PELLET STOVES Chapter 3

INSTALLATION AND USE MANUAL

page 26

Installation and assembly Technical service - Rights reserved MCZ Group S.p.A. - Reproduction prohibited

In case of crossing walls built of flammable material, THE INSTALLER

MUST suitably insulate the pipe of the stove that crosses the walls,

using suitable insulating material (1.3-5 thick with a min. thermal

conductivity of 0.07 W/m°K).

A pipe which is inserted in the wall must be properly insulated so that it

does not lose heat and so that air outlet is silent.

You should use ducts of the same length so that the

air is evenly distributed. Otherwise, the air will tend

to flow through the shortest or least twisted ducts

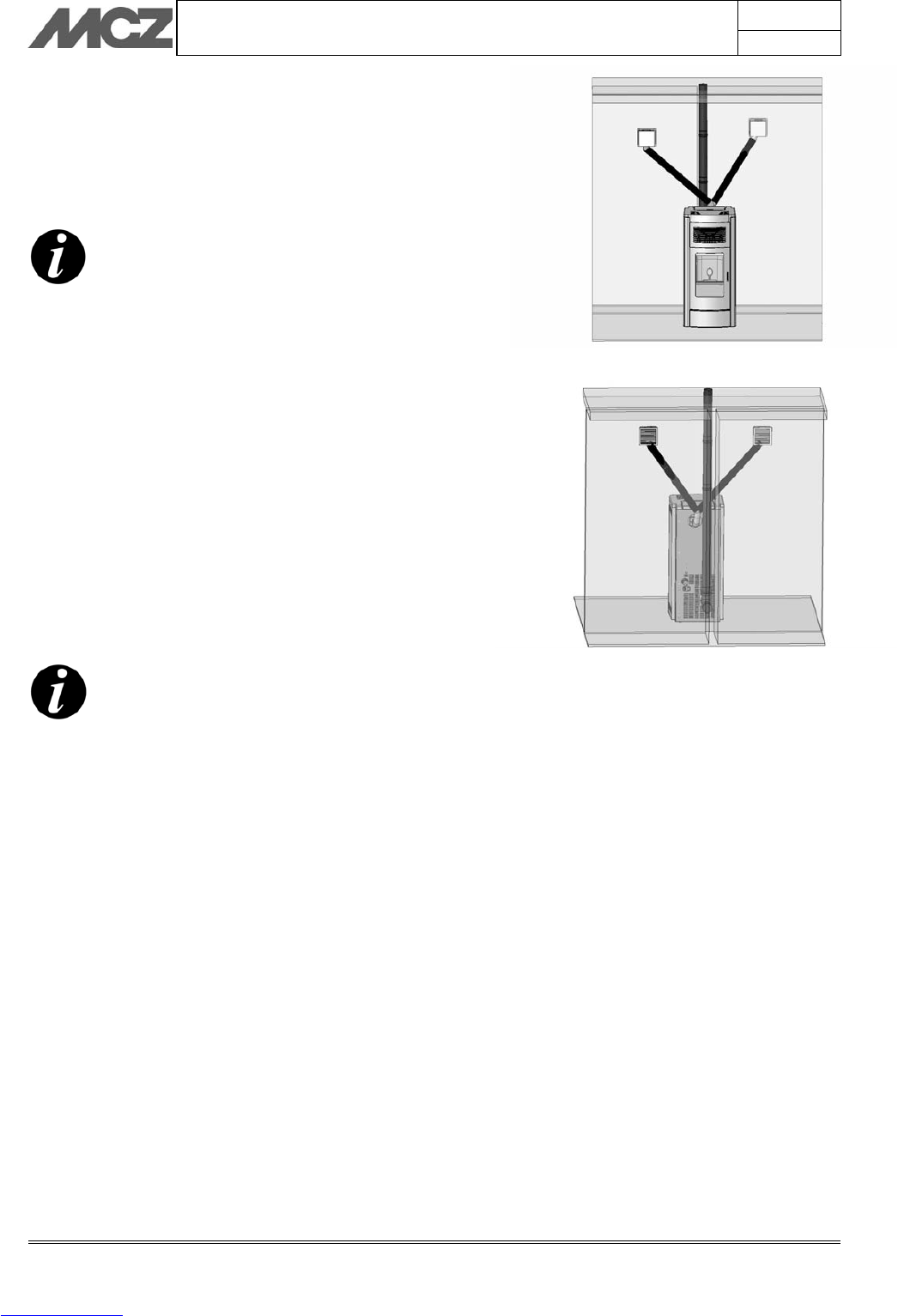

In the example in figures 6 and 7 (front and rear view) the air duct is

an equal length totaling 8 meters, or in other words the pipes (B) will

have a length of approximately 4 meters each. In the case of ducts

with different lengths, the total must always be maximum 8 meters

(example 3 + 5 meters). In this case the heat will spread through the

rooms in an uneven manner.

The recirculation of air in the room occurs using the perforated sheet

metal placed in the rear of the stove C and the holes placed on the

metal sheet bottom

It is possible to choose the volume of air you wish to discharge from

the front part and from the rear part of the stove in an independent

manner, by adjusting the ventilation power directly with the remote

control.

3.4. INSTALLATION OF CERAMIC CLADDING FOR

SUITE AND CLUB

It is advisable to place small felt pads on the

ceramics where these touch the metallic parts of the

stove structure and in the contact between the

ceramic.

3.4.1. Assembly of the lower panel – Suite and Club Stoves

The stove is delivered with all the ceramics packed. Therefore, before

assembling the side tiles and the top, it is necessary to insert the lower

panel.

Proceed in the following way (fig.8):

Remove the micro-perforated sheet metal grill B on the right

side (handle side) on the upper part by removing the two

screws C.

Remove the screw D on the sheet metal E in a way that the

profile A is no longer locked.

At this point slightly lift the sheet metal E and remove the

profile A.

To remove the profile A lift it (sliding it from the base) and

tilt it slightly in a way that the plugs inserted on the base

come out.

Take the lower panel F and insert it from the right (handle

side) towards the left in a way that it enters exactly in the

housings

Reinsert the profile A making the plugs enter the case, and

lift the sheet metal E in a way to realign the profile “A”. Work

in a way that the upper plugs of the profile “A” are inserted

in the housings of the sheet metal “E”.

Figure 6 – Front view of air outlet system

Figure 7 – Rear view of air outlet system

A

B

B

B B

A