-

Mijn pelletinbouwcasette terug aangezet na lange tijd. de kachel brandt maar de ventilatoren blazen niet. Kan iemand me helpen? Gesteld op 18-12-2024 om 17:03

Reageer op deze vraag Misbruik melden -

wij hebben een pelletkachel in ons nieuw aangekocht huis. Nu heeft de vorige eigenaar niets meer van deze kachel en hij bediende dit met zijn mobiel. Hoe kunnen wij dit nu op ons mobiel installeren zodat wij de kachel kunnen bedienen?

Reageer op deze vraag Misbruik melden

mvrgr Lou

Gesteld op 16-11-2023 om 13:30 -

Hoe kan ik de pellet kachel constant op dezelfde temperatuur laten branden Gesteld op 8-11-2023 om 19:59

Reageer op deze vraag Misbruik melden-

Zet de kachel op auto en bijvoorbeeld op 21° dan zal het als het buiten niet zeer koud is 23° graden worden en zal de kachel deze temperatuur aanhouden.

Waardeer dit antwoord Misbruik melden

Vriest het zet dan de kachel op bjjvoorbeeld op22° en dan zal het ook steeds 23° bliiven.

Dus experimenteren met temperatuur stand kachel en buitentemperatuur!

Succes Geantwoord op 8-11-2023 om 22:24

-

-

Onze ventilatoren vallen telkens uit...vorig onderhoud een nieuw moederbord geplaats, we dachten dat het probleem ermee zou opgelost zijn...heeft nu welgeteld 1 week goed gebrqnd en terug hetzelfde probleem...en als ze uitvqllen hoor je om de zoveel sec.een zoemend geluid...tot je hem mer de bediening afzet, dan blaast hij even maar niet zoals ervoor... Gesteld op 7-11-2023 om 11:59

Reageer op deze vraag Misbruik melden -

Ons pelletkachel kunnen wij niet laten werken als er veel wind is!

Reageer op deze vraag Misbruik melden

De kachel is nu 5 jaar en daarvoor hebben wij dat niet ondervonden,ze ruikt naar verbranding in huis. Gesteld op 4-4-2022 om 12:56-

wellicht sluit uw deurtje niet meer perfect en moet het koord vervangen worden omdat uw kachel valse lucht trekt! Geantwoord op 4-4-2022 om 15:32

Waardeer dit antwoord Misbruik melden

-

-

onze mcz stream (2 maand oud) heeft volgend probleem.steeds veel koek in het bakje.al 5 soorten pellets geprobeerd waar vrienden geen probleem mee hebben maar geen verbetering .welke afstelling heb ik nodig,of is er een andere oplossing? Gesteld op 27-12-2020 om 18:15

Reageer op deze vraag Misbruik melden

-

Hoe komt het als ik hem op dynamiek zet is automatisch zijn temperatuur niet kan inzetten hij verhoogd altijd maar van graden Gesteld op 11-11-2020 om 15:32

Reageer op deze vraag Misbruik melden -

Hoi,vraag mijn wifi naar de kachel werkt niet

Reageer op deze vraag Misbruik melden

Hoe kan ik dit oplossen Gesteld op 16-7-2020 om 16:18 -

het signaal van de afstandsbediening wordt die opgepikt door de kachel zelf. Iemand een idee hoe op te lossen (de batterijen zijn nog goed). Gesteld op 6-4-2019 om 11:58

Reageer op deze vraag Misbruik melden-

Ik begrijp uw vraag niet!

Waardeer dit antwoord Misbruik melden

Kunt u deze anders stellen aub, want het is toch logisch dat het signaal door de kachel ontvangen wordt!

Wellicht bedoelt u dat de kachel het signaal niet goed ontvangt?

Grtz Michel Geantwoord op 6-4-2019 om 12:48

-

-

Heb mijn mcz straem gevuld en zet de kachel aan de ontsteking brandt maar krijg geen pallets heeft vanmorgen gebrand uit gedaan, uitgekuist ( wordt dagelijks gedaan ) weet niet wat wat er scheelt Gesteld op 2-12-2018 om 13:21

Reageer op deze vraag Misbruik melden-

De pellettoevoer werkt niet!

