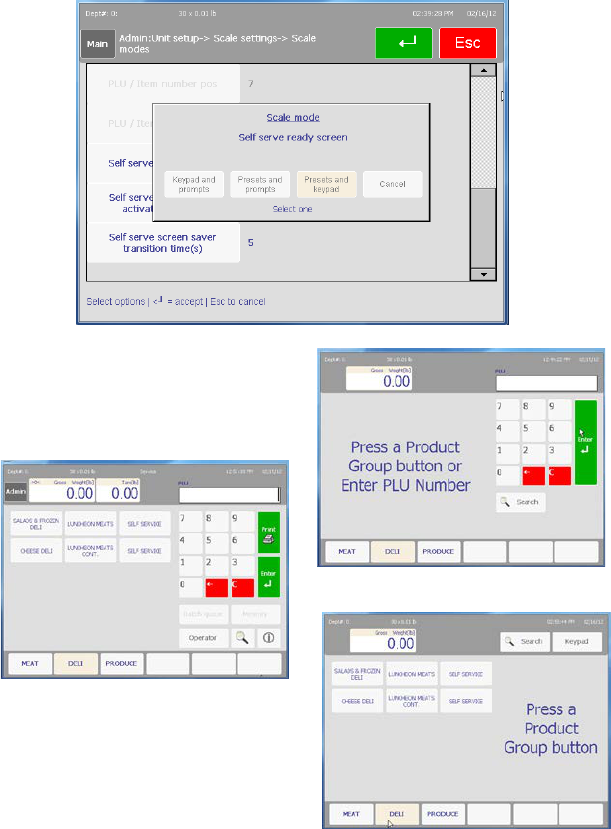

Scale Mode ............................................................................................................................ 3-37

Operator Permissions .............................................................................................................. 3-37

Supervisor Permissions ........................................................................................................... 3-38

Transaction Overrides .............................................................................................................. 3-38

PLU Access Parameters ........................................................................................................... 3-38

