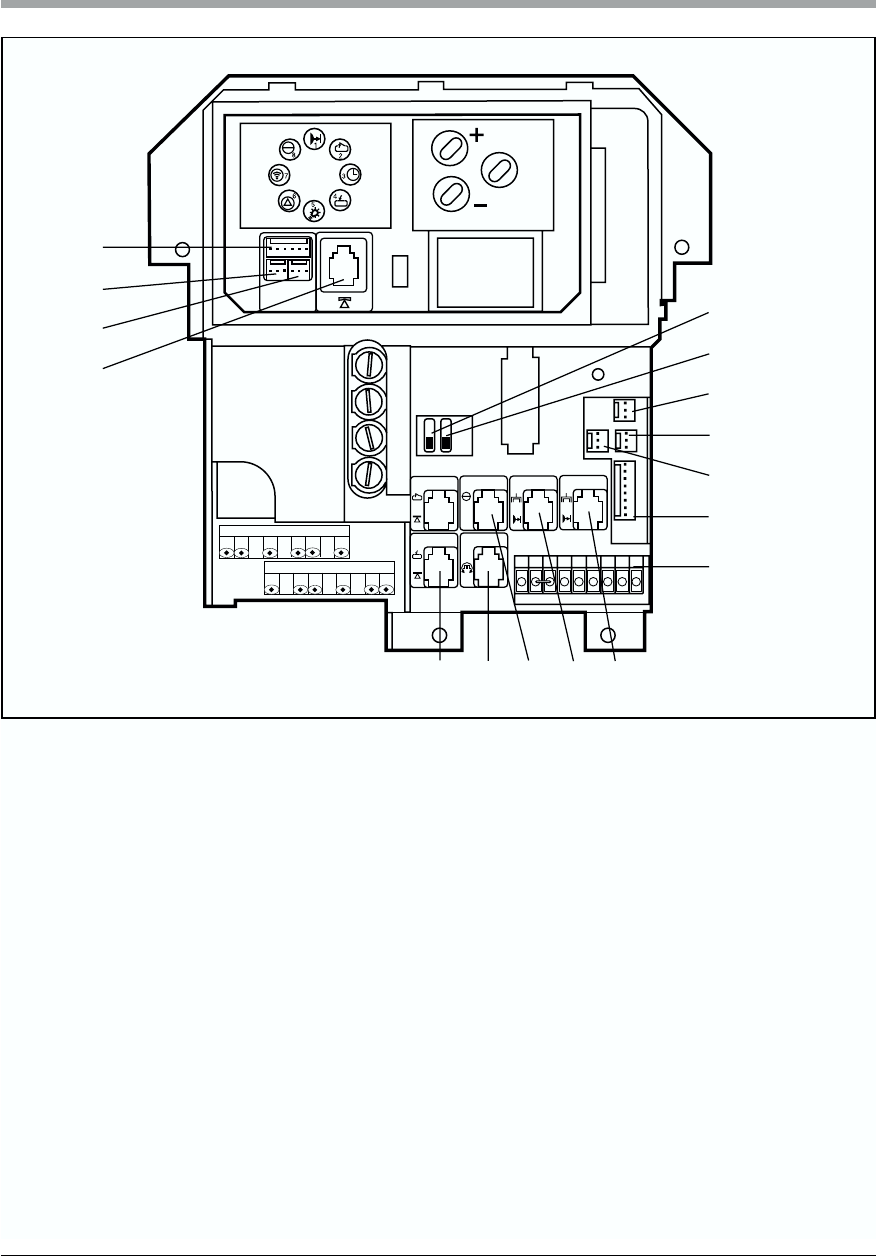

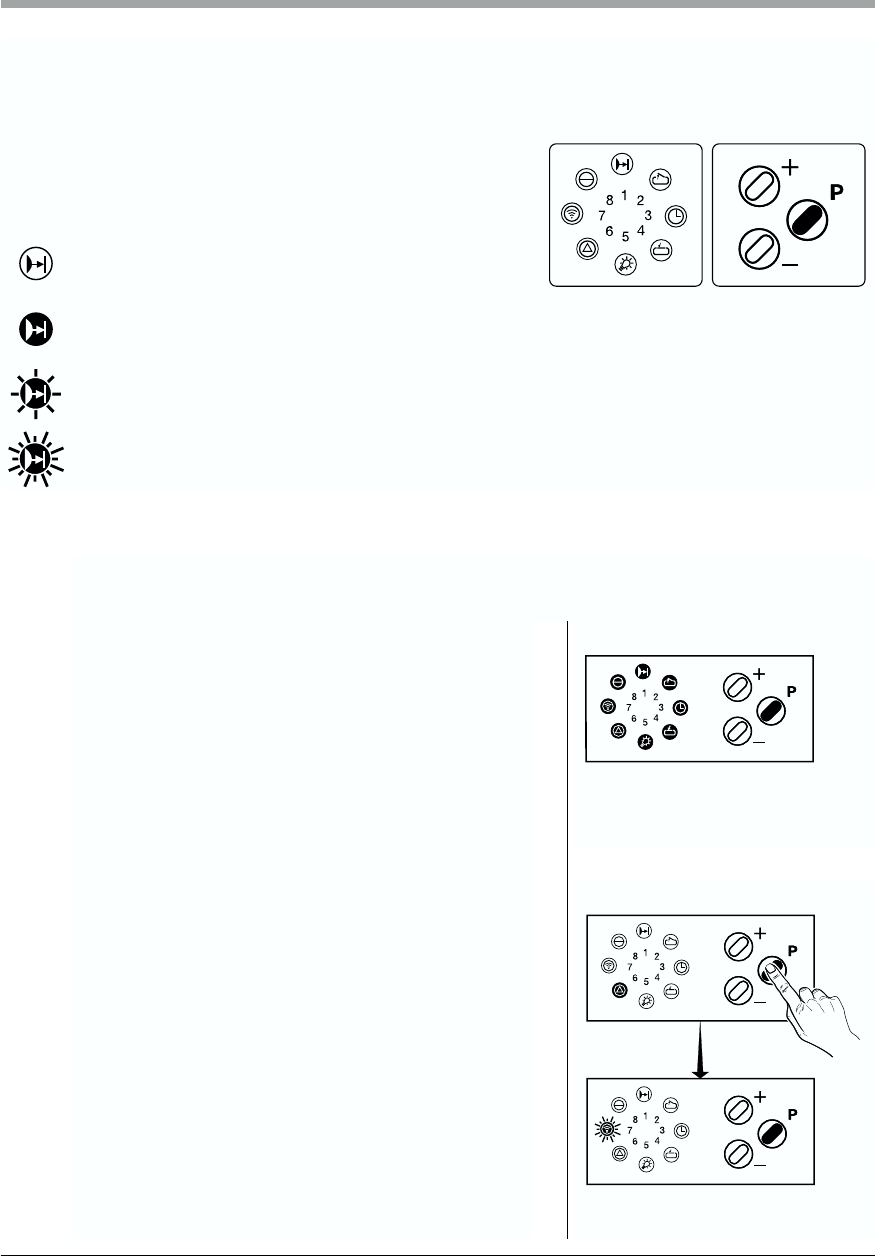

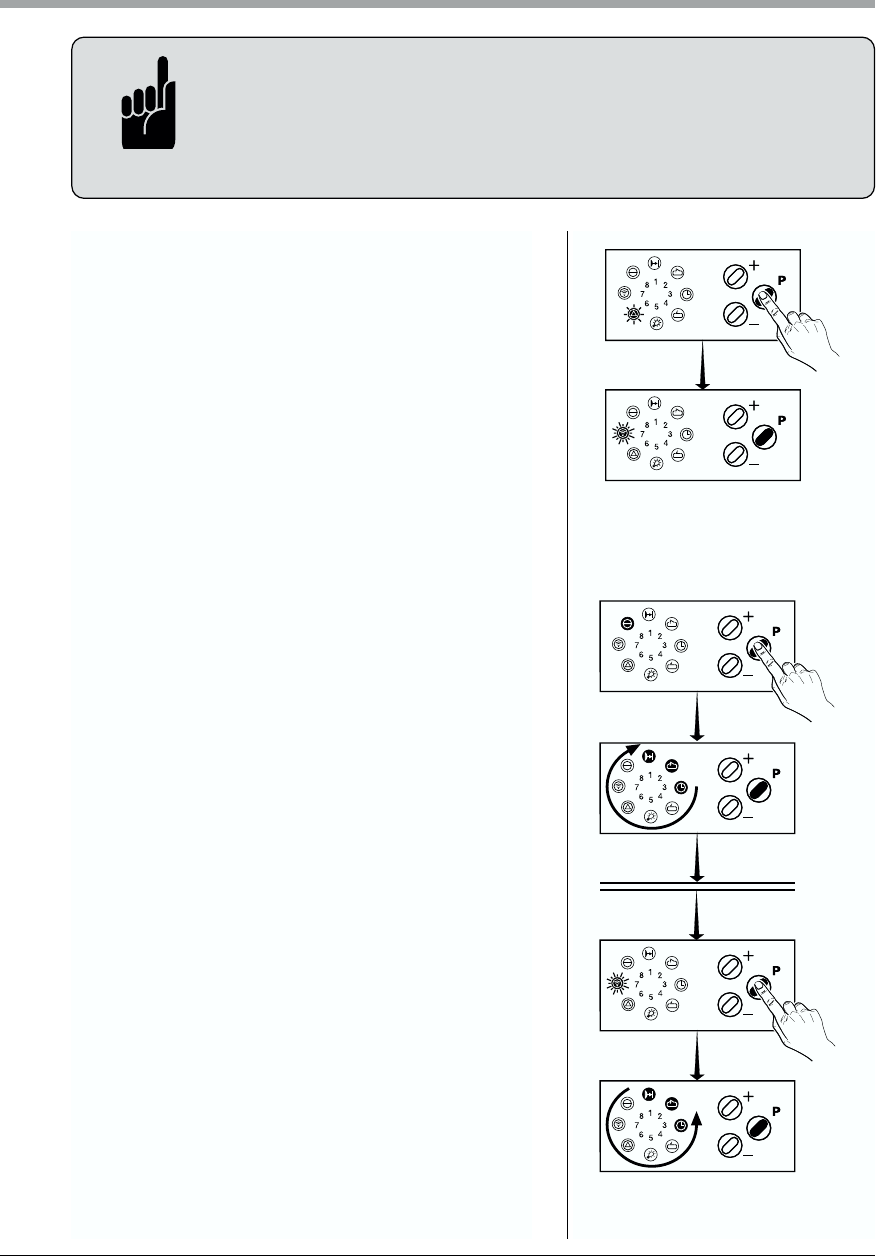

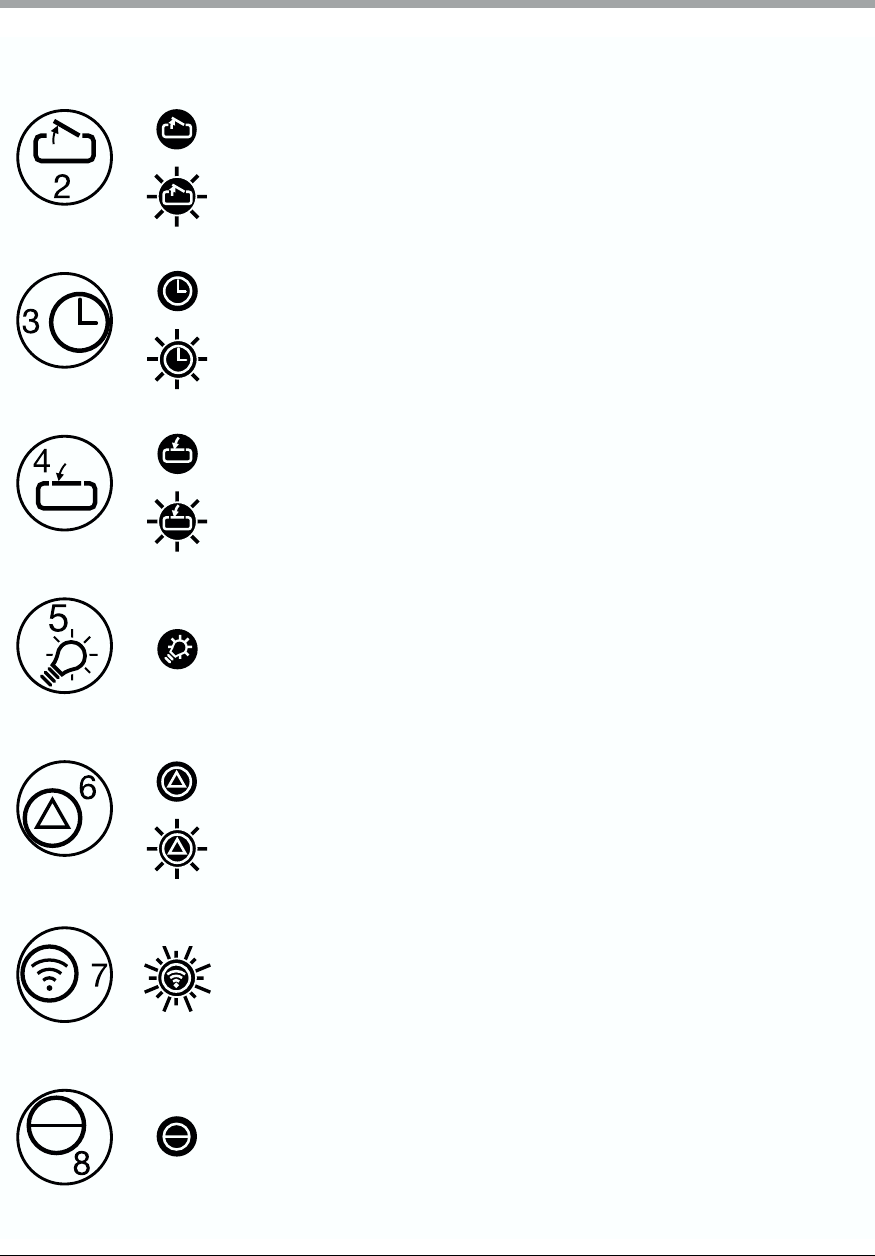

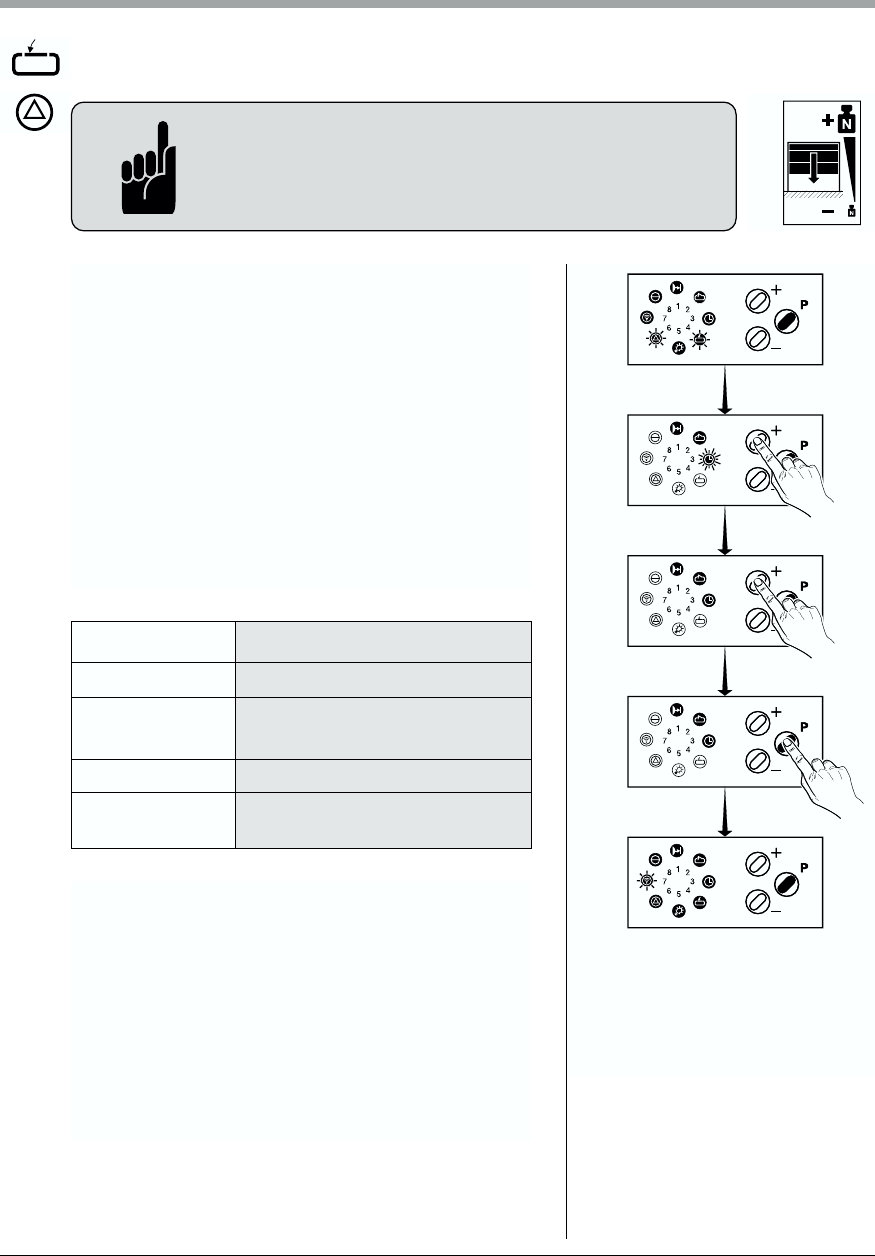

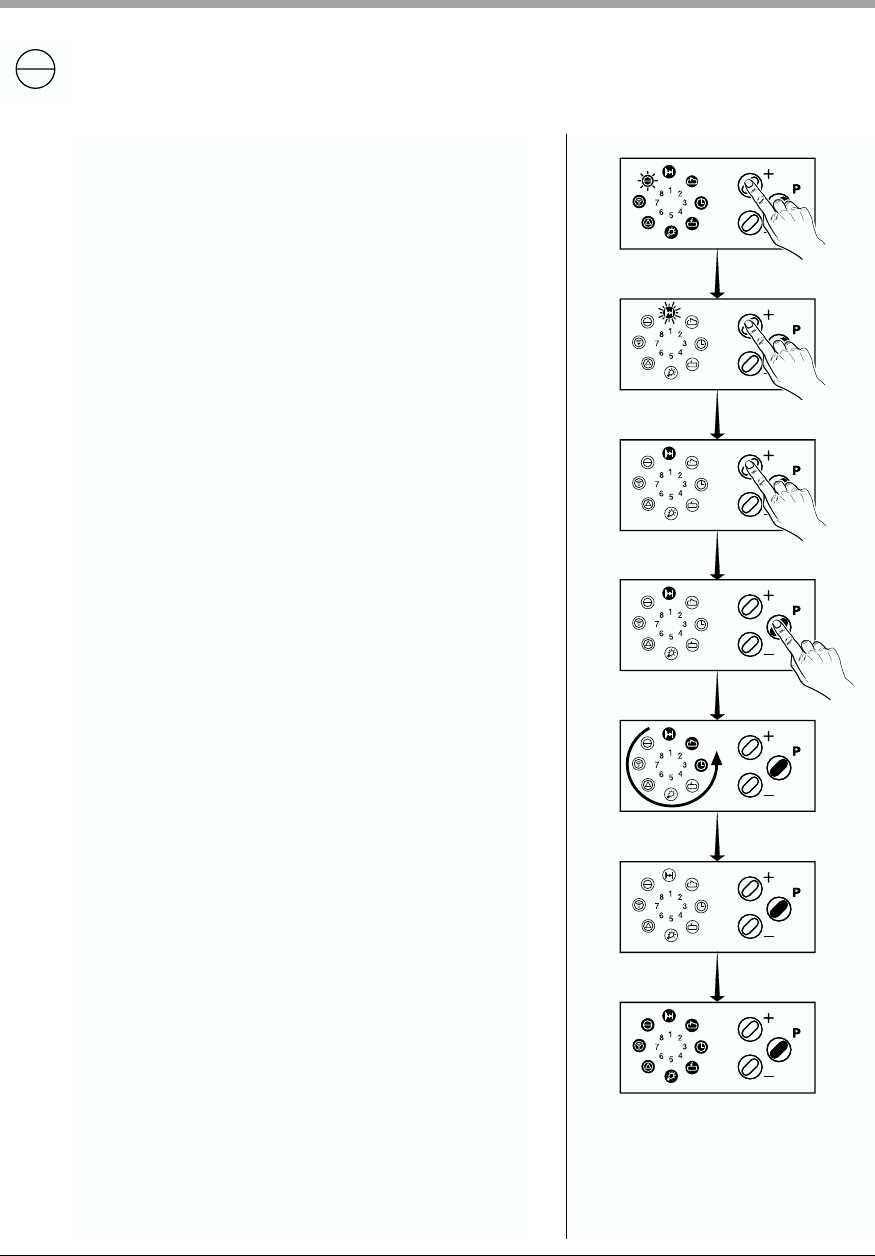

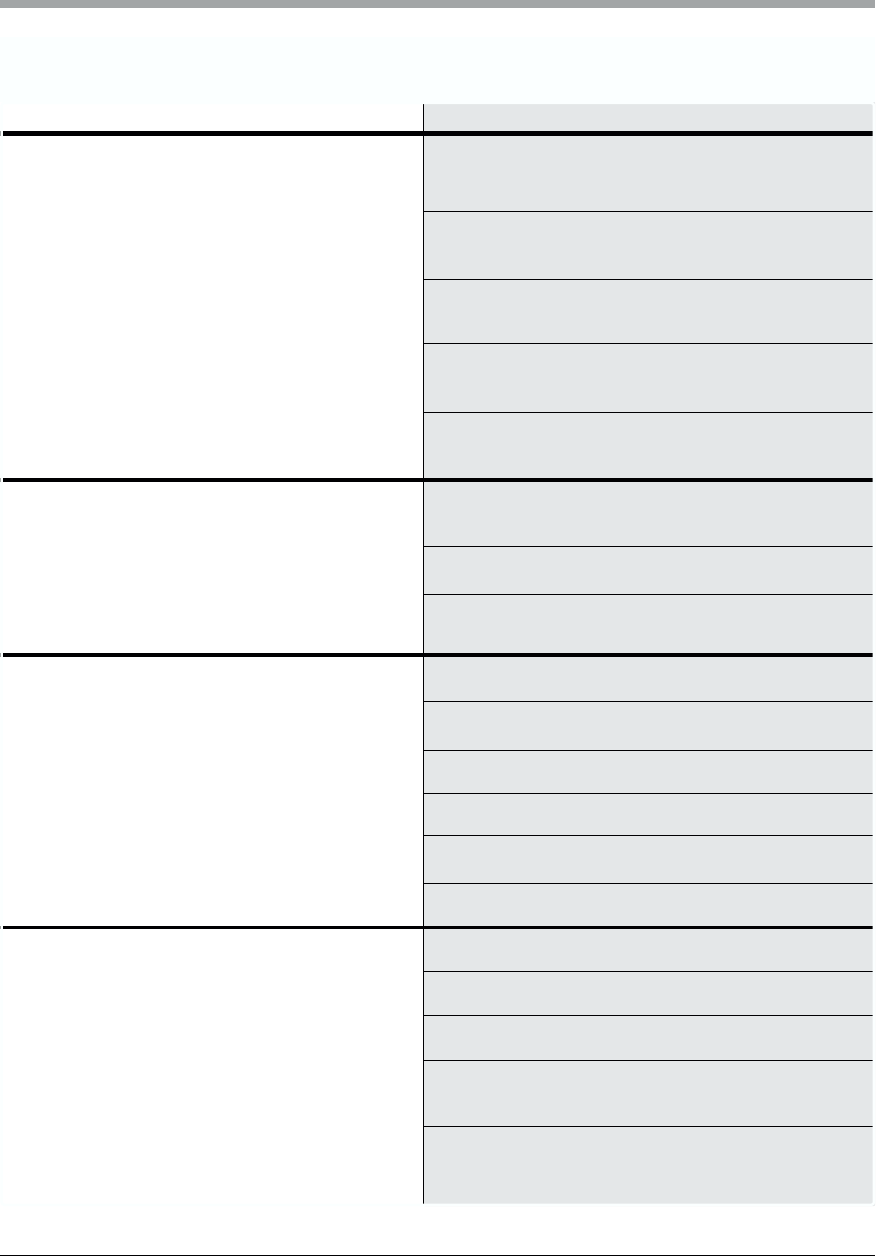