Waardeer dit antwoord Misbruik melden

Zie handleiding voor opstarten pellettoevoer! Geantwoord op 2-12-2018 om 14:32

-

-

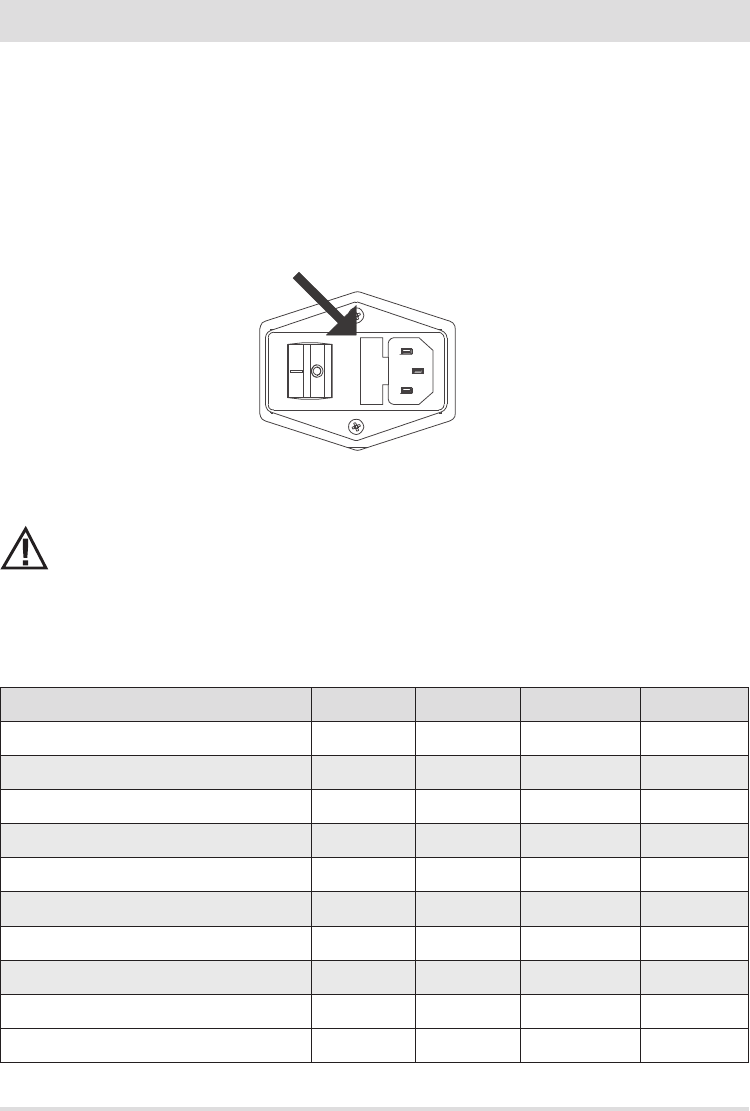

Zet aan de zijkant de kachel op off en medium.

Waardeer dit antwoord Misbruik melden

Controleer of off verschijnt

Druk binnen 2 seconden 3x op testknop

Display geeft aan: toevoer-schroef

Als je de pellets hoort vallen druk dan op test

en wacht tot deze toevoer - schroef verdwijnt ( kan 6 minuten duren)

Schakel.de kachel weer in!

Succes Michel Snels

Geantwoord op 2-12-2018 om 14:40 -

iN DE ECO MODUS BLIJFT DE KACHEL BRANDEN WANNEER DE TEMPERATUUR HOGER IS DAN GEVRAAGD Gesteld op 22-2-2018 om 15:39

Reageer op deze vraag Misbruik melden-

De kachel gaat in de eco modus pas uit als de gevraagde temperatuur gedurende 20 minuten na het bereiken van de gevraagde temperatuur nog niet is gedaald.

Waardeer dit antwoord (13) Misbruik melden

Succes Michel Geantwoord op 22-2-2018 om 19:57

-

-

Bedankt Michel, hou de werking in de gaten. Laat U nog iets weten.

Waardeer dit antwoord (1) Misbruik melden

Grtjs Omer Geantwoord op 23-2-2018 om 06:51 -

Michel de kachel werkt terug normaal na herop starting

Waardeer dit antwoord Misbruik melden

Grtj Geantwoord op 24-2-2018 om 11:14 -

Mijn mcz stream gaat uit en dan na 20 minuten geeft hij weer pellets maar komt er geen vlam.

Reageer op deze vraag Misbruik melden

Daarna kachel uitgezet en opnieuw opgestart.

Heeft iemand de verklaring hiervoor?

Gesteld op 25-12-2017 om 21:08-

Ik heb hetzelfde probleem!

Waardeer dit antwoord (9) Misbruik melden

Hoe is uw probleem opgelost.

Grtz Michel Geantwoord op 2-2-2018 om 14:40

-