A Blast chiller is a professionally designed household equipment for blast chilling and shock freezing food

and fast chilling beverages.

Food that is blast chilled with the blast chiller after cooking maintains its original texture flavour and aroma

for 5-7 days. Shock-frozen foods do not collapse and maintain its original texture and taste once thawed.

Foreword

IMPORTANT NOTICE TO USERS

• These Use and Maintenance instructions are part of the product and provide all the instructions that

are needed for the correct installation, use and maintenance of this equipment.

• Users and installers should read these instructions carefully and always refer to them. These

instructions must be kept in a known, easily accessible location.

• Store these instructions carefully and give them to any future owner of the equipment.

• If you notice any problems with the equipment (for example if the power cable is damaged or if the

control panel is not working) do not use the blast chiller and notify your dealer immediately.

• This equipment must be used exclusively by competent adults; DO NOT allow children or disabled

adults to use the equipment without correct supervision!

• This equipment has been designed exclusively for its intended use, i.e. blast chilling and shock freezing

food. Any other use is considered inappropriate and potentially dangerous.

• In the case of a power supply interruption during the blast chilling or shock freezing cycle, the

equipment will extend the remaining cycle by 30 minutes when it restarts.

• Caution! Do not obstruct the blast chiller’s top and front air vents, otherwise the equipment may

overheat and suffer damage.

BEFORE YOU USE THE BLAST CHILLER...

The following instructions will help you make the best use of use the

blast chiller.

Preliminary cleaning of the chamber

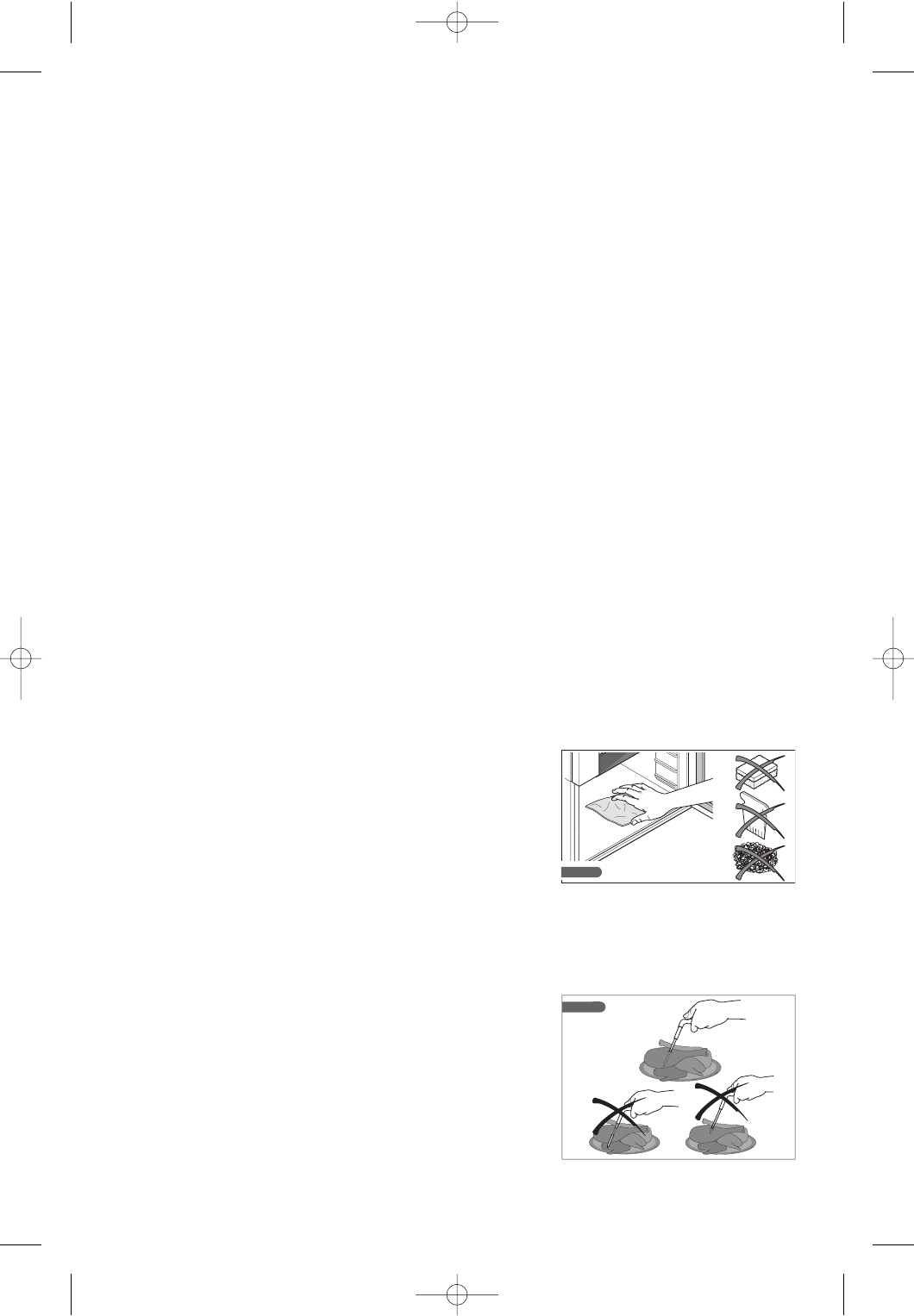

Before you start the equipment clean the inside of the chamber with

a soft cloth and neutral detergent.

Do not use stainless steel scouring pads, scrapers or abrasive or acid

substances which could permanently damage the stainless steel

surface (fig. 1.2.1).

Rinse thoroughly after cleaning.

Available operating modes

Core probe controlled cycle

The core probe is attached to the door of the equipment. It is used

to measure the temperature at the centre, or core of the food to be

blast chilled or shock frozen. When the core probe detects that the

temperature at the core of the food product has reached +3°C

(during the blast chilling cycle) or -18°C (during the shock freezing

cycle) it stops the cycle automatically.

The core probe must be inserted into the food to be blast chilled or

shock frozen before the cycle is started.

Caution! Insert the core probe deep into the centre of the food

product, making sure it does not come out (fig. 1.2.2). Handle with

care as it is sharp. At the end of the blast chilling/shock freezing cycle

clean with a soft cloth and lukewarm water, and then replace in the

bracket.

Caution! If you are blast chilling or shock freezing products of

different sizes, insert the core probe into the thickest product.

Use

6