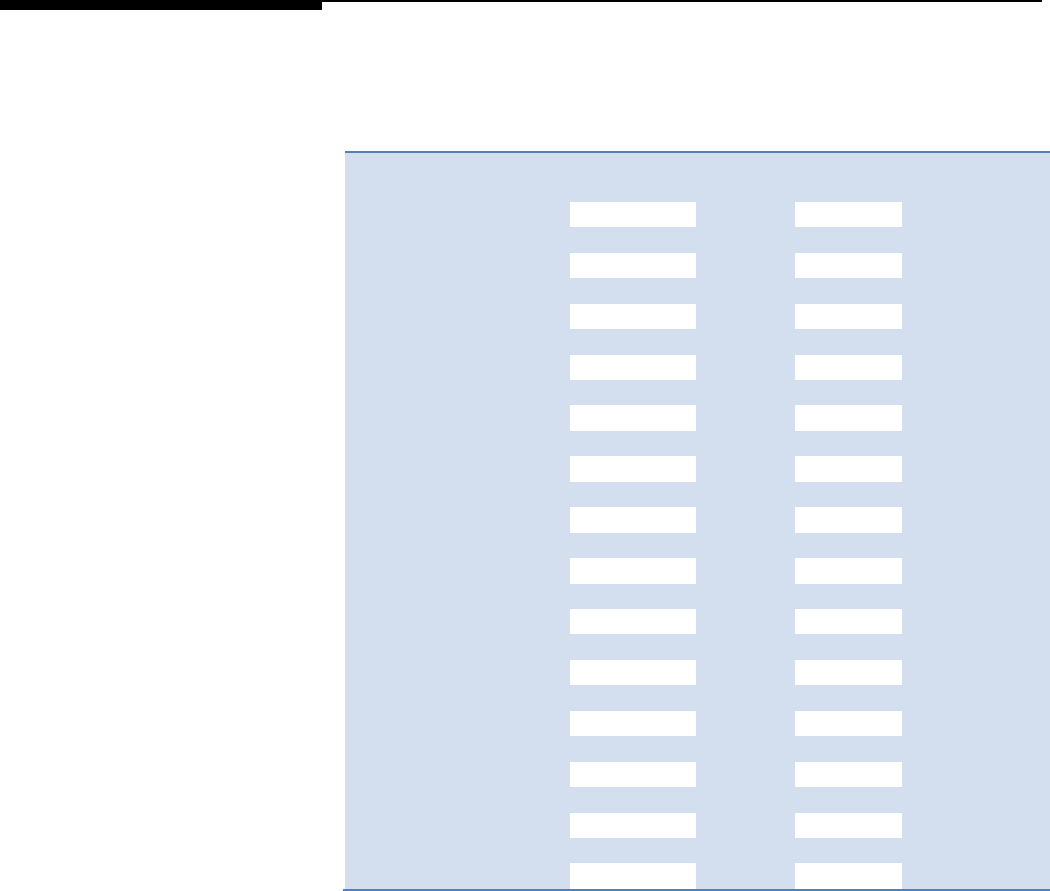

Barcode Settings ..................................................................................................................... 3-40

GS1 Bar Code Setup ................................................................................................................ 3-42

COOL .................................................................................................................................... 3-46

Store Logo.............................................................................................................................. 3-46

Database ............................................................................................................................... 3-47

Screen Saver .......................................................................................................................... 3-49

Preset Reaction ....................................................................................................................... 3-50

Nutrition Settings ..................................................................................................................... 3-51

2011 Nutrition Facts Formats ................................................................................................... 3-52

Safe Handling Graphics ........................................................................................................... 3-53

Set Home Screen ................................................................................................................ 3-53

Language .......................................................................................................................... 3-54

