15

Important! DO NOT drain more water than what is

formed during defrosting. Subsequent cleaning must

be performed with the drain closed.

In order to ensure hygiene and protection of the

quality of food products treated, the cell inside must

be cleaned at the end of defrosting.

The shape of the cell, and of the internal parts, allow

washing, it is recommended to use a soft cloth or

sponge and mild detergent.

It is recommended not to use wire sponges, scrapers

or abrasive, acidic or aggressive substances that

could irreparably damage the stainless steel surfaces.

After cleaning is recommended to rinse and dry

thoroughly the inside of the chamber.

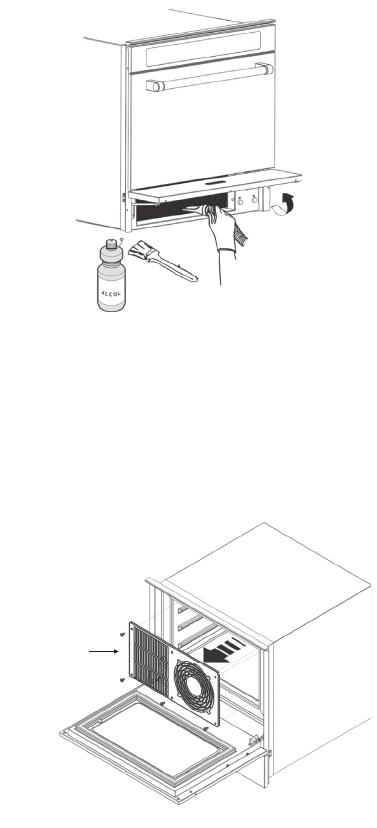

CONDENSER CLEANING

Important! Disconnect the power supply before

carrying out maintenance.

Once a month it is recommended to clean the

condenser to remove all dirt and dust from the

condenser fins.

The condenser is accessed by lifting the lower cover

and turning it 90° (fig. 7).

Important! The condenser fins are delicate. To

clean them, use a brush with soft bristles, making a

vertical movement along the direction of the fins, or

use a vacuum cleaner to avoid releasing to the

environment the dust removed. If there are greasy

deposits, use a brush soaked in alcohol.

Important! Do not scrape the surfaces with sharp or

abrasive objects.

During cleaning always wear protective gloves.

EVAPORATOR CLEANING

Important! Disconnect the power supply before

carrying out maintenance.

For proper and efficient operation of the blast

chiller, it is necessary that the evaporator is kept

clean to allow free air circulation.

To access the evaporator unscrew the 6 screws that

hold the protection grid inside the chamber (fig. 8).

Fig. 7

Fig. 8

Protection

grid