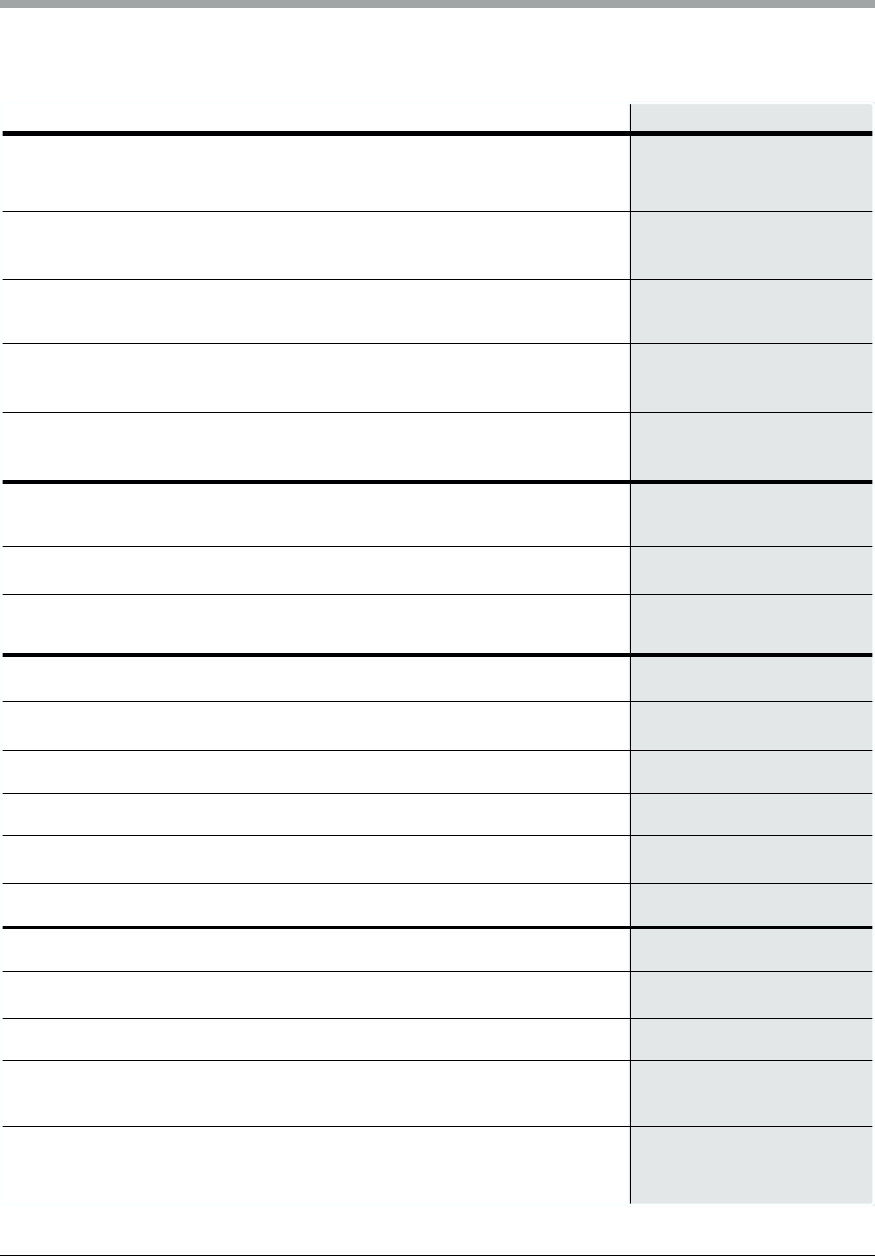

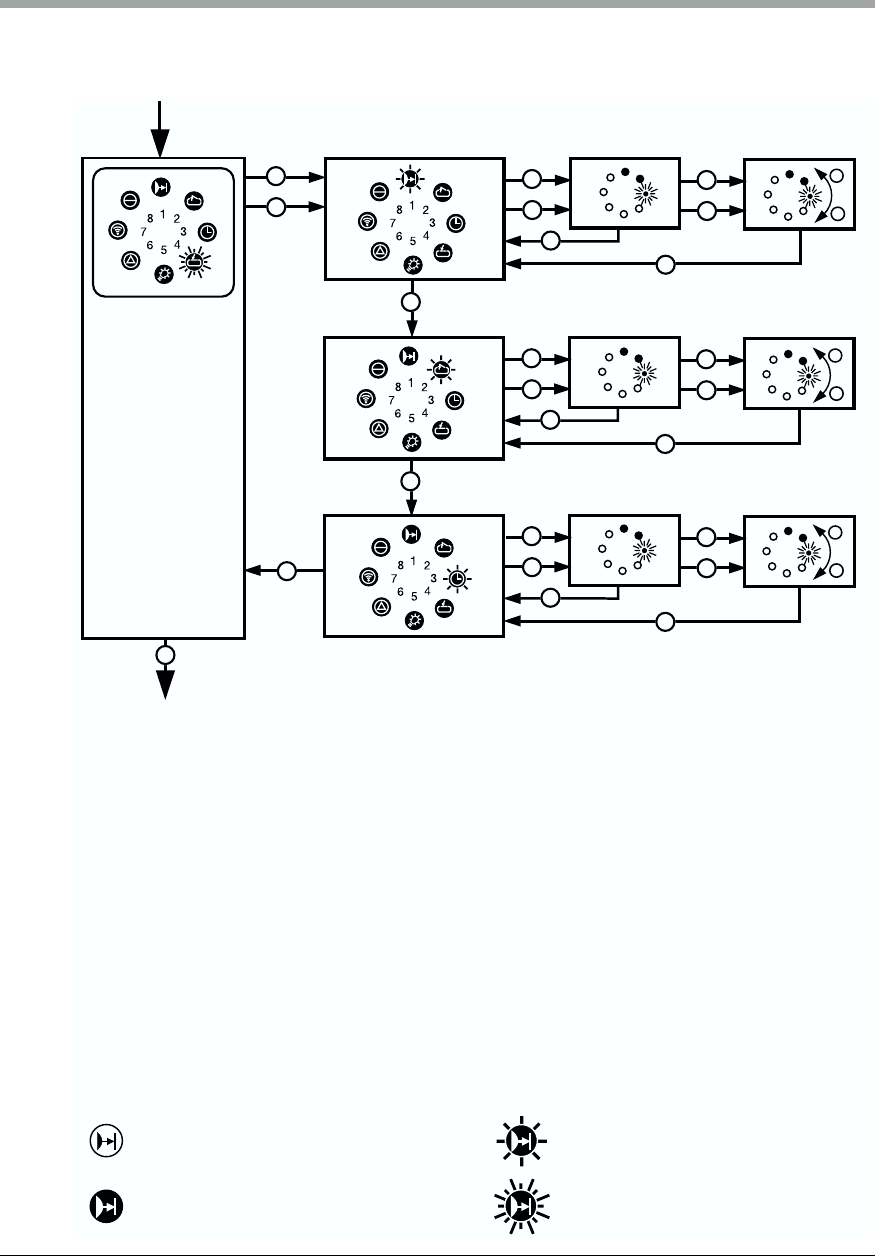

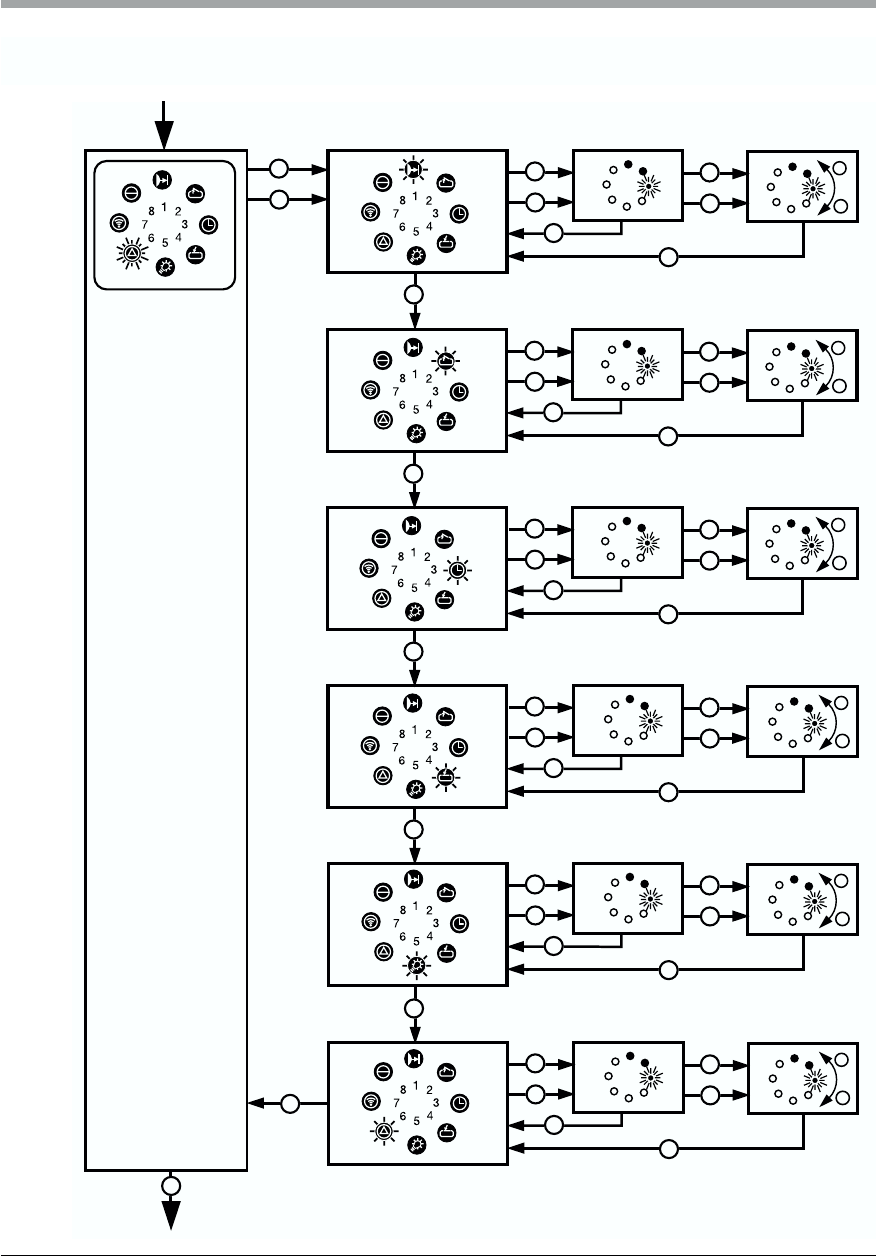

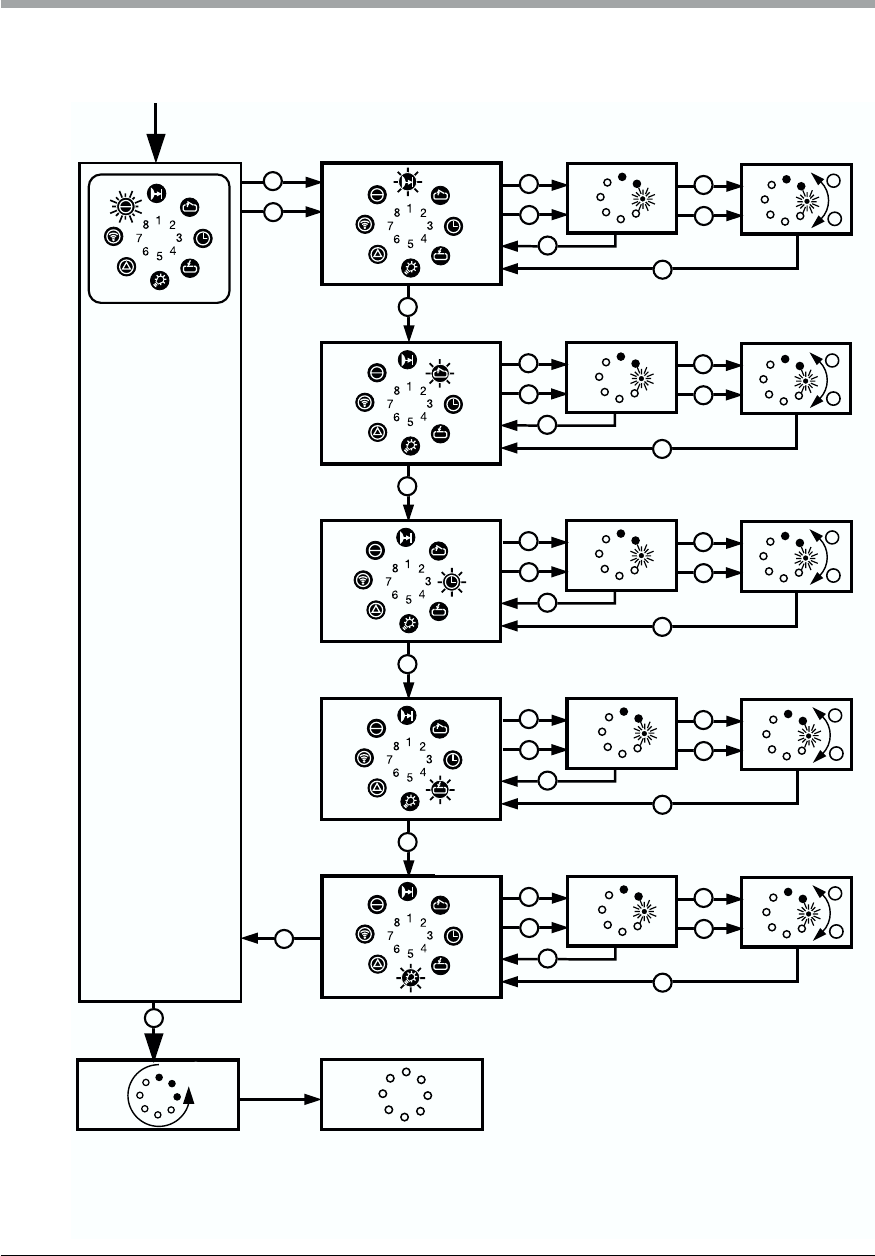

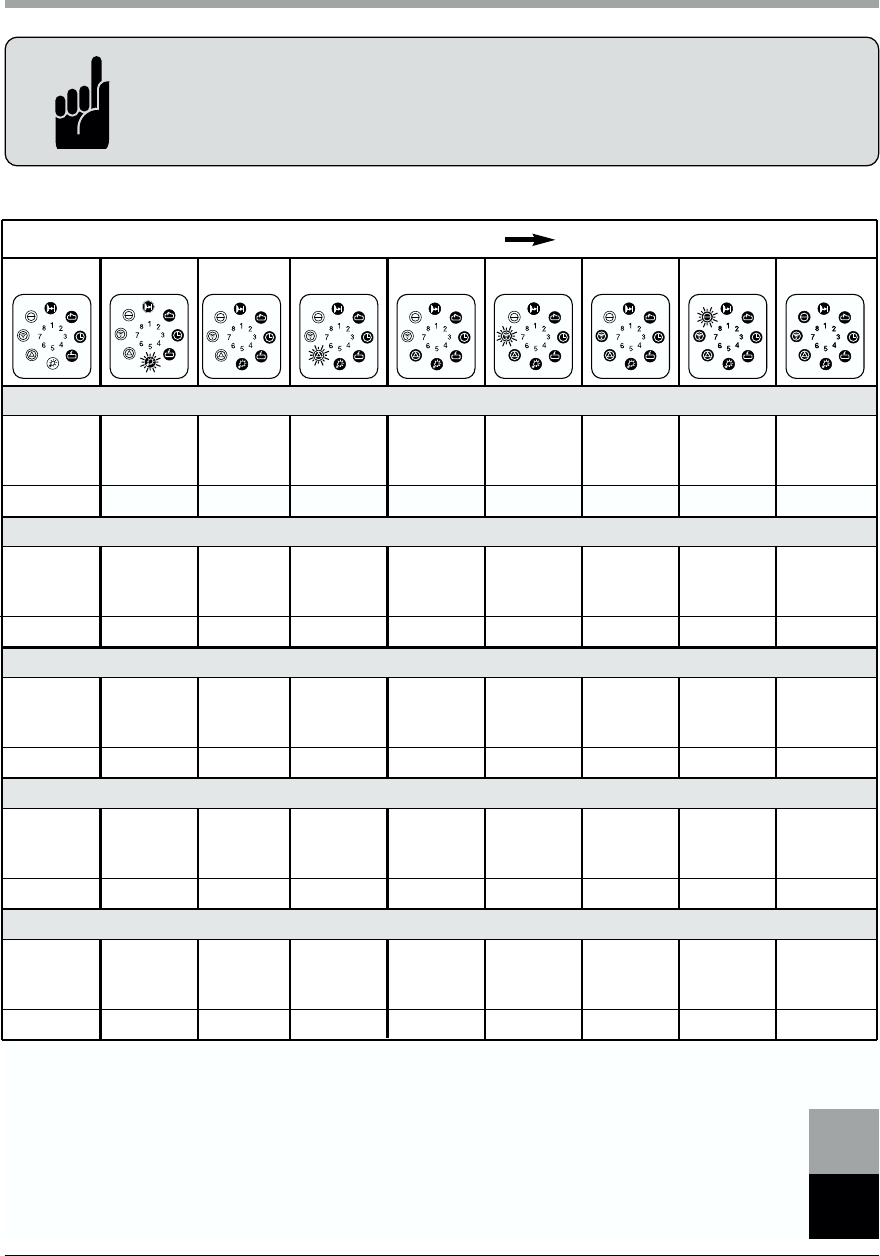

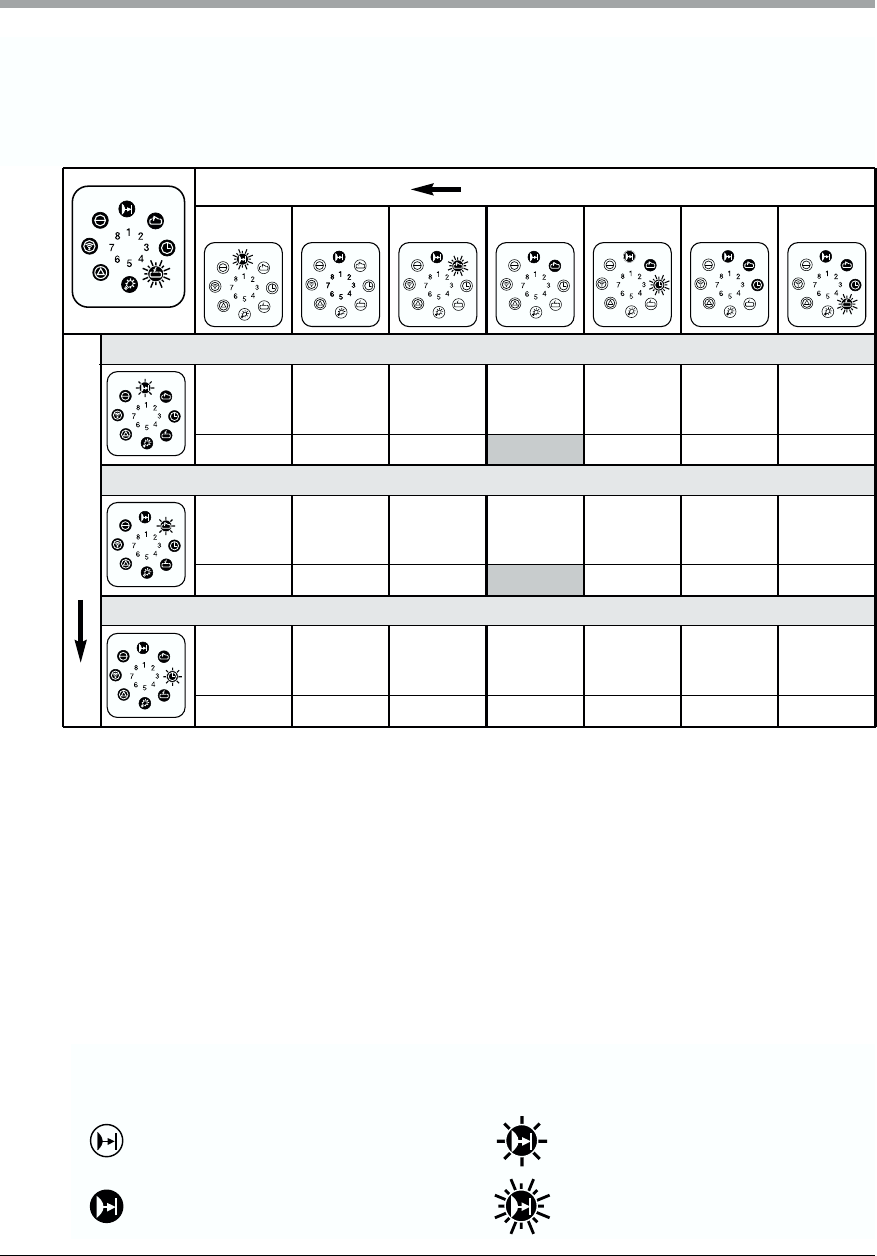

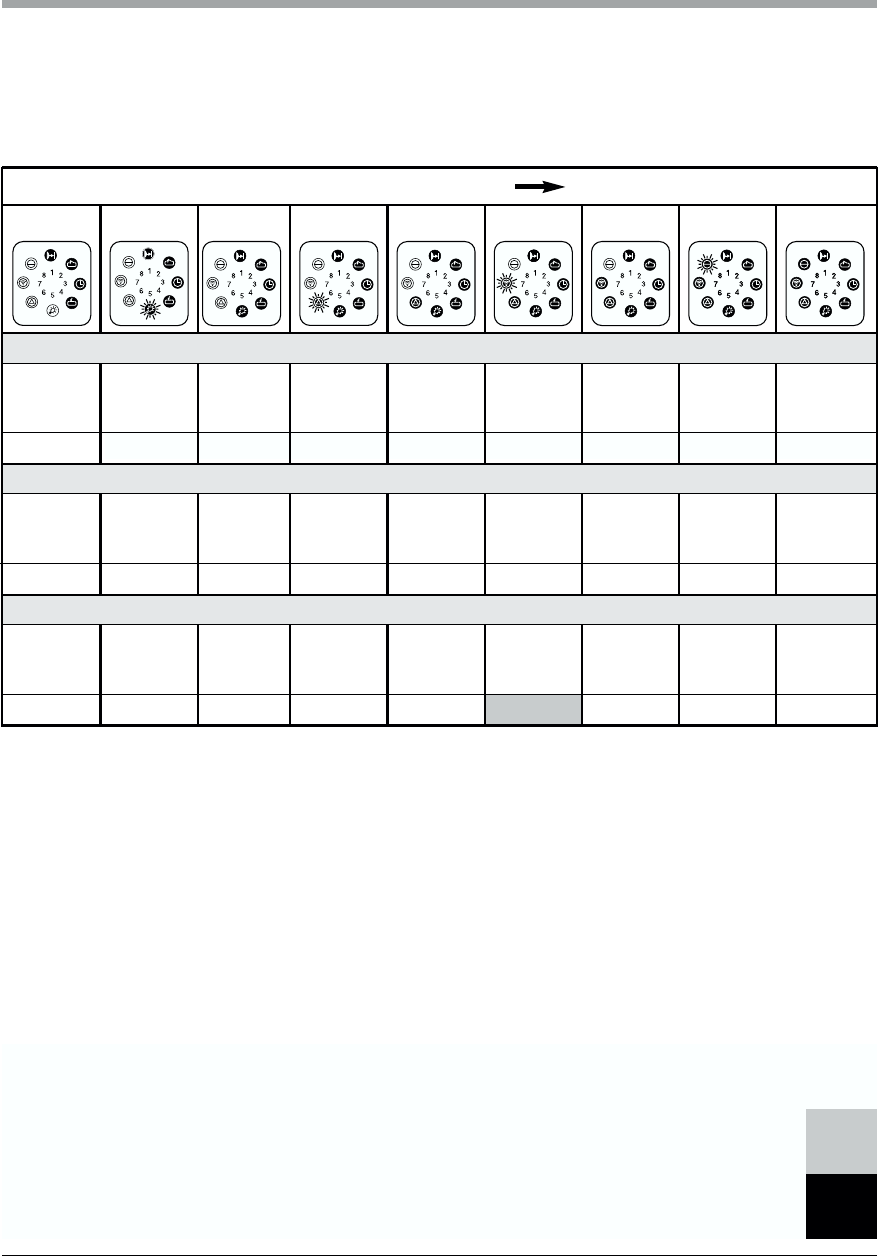

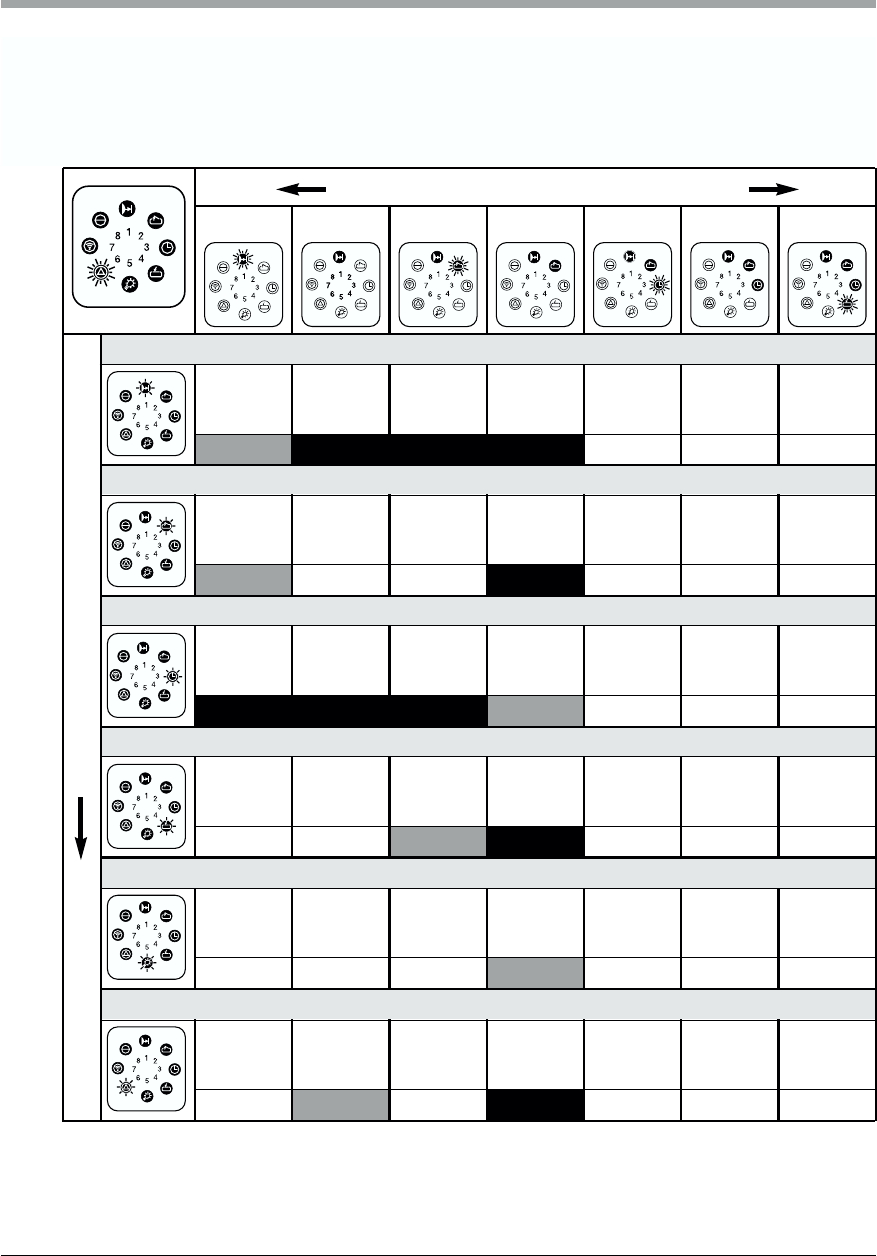

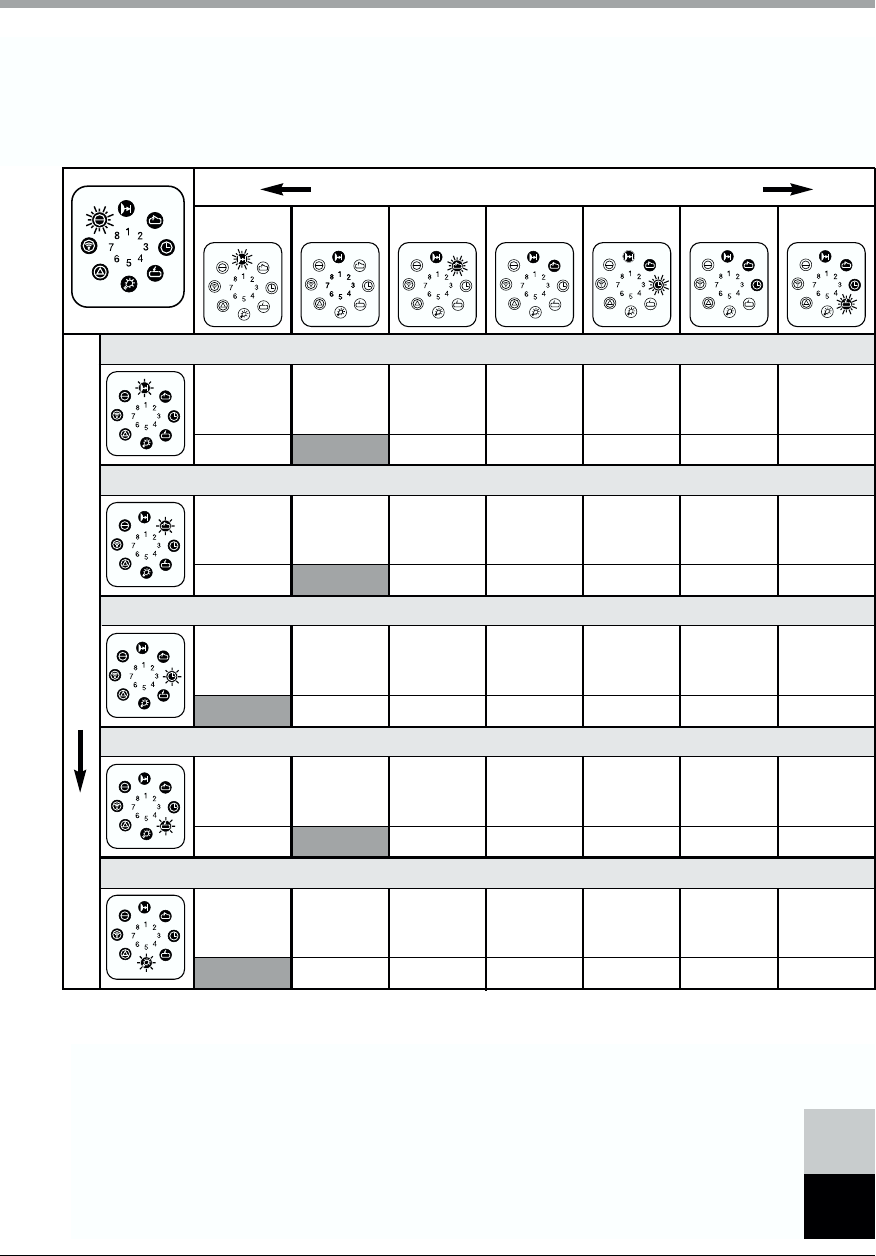

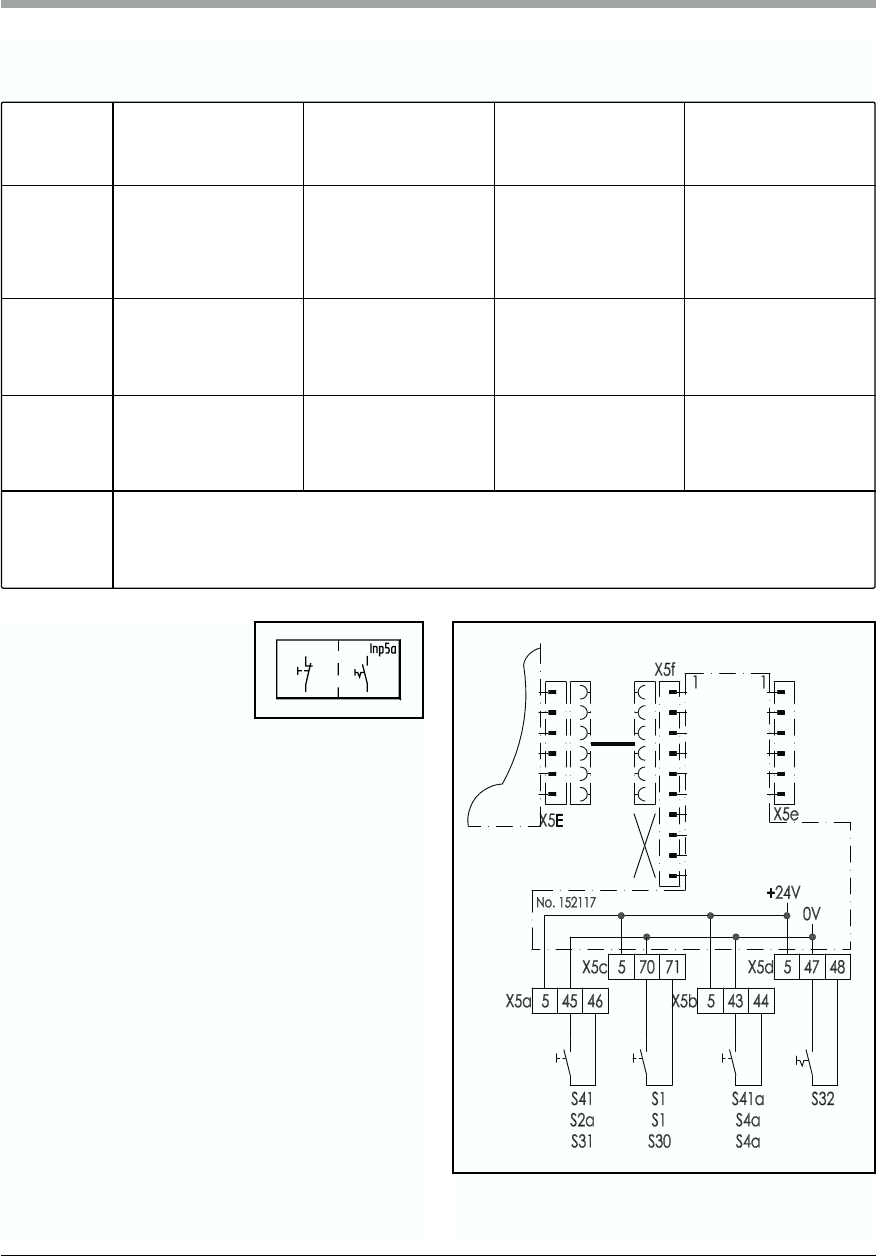

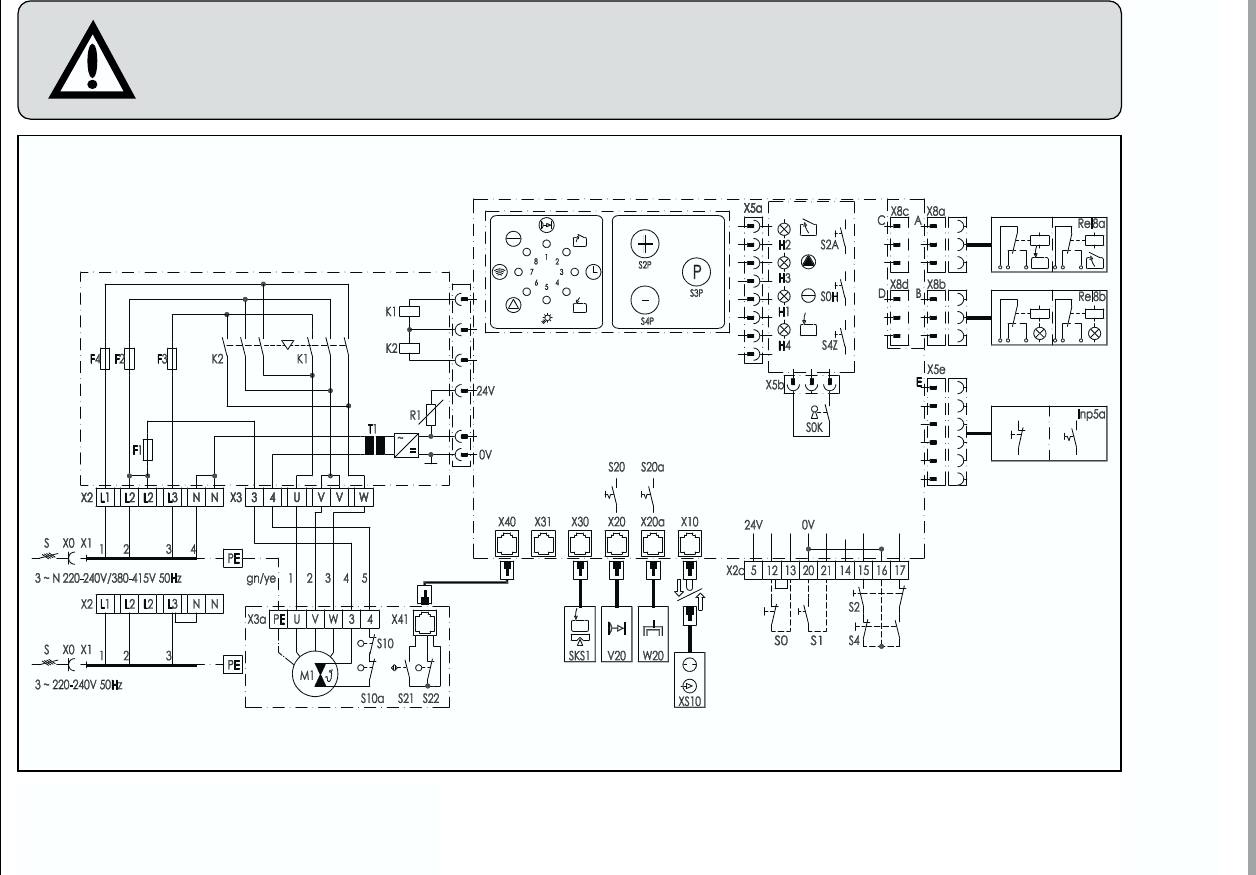

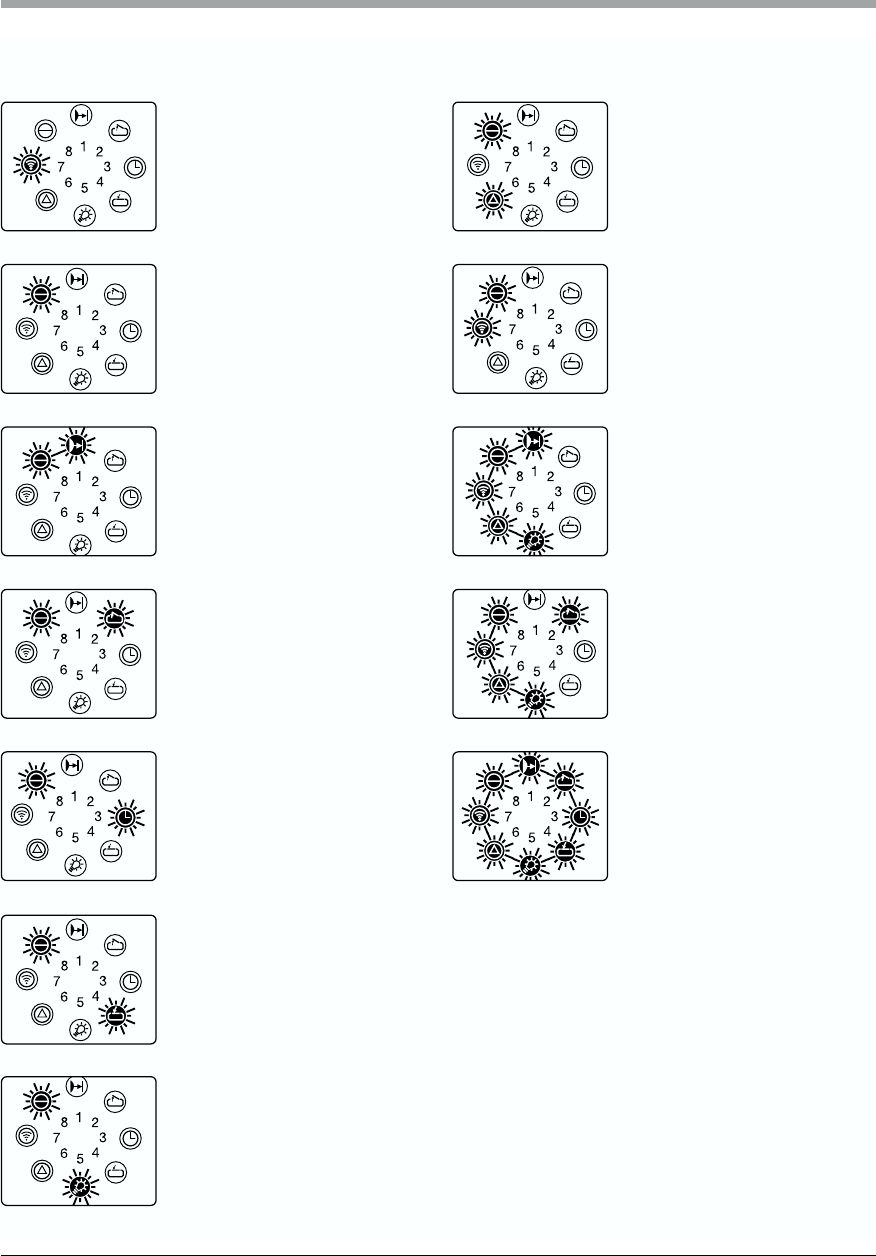

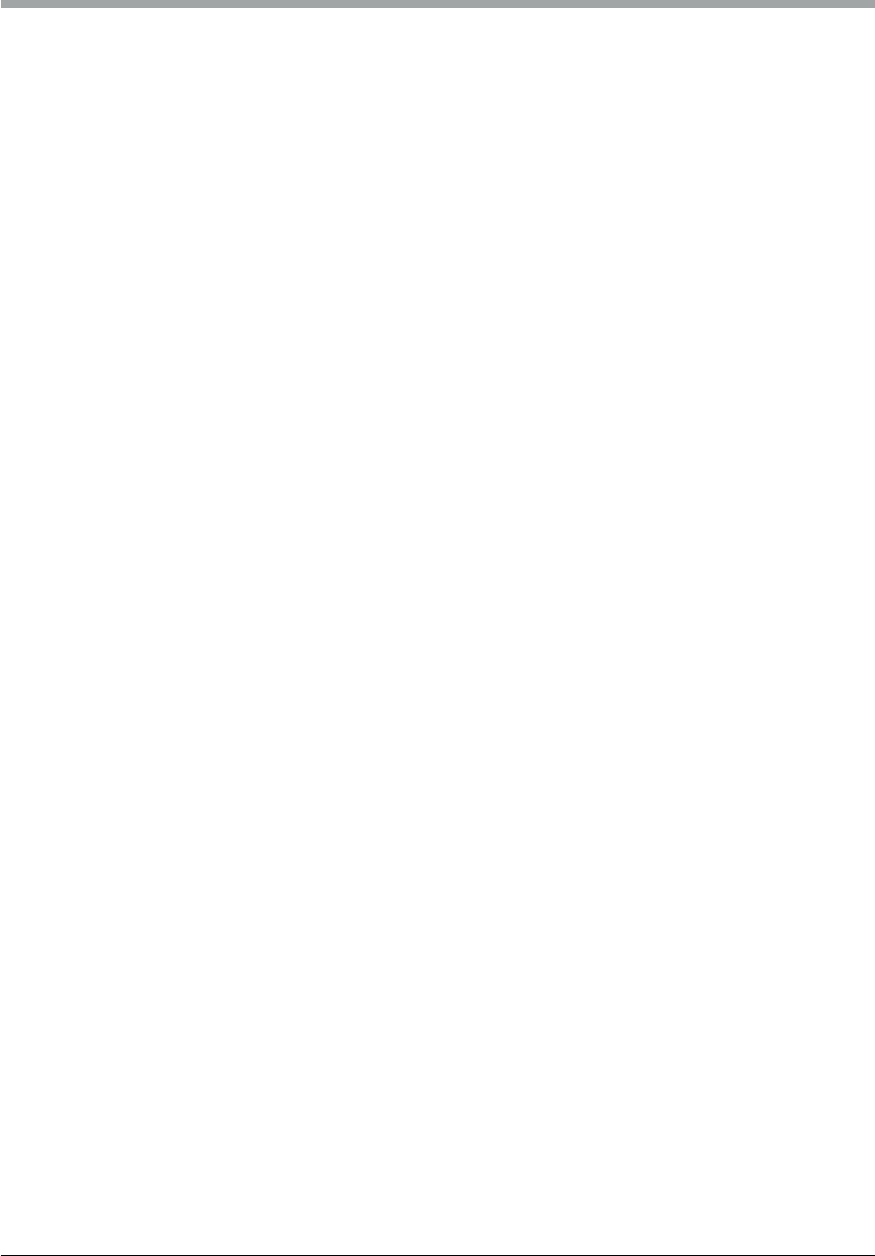

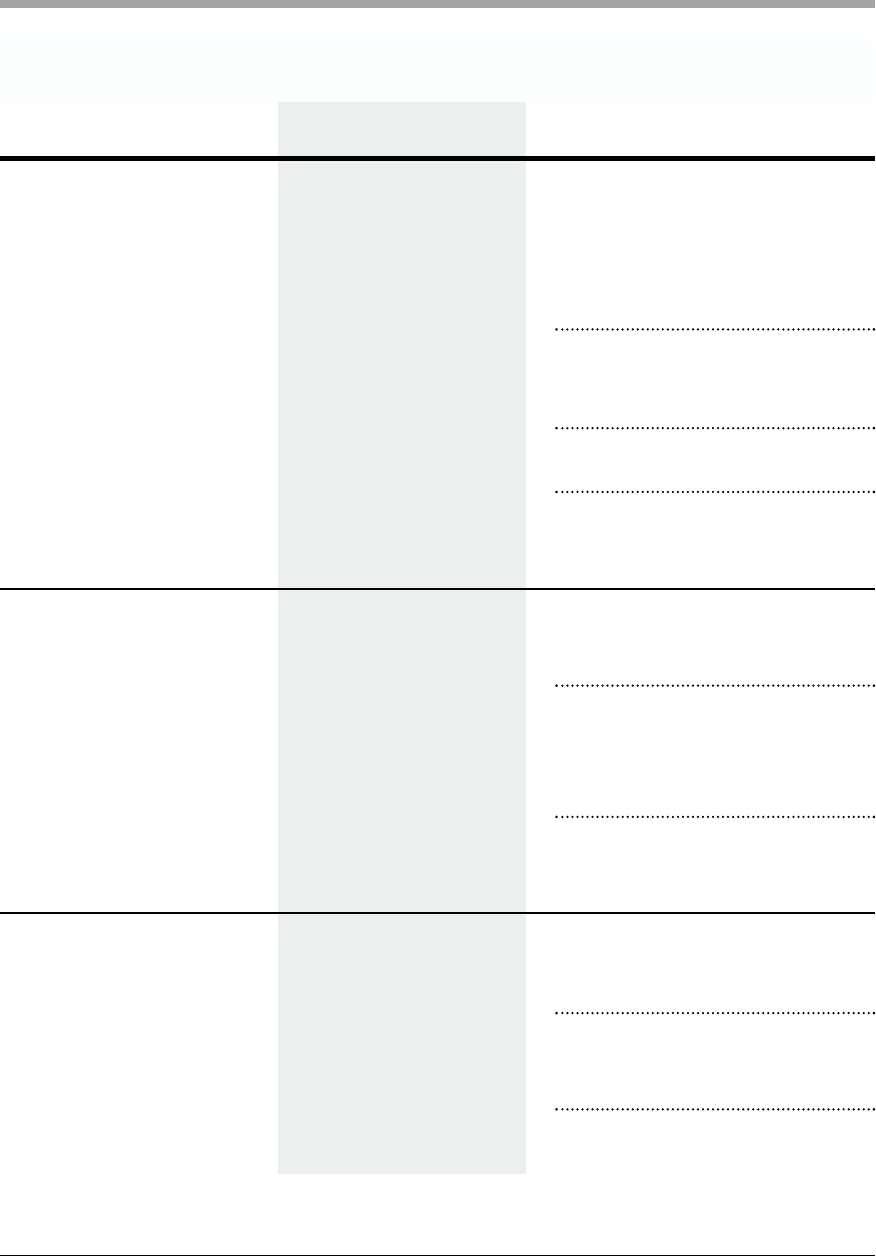

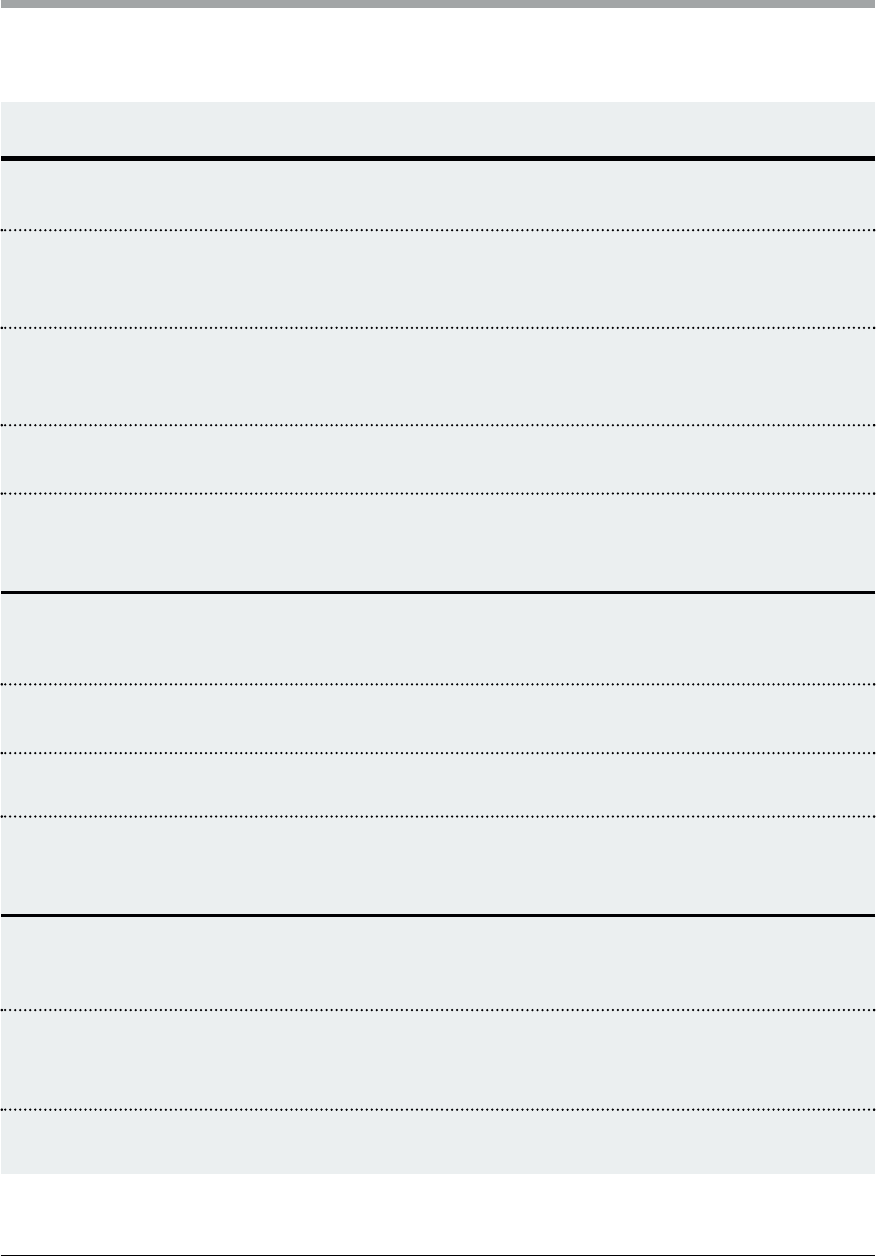

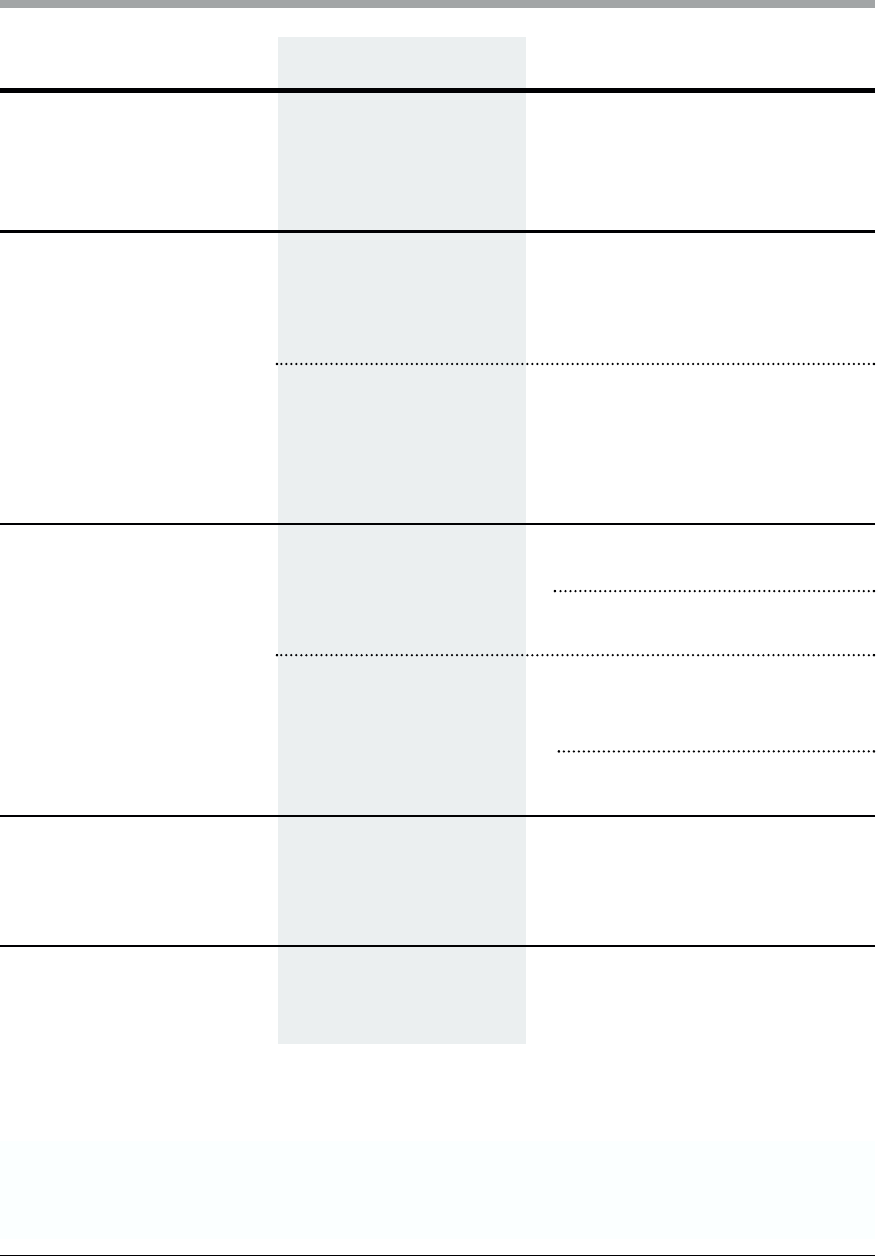

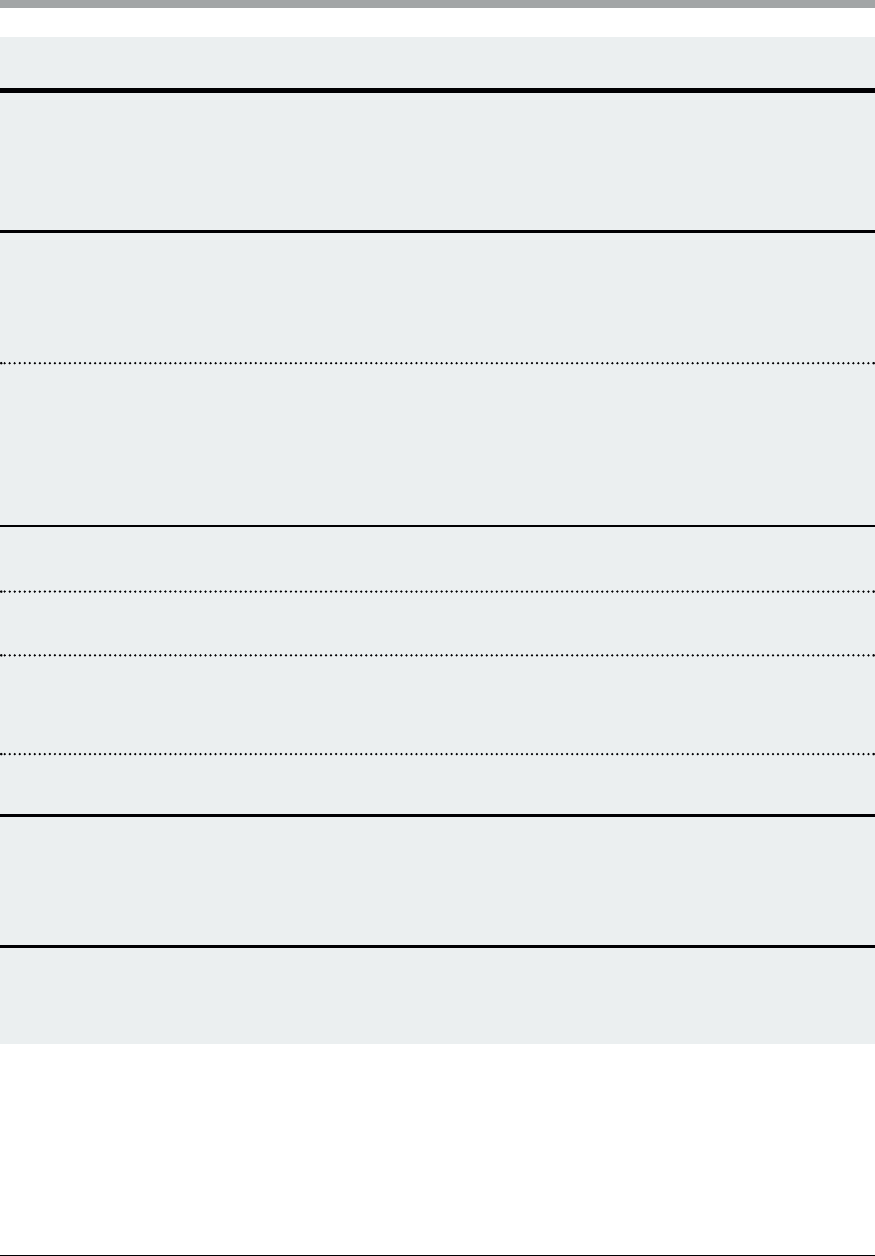

6. Display Functions and Programming Possibilities

English / Page 41

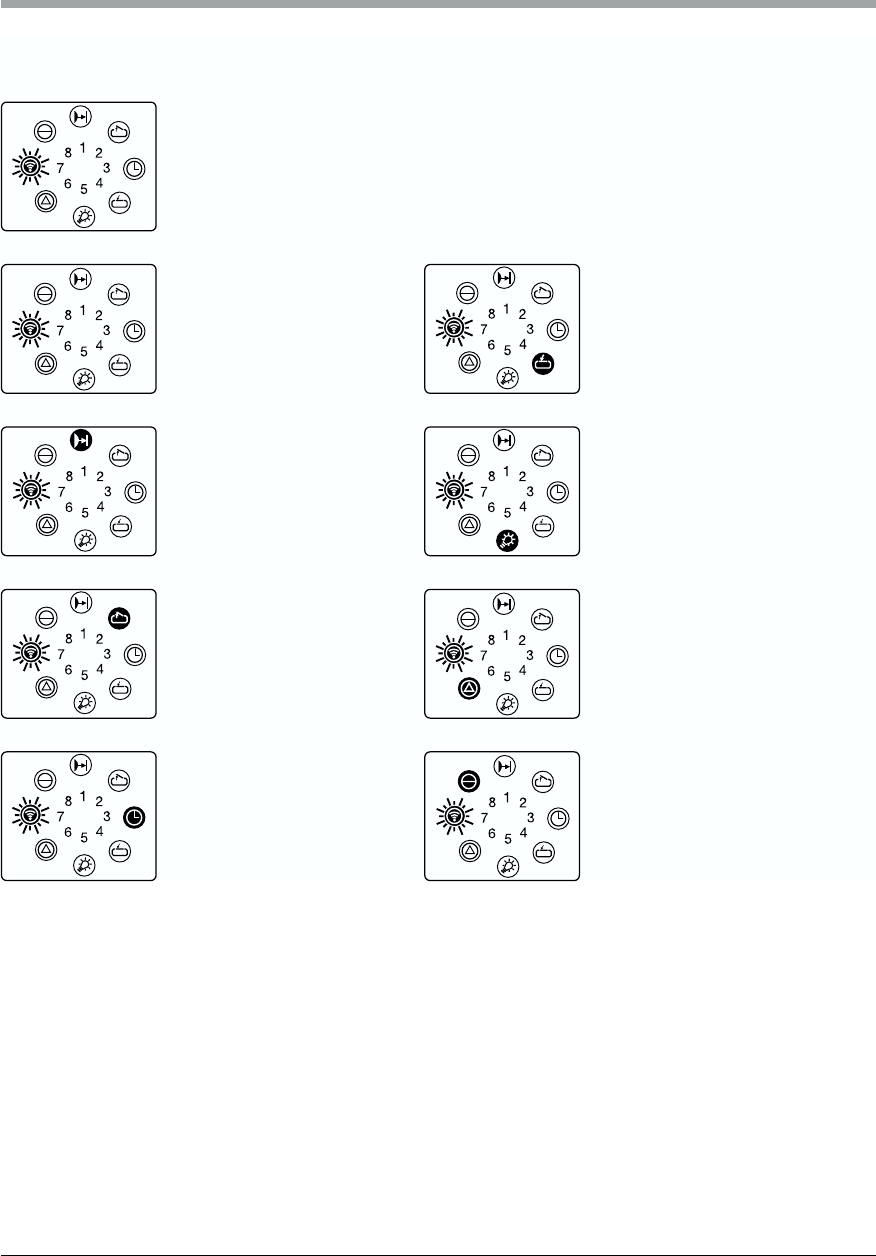

Explanation

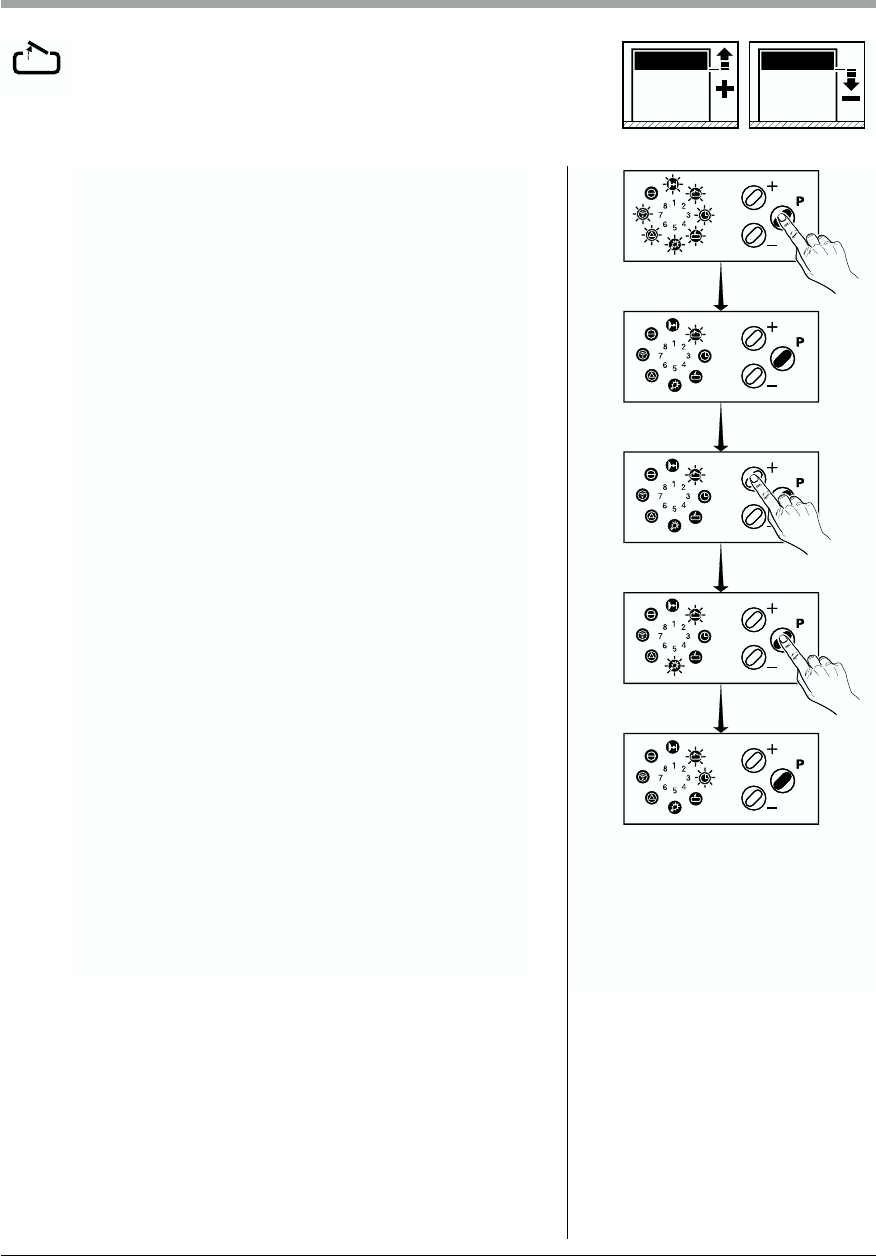

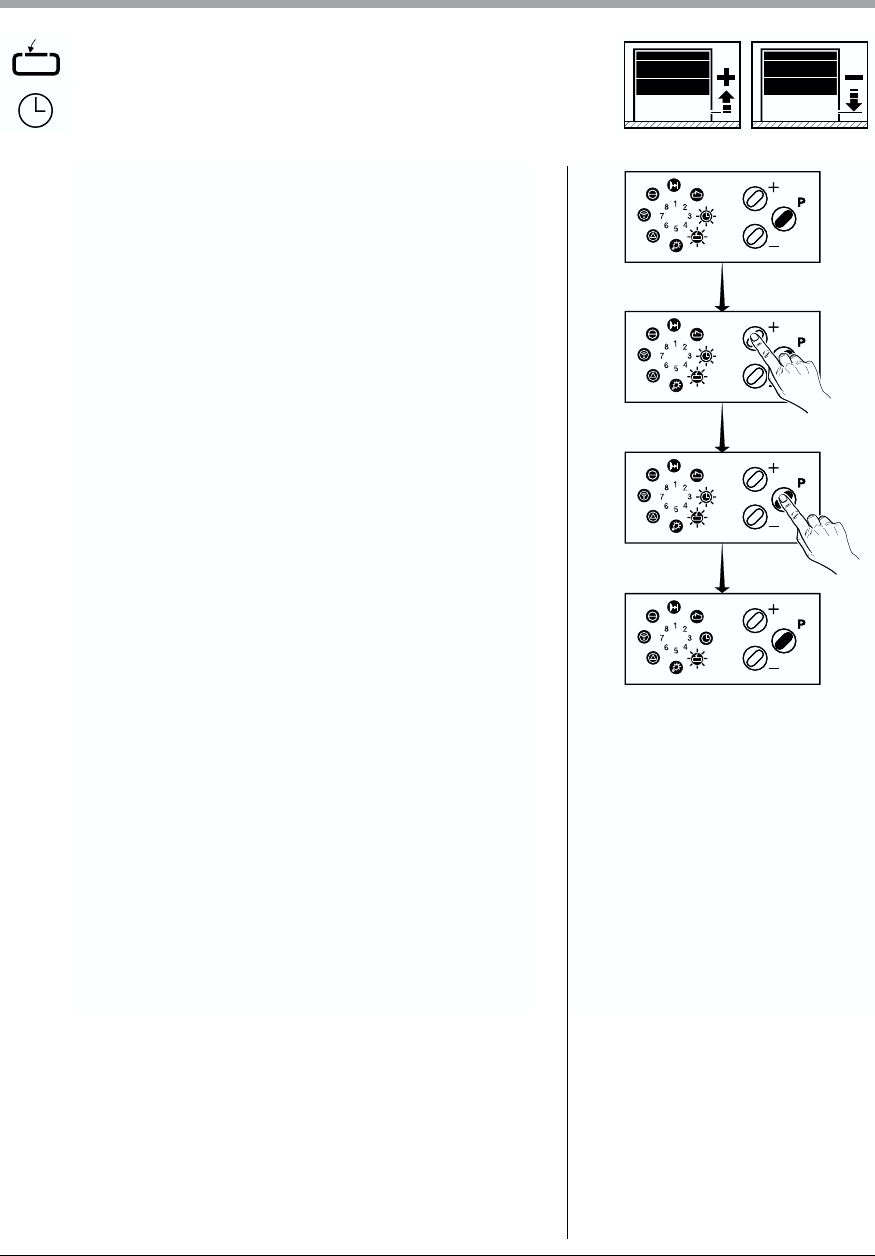

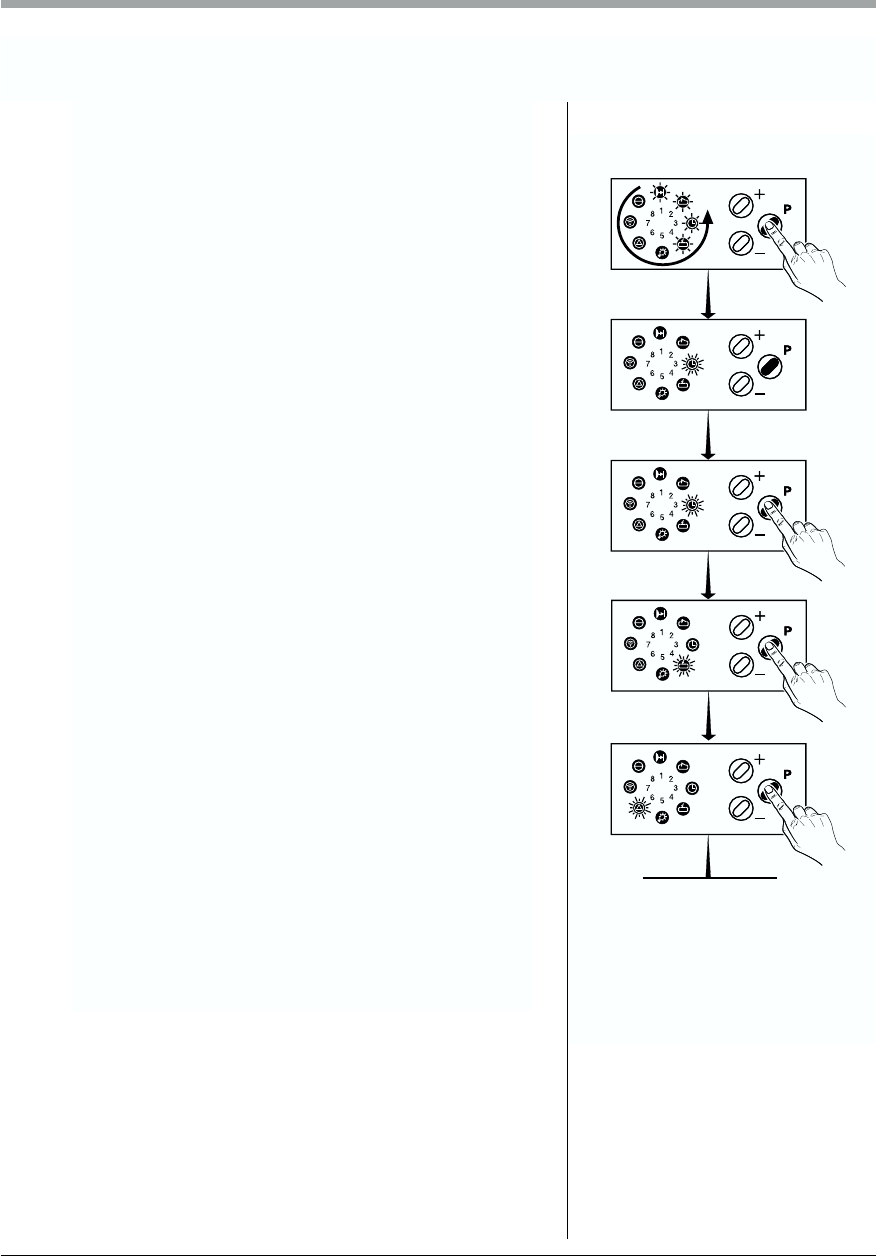

Time, in which the door is open, before door closes automatically.

Time period, in which signal light flashes, before door closes

automatically.

Time period, in which signal light flashes, before door starts to move

The door closes either after set open time or early after passing

photocell

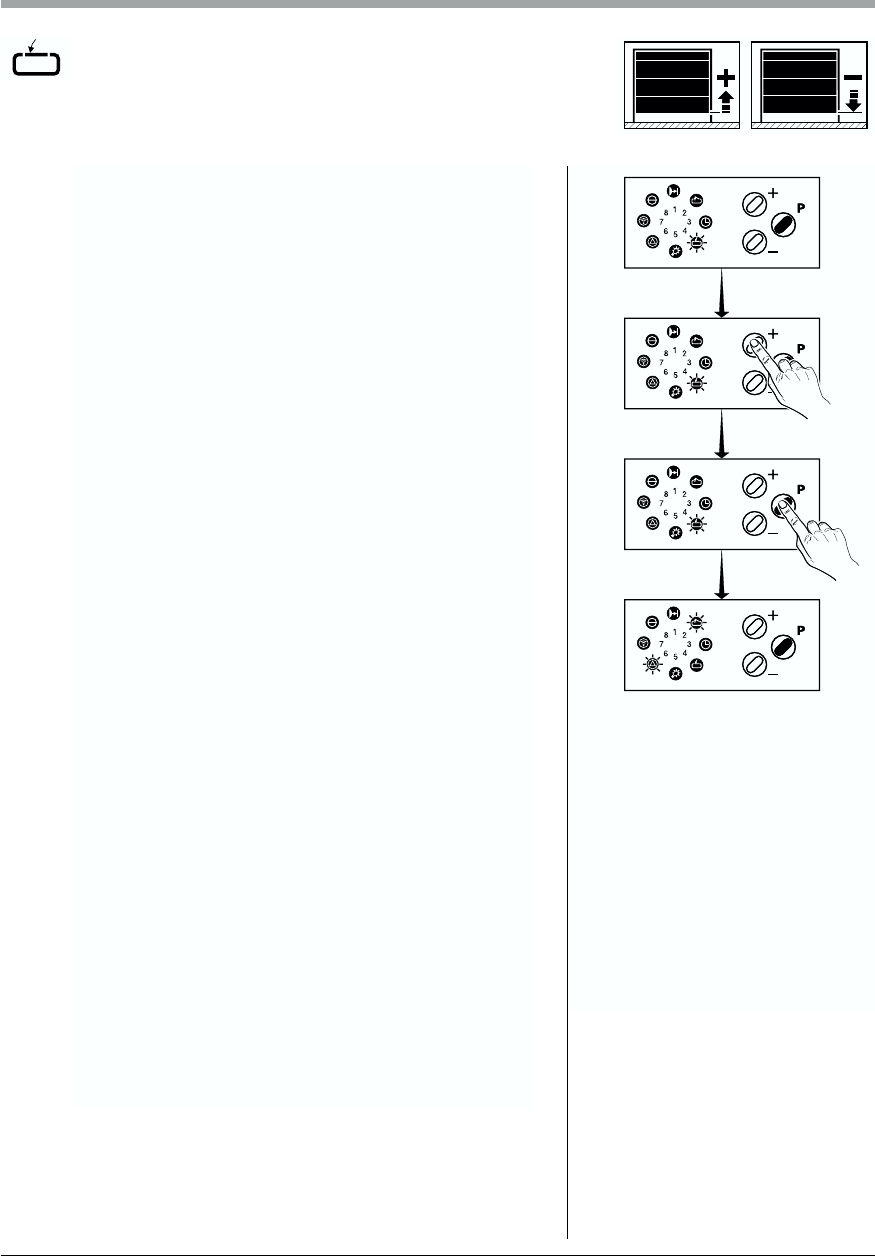

You have the choice between flashlight or permanent light for the

operation mode of the signal lights.

Time period in which the operater switches off without having reached

one of the end positions.

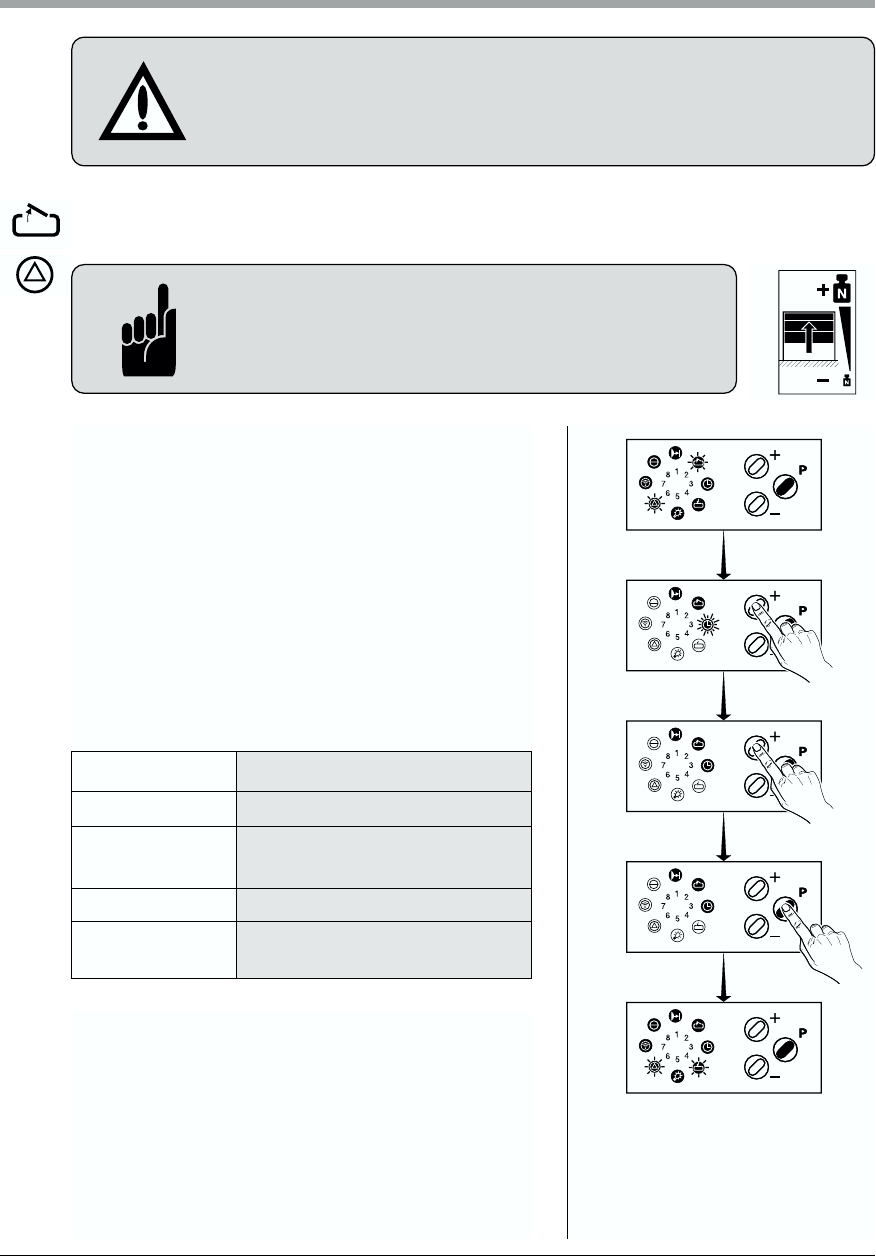

The learned power limit can be set in steps from 1 - 16

The sensibility of power limit can be set in steps from 1 - 16

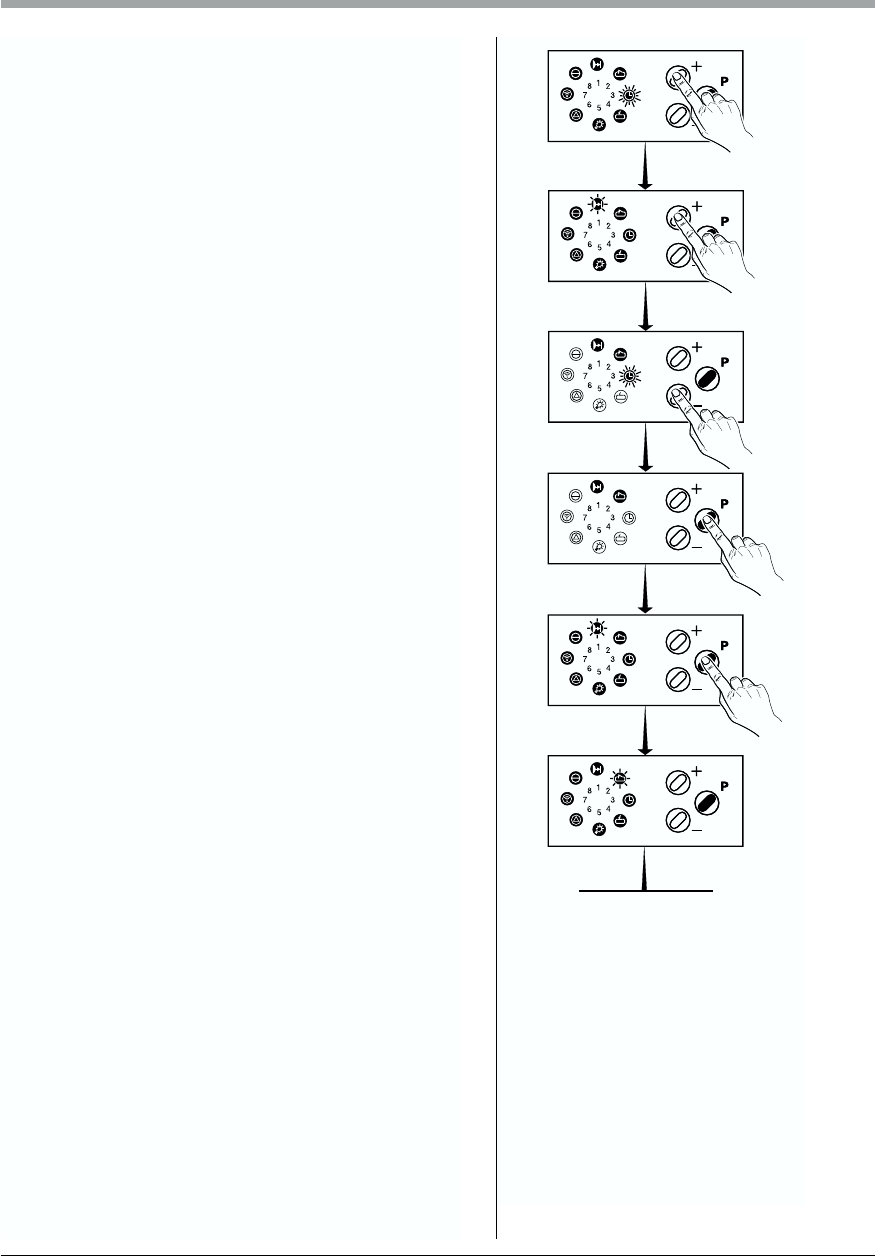

Possible settings: Operator STOP, short or long reversion

Possible settings: Operator STOP, short or long reversion

Possible settings: Operator STOP, short or long reversion

Possible settings: Operator STOP, short or long reversion

Possible settings: Operator STOP, short or long reversion

Possible settings: Operator STOP, short or long reversion

After start the operator travels to the pre-selected position

After start the operator travels to the pre-selected position

Actuation of the IMPULSE button when operator is running

Actuation of the direction button when operator is running

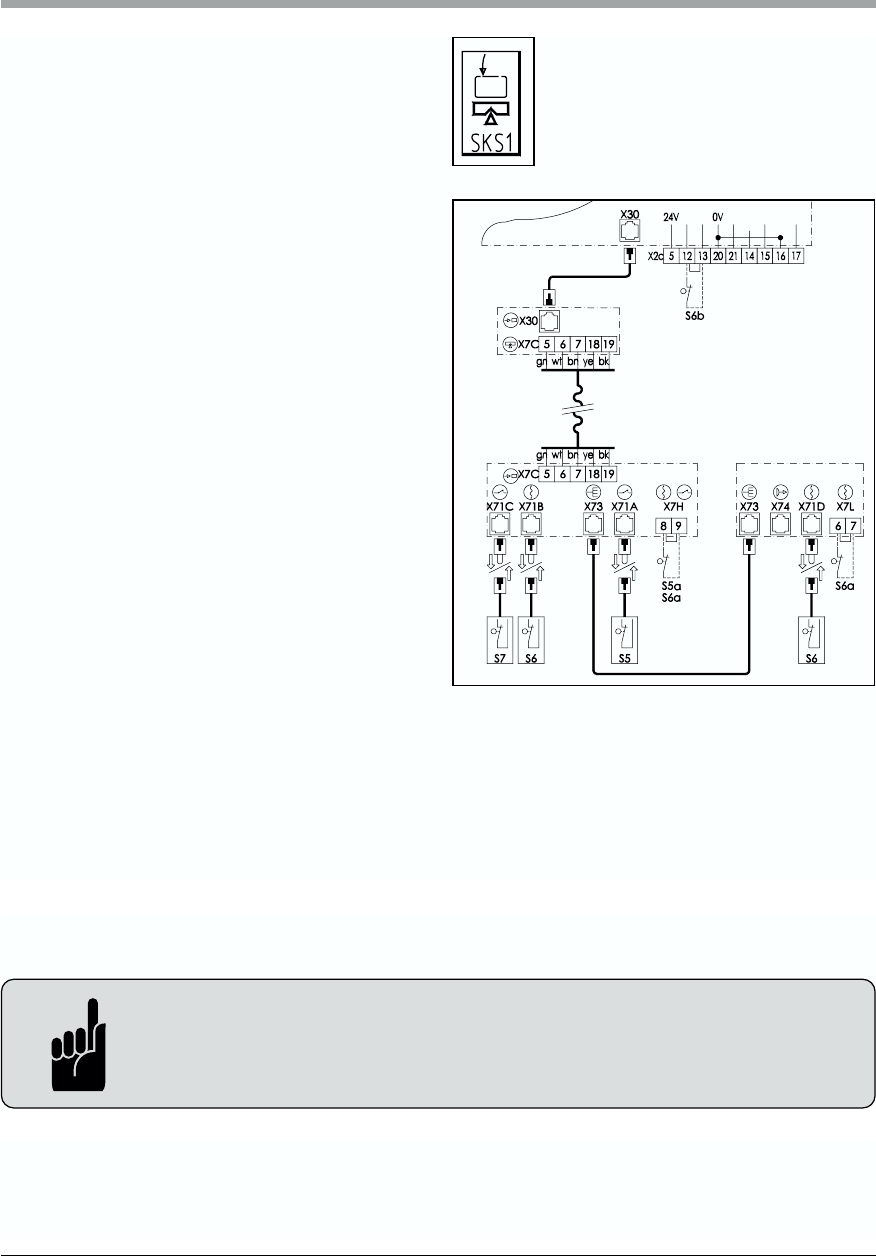

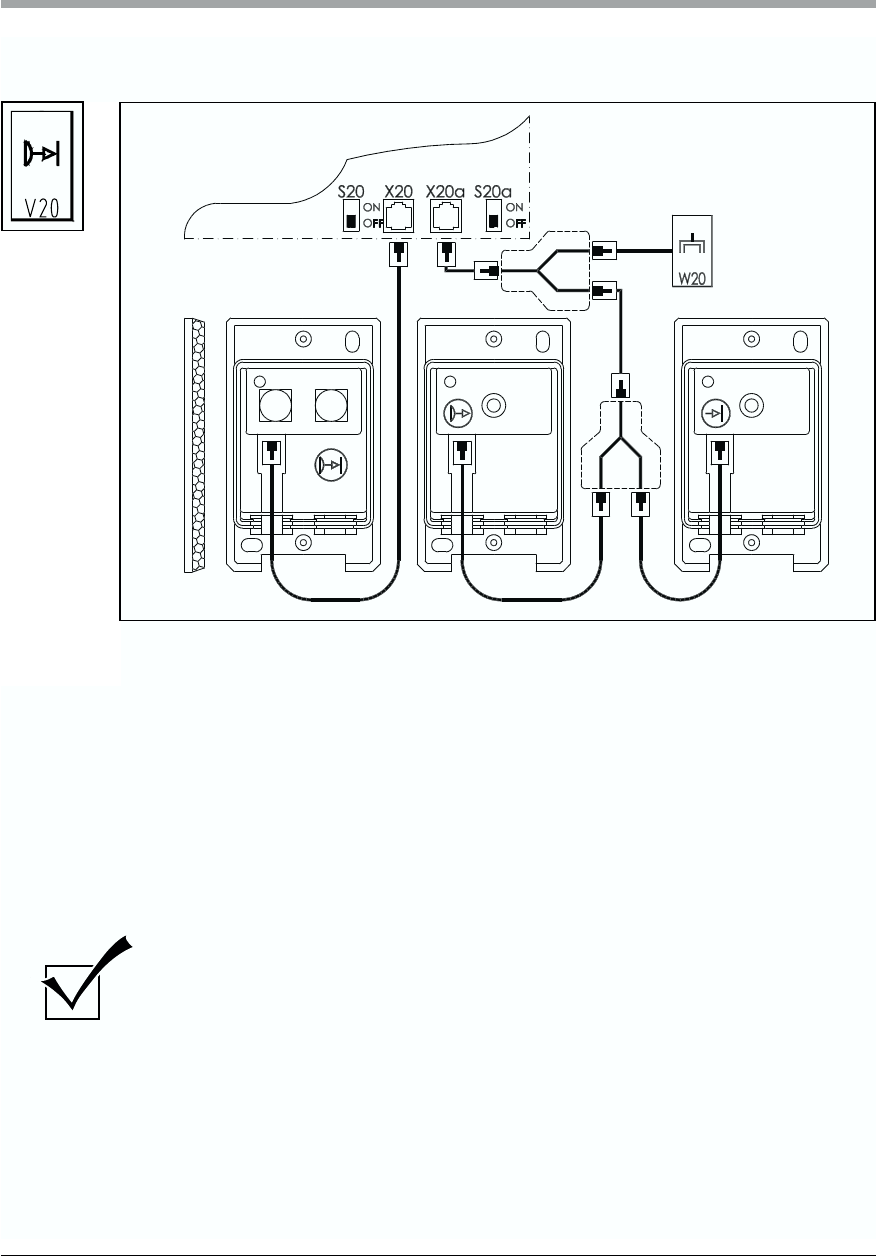

Intermediate positions, central control, master button, traffic control

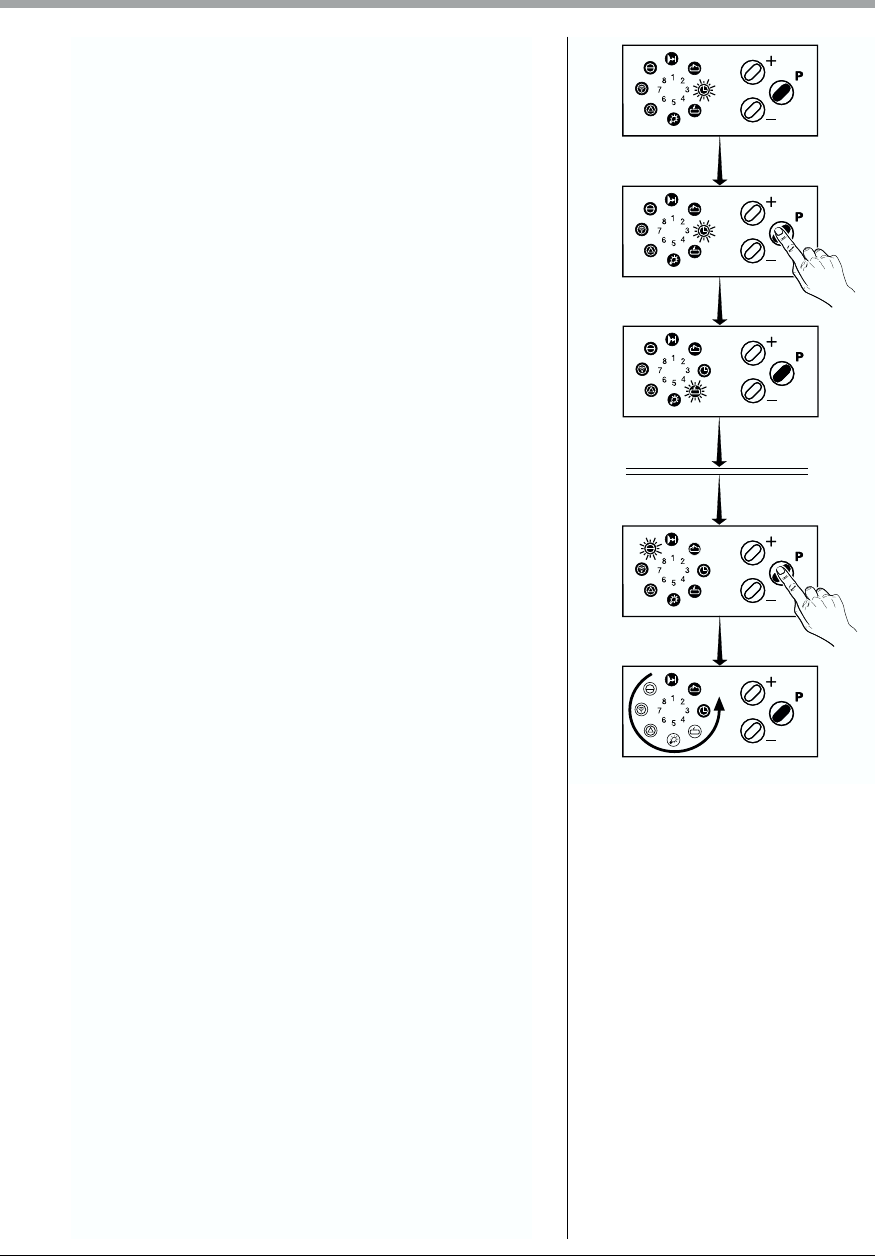

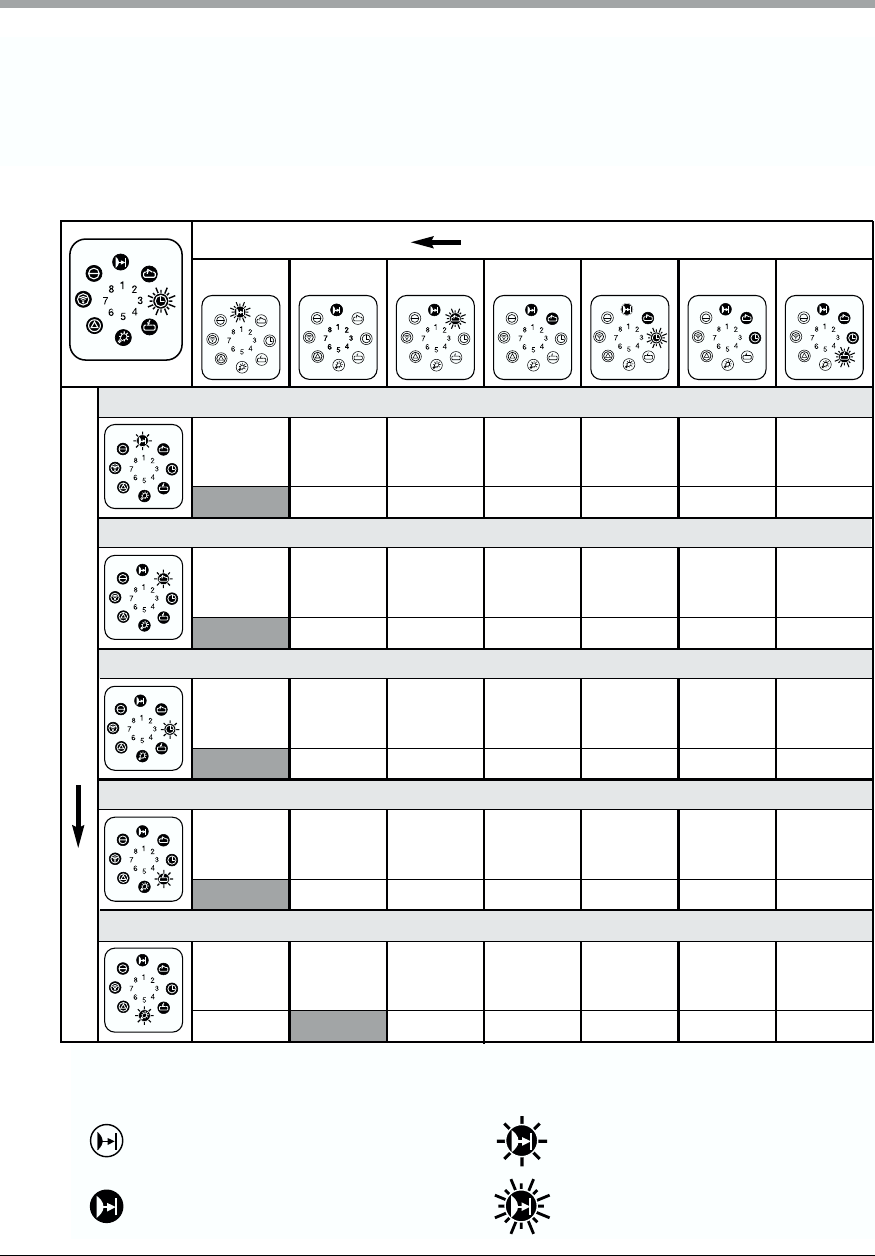

Settings from factory

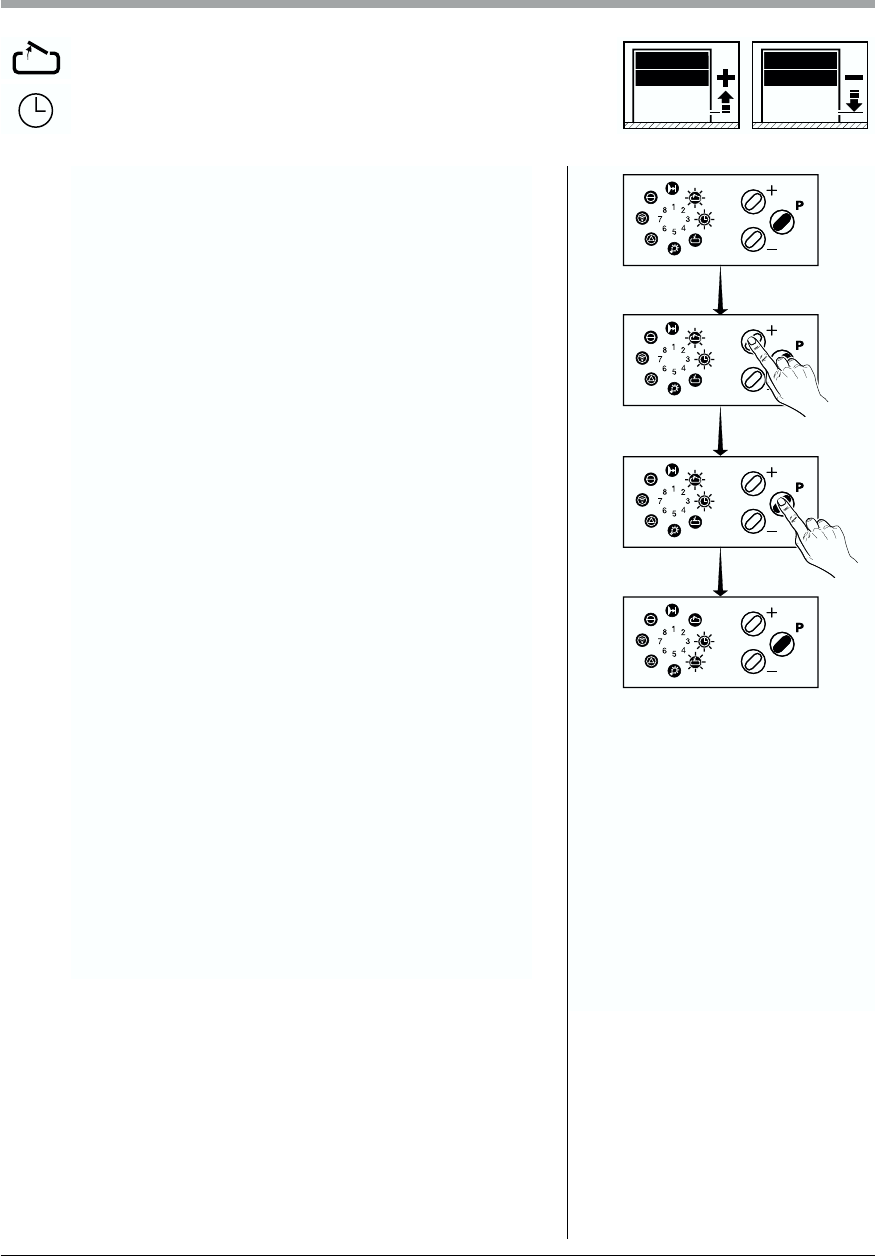

Automatic timer function

not activated

Automatic timer function

not activated

0 sec.

No

Flashlight

55 sec.

Step 4

Step 13

STOP

STOP

Not existing

Long reversion

Not existing

Short reversion

ON

ON

OFF

ON

Intermediate position