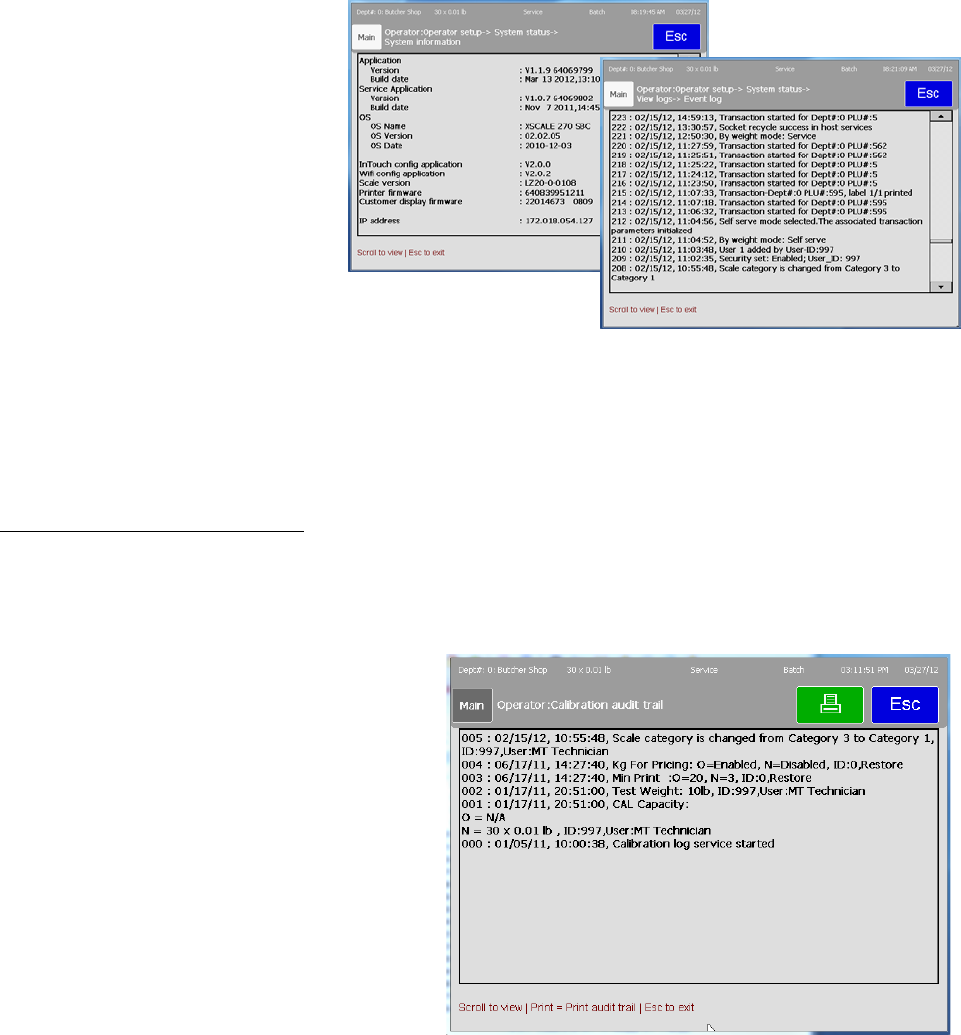

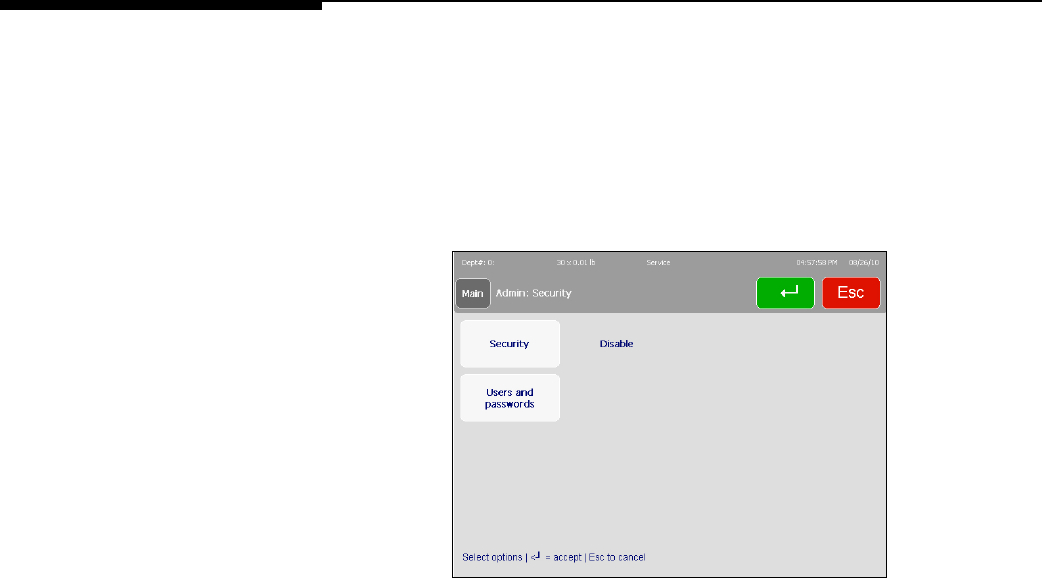

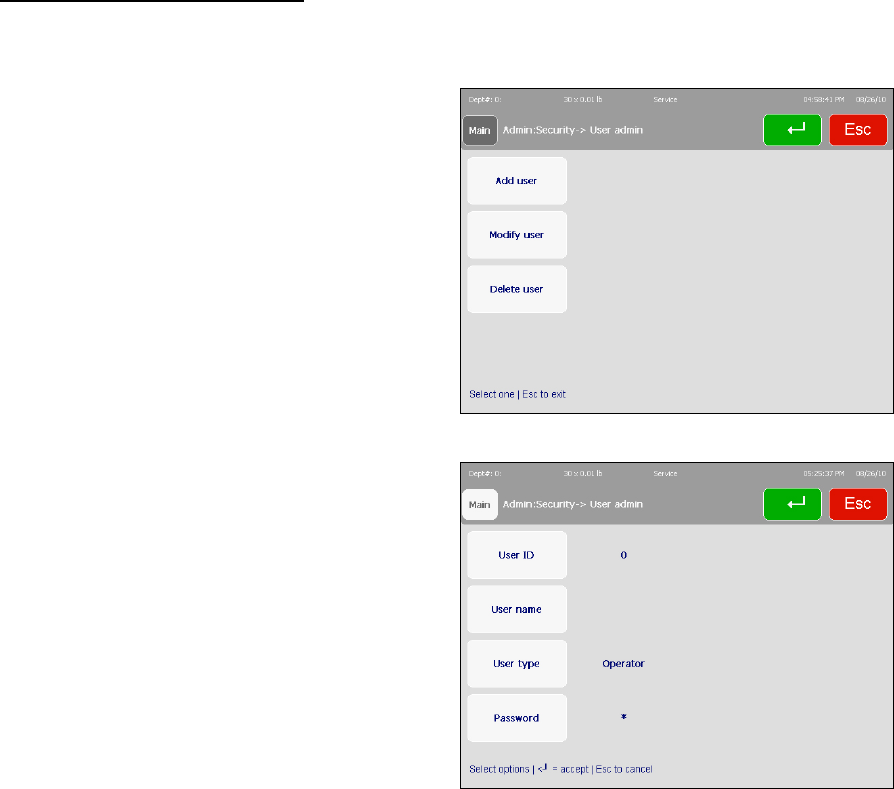

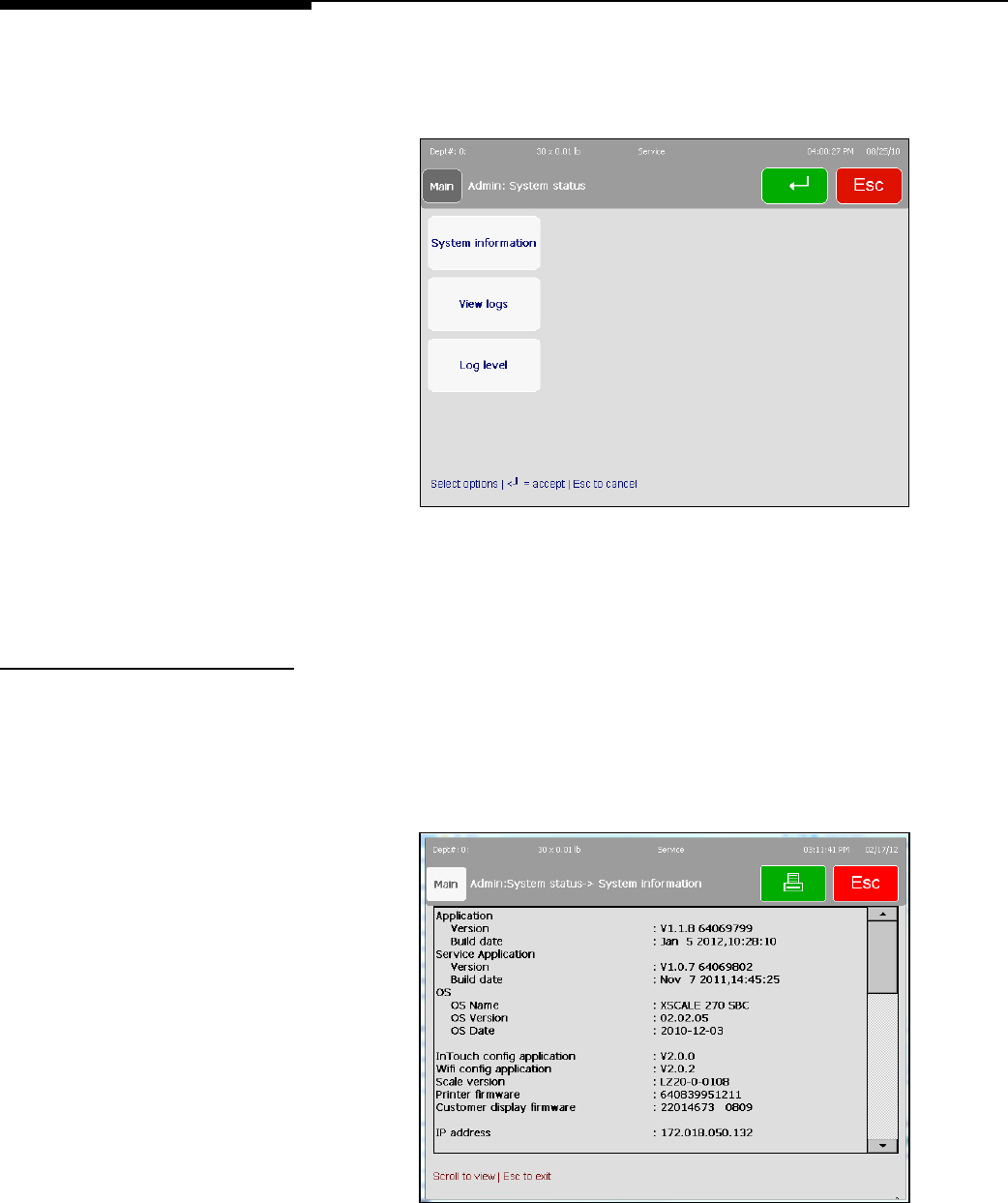

Technician......................................................................................................................... 